Safety Checklist Program for Schools

October 2003

DHHS (NIOSH) Publication Number 2004-101

Chapter 3. Implementing a Safety Checklist Program

Safety and Health (S&H) Coordinator Instructions

A well-run checklist program can help launch a school’s environmental safety, and occupational safety and health efforts, or it can strengthen an existing program. One of several ways to develop a checklist program is described below. The coordinator should set realistic expectations. In the first year of your school’s checklist program, it may not be possible to evaluate all of the programs. Select first the courses in the program that present the greatest hazards, then phase in the others.

The Safety Checklist Program has three major features:

- The S&H coordinator who puts the program together and trains teachers and others to use the checklists.

- A plan and procedures for teacher training, checklist dissemination, followup, and record keeping.

- Trained teachers, safety committee members, and other persons to use the checklists regularly in career-technical classrooms, shops, and labs.

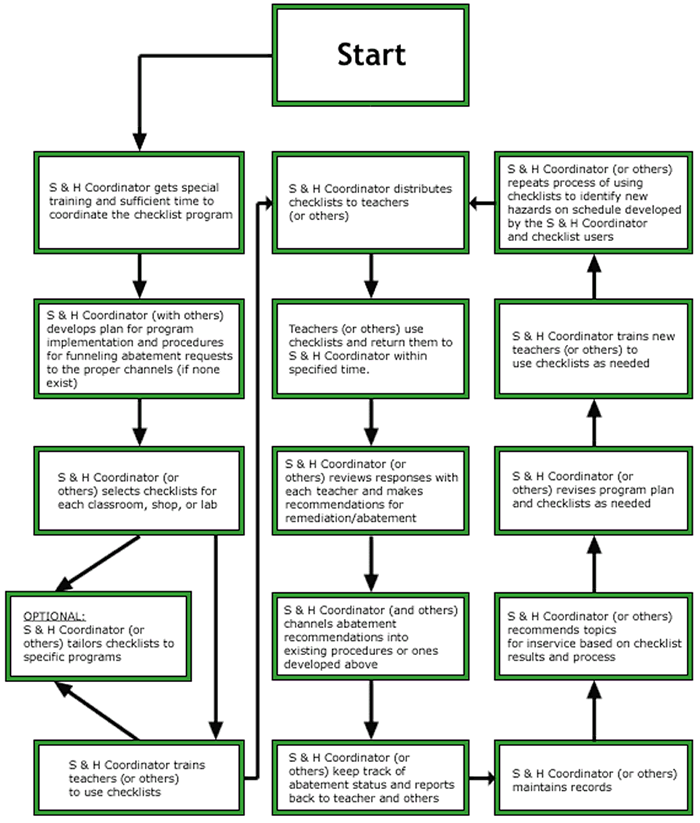

Checklist Program Flow Chart

The flow chart summarizes the checklist program. It is then described in greater detail afterwards.

Implementing the Checklist Program

The safety and health coordinator is responsible for developing the checklist program for the organization with input and assistance from supervisors and teachers. Described below is an example of a guide for setting up the checklist program. The Safety and Health Coordinator can tailor it to the needs of the school. Refer to Appendix A: Resource Agencies and Organizations to identify people who can help answer questions.

A. Preparations

- Attend training sessions on occupational safety and health and environmental safety. Refer to Appendix A: Resource Agencies and Organizations to identify appropriate courses, see NIOSH Education and Research Centers.

- Review the material covered in the Safety Checklist Program manual, especially in this chapter. Skim the Alphabetic Checklists in Chapter 4.

- Complete one or two checklists for practice.

- Prepare a checklist program plan for teacher training, checklist selection and use, followup, and record keeping. (These topics are discussed in greater detail below.) Involve the appropriate school personnel, such as the safety committee, school principal, supervisors, teacher representatives, etc., in the development of the plan.

B. Selecting Checklists

- Review the Career-Technical Programs Index. This index was designed as an aid for selecting the checklists for each course or program and to keep track of the checklists as they are completed. It contains the following:

- Lists of career-technical programs typically offered in public secondary schools. These lists are first grouped broadly by topic (they are referred to as Major Career-Technical Programs in the contents for the Index). Under each major career-technical program are listed generic program names. Find the one that most closely resembles your program.

- Names and links to the checklists that may apply to each list of career-technical programs.

The Career-Technical Programs Index to Checklists is divided into three categories:

- Applicable Checklists to All Programs. This part of the Index lists checklists that should be completed for all career-technical classes, shops, or labs at your school.

- Potentially Applicable Checklists to All Programs. This part of the Index lists checklists that deal with regulations concerning “generic” hazards found in shops or classrooms. These checklists apply to a program if the teachers or students use the substance, have the substance in the classroom, or perform the procedure indicated.

