|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

||||

| ||||||||||

|

|

|

|

|

Persons using assistive technology might not be able to fully access information in this file. For assistance, please send e-mail to: mmwrq@cdc.gov. Type 508 Accommodation and the title of the report in the subject line of e-mail. Guidelines for Infection Control in Dental Health-Care Settings --- 2003Prepared by The material in this report originated in the National Center for Chronic Disease Prevention and Health Promotion, James S. Marks, M.D., M.P.H., Director; and the Division of Oral Health, William R. Maas, D.D.S., M.P.H., Director. SummaryThis report consolidates previous recommendations and adds new ones for infection control in dental settings. Recommendations are provided regarding 1) educating and protecting dental health-care personnel; 2) preventing transmission of bloodborne pathogens; 3) hand hygiene; 4) personal protective equipment; 5) contact dermatitis and latex hypersensitivity; 6) sterilization and disinfection of patient-care items; 7) environmental infection control; 8) dental unit waterlines, biofilm, and water quality; and 9) special considerations (e.g., dental handpieces and other devices, radiology, parenteral medications, oral surgical procedures, and dental laboratories). These recommendations were developed in collaboration with and after review by authorities on infection control from CDC and other public agencies, academia, and private and professional organizations. IntroductionThis report consolidates recommendations for preventing and controlling infectious diseases and managing personnel health and safety concerns related to infection control in dental settings. This report 1) updates and revises previous CDC recommendations regarding infection control in dental settings (1,2); 2) incorporates relevant infection-control measures from other CDC guidelines; and 3) discusses concerns not addressed in previous recommendations for dentistry. These updates and additional topics include the following:

These guidelines were developed by CDC staff members in collaboration with other authorities on infection control. Draft documents were reviewed by other federal agencies and professional organizations from the fields of dental health care, public health, and hospital epidemiology and infection control. A Federal Register notice elicited public comments that were considered in the decision-making process. Existing guidelines and published research pertinent to dental infection-control principles and practices were reviewed. Wherever possible, recommendations are based on data from well-designed scientific studies. However, only a limited number of studies have characterized risk factors and the effectiveness of prevention measures for infections associated with dental health-care practices. Some infection-control practices routinely used by health-care practitioners cannot be rigorously examined for ethical or logistical reasons. In the absence of scientific evidence for such practices, certain recommendations are based on strong theoretical rationale, suggestive evidence, or opinions of respected authorities based on clinical experience, descriptive studies, or committee reports. In addition, some recommendations are derived from federal regulations. No recommendations are offered for practices for which insufficient scientific evidence or lack of consensus supporting their effectiveness exists. BackgroundIn the United States, an estimated 9 million persons work in health-care professions, including approximately 168,000 dentists, 112,000 registered dental hygienists, 218,000 dental assistants (3), and 53,000 dental laboratory technicians (4). In this report, dental health-care personnel (DHCP) refers to all paid and unpaid personnel in the dental health-care setting who might be occupationally exposed to infectious materials, including body substances and contaminated supplies, equipment, environmental surfaces, water, or air. DHCP include dentists, dental hygienists, dental assistants, dental laboratory technicians (in-office and commercial), students and trainees, contractual personnel, and other persons not directly involved in patient care but potentially exposed to infectious agents (e.g., administrative, clerical, housekeeping, maintenance, or volunteer personnel). Recommendations in this report are designed to prevent or reduce potential for disease transmission from patient to DHCP, from DHCP to patient, and from patient to patient. Although these guidelines focus mainly on outpatient, ambulatory dental health-care settings, the recommended infection-control practices are applicable to all settings in which dental treatment is provided. Dental patients and DHCP can be exposed to pathogenic microorganisms including cytomegalovirus (CMV), HBV, HCV, herpes simplex virus types 1 and 2, HIV, Mycobacterium tuberculosis, staphylococci, streptococci, and other viruses and bacteria that colonize or infect the oral cavity and respiratory tract. These organisms can be transmitted in dental settings through 1) direct contact with blood, oral fluids, or other patient materials; 2) indirect contact with contaminated objects (e.g., instruments, equipment, or environmental surfaces); 3) contact of conjunctival, nasal, or oral mucosa with droplets (e.g., spatter) containing microorganisms generated from an infected person and propelled a short distance (e.g., by coughing, sneezing, or talking); and 4) inhalation of airborne microorganisms that can remain suspended in the air for long periods (5). Infection through any of these routes requires that all of the following conditions be present:

Occurrence of these events provides the chain of infection (6). Effective infection-control strategies prevent disease transmission by interrupting one or more links in the chain. Previous CDC recommendations regarding infection control for dentistry focused primarily on the risk of transmission of bloodborne pathogens among DHCP and patients and use of universal precautions to reduce that risk (1,2,7,8). Universal precautions were based on the concept that all blood and body fluids that might be contaminated with blood should be treated as infectious because patients with bloodborne infections can be asymptomatic or unaware they are infected (9,10). Preventive practices used to reduce blood exposures, particularly percutaneous exposures, include 1) careful handling of sharp instruments, 2) use of rubber dams to minimize blood spattering; 3) handwashing; and 4) use of protective barriers (e.g., gloves, masks, protective eyewear, and gowns). The relevance of universal precautions to other aspects of disease transmission was recognized, and in 1996, CDC expanded the concept and changed the term to standard precautions. Standard precautions integrate and expand the elements of universal precautions into a standard of care designed to protect HCP and patients from pathogens that can be spread by blood or any other body fluid, excretion, or secretion (11). Standard precautions apply to contact with 1) blood; 2) all body fluids, secretions, and excretions (except sweat), regardless of whether they contain blood; 3) nonintact skin; and 4) mucous membranes. Saliva has always been considered a potentially infectious material in dental infection control; thus, no operational difference exists in clinical dental practice between universal precautions and standard precautions. In addition to standard precautions, other measures (e.g., expanded or transmission-based precautions) might be necessary to prevent potential spread of certain diseases (e.g., TB, influenza, and varicella) that are transmitted through airborne, droplet, or contact transmission (e.g., sneezing, coughing, and contact with skin) (11). When acutely ill with these diseases, patients do not usually seek routine dental outpatient care. Nonetheless, a general understanding of precautions for diseases transmitted by all routes is critical because 1) some DHCP are hospital-based or work part-time in hospital settings; 2) patients infected with these diseases might seek urgent treatment at outpatient dental offices; and 3) DHCP might become infected with these diseases. Necessary transmission-based precautions might include patient placement (e.g., isolation), adequate room ventilation, respiratory protection (e.g., N-95 masks) for DHCP, or postponement of nonemergency dental procedures. DHCP should be familiar also with the hierarchy of controls that categorizes and prioritizes prevention strategies (12). For bloodborne pathogens, engineering controls that eliminate or isolate the hazard (e.g., puncture-resistant sharps containers or needle-retraction devices) are the primary strategies for protecting DHCP and patients. Where engineering controls are not available or appropriate, work-practice controls that result in safer behaviors (e.g., one-hand needle recapping or not using fingers for cheek retraction while using sharp instruments or suturing), and use of personal protective equipment (PPE) (e.g., protective eyewear, gloves, and mask) can prevent exposure (13). In addition, administrative controls (e.g., policies, procedures, and enforcement measures targeted at reducing the risk of exposure to infectious persons) are a priority for certain pathogens (e.g., M. tuberculosis), particularly those spread by airborne or droplet routes. Dental practices should develop a written infection-control program to prevent or reduce the risk of disease transmission. Such a program should include establishment and implementation of policies, procedures, and practices (in conjunction with selection and use of technologies and products) to prevent work-related injuries and illnesses among DHCP as well as health-care--associated infections among patients. The program should embody principles of infection control and occupational health, reflect current science, and adhere to relevant federal, state, and local regulations and statutes. An infection-control coordinator (e.g., dentist or other DHCP) knowledgeable or willing to be trained should be assigned responsibility for coordinating the program. The effectiveness of the infection-control program should be evaluated on a day-to-day basis and over time to help ensure that policies, procedures, and practices are useful, efficient, and successful (see Program Evaluation). Although the infection-control coordinator remains responsible for overall management of the program, creating and maintaining a safe work environment ultimately requires the commitment and accountability of all DHCP. This report is designed to provide guidance to DHCP for preventing disease transmission in dental health-care settings, for promoting a safe working environment, and for assisting dental practices in developing and implementing infection-control programs. These programs should be followed in addition to practices and procedures for worker protection required by the Occupational Safety and Health Administration's (OSHA) standards for occupational exposure to bloodborne pathogens (13), including instituting controls to protect employees from exposure to blood or other potentially infectious materials (OPIM), and requiring implementation of a written exposure-control plan, annual employee training, HBV vaccinations, and postexposure follow-up (13). Interpretations and enforcement procedures are available to help DHCP apply this OSHA standard in practice (14). Also, manufacturer's Material Safety Data Sheets (MSDS) should be consulted regarding correct procedures for handling or working with hazardous chemicals (15). Previous RecommendationsThis report includes relevant infection-control measures from the following previously published CDC guidelines and recommendations:

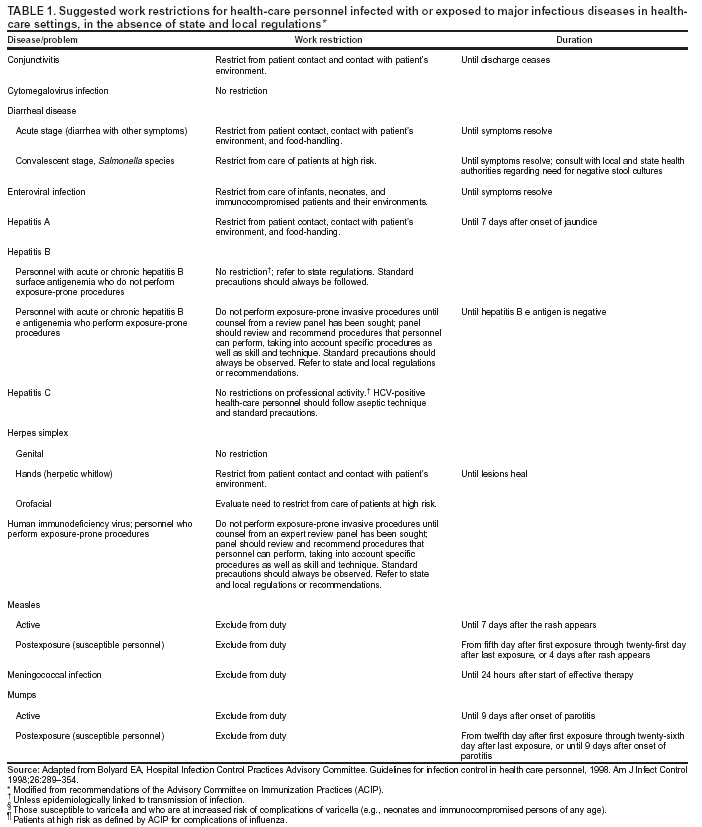

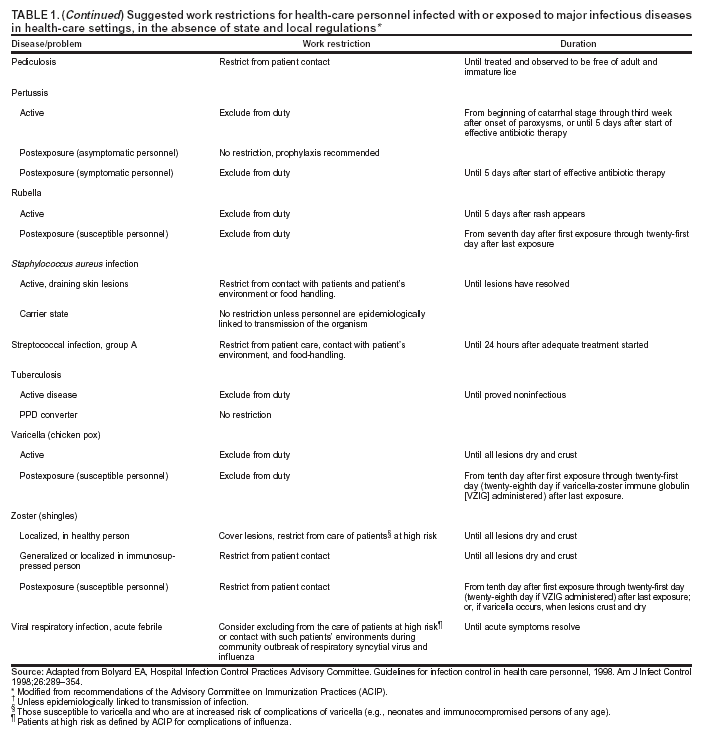

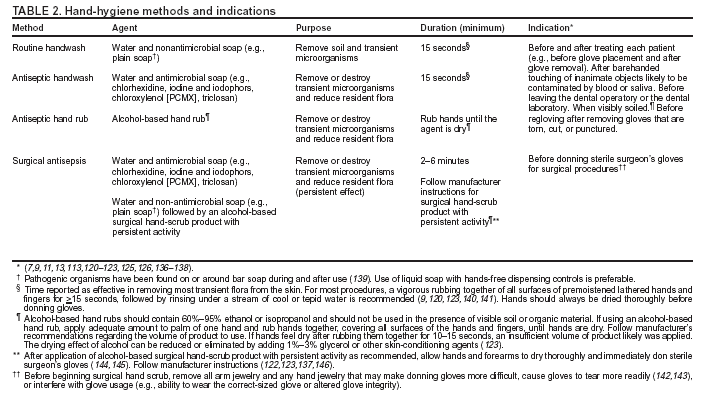

Selected DefinitionsAlcohol-based hand rub: An alcohol-containing preparation designed for reducing the number of viable microorganisms on the hands. Antimicrobial soap: A detergent containing an antiseptic agent. Antiseptic: A germicide used on skin or living tissue for the purpose of inhibiting or destroying microorganisms (e.g., alcohols, chlorhexidine, chlorine, hexachlorophene, iodine, chloroxylenol [PCMX], quaternary ammonium compounds, and triclosan). Bead sterilizer: A device using glass beads 1.2--1.5 mm diameter and temperatures 217ºC--232ºC for brief exposures (e.g., 45 seconds) to inactivate microorganisms. (This term is actually a misnomer because it has not been cleared by the Food and Drug Administration [FDA] as a sterilizer). Bioburden: Microbiological load (i.e., number of viable organisms in or on an object or surface) or organic material on a surface or object before decontamination, or sterilization. Also known as bioload or microbial load. Colony-forming unit (CFU): The minimum number (i.e., tens of millions) of separable cells on the surface of or in semisolid agar medium that give rise to a visible colony of progeny. CFUs can consist of pairs, chains, clusters, or as single cells and are often expressed as colony-forming units per milliliter (CFUs/mL). Decontamination: Use of physical or chemical means to remove, inactivate, or destroy pathogens on a surface or item so that they are no longer capable of transmitting infectious particles and the surface or item is rendered safe for handling, use, or disposal. Dental treatment water: Nonsterile water used during dental treatment, including irrigation of nonsurgical operative sites and cooling of high-speed rotary and ultrasonic instruments. Disinfectant: A chemical agent used on inanimate objects (e.g., floors, walls, or sinks) to destroy virtually all recognized pathogenic microorganisms, but not necessarily all microbial forms (e.g., bacterial endospores). The U.S. Environmental Protection Agency (EPA) groups disinfectants on the basis of whether the product label claims limited, general, or hospital disinfectant capabilities. Disinfection: Destruction of pathogenic and other kinds of microorganisms by physical or chemical means. Disinfection is less lethal than sterilization, because it destroys the majority of recognized pathogenic microorganisms, but not necessarily all microbial forms (e.g., bacterial spores). Disinfection does not ensure the degree of safety associated with sterilization processes. Droplet nuclei: Particles <5 µm in diameter formed by dehydration of airborne droplets containing microorganisms that can remain suspended in the air for long periods of time. Droplets: Small particles of moisture (e.g., spatter) generated when a person coughs or sneezes, or when water is converted to a fine mist by an aerator or shower head. These particles, intermediate in size between drops and droplet nuclei, can contain infectious microorganisms and tend to quickly settle from the air such that risk of disease transmission is usually limited to persons in close proximity to the droplet source. Endotoxin: The lipopolysaccharide of gram-negative bacteria, the toxic character of which resides in the lipid protein. Endotoxins can produce pyrogenic reactions in persons exposed to their bacterial component. Germicide: An agent that destroys microorganisms, especially pathogenic organisms. Terms with the same suffix (e.g., virucide, fungicide, bactericide, tuberculocide, and