Construction Worker Dies After Being Run Over By a Bulldozer at a Commercial Construction Site - North Carolina

NIOSH In-house FACE Report 2005-11

April 7, 2006

Summary

On August 13, 2005, a 56-year-old male construction worker (the victim) was fatally injured when he was run over by a bulldozer. While performing the role of a spotter, the victim apparently stepped in front of a pile of gravel to direct a truck driver to move his truck when he was struck by a bulldozer that was traveling in reverse. The company owner was operating the bulldozer in reverse, with its back up alarm sounding, and spreading gravel over the excavated area. A coworker, who was sitting in a skid-steer loader located near the gravel pile, saw the victim directing the truck driver and saw the bulldozer backing toward him. He yelled a warning to both the victim and the company owner. The company owner did not hear the warning and the victim did not react. The track of the bulldozer struck the victim on the back of his legs and rolled over his legs and torso. The company owner, still unaware of the run over, drove the bulldozer forward about 50 feet and stopped. The coworker ran to the bulldozer operator and told him what had occurred. The company owner looked back toward the gravel pile and saw the victim lying on the ground. He called 911 using his cell phone. He ran to the victim and began cardiopulmonary resuscitation (CPR). A police officer arrived approximately one minute after the 911 call and assisted in providing CPR. Emergency medical services (EMS) personnel arrived approximately two minutes after the 911 call and found, through examination and cardiac monitoring, that the victim had no signs of life. The county coroner pronounced the victim dead at the site.

|

|

Incident Scene

|

NIOSH investigators concluded that, to help prevent similar occurrences, employers should:

- develop, implement, and enforce a policy that requires workers on foot to maintain a safe clearance from mobile equipment and train all workers regarding this policy

- develop, implement, and enforce a policy that requires mobile equipment operators to operate mobile equipment in accordance with safety guidance provided in the equipment operator’s manual and provide additional training to all mobile equipment operators regarding this policy

- consider conducting a pre work safety meeting each day to discuss the work to be performed, potential safety hazards and safe work procedures, and means to be used for communicating changes to the work plan

- ensure that personal protective equipment, including high-visibility clothing, is provided and used in accordance with company policy.

Additionally,

- Manufacturers of heavy equipment, such as bulldozers, should explore the possibility of incorporating collision avoidance technology on their equipment.

Introduction

On August 13, 2005, a 56-year-old male construction worker (the victim) was fatally injured when he was run over by a bulldozer. On August 26, 2005, the North Carolina Occupational Safety and Health Administration (NCOSHA) office notified the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR), of the incident. On September 20, a DSR safety and occupational health specialist met with the NCOSHA compliance officer assigned to the incident. The DSR safety and occupational health specialist accompanied the NCOSHA compliance officer to the construction site and interviewed the victim’s employer in the construction office trailer. The general contractor on the site declined an interview and denied access to the incident site, but offered to discuss the case after NCOSHA’s investigation was closed. The police report and medical examiner’s report were reviewed. The cause of death was obtained from the medical examiner’s report.

Employer: The victim’s employer, a utility construction company, employed 13 employees and had been in business for thirty-one years. On the day of the incident, the company owner and three employees were working at the construction site. One of these employees was involved in work on another area of the construction site and was not involved in the incident.

Victim: The victim was initially employed by the employer as a truck driver from May 1995 to June 1999. He worked for another contractor in the area from 1999 until February 2005 when he was rehired by the utility construction employer and worked as a truck driver until the incident occurred. The victim had attended a “Newly Hired Experienced Miner Trainer Course” on February 19, 2005, and his attendance was documented. This training included instruction on the recognition and avoidance of hazards associated with working around mobile equipment. The victim’s primary job duty was to drive a dump truck and he had a valid driver’s license and a commercial driver’s license (CDL). His duties also included working as a mechanic, operating heavy equipment, and performing other duties, as assigned.