- Potentially Applicable Checklists—Grouped by General Program Areas. This is the biggest part of the Index. The checklists correspond to regulations that apply to hazards found in specific programs. Do the following to select checklists from this section:

- Find the general program area of interest.

- Identify the program name that most closely resembles the one you are looking for. (The exact program names may vary from school to school.)

- Review the checklists listed under the program names to find the ones that apply to your program or course. As a general rule, use these checklists if the applicable substance, equipment or procedure is used or located in the classroom. For example, if the students in the shop, lab, or class within the General Agricultural Business and Management Program operate abrasive wheel machinery, select that checklist.

- Depending on the general program area, two checklists may apply to all of the programs listed: Personal Protective Equipment and Accident Prevention Signs and Tags.

- Decide which checklists to use. Print the appropriate pages of the Career-Technical Program Index for each classroom, lab or shop. Use these pages as a worksheet to keep track of which checklists were selected. The categories given on the Career-Technical Program Index pages are explained below:

- Need

Check this line if the checklist applies. (Note: This category is not given on the Career-Technical Program Index page titled Applicable Checklists—All Programs.) - Priority

If many checklists apply to a shop, lab, or classroom, put them in the order in which they are to be completed. (Consult with the teacher after he or she has attended the training described in the next section.) - Date Distributed

Use this to help you remember when you have distributed the checklists. (To establish a realistic timeframe, consult with the teacher after he or she has attended the training described in the next section.) - Date Returned

Use this to indicate when the completed checklists were returned to you. (Pencil in when you expect them back, as a reminder for followup action if needed.)

- Need

- Look at the checklists you’ve selected to be sure that they apply to the particular classroom, lab, or shop. (Include the teacher in this review.)

- Adapt the checklists to your setting. Set up committees to do this, or have each teacher do it with your help. (See the Special Notes below.)

- Use the Hazard Index to Checklists if you want to find a checklist to evaluate a hazard. Note that there are no checklists available for certain hazards because no Federal regulations apply to that hazard. However, it does not mean that the hazard is of no consequence! If there is no checklist for a hazard, contact a representative from the appropriate agency to get more information about the hazard. Also look through Appendix A: Resource Agencies and Organizations .

C. Deciding Who Selects the Checklists

The checklists may be selected by teachers or by the Safety and Health Coordinator. Pilot-test participants preferred to make the initial selection to pass on to teachers. Make master copies of each package of checklists that you give out, so you will not have to repeat this task in the future.

D. Teacher Training

- Review, modify as needed, and make copies of the items listed below to hand out during the teacher inservice training. Most of these are located in the Training Handouts section of this chapter. You may want to set up a folder or binder for each teacher.

- Sample cover letter to teachers. Rewrite this for your school or omit it if you do not think it is necessary

- Checklist Instructions

- Common Abbreviations

- Commonly Asked Questions

- A sample checklist. (To make things easier you might use one that applies to all programs. Use this checklist when doing the practice inspection described in the following numbered sections (2 and 3))

- Appendix B: Using the Safety Checklists to Teach Students about Occupational Safety and Health

- Do a trial run of the sample checklist you plan to use when you train the teachers to be sure that you understand all of the questions

- Meet with teachers either individually or hold general inservice training. The agenda might include the following:

- Describe the rationale for the checklist program. Some examples include the following:

- The checklist program is being implemented in your school to help reduce occupational safety and health hazards on the premises.

- The checklist program will help the school maintain compliance with regulations.

- The checklists provide a way to help ensure a classroom environment that minimizes occupational injuries and illnesses.

Refer to the Introduction section of the Safety Checklist Program for more ideas on what to include in your rationale.

- Describe briefly what is in the Safety Checklist Program manual (optional).

- Review the handouts that were copied from the list above, especially the sample checklist. Emphasize that it is important to answer all of the questions, even the ones that don’t apply (use the N/A option).

- Describe the school’s followup and remediation procedures.

- Do a practice inspection using the sample checklist. A hazard simulation may be feasable for training purposes.

- Describe the rationale for the checklist program. Some examples include the following:

E. Dissemination and Use of the Checklists

- Have the teachers complete the checklists. Having a safety committee representative or another teacher accompany them may be helpful to get an objective perspective.

- Arrange for technical assistance if needed. Some of the checklists, such as those pertaining to air contaminant monitoring, may be too hard to complete without outside technical expertise. To identify consultants, see Appendix A: Resource Agencies and Organizations .

F. Followup and Record Keeping

- Meet with teachers to review the completed checklists and discuss remediation strategies for any problems.