sporicide) indicate agents that destroy the specific microorganism identified by the prefix. Germicides can be used to inactivate microorganisms in or on living tissue (i.e., antiseptics) or on environmental surfaces (i.e., disinfectants). Hand hygiene: General term that applies to handwashing, antiseptic handwash, antiseptic hand rub, or surgical hand antisepsis. Health-care--associated infection: Any infection associated with a medical or surgical intervention. The term health-care--associated replaces nosocomial, which is limited to adverse infectious outcomes occurring in hospitals. Hepatitis B immune globulin (HBIG): Product used for prophylaxis against HBV infection. HBIG is prepared from plasma containing high titers of hepatitis B surface antibody (anti-HBs) and provides protection for 3--6 mos. Hepatitis B surface antigen (HBsAg): Serologic marker on the surface of HBV detected in high levels during acute or chronic hepatitis. The body normally produces antibodies to surface antigen as a normal immune response to infection. Hepatitis B e antigen (HBeAg): Secreted product of the nucleocapsid gene of HBV found in serum during acute and chronic HBV infection. Its presence indicates that the virus is replicating and serves as a marker of increased infectivity. Hepatitis B surface antibody (anti-HBs): Protective antibody against HBsAg. Presence in the blood can indicate past infection with, and immunity to, HBV, or immune response from hepatitis B vaccine. Heterotrophic bacteria: Those bacteria requiring an organic carbon source for growth (i.e., deriving energy and carbon from organic compounds). High-level disinfection: Disinfection process that inactivates vegetative bacteria, mycobacteria, fungi, and viruses but not necessarily high numbers of bacterial spores. FDA further defines a high-level disinfectant as a sterilant used for a shorter contact time. Hospital disinfectant: Germicide registered by EPA for use on inanimate objects in hospitals, clinics, dental offices, and other medical-related facilities. Efficacy is demonstrated against Salmonella choleraesuis, Staphylococcus aureus, and Pseudomonas aeruginosa. Iatrogenic: Induced inadvertently by HCP, medical (including dental) treatment, or diagnostic procedures. Used particularly in reference to an infectious disease or other complication of treatment. Immunization: Process by which a person becomes immune, or protected against a disease. Vaccination is defined as the process of administering a killed or weakened infectious organism or a toxoid; however, vaccination does not always result in immunity. Implantable device: Device placed into a surgically or naturally formed cavity of the human body and intended to remain there for >30 days. Independent water reservoir: Container used to hold water or other solutions and supply it to handpieces and air and water syringes attached to a dental unit. The independent reservoir, which isolates the unit from the public water system, can be provided as original equipment or as a retrofitted device. Intermediate-level disinfection: Disinfection process that inactivates vegetative bacteria, the majority of fungi, mycobacteria, and the majority of viruses (particularly enveloped viruses) but not bacterial spores. Intermediate-level disinfectant: Liquid chemical germicide registered with EPA as a hospital disinfectant and with a label claim of potency as tuberculocidal (Appendix A). Latex: Milky white fluid extracted from the rubber tree Hevea brasiliensis that contains the rubber material cis-1,4 polyisoprene. Low-level disinfection: Process that inactivates the majority of