Apprentice Lineman Dies When the Vibratory Plow He was Operating Struck a High Pressure Natural Gas Line.

Michigan Case Report: 06MI207

Summary

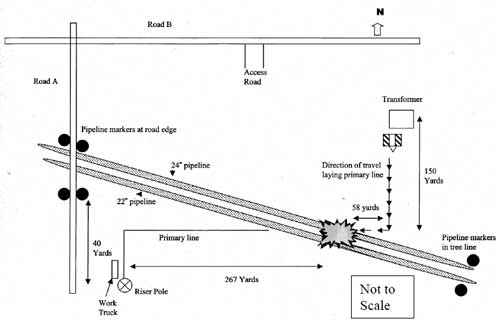

On December 19, 2006, a 27-year-old male lineman was killed when the Flextrak 75 vibratory plow he was operating struck a 24-inch diameter high-pressure natural gas line. The decedent was a member of a three-person crew installing a transformer, and an underground secondary and primary service for two residential homes. The electrical company had contacted MISS DIG to identify all underground lines. The work area had been “staked” as clear by both a television and telephone provider. The MISS DIG ticket response inquiry indicated that one of the two natural gas companies contacted had provided a Positive Response. The gas company provider whose pipeline was involved in the incident did not make a Positive Response. Beginning at the transformer location, the decedent began to plow the cable approximately 36 inches deep into the ground, heading south towards a corner marker where he had to make a 90-degree turn to the west. Approximately 58 yards after he turned the corner, the vibratory plow hit a 24-inch high-pressure natural gas pipeline that was buried approximately 36 to 40 inches below the existing grade. The rupturing pipeline created an explosion throwing dirt and debris into the air and created an 80-foot crater (Figure 1). His coworkers, who were uninjured, called 911. After the explosion occurred, Coworker #1 and Coworker #2 noticed two yellow natural gas pipeline markers at the edge of the road. Approximately eight hours later, the pressure in the line was stabilized and reduced to a condition so firefighters could approach the crater to remove the decedent and the vibratory plow from the crater. The decedent was pronounced dead at the scene.

|

|

Figure 1. Incident scene showing crater and pipeline

|

Recommendations:

- Employers conducting excavating or tunneling operations should ensure employees receive hazard recognition training pertaining to utility markers.

- Employers conducting excavating or tunneling operations should instruct and ensure employees conduct a thorough site inspection to determine if all potential underground utilities are marked prior to beginning digging operations.

- Employers conducting excavating or tunneling operations should contact MISS DIG if public utilities/agencies listed on the MISS DIG ticket have not marked their lines or provided a Positive Response in response to the MISS DIG request.

- Employers conducting excavating or tunneling operations should describe the area to be staked as specifically as possible when calling MISS DIG.

- Michigan Public Act 53 of 1974, Protection of Underground Facilities should be amended to reflect damage prevention Common Ground Alliance (CGA) Best Practices Version 4.0 as applicable to each stakeholder group.

Introduction

On December 19, 2006, a 27-year-old male lineman was killed when the Flextrak 75 vibratory plow he was operating struck a high-pressure natural gas line. The Michigan Occupational Safety and Health Administration (MIOSHA) personnel received the fatality report on their 24-hour-a-day hotline on December 19, 2006. MIOSHA notified MIFACE personnel later that day. The MIFACE researcher interviewed several individuals from the firm including the President/CEO and Vice President on April 25, 2007, at the company headquarters. The company personnel shared the picture used in Figure 2. The company also provided MIFACE with some of the paperwork from their internal investigation including the MISS DIG ticket response inquiry, training records and employee statements. During the interview, company personnel indicated that a review of and possible amendment of Public Act 53 of 1974, Protection of Underground Facilities was underway by State agencies. After the interview, the MIFACE researcher drove to the incident site and took the picture used in Figure 3. During the course of writing this report, the death certificate, medical examiner’s report, police report and MIOSHA file and citations were reviewed. The pictures used in Figures 1 and 4 are courtesy of the MIOSHA file.