- Use the followup system that was established in your plan to deal with problems that were identified. This system should address who oversees the followup and monitors the progress of the remediation, the role of the Safety and Health Coordinator and the teacher in the followup, budgeting for followup, and procedures to follow if no problems are identified. See the sample remediation form letter in the Training Handouts section of this chapter. You can adapt it to your school.

- Check that the remediation was completed and report this information to the teacher and others who should know. It will be important to the success of the checklist program for people to see that their efforts to find and control the hazards have paid off.

- Keep copies of the completed checklists and memos concerning followup procedures. This information will help your school comply with potentially applicable regulations. The teacher should also keep copies of checklists and memos pertaining to his or her classroom.

- Identify potential inservice topics from issues and questions raised during the use of the checklists and pass this information on to the appropriate people. Use Appendix A: Resource Agencies and Organizations for ideas for possible inservice speakers.

G. Repeating the Cycle

- Review the checklist program plan and revise as needed. Include in the process the same people who participated in the preparation of the plan.

- Establish a time frame for repeating the checklist program. Once a year is probably sufficient, depending on the type of hazards found in a classroom, lab, or shop. However, hazardous conditions can crop up unexpectedly, such as when a light switch is removed for repairs and does not get reinstalled or when temporary wiring becomes a “permanent” solution.

- Update checklists as needed. Some regulations may have changed since the checklists were last used. Check the OSHA and EPA Web sites for these changes. Refer to Appendix A: Resource Agencies and Organizations .

- Alert teachers when it is time to begin the process again, and train new teachers as needed before disseminating the checklists.

- Repeat the process of using the checklists, using the established schedule.

Special Note:

Selection of a Person to Implement the Checklist Program

At least one person in each school or school district should assume responsibility for implementation of the checklist program. This person is referred to in the Safety Checklist Program as the Safety and Health Coordinator. Two recommendations are important regarding the Safety and Health Coordinator.

- The person should have a background in career-technical education and sufficient authority to supervise teachers in completing the checklists.

Possible candidates to coordinate the checklist program include the principal, the career-technical education director, a supervisor or chairperson of career-technical education courses, a school health and safety committee representative, the buildings and grounds supervisor, the designated person for asbestos, the school business administrator, or a well-respected and experienced teacher. - The person should be given sufficient time to do the job right.

Pilot-test coordinators felt that the success of the program would be seriously compromised if the person had too heavy a workload.

Strategies for “Selling” the Checklist Program to Teachers

Introducing any new program, no matter how useful, may place additional burdens on staff members. Putting a good “spin” on the program may help encourage the use of the Checklists Program.

- Use a phased-in approach to keep people from feeling overwhelmed. Distribute checklists piecemeal, perhaps as “the hazard of the week,” or in batches over the course of the year. This is especially important for teachers with labs, shops or classrooms having a lot of checklists.

- Emphasize that nobody is penalized for finding problems—this is a proactive way to maintain safety and health in the classroom, shop, or lab.

- Stress that the checklists are an easy way to determine compliance without having to locate and plow through all the regulations.

- Point out that similar regulations apply to the private sector. Therefore the checklists can help teachers evaluate cooperative experiences (this was found to be the case from the pilot test).

- Show how the checklists can be used to enhance teaching safety and health to students (refer to Appendix B: Using the Safety Checklist Program to Teach Students About Occupational Safety and Health).

Keep in mind that the checklists offer the potential for learning more about occupational safety and health.

Case Study

Below is a case study describing how staff at the Elizabeth Public School District, in Elizabeth, New Jersey, implemented a checklist program [Special thanks are extended to Robert Rossow, Supervisor of Industrial Arts/Career-Technical Education, for sharing this information for inclusion in the Safety Checklist Program manual].

- Overview of the Elizabeth Public School District

The Elizabeth Public School District is classified as a comprehensive school district, offering middle and high school industrial arts and career-technical courses in 28 program areas. Approximately 3,400 students are in grades 6-8; all are enrolled in industrial arts courses. In grades 9-12, there are 4,400 students; 800 are enrolled in industrial arts courses, and 750 in career-technical programs.The checklist program was coordinated by the school’s Supervisor of Industrial Arts/Career-Technical Education. The decision to have a high-level administrator take on this task was made to send a clear message to faculty and staff that the district is committed to the program. The Safety and Health Coordinator brought to the position many years of experience in career-technical education and a demonstrated commitment to safety and health.It was a big job to get the checklist program off the ground because there were 13 buildings to cover and 48 teachers with career-technical education responsibilities. Efforts were made to use existing channels for inservice training, distributing information, etc. Input into the program came from the newly established district safety committee. This committee was chaired by the Assistant Superintendent of Secondary Programs. Committee members included the Safety and Health Coordinator, the Science Coordinator, the Director of Buildings and Grounds, the Supervisor of Custodians, a physical education and health representative, and a school nurse. The district already had a mandated maintenance and repair program to which the checklist program could funnel requests for remediation. - Disseminating the Checklists

