Silica…It’s Not Just Dust: Silica Dust Causes Silicosis – What rock drillers can do to protect their lungs from silica dust

July 1998

DHHS (NIOSH) Publication Number 97-118

What is Silicosis?

Silica Dust Causes Silicosis

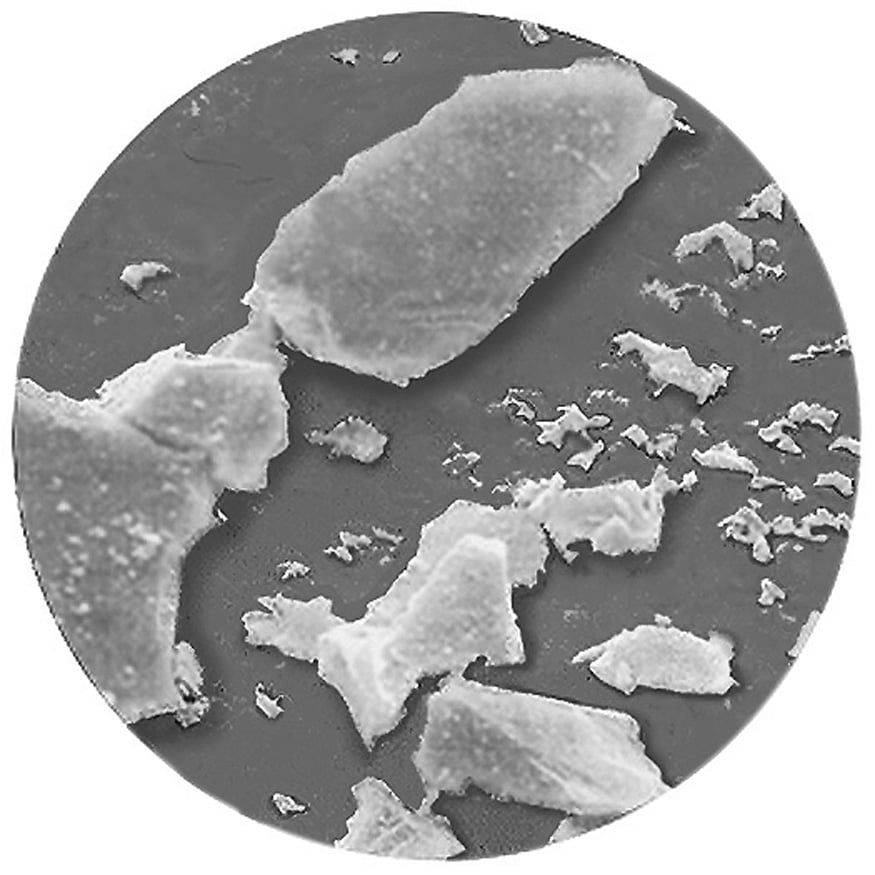

Silica is found in many rocks, sand, and construction materials. Silica dust is produced while drilling these materials. You can get a lung disease called silicosis by breathing very small silica particles into your lungs. These particles can be seen only with a microscope.

Silica is found in many rocks, sand, and construction materials. Silica dust is produced while drilling these materials. You can get a lung disease called silicosis by breathing very small silica particles into your lungs. These particles can be seen only with a microscope.

Silica Can Disable Or Kill You

Silicosis damages your lungs and makes it hard to breathe, increases your risk of lung infections, and may lead to heart failure. Silica may also cause cancer.

Silicosis Can Be Prevented But Not Cured.

How To Protect Yourself

Protect Yourself by Controlling Silica Dust

Maximize Dry Dust Collection

- Provide inside corner flaps for deck shrouds (skirts).

- Install an air-ring seal where the drill pipe passes through the drill deck.

- Install or upgrade dust collector fans so the collector airflow/bailing airflow ratio is greater than 3:1.

- When safe to do so, raise the level of the drill in steps as the job progresses to minimize dust leakage between the deck shrouds (skirt) and the ground.

- Enclose the area around the collector discharge with brattice cloth or a flexible hose to prevent recirculation of dust that has already been collected.

- Lower the deck shroud (skirt) after it has been lifted to shovel cuttings.

- Use proper dust control equipment.

Properly Maintain Dry Dust Collectors

- Change collection filters according to the manufacturers’ directions or when they no longer clean properly.

- Maintain deck shrouds (skirts). Replace torn shroud material and make sure the shroud is as long as possible, but try not to drag it on the ground when the drill is lowered.

Maximize Wet Suppression

- Add small amounts of water into bailing air. This is known as “wet drilling.”

- Use equipment with a needle valve control for proper regulation of the water flow rate.

- Add water slowly until the visible dust cloud has been significantly reduced.

Properly Maintain Wet Suppression Devices

- Use a water filter in front of the needle valve control so that it does not get blocked by small debris in the water system.

- To increase bit life, do not use more water than is needed to control dust.

Properly Use and Maintain Enclosed Cabs

- Make sure enclosed cabs provide a sufficient flow of heating and cooling air.

- Wash out the cab frequently, but do not sweep or use compressed air to blow out dust.

- Replace torn or missing cab seals.

- Keep the cab door closed when drilling.

- Change air filters frequently.

General Health Tips

- When possible, do not stand in any visible cloud of dust.

- Position drills with respect to prevailing winds whenever possible, and remain upwind of drill dust sources.

- When using a respirator, follow directions and guidelines that are based on OSHA or MSHA regulations.

For More Information

- To order a free publication on preventing silicosis and deaths in rock drillers, or a respirator guide, call 1-800-35-NIOSH.

- For more information on dust control techniques, call 1-800-35-NIOSH or the NIOSH Office of Mine Safety and Health Research at (412) 386-6602.

- MSHA requires that water of other effective means be used to control dust when drilling. For more information call (703) 235-1358.

- For more information on respirators, refer to OSHA’s publications office at (202) 219-4667.

This bulletin was produced by an interagency team from the Mine Safety and Health Administration (MSHA), Occupational Safety and Health Administration (OSHA), and National Institute for Occupational Safety and Health (NIOSH).