The company for whom the decedent worked was an electric distribution company. The company employs 80 people, four of whom had the same job title as the decedent, apprentice lineman. The company had been in business for 70 years. The decedent worked full time, 7:30 a.m. to 4:00 p.m. He had worked for the company for eight months. The company had a unionized workforce.

The company had a written safety program and provided safety and health training to its employees. Employees attended both in-house training and training given by the statewide electric cooperative association. The company had a person responsible for safety program implementation. Management required all employees attend an 8-hour safety meeting on a monthly basis and documented employee attendance. Safety rules were a part of the union contract. Employee training covered many topics such as CPR/First Aid, pole top rescue, bloodborne pathogens, tools, emergency plan, etc., but did not include identification of utility markers. Additionally, the job foreman assumed safety responsibilities at the job site and held a jobsite overview that included potential safety and health issues prior to the start of each job. The company’s disciplinary procedure required “group” discipline rather than “individual” discipline to encourage group-oriented safety practices. The company did not have a joint management/union health and safety committee.

The electrical company representative stated that employees relied upon MISS DIG markers to indicate underground utility location. He also indicated that employees were under the impression that buried pipelines were at least five feet deep. At the time of the incident, the electric company and the statewide electric cooperative association did not offer hazard recognition training pertaining to utility markers. After the incident, a program was developed by the statewide electric cooperative association to provide this training. The company whose pipeline was struck had not provided any training to the employees of the company for whom the decedent worked.

The Ditchwitch Flextrack 75 Vibratory plow, Vermeer Model 0354 was purchased in new condition in 2005. The decedent had operated the plow in the past. The electrical company representatives indicated that employees attempt to operate the plow in a non-vibratory mode approximately 12 inches from the ground.

MIOSHA Construction Safety and Health Division issued the following Serious citations to the employer:

- GENERAL RULES, PART 1, RULE 114(2): The employer’s accident prevention program did not provide instructions to employees in the recognition and avoidance of hazards applicable to his or her work environment. Employees did not recognize safety yellow markers along Road A when staking location of work and prior to start of job.

- EXCAVATING, TRENCHING, AND SHORING, PART 9, RULE 931(1): The employer excavated without having first ascertained the location of all underground facilities of a public utility in the proposed area of excavation.

Investigation

Site Preparation

Property Owner #1 contacted the electric company because he wanted to bring power to his proposed new buildings. A line layout technician with 29 years of experience spoke with the property owner about the options of using overhead or underground lines as well as a combination of the two. The underground option was decided upon. Following this initial meeting, there were numerous subsequent telephone conversations with Property Owner #1 and another property owner (Property Owner #2) who owned an adjoining piece of property to the east. Property Owner #2 was also interested in electric power for future construction of a new home on his property. The two property owners decided to share the cost of an underground installation to serve them both. An underground route along the south property line of Property Owner #1 to the east and then north along the shared property line to a central location where one transformer would serve both new customers was agreed upon. After both property owners had their meter assemblies installed, the line layout technician staked the job. Staking the job entailed taking measurements, marking the route of the underground lines, and the marking of poles and transformer locations. The company invoiced the property owners for the work, and after the fees were paid, another company representative called MISS DIG. The time from staking the route to the call to MISS DIG was approximately one month. The MISS DIG request was returned to the line layout technician. The job had a MISS DIG number on it as well as a ready date and time. When the ready date arrived, the line layout technician revisited the job site and made certain it was ready for construction. The technician’s job responsibility was to check for route flagging, stake locations and verification that MISS DIG had been to the location. The field inspection was performed on December 6, 2006. The technician drove around in the cornfield and replaced the company’s route flags that had been dislocated by corn harvesting. At the entrance to the field off Road B, the cable company’s MISS DIG flag indicated the all clear, and the telephone company’s MISS DIG flags indicated the all clear near the riser pole. There were no other markings present. The job was released to construction upon the technician’s return to the office.