vegetative bacteria, certain fungi, and certain viruses, but cannot be relied on to inactivate resistant microorganisms (e.g., mycobacteria or bacterial spores). Low-level disinfectant: Liquid chemical germicide registered with EPA as a hospital disinfectant. OSHA requires low-level hospital disinfectants also to have a label claim for potency against HIV and HBV if used for disinfecting clinical contact surfaces (Appendix A). Microfilter: Membrane filter used to trap microorganisms suspended in water. Filters are usually installed on dental unit waterlines as a retrofit device. Microfiltration commonly occurs at a filter pore size of 0.03--10 µm. Sediment filters commonly found in dental unit water regulators have pore sizes of 20--90 µm and do not function as microbiological filters. Nosocomial: Infection acquired in a hospital as a result of medical care. Occupational exposure: Reasonably anticipated skin, eye, mucous membrane, or parenteral contact with blood or OPIM that can result from the performance of an employee's duties. OPIM: Other potentially infectious materials. OPIM is an OSHA term that refers to 1) body fluids including semen, vaginal secretions, cerebrospinal fluid, synovial fluid, pleural fluid, pericardial fluid, peritoneal fluid, amniotic fluid, saliva in dental procedures; any body fluid visibly contaminated with blood; and all body fluids in situations where differentiating between body fluids is difficult or impossible; 2) any unfixed tissue or organ (other than intact skin) from a human (living or dead); and 3) HIV-containing cell or tissue cultures, organ cultures; HIV- or HBV-containing culture medium or other solutions; and blood, organs, or other tissues from experimental animals infected with HIV or HBV. Parenteral: Means of piercing mucous membranes or skin barrier through such events as needlesticks, human bites, cuts, and abrasions. Persistent activity: Prolonged or extended activity that prevents or inhibits proliferation or survival of microorganisms after application of a product. This activity can be demonstrated by sampling a site minutes or hours after application and demonstrating bacterial antimicrobial effectiveness when compared with a baseline level. Previously, this property was sometimes termed residual activity. Prion: Protein particle lacking nucleic acid that has been implicated as the cause of certain neurodegenerative diseases (e.g., scrapie, CJD, and bovine spongiform encephalopathy [BSE]). Retraction: Entry of oral fluids and microorganisms into waterlines through negative water pressure. Seroconversion: The change of a serological test from negative to positive indicating the development of antibodies in response to infection or immunization. Sterile: Free from all living microorganisms; usually described as a probability (e.g., the probability of a surviving microorganism being 1 in 1 million). Sterilization: Use of a physical or chemical procedure to destroy all microorganisms including substantial numbers of resistant bacterial spores. Surfactants: Surface-active agents that reduce surface tension and help cleaning by loosening, emulsifying, and holding soil in suspension, to be more readily rinsed away. Ultrasonic cleaner: Device that removes debris by a process called cavitation, in which waves of acoustic energy are propagated in aqueous solutions to disrupt the bonds that hold particulate matter to surfaces. Vaccination: See immunization. Vaccine: Product that induces immunity, therefore protecting the body from the disease. Vaccines are administered through needle injections, by mouth, and by aerosol. Washer-disinfector: Automatic unit that cleans and thermally disinfects instruments, by using a high-temperature cycle rather than a chemical bath. Wicking: Absorption of a liquid by capillary action along a thread or through the material (e.g., penetration of liquids through undetected holes in a glove). Review of Science Related to Dental Infection ControlPersonnel Health Elements of an Infection-Control ProgramA protective health component for DHCP is an integral part of a dental practice infection-control program. The objectives are to educate DHCP regarding the principles of infection control, identify work-related infection risks, institute preventive measures, and ensure prompt exposure management and medical follow-up. Coordination between the dental practice's infection-control coordinator and other qualified health-care professionals is necessary to provide DHCP with appropriate services. Dental programs in institutional settings, (e.g., hospitals, health centers, and educational institutions) can coordinate with departments that provide personnel health services. However, the majority of dental practices are in ambulatory, private settings that do not have licensed medical staff and facilities to provide complete on-site health service programs. In such settings, the infection-control coordinator should establish programs that arrange for site-specific infection-control services from external health-care facilities and providers before DHCP are placed at risk for exposure. Referral arrangements can be made with qualified health-care professionals in an occupational health program of a hospital, with educational institutions, or with health-care facilities that offer personnel health services. Education and Training Personnel are more likely to comply with an infection-control program and exposure-control plan if they understand its rationale (5,13,16). Clearly written policies, procedures, and guidelines can help ensure consistency, efficiency, and effective coordination of activities. Personnel subject to occupational exposure should receive infection-control training on initial assignment, when new tasks or procedures affect their occupational exposure, and at a minimum, annually (13). Education and training should be appropriate to the assigned duties of specific DHCP (e.g., techniques to prevent cross-contamination or instrument sterilization). For DHCP who perform tasks or procedures likely to result in occupational exposure to infectious agents, training should include 1) a description of their exposure risks; 2) review of prevention strategies and infection-control policies and procedures; 3) discussion regarding how to manage work-related illness and injuries, including PEP; and 4) review of work restrictions for the exposure or infection. Inclusion of DHCP with minimal exposure risks (e.g., administrative employees) in education and training programs might enhance facilitywide understanding of infection-control principles and the importance of the program. Educational materials should be appropriate in content and vocabulary for each person's educational level, literacy, and language, as well as be consistent with existing federal, state, and local regulations (5,13). Immunization Programs DHCP are at risk for exposure to, and possible infection with, infectious organisms. Immunizations substantially reduce both the number of DHCP susceptible to these diseases and the potential for disease transmission to other DHCP and patients (5,17). Thus, immunizations are an essential part of prevention and infection-control programs for DHCP, and a comprehensive immunization