A special ad-hoc committee was formed to select checklists for each career-technical offering. The committee was made up of a middle school industrial arts teacher, a high school industrial arts teacher, a career-technical program teacher, a technology teacher, and the Safety and Health Coordinator. They decided not to modify the checklists initially. This allowed teachers to get a sense of what the regulations in the checklists cover even if only a few questions apply to their situation. - Each teacher involved in industrial arts and career-technical education received an instructional packet made up of a curriculum guide that includes safety material for the class and a district lab or shop safety handbook. The following items were added to the packet: a customized cover letter listing what checklists are enclosed and the timeframe for completing them, the appropriate checklists, training handouts, and a copy of Appendix B: Using the Safety Checklist Program to Teach Students About Occupational Safety and Health. The first completed checklists were the generic ones, followed by the shop or lab-specific ones. The timeframe was set so that all of the teachers would complete the same checklists at the same time. For example, within one month, all teachers completed fire safety checklists. This way, any service repairs needed in the particular area could all be done at once.

- The Safety and Health Coordinator incorporated teacher training into the regular meeting schedule. Teachers were told that they would have to sign the checklists. Other strategies for “selling” the checklist program included emphasizing that the checklists would:

- Alert teachers to regulations without having to read them

- Become an enhancement to the district’s safety and health program

- Provide learning opportunities for students

- Become part of the district’s safety and health manual

- Help the district comply with potentially applicable regulations

The Safety and Health Coordinator designated a head teacher (one with the most experience/seniority) to help facilitate the program at each site. This person helped collect the checklists and was available for answering questions. (This was done because some teachers may have felt more comfortable approaching a fellow teacher than the Safety and Health Coordinator.) The district used a buddy system to match new teachers with experienced ones. This system was used to help new teachers complete checklists.

- Followup Activities

The completed checklists were not copied to anyone except the Safety and Health Coordinator, who kept a master file. He reviewed the checklists and funneled potential violations to the appropriate people, citing the relevant regulations to strengthen his request for action. Emergency situations identified from the checklists were handled immediately. Building-related problems were reported to the Building Administrator, with copies of memos sent to the Safety and Health Coordinator. Shop or lab-related problems were reported to the supervisors. Then the Safety and Health Coordinator arranged for repairs and forwarded this information to the building principal and custodians. Using the checklists may help with budget planning for repairs.

Special Notes

- Pros and Cons of Modifying the Checklists

Since the checklists are generic, some questions may not apply to every classroom situation. Some schools that have used the checklists have established committees to tailor the checklists to their needs. Although this could be a time consuming task, it will only have to be done once, with periodic updating as regulations change. Other schools have decided to use the checklists as they are because they thought it was helpful to have a sense of the whole regulation. - A few teachers may feel that the checklists are too technical. Checklists are based on highly technical regulations. Many of the terms used have specific meanings and if substitute words are used, the meanings may be changed. If you rewrite parts of checklists, be sure to refer to the definitions at the end of each checklist and check the appropriate regulation to ensure that it meets all the requirments of the regulation.

- The Checklist “Optional Information” Box and Liability

The purpose of a checklist program is to protect teachers and students by identifying and eliminating environmental, safety, and health hazards in classrooms, shops, and labs. You will be able to make a stronger case for an adequate remediation budget if you can document problems in writing and indicate which regulations have not been met. The information from completed checklists will be most useful if the “optional information” box at the top is completed. (This box includes space for the name of your school, date of inspection, the career-technical program/course/room, and signature of the person completing the checklist.) However, you may encounter resistance from some teachers because they are concerned about being held liable for hazards found in their classroom, lab or shop if they sign the checklist. In recent lawsuits, teachers have fared best if they could demonstrate that they documented hazards and tried to take appropriate actions to correct them. Teachers who took the approach that they did not know about a hazard frequently were not released from liability. The rationale for this was teachers were presumed to be the experts in their field, so they should know how to ensure safety and health in their classrooms, shops, and labs. - Having the checklists completed by a team, such as members of your school’s safety and health committee may be one way to diffuse the liability issue. At a minimum, keep track of which checklists are completed by whom for which classroom, lab or shop. Otherwise, depending on the checklist, you will not be able to tell if the checklist was completed for a print shop or an autobody repair class and therefore will not be able to give accurate direction for remediation and followup.