MISS DIG Ticket

MISS DIG is a non-profit entity that processes requests for the marking of underground utility lines and structures prior to construction. The MISS DIG ticket response inquiry indicated the street address on Road B (Diagram A) as the staking location. The MISS DIG ticket response indicated that two natural gas distributors, two cable companies, one electrical distribution company, two phone companies and the county road commission may have had underground facilities present. Three companies positively responded as indicated on the ticket; one cable, one telephone and one natural gas distributor (who contacted MISS DIG indicating no pipelines in the construction area). The natural gas distributor whose pipeline was struck did not positively respond, and the associated response box was blank, as were the boxes for one phone company, one cable company and the county road commission.

Per the MISS DIG website: “Positive Response is a system housed at the MISS DIG center that will allow any participating member or their authorized locating contractor to provide status of dig tickets sent to them by MISS DIG. Once the member or the locating contractor determines the status of the ticket, such as clear or marked, they can then post that response to the system. The posted status is then attached to the ticket and stored on the Positive Response server. The posted status can then be retrieved by the requester of the ticket via the Internet, or by using the interactive voice response (IVR) system via a touch-tone phone. For the excavator (the requestor of the ticket), this means that if a member does participate in Positive Response and has provided and posted a response to the ticket, then the excavator will be able to check the status of the request prior to starting the work. The excavator can check the status by using the Internet option or by calling the IVR. The IVR option could also be used from the job site to determine that the absence of markings by a specific facility may be the result of a “Clear” provided by that member and posted to the Positive Response system.”

Pipeline Information

There were two natural gas pipelines in the construction area. One pipeline was 22 inches in diameter. The pipeline that was struck was 24 inches in diameter. The electric company indicated that the pipelines had been laid in the 1950s. The 24-inch pipeline was pressurized to 800 psi. Pipe composition, integrity, and maintenance are unknown. The electric company indicated that the area had a high water table and that the pipes were “held” in place by straps with cement weights. The electric company indicated that as part of their investigation of this incident, local farmers had stated that they had hit the pipes during plowing and had contacted the gas company to inform them that the pipes had been hit during plowing.

|

|

Figure 2. Weighting straps on pipeline.

|

Day of Incident

The location of the incident was an active cornfield. The work crew consisted of two journeyman linemen (Coworker #1 and Coworker #2) and the decedent. The crew started the day getting all the material for the job loaded on three trucks. Coworker #1 and the decedent left the shop at around 7:45 a.m. and arrived at the jobsite around 8:15 a.m. Coworker #1 was the lineman in charge (job foreman). Coworker #2 arrived at the jobsite about 15-20 minutes after Coworker #1 and the decedent (Diagram A).

Coworker #1 and the decedent set up the road signs on the south and northbound lane of Road A, because in the afternoon they would be working on the road side and also would be trenching along the road. When Coworker #2 arrived, he turned onto Road A and noted the road signs on road A near the riser pole. Coworker #1 radioed him and told him to drive to the transformer location by using the access road off Road B. In his statement he indicated that he saw Coworker #1 and the decedent to the east in the field. He went by the riser pole and looked in the ditch line for flags to mark other utilities and there were no others. He noted the electrical company’s proposed route flags for the underground primary service. He then drove north on Road A to Road B and accessed the jobsite via the access road. He noted MISS DIG utility flags by Road B.

|

|

Diagram A. Incident Scene

|

Parking their trucks near the location where the service transformer was to be set, the crew sat on the tailgate of one of the trucks and Coworker #1 held a tailgate discussion to decide what was to be done and by whom. The crew looked over the job description sheet, which indicated that the job had been staked by MISS DIG and had been inspected and cleared by the electrical company technician. After discussing jobsite duties, the decedent unloaded the Flextrack 75 Vibratory plow from the trailer. Coworker #2 indicated that the crew looked across the field and did not see the flags or markers so decided to start digging.