Equipment: The bulldozer used at the time of the incident was rented by the general contractor and the operator had been given permission to use it. The NCOSHA compliance officer inspected the bulldozer the day after the incident and determined that it was in good operating condition and had a functioning back up alarm.

Safety program and training: The NCOSHA compliance officer reviewed the company’s safety and health and training programs. His review indicated that the employer’s safety and health program and initial training were developmental in nature and not comprehensive. The safety and health program did not specifically address the company’s safety procedures and training for equipment operators or for workers on foot in construction and excavation areas, nor did it provide specific procedures for protection of workers serving as spotters.

The company provided each employee with a copy of a safety publication entitled, Keller’s Official Construction Safety Handbook Third Edition;1 a verbal review of the company’s safety manual; a presentation highlighting specific duties of the appointed Safety Coordinator (employer) and foreman; and a verbal review of general safety rules on topics such as, but not limited to, protective clothing and equipment (e.g., steel-toed boots, hearing protection, gloves, safety glasses, vests for flagmen), equipment operation (hand and power tools), electrical safety, excavation and trenching safety (to include flagmen), explosives and blasting, ladders, lasers, motor vehicles and mechanized equipment. Employees, including the victim, attended a course on 02/19/05 which met requirements of 30 CFR 46.6 (b)(2), Newly Hired Experienced Miner Training.2 Part of this training curriculum involved instruction on the recognition and avoidance of hazards associated with working around mobile equipment. The company conducted weekly “toolbox” safety talks. Examples of topics included: barricades and warning devices, clothing, concrete hazards, construction equipment, safe methods for entering and leaving the work area, electrical shock, excavations and trenches, and fall prevention. Employee-signed documents were obtained for some but not all of this training.

This was the employer’s first fatality.

Back to Top

Investigation

The incident site was a commercial construction site where a chiller plant (facility for above and below ground steam and chilled water systems) was being constructed behind a university residence hall. The victim’s employer (utility construction company) had entered into a contract with a general contractor to remove and reinstall existing catch basins and piping as required for installation of chilled water, install new steam and chill water lines, excavate and backfill excavated areas, and remove waste soil located in a spoil pile nearby.

The crew (owner and two employees) had begun work between 6:30 a.m. and 8:00 a.m. on the day of the incident. They had completed the installation of steam and chilled water lines earlier in the project, and were in the process of backfilling when the incident occurred. The backfilling process involved spreading gravel with the use of a skid steer loader and a bulldozer. Gravel was delivered by various truck drivers and was dumped on the perimeter of the excavation site, usually in the same location. Due to the confined area, approximately 48 feet wide by 60 feet long, the skid steer loader operator normally pushed the pile of gravel toward the center of the area and the bulldozer operator then spread the gravel as needed over the area to make it level.

Gravel trucks had delivered an estimated four loads (approximately 21 tons each) of gravel to the same location during the morning of the incident. The trucking company had provided 20-30 loads to the same location over the previous two-to-three weeks without incident.

During lulls in delivery and spreading of the gravel, the company owner parked the bulldozer and operated a hydraulic excavator, loading the dump truck the victim operated with waste soil from the spoil pile. Once loaded, the victim would haul waste soil to an off-site location for disposal and return to wait for another load. According to the company owner, if he was busy operating the bulldozer when the victim returned, the victim would sit in his truck, get out of the truck and mingle with other workers, use the rest room, get water from the cooler, or perform other duties as assigned.

On the day of the incident, the skid steer loader operator was told by the company owner not to move the gravel out into the center of the lot, as the area they were filling in was now too close to an area where a hydraulic excavator was located and space was very limited. The area where truckers entered the lot to dump the gravel was restricted due to existing buildings and the location of the hydraulic excavator. Several loads of gravel had been dumped that morning. Just before the incident occurred, the skid steer loader operator reportedly saw the victim directing a gravel truck driver into the area to dump his load. Normally the truck drivers dumped the load, lowered the box of the truck, and moved out of the area. At about 10:30 a.m., a truck driver delivered and dumped a load of gravel but did not lower the box and did not immediately move his truck out of the area.

