Engineering Controls Database

Hot Mix Asphalt Pavers – Engineering Controls

| Approximately 300,000 workers are employed at hot-mix asphalt facilities and paving sites. | |

| Studies of asphalt workers show an excess of lung, bladder, brain, liver, and digestive system cancers among roofers and workers in other occupations with the potential for exposure to asphalt. The extent to which these findings may be caused by asphalt fume exposure is unknown. Asphalt fumes have been reported to cause coughing and headaches and to irritate the mucous membranes of the eyes, nose, and respiratory tract. Observations of acute irritation in workers from airborne and dermal exposures to asphalt fumes and aerosols and the potential for chronic health effects, including cancer, warrant continued diligence in the control of exposures. | |

|

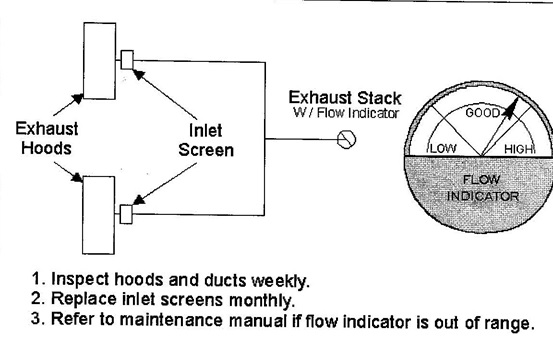

NIOSH, in collaboration with industry, labor, and other governmental agencies developed engineering controls for the asphalt paving industry. These controls are relevant for new highway-class self-propelled hot mix asphalt (HMA) pavers weighing 16,000 pounds or more. Specifics for the engineering controls provided in this data entry form can be found in the NIOSH document noted below. Ventilation Systems Each paver manufacturer should develop and install exhaust ventilation systems with a minimum controlled indoor capture efficiency of 80% (as determined by the tracer gas method provided in NIOSH 97-105) on all new self-propelled HMA pavers weighing 16,000 pounds or more and manufactured after July 1, 1997. Each paver manufacturer should test the exhaust ventilation system for each model of paver and should certify that each model year meets the minimum indoor capture efficiency specified above. Each manufacturer should install an indicating device on each paver so that the system flow rate can be determined. The indicating device should incorporate a means for visually determining whether the exhaust ventilation system is operating within the designed operating range. Each manufacturer should develop and implement a quality control plan designed to ensure that exhaust ventilation systems on each paver will develop and install exhaust ventilation systems with a minimum controlled indoor capture efficiency of 80% (as determined by the tracer gas method). Each manufacturer should attach a plate to the paver showing a simple schematic of the exhaust ventilation system and a list of field-maintenance procedures. An example of this schematic is shown in Figure 1.  Certification Manufacturers of highway-class HMA pavers should certify the following to purchasers of new pavers: [Manufacturing company] hereby certifies that (1) the paver (model number) being purchased has been tested on (Date) in accordance with the Appendix of the Engineering Control Guidelines for Hot Mix Asphalt Pavers: Part I, published by the National Institute for Occupational Safety and Health (NIOSH) and, (2) the paver model has been found to achieve at least an 80% indoor capture efficiency (standard tests provide 95% confidence that indoor capture efficiency is T% or better). [T% is the T-statistic calculated in accordance with the guidance provided in NIOSH 97-105.] The manufacturer should keep a copy of all such certifications and their supporting test data for at least 3 years. Operation and Maintenance For each exhaust ventilation system, HMA paver manufacturers should provide an operator’s manual that contains a maintenance schedule. Each operator’s manual should also include detailed sketches and performance criteria for equipment owners to use in their annual assessment of the exhaust ventilation systems; troubleshooting instructions should also be included for low or high exhaust flows. Owners of HMA pavers with exhaust ventilation systems are advised to inspect and maintain the systems according to the manufacturer’s recommendations and to record the dates of annual performance inspections within the operator’s manual. Training Equipment mechanics trained in the maintenance and repair of asphalt paving equipment may require additional training to perform these services on exhaust ventilation systems. Equipment manufacturers should create or identify training manuals and instructions designed to train equipment owners in the operation, maintenance, and repair of exhaust ventilation systems for HMA pavers. NOTE: The above information is taken directly from the following publication: NIOSH [1997]. Engineering control guidelines for hot mix asphalt pavers – Part 1: New highway-class pavers. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 97-105. |

|

| 208-12-A; 208-13-A; 208-14-A; 208-15-A; 208-17-A; 208-18-A; 208-19-A; 208-20-A; 208-21-A; 208-22-A; 208-23-A; | |

|

asphalt pavers asphalt pavers paver operators rakers tackmen |