Coworker #2 got on the truck and pulled the primary wire to the south to the property corner, where the electrical company’s route flag was located. He looked at the area one more time and only saw the proposed route flags. Coworker #2 walked back to the transformer location. The crew agreed that the decedent would operate the vibratory plow. The decedent dug in the secondary service and part of the primary wire. Coworkers #1 and #2 started with the transformer and the meter base. They took a short break before starting to plow in the remaining primary service wire.

Coworker #1 helped Coworker #2 make up the transformer on the front of the line truck. The decedent started plowing the primary wire into the ground approximately 36 inches deep, heading south towards the electrical company’s corner marker. Coworker #1 watched the decedent plowing and when the decedent started to get close to the area where the stake line indicated a 90-degree turn from the south to the west, Coworker #1 left Coworker #2 and helped the decedent maneuver the plow around the corner. After the decedent was around the corner, Coworker #1 got in the truck that had the primary wire reel on it and started driving, pulling out the remaining stretch of wire. Coworker #1 looked in the truck mirrors to watch the wire so it wouldn’t get caught as he was pulling it toward the riser pole.

The decedent continued plowing in the wire. Coworker #2 was working on the transformer. Coworker #1 drove to the riser pole that was located on Road A about 1/8 mile south of Road B. When he parked the truck, he pulled the amount of wire needed to go up the pole.

Approximately 58 yards from the corner, the vibratory plow hit a 24-inch high-pressure natural gas pipeline belonging to the company that had not provided a Positive Response on the MISS DIG ticket. The pipeline was buried 36 to 40 inches below the existing grade. The rupturing pipeline created an explosion throwing dirt and debris into the air and created an 80-foot crater. Coworker #1 was knocked to the ground. Coworker #2, who was also thrown to the ground, found his way to a nearby truck and called a May Day on the truck radio. After Coworker #1 picked himself up from the ground, he turned to look at where the roaring sound was coming from and saw about 150-200 feet of dirt flying in the air. He crossed the street to the west side of Road A and dialed 911 on the cell phone provided by the electrical company. He told the dispatcher that he thought that a high-pressure gas line had been hit and gave the dispatcher the incident location. He then called the electrical company and informed his boss that they may have hit a high-pressure gas line and that the decedent was still in that location.

Coworker #1 ran toward the transformer location to try and find Coworker #2 to make sure he was not hurt. As he was running to the transformer, he could see Coworker #2 running towards him. The noise was deafening and the two workers had difficulty communicating. The coworkers started to look for markers for a gas line and did not see any in the field where the decedent was plowing the wire in the ground. Looking towards Road A, they then saw the pipeline markers on the roadside west about 150 yards from the blast. The pipeline markers were High Visibility Safety Yellow approximately 40 yards from the riser pole where Coworker #1 had parked his truck.

The coworkers started to work their way around to the south and east of the blast to see if they could find the decedent. When they approached the south side of the field, they saw the vibratory plow on its side and the decedent laying on the side of the blast hole. As they started to move closer, the blast hole caved in and the decedent and the plow fell into the crater.

The electrical company representatives stated that they attempted to call the emergency number located on the pipe marker and no one answered the phone. Approximately one hour later, the gas company representative arrived. The gas company representative indicated that the pressure had to be reduced to 200 psi and stabilized before emergency responders could get close to the hole. After the gas pressure subsided, fire department representatives approached the crater, were lowered into the hole, and located both the decedent and the vibratory plow. The decedent was pronounced dead at the scene.

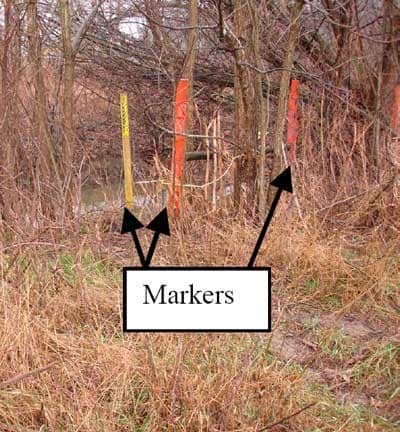

MIOSHA personnel, upon walking the field where the excavation was being performed, noted additional utility markers in the tree line.

