Engineering Controls Database

Postal Culling System

|

In 2001, terrorist attacks took place where anthrax spores were sent by mail to a U.S. Senator and to media offices [CDC 2001]. These attacks resulted in exposure to anthrax spores by postal employees working in a mail processing facility that serves the U.S. Capitol and resulted in inhalation disease in several of the workers [Mayer et al. 2001]. One potential area of exposure in the United States Postal Service (USPS) is the automated mail processing equipment used to sort incoming mail. As the mail passes through the machinery, it is compressed and impacted in a number of places that could cause release of substances from the mail. |

|

| Bacillus anthracis is a large spore forming bacteria. In the vegetative state, it is rod shaped and ranges in size from 1-1.5 X 3-10 µm. The anthrax spores are typically in the 1-5 µm size range and can enter the body by being inhaled, through the skin, or through ingestion. Disease occurs when spores enter the body, germinate, and multiply. The cutaneous form of the disease generally develops 2-5 days following exposure and can usually be successfully treated with antibiotics. The onset for the inhalation form is typically l-6 days after exposure. The inhalation form generally has a high fatality rate even with appropriate treatment [Pile et al. 1998]. | |

|

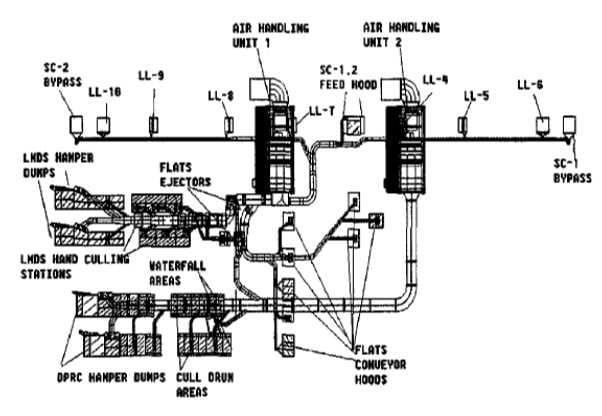

Researchers from the National Institute for Occupational Safety and Health (NIOSH) were requested to assist the USPS in the evaluation of particulate controls for various mail processing equipment. These controls were installed to reduce operator exposure to any potentially hazardous contaminants emitted from letter mail during normal mail processing. This effort is driven by the terrorist attacks which used the mail as a delivery system for anthrax. There were a number of reports generated by NIOSH that evaluated controls put in place by the USPS to control release of contaminants into work areas of postal employees. This summary describes four reports (see EPHB report numbers above) that evaluated the capture effectiveness of the Ventilation/Filtration System of the 010 Culling System. The USPS 010 Culling System is comprised of two conveyor systems that size the collected mail brought to the post office distribution center into letters, flats (magazine size), and parcels. The first system is called the Dual Pass Rough Cull (DPRC) and the second is the Loose Mail Distribution System (LMDS). The hampers of raw mail are loaded into the DPRC. Flats and parcels are separated from the letter mail and sent to the appropriate areas of the facility for processing. The output of the LMDS sends letter mail to the cancellation equipment. Figure 1 shows an overview of the 010 system.  At the time of these evaluations, the Ventilation/Filtration System (VFS) for the 010 Culling System consisted of two separate air handling filtration units that provided exhaust for various locations of possible contaminant release. Air-Handling Unit #l processed about 19,000 cubic feet per minute (cfm) and could be switched to service various areas depending upon USPS processing needs, including the LMDS area and conveyors that send mail to equipment downstream of the 010 Culling System. Air-Handling Unit #2 processed about 18,000 cfm and serviced the primary areas of the DPRC. Each of these air-handling units was fitted with three stages of filtration composed of a pre-filter, a MERV 14 filter and a High Efficiency Particulate Air (HEPA) filter. Furthermore, several areas of potential contaminant release were enclosed or partially enclosed by the manufacturer so that the VFS could more effectively protect the worker from exposure. |

|

| 279-14A1; 279-14A2; 279-20A; 279-22; | |

|

CDC (Centers for Disease Control and Prevention) [2001]. Investigation of bioterrorism-related anthrax and interim guidelines for exposure management and antimicrobial therapy. MMWR 50:909-919. Mayer TA, Bersoff-Matcha S, Murphy C, Earls J, Harper S, Pauze D, Nguyen M, Rosentahal J, Cerva D, Druckenbrod G, Hanfling D, Fatteh N, Napoli A, Nayyar A, Berman EL [2001]. Clinical presentation of inhalation anthrax following bioterrorism exposure. JAMA 286(20): 2549-2553. Pile JC, Malone JD, Eitzen EM, Friedlander AM [1998]. Anthrax as a potential biological warfare agent. Arch Intern Med 158:429-434. |

|

| 333318 | |

|

anthrax culling system engineering control mail handlers mail handlers United States Postal Service |

|

|

The 010 Culling System consists of two conveyor systems (DPRC and LMDS) that size the collection mail. Evaluations were based on a variety of tests including tracer gas experiments, air velocity measurements and smoke release observations. The experiments showed that generally there is good capture (greater than 95% at most of the areas evaluated) by the ventilation system; however, there are some points that required improvement. Based on the results as discussed in these reports, a number of specific and general changes were made to further improve the control of potential contaminants by this mail sorting system. Several of the improvements made were: • Improvements were made to the ventilation on the letter channels exiting the waterfall area of the DPRC near the ends where the mail pieces undergo the most agitation; • Exhaust was added to the area above the cull belt just after the hamper dumper; • Ventilation was improved for the flats extractors on the DPRC; • The exhaust hood for the letter channel drop was redesigned to prevent the hood face from being covered with mail during operation; • To ensure optimal filtration, the USPS took steps to guarantee that filters were changed often enough to be operating within prescribed parameters and that filters were protected from physical damage; • Proper and regular maintenance of the filtration component of the VFS unit is essential for effective filtration. Work procedures for maintenance were designed with this in mind and should be closely followed; and • Workers at the Hand-Cull stations were encouraged to work with curtains down (containment device previously installed on unit) to optimize the effectiveness of the VFS. |