The skid steer loader operator saw the victim step out in front of the gravel pile and position himself so the truck driver could see him out of his side mirror, and signal to the truck driver to lower his truck box and move his truck. At about the same time, the skid steer loader operator saw the bulldozer backing toward the gravel pile and the victim. He yelled a warning to both the victim and the company owner. The owner did not hear the warning and backed over the victim running over his legs and torso. The company owner drove the bulldozer forward about 50 feet and then stopped the bulldozer at the far end of the lot. The skid steer loader operator ran over to the truck driver and yelled “man down” and then ran to the company owner and told him that he had backed over the victim. The owner looked back toward the gravel pile, saw the victim lying on the ground, and called 911 using his cell phone. He ran to the victim and began cardiopulmonary resuscitation (CPR). A police officer arrived approximately one minute after the 911 call and assisted in providing CPR. EMS personnel arrived approximately two minutes after the 911 call and found, through examination and cardiac monitoring, that the victim had no signs of life. The county coroner pronounced the victim dead at the site and indicated that the time of death and injury was 10:44 a.m.

The gravel truck driver reported that the victim and other workers on site had provided hand signals to truck drivers on previous occasions, without any apparent problems. When the victim directed trucks, he normally stood to the rear and on the driver’s side of the truck, in view of the driver through the driver’s side rear view mirror, and provided signals of a raised “closed fist” for stopping, a “thumbs up” for okay/dump, and a “wave away” for pull forward. The driver stated that after the signal to dump was given, the ground guide would normally walk away. After the load was dropped, the driver would normally pull forward approximately 2 feet to ensure an empty bed, lower the bed, and proceed forward to depart the area. He was not sure if there was always a ground guide for the deliveries, but the victim had guided each of his loads that morning. The path of travel for the gravel trucks was adequate, but narrow. A parking deck building under construction bordered one side of the travel path and equipment and stacked materials bordered the other. He and other drivers had delivered many loads to the same location in the recent past and according to him, he and other drivers were comfortable with the conditions. On the day of the incident, while lowering the bed of the truck, the gravel truck driver stated that someone (later identified as the skid steer loader operator) ran up to the driver’s side of the truck and yelled “man down,…man down.” The gravel truck driver climbed out of the truck, walked to the rear, and saw the victim laying on the edge of the gravel pile.

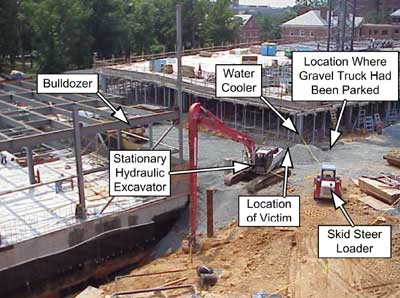

The company owner was interviewed and told investigators that he was an experienced heavy equipment operator and had routinely operated equipment during the 31 years he had owned the business. He reported that he had seen the victim a short time before the incident as he was operating the bulldozer at the end of the site opposite the gravel pile. He last saw the victim standing approximately 20 feet away next to the parking deck that was still under construction and to the side of the operating bulldozer. The victim yelled to him and asked where he wanted the gravel dumped. The company owner yelled back “at the same place” and resumed back-blading and spreading the gravel. The company owner stated that he believed he was clear in backing the bulldozer as he thought the victim was under the parking deck in the vicinity of the water cooler or that he had gone back to sit in the cab of his truck. He also indicated that the victim sometimes took on other tasks without being directed by him to do so. He said he had not directed the victim to work as a spotter that day. He stated that while he was backing the bulldozer, he primarily maintained his attention on clearance from the hydraulic excavator that was parked to his left rear. Just before driving forward, he believed the bulldozer was around 10 inches away from the excavator located on his left side and felt the right track of the bulldozer climbing the gravel pile located to his right rear. Measurements taken of the bulldozer tracks on the side of the gravel pile by the NCOSHA compliance officer after the incident revealed that the bulldozer had actually been between 1 to 2 feet from the excavator. Photo 1 illustrates the incident site.

|

|

Photo 1. This photograph illustrates the location of the bulldozer following the incident and the location of the victim by the gravel pile. The location of other equipment, skid steer loader, hydraulic excavator, and gravel truck as well as the location of the water cooler is identified.