Back to Top

Cause of Death

The death certificate listed the cause of death as craniocerebral trauma. No alcohol or illicit drugs were detected upon autopsy.

Back to Top

Recommendations/Discussion

Employers conducting excavating or tunneling operations should ensure employees receive hazard recognition training pertaining to utility markers.

Following their training, electrical company personnel looked for and recognized utility MISS DIG flags, but did not appear to look for other markings for underground facilities, such as the high visibility yellow markers for the two underground, high-pressure, natural gas pipelines. Although the markers were in plain sight on Road A, apparently they were missed (Figure 3) or the workers may have thought that the lines were deeper than the level they were digging. Employers should include in their excavation training a segment that requires workers to look for all utility markers in addition to MISS DIG flags and to not assume lines are deep.

|

|

Figure 3. High visibility yellow markers on Road A

|

Employers conducting excavating or tunneling operations should instruct and ensure employees conduct a thorough site inspection to determine if all potential underground utilities are marked prior to beginning digging operations.

Farming activities, construction activities, grading changes, settling of the earth, or poor installation practices often can leave a utility much shallower than three feet. MIOSHA personnel, upon walking the field where the excavation was being performed noted additional utility markers in the tree line (Figure 4). Prior to performing any excavation work, the crew should perform a walkthrough of the area to note any potential hazards or previously missed utility markers.

|

|

Figure 4. Markers in tree line

|

Employers conducting excavating or tunneling operations should contact MISS DIG if public utilities/agencies listed on the MISS DIG ticket have not marked their lines in response or provided a Positive Response to the MISS DIG request.

MIOSHA Construction Safety Standard, Excavating, Trenching, and Shoring, Part 9, Rule 931 requires that “an employer shall not excavate in a street, highway, public place, a private easement of a public utility, or near the location of a public utility facility owned, maintained, or installed on a customer’s premises, without having first ascertained the location of all underground facilities of a public utility in the proposed area of excavation”. (Emphasis added)

The MISS DIG inquiry response ticket had several blank areas that indicated the utility/public agency had not made a Positive Response. Three companies had positively responded and marked their lines or indicated that they were clear, and four companies had not marked the lines or indicated that there were no lines in the area. When a company conducting excavation activities arrives at the site and finds that all contacted companies have not marked their lines or indicated an all clear, the company, prior to beginning excavation activities, should contact MISS DIG so MISS DIG may make a repeat request. MISS DIG states in their dig safety pamphlet that if there are indications of unmarked facilities, MISS DIG must be called whether or not an all clear has been received from the utility.

Employers conducting excavating or tunneling operations should describe the area to be staked as specifically as possible when calling MISS DIG.

Construction activities, grading changes, settling of the earth, and poor installation practices often can leave a utility much shallower than 3 feet. Callers to MISS DIG should provide the most detailed information they can to describe the area in which the excavation will be taking place. Persons staking the area for the utilities are most likely unfamiliar with the area to be staked. Callers should use landmarks, distances in feet or yards, etc., to describe the boundaries of the excavation/construction area. The MISS DIG ticket inquiry request indicated that the area to be staked was an 11.5-acre property. The cooperative had laid out its route marking flags one month prior to the MISS DIG contact. Per the technician’s statement, he had to replace cooperative route flags that had been dislocated by corn harvesting. The number of flags displaced and whether the route flags were visible to utility marking representatives to ascertain the area to be identified by them is unknown.

Michigan Public Act 53 of 1974, Protection of Underground Facilities should be amended to reflect damage prevention Common Ground Alliance (CGA) Best Practices Version 4.0 as applicable to each stakeholder group.