policy should be implemented for all dental health-care facilities (17,18). The Advisory Committee on Immunization Practices (ACIP) provides national guidelines for immunization of HCP, which includes DHCP (17). Dental practice immunization policies should incorporate current state and federal regulations as well as recommendations from the U.S. Public Health Service and professional organizations (17) (Appendix B). On the basis of documented health-care--associated transmission, HCP are considered to be at substantial risk for acquiring or transmitting hepatitis B, influenza, measles, mumps, rubella, and varicella. All of these diseases are vaccine-preventable. ACIP recommends that all HCP be vaccinated or have documented immunity to these diseases (5,17). ACIP does not recommend routine immunization of HCP against TB (i.e., inoculation with bacille Calmette-Guérin vaccine) or hepatitis A (17). No vaccine exists for HCV. ACIP guidelines also provide recommendations regarding immunization of HCP with special conditions (e.g., pregnancy, HIV infection, or diabetes) (5,17). Immunization of DHCP before they are placed at risk for exposure remains the most efficient and effective use of vaccines in health-care settings. Some educational institutions and infection-control programs provide immunization schedules for students and DHCP. OSHA requires that employers make hepatitis B vaccination available to all employees who have potential contact with blood or OPIM. Employers are also required to follow CDC recommendations for vaccinations, evaluation, and follow-up procedures (13). Nonpatient-care staff (e.g., administrative or housekeeping) might be included, depending on their potential risk of coming into contact with blood or OPIM. Employers are also required to ensure that employees who decline to accept hepatitis B vaccination sign an appropriate declination statement (13). DHCP unable or unwilling to be vaccinated as required or recommended should be educated regarding their exposure risks, infection-control policies and procedures for the facility, and the management of work-related illness and work restrictions (if appropriate) for exposed or infected DHCP. Exposure Prevention and Postexposure Management Avoiding exposure to blood and OPIM, as well as protection by immunization, remain primary strategies for reducing occupationally acquired infections, but occupational exposures can still occur (19). A combination of standard precautions, engineering, work practice, and administrative controls is the best means to minimize occupational exposures. Written policies and procedures to facilitate prompt reporting, evaluation, counseling, treatment, and medical follow-up of all occupational exposures should be available to all DHCP. Written policies and procedures should be consistent with federal, state, and local requirements addressing education and training, postexposure management, and exposure reporting (see Preventing Transmission of Bloodborne Pathogens). DHCP who have contact with patients can also be exposed to persons with infectious TB, and should have a baseline tuberculin skin test (TST), preferably by using a two-step test, at the beginning of employment (20). Thus, if an unprotected occupational exposure occurs, TST conversions can be distinguished from positive TST results caused by previous exposures (20,21). The facility's level of TB risk will determine the need for routine follow-up TSTs (see Special Considerations). Medical Conditions, Work-Related Illness, and Work Restrictions DHCP are responsible for monitoring their own health status. DHCP who have acute