[Photograph courtesy of NCOSHA] |

Back to Top

Cause of Death

The medical examiner’s office reported that the cause of death was multiple blunt force injuries.

Recommendations/Discussion

Recommendation #1: Employers should develop, implement, and enforce a policy that requires workers on foot to maintain a safe clearance from mobile equipment and train all workers regarding this policy.

Discussion: Given the hazards associated with operating heavy construction equipment in areas where workers on foot are also working (e.g., hazards of being struck by or run over by vehicles and/or equipment),3 employers should develop standard operating procedures that are to be followed when a worker on foot is required to work on or near moving vehicles and /or equipment. Safe equipment operation around workers on foot, for example, should include isolating workers on foot from equipment as much as possible, scheduling work tasks to keep workers on foot out of areas where heavy equipment is used whenever possible, and training workers on foot and equipment operators in appropriate communication methods (e.g., two-way radio, personal one-on-one, hand signals, etc.) that are to be used on site.3

When workers on foot act as spotters and must be in the area, they should always maintain direct communication with all equipment operators in the area and should be located in a marked designated area that is out of reach of moving equipment. OSHA regulations require employers to train workers to recognize and avoid unsafe conditions that may be present in their work environments [29 CFR 1926.21(b)(2)].4 Although training records are not required under 29 CFR 1926.21 (b)(2), maintaining company training records that include a summary of the training session, employee signatures of those attending the training, and the dates of training provide employers with a useful way to track employee training needs and to verify that training was provided.

Recommendation #2: Employers should develop, implement, and enforce a policy that requires mobile equipment operators to operate mobile equipment in accordance with safety guidance provided in the equipment operator’s manual and provide additional training to all mobile equipment operators regarding this policy.

Discussion: The employer’s safety policies and procedures for safe operation of mobile equipment should be written in accordance with safety guidance found in the operator’s manual. The manual for the bulldozer used in the incident provided safe operating instructions. One of the safety sections indicated that equipment operators should: (1) always know the location of all workers in their area; (2) warn workers before they start working the machine; (3) always keep all other persons away from their area.5 A safety manual incorporated into the company’s safety program by reference included that operators should always conduct a pre-operational inspection and that part of that inspection could include checking that barricades are set up to protect employees from being struck or crushed by equipment.1 The company’s safety procedures for equipment operators should include all guidance provided in the operator’s manual and any additional safety manuals incorporated into the company’s safety policy by reference, and ensure compliance. For example, procedures that would help prevent run over incidents might include:

- Setting up barriers around the work area to mark areas that prohibit entry of workers on foot

- Checking the backup alarm to ensure that it is functioning properly

- Verbally warning all workers that equipment will be operating or making visual contact and hand signaling them as to the planned movement of equipment

- Inspecting the area around and behind the equipment before starting the equipment to ensure that no workers have entered the area

- Minimizing backing of equipment and requiring that whenever equipment is operated in reverse, that operators stop the equipment, dismount, visually examine the area behind the machine, and clear the area of workers and equipment before backing.

Although maintaining company training records for bulldozer operator training is not required, maintaining company training records that include a summary of the training session, employee signatures of those attending the training, and the dates of training provide employers with a useful way to track employee training needs and to verify that training was provided.

Recommendation #3: Employers should consider conducting a pre work safety meeting each day to discuss the work to be performed, potential safety hazards and safe work procedures, and means to be used for communicating changes to the work plan.