In June 1999, the United States Department of Transportation (DOT) sponsored the Common Ground Study of One Call Systems and Damage Prevention Best Practices (Study). The Study provided a guide to underground utility damage prevention best practices in use throughout the United States and Canada. Following the completion of the Study, the Common Ground Alliance (CGA) was created to further the work begun by the 160-member Common Ground Task Force established by the DOT in 1998. The CGA established several committees, one of which was the Best Practices Committee. The purpose of this committee was to continue to focus on identifying those Best Practices that are appropriate for each stakeholder group, gauge current levels of implementation and use of those Best Practices, and encourage and promote increased implementation of the Best Practices. In March, 2007, the CGA published Best Practices Version 4.0, which contains the practices statements and supporting descriptions contained in the original Study as well as new practices passed by the Best Practice Committee since the completion of the Study in 1999.

Public Act 53 was signed into Michigan Law over 30 years ago and does not reflect current best practice. To promote damage prevention, it is important that all stakeholders implement the damage prevention Best Practices as applicable to each stakeholder group. The CGA Best Practices Version 4.0 is divided into eight damage prevention chapters:

- Planning & Design Best Practices

- One Call Center Best Practices

- Location & Marking Best Practices

- Excavation Best Practices

- Mapping Best Practices

- Compliance Best Practices

- Public Education Best Practices

- Reporting & Evaluation Best Practices

Version 4.0 is available on the CGA websiteexternal icon: (http://www.commongroundalliance.com/Template.cfm?Section=Best_Practices).

References

MIOSHA Standards cited in this report can be directly accessed from the Michigan Department of Labor and Economic Growthexternal icon, MIOSHA website www.michigan.gov/mioshastandards. The Standards may also be obtained for a fee by writing to the following address: Michigan Department of Labor and Economic Growth, MIOSHA, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan, 48909-8143. MIOSHA Standard Section phone number is (517) 322-1845.

- MIOSHA Construction Safety Standard, General Rules, Part 1.

- MIOSHA Construction Safety Standard, Excavating, Trenching, and Shoring, Part 9.

- Common Ground Alliance, Best Practices Version 4.0external icon. Published March 2007. Internet Address: http://www.commongroundalliance.com/

- Michigan Public Act 53 of 1974. Michigan Legislature Websiteexternal icon. Internet Address: http://www.legislature.mi.gov/(S(y4ycdkye2ofl3xzftyctsx45))/mileg.aspx?

page=GetObject&objectname=mcl-Act-53-of-1974 (Link updated 4/1/2013) - NTSB PB96-916501: Pipeline Accident Report. UGI Utilities, Inc., Natural Gas Distribution Pipeline Explosion and Fire, Allentown, Pennsylvaniapdf iconexternal icon, June 9, 1994. Internet Address: http://www.ntsb.gov/investigations/AccidentReports/Reports/PAR9601.pdf (Link updated 4/9/2015)

- Hazards Associated With Striking Underground Gas Linesexternal icon. Safety and Health Bulletin SHIB 03-05-21. U.S. Department of Labor, Occupational Safety and Health Administration.

Internet Address: https://www.osha.gov/dts/shib/shib_05_21_03_sugl.html - National Transportation Safety Board, Pipeline Accident Brief. Accident # DCA-99-MP-004. Internet Address: http://www.ntsb.gov/investigations/AccidentReports/Reports/PAB0001.pdf (Link updated 4/9/2015)

- National Transportation Safety Board, Pipeline Accident Brief. Accident # DCA-03-MP-004. Internet Address: http://www.ntsb.gov/investigations/AccidentReports/Reports/PAB0401.pdf (Link updated 4/9/2015)

Michigan FACE Program

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicineexternal icon, 117 West Fee Hall, East Lansing, Michigan 48824-1315; http://www.oem.msu.edu/MiFACE_Program.aspx. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 10/23/07

MIFACE Investigation Report # 06MI207 Evaluationpdf iconexternal icon (see page 12 of report)

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.