Discussion: Construction sites continually change as work progresses. While a company’s comprehensive written safety program and its training program provide an overall framework for worker safety on construction sites, daily pre work meetings provide a useful opportunity for discussing the work scheduled for the day and the potential hazards that may arise. Prework safety meetings might include, for example: tasks of each worker (including assignment of spotters when necessary), discussion about placement and travel of heavy equipment, appropriate travel paths to be used by delivery truck drivers as they deliver materials to the work area, means of communication (such as use of two-way radios or personal one-on-one communication) between company employees and also between company employees and delivery truck drivers that enter the site, travel paths that workers on foot are to use to avoid the paths used by heavy equipment, the correct location for spotters, and a reminder that use of a high-visibility vest is required. During the pre work safety meeting, workers can be assigned to place barriers around the area where equipment will be in operation and discuss ways that the work can be completed with a minimum of backing.

Recommendation #4: Employers should ensure that personal protective equipment, including high visibility clothing, is provided and used in accordance with company policy.

Discussion: Employers should enforce existing company policies regarding personal protective equipment use and ensure that all employees exposed to hazards at the work site are covered under the policy. In work environments where mobile equipment is being operated, workers on foot are exposed to potential run over hazards. When appropriate high visibility clothing is provided and used, it is more likely that mobile equipment operators will be able to distinguish workers from the environment surrounding them. The American National Standards Institute has developed voluntary guidelines for the selection of high visibility garments that employers can use as a guide.6 After this incident occurred, the general contractor and the victim’s employer enforced their existing policy and expanded it to include a requirement that all employees wear a high-visibility vest when working on site. The high-visibility vests are provided by the employers.

Recommendation #5: Manufacturers of heavy equipment, such as bulldozers, should explore the possibility of incorporating collision avoidance technology on their equipment.

Discussion: Equipment manufacturers should evaluate research currently being conducted on navigation and warning aids for mobile equipment in the mining industry and consider utilizing this information to develop collision warning systems for construction equipment. One promising technology for this application uses radio frequency identification (RFID) tags and tag readers.

Each worker on foot wears a small RFID tag. A tag reader is mounted on each piece of mobile equipment. When a tag is sensed within the tag reader’s sensing range, the equipment operator receives a warning. Manufacturers can obtain additional information pertaining to research on navigation and warning aids for mobile equipment in NIOSH documents (DHHS (NIOSH) Publications 98-114, 2001-128, and RI9652).3, 7, 8

Back to Top

References

- J.J. Keller & Associates (2003). Keller’s Official OSHA Construction Safety Handbook Third Edition. Neenah, WI: J. J. Keller & Associates.

- Code of Federal Regulations [2003]. 30 CFR 46.6. Newly Hired Experienced Miner Training. Washington, DC: U.S. Printing Office, Office of the Federal Register.

- NIOSH [2002]. Building safer highway work zones: measures to prevent worker injuries from vehicles and equipment. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2001-128.

- Code of Federal Regulations [2004]. 29 CFR 1926.21(b)(2). Safety Training and Education. Washington, DC: U.S. Printing Office, Office of the Federal Register.

- Case Corporation (2004). Operators Manual for Case 850 Series 2 Crawler. Racine WI: Case Corporation.

- ANSI/ISEA [1999]. American National Standard for high-visibility safety apparel. New York, NY: American National Standards Institute, ANSI/ISEA 107 -1999.

- NIOSH [1998]. Program for mining research, navigation and warning aides for mobile equipment, pg 20. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 98-114.

- NIOSH [2000]. Test results of collision warning systems for surface mining dump trucks. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) RI 9652.

Back to Top

Investigator Information

This investigation was conducted by Doloris N. Higgins, Safety and Occupational Health Specialist, Fatality Investigations Team, Surveillance and Field Investigations Branch, Division of Safety Research, National Institute for Occupational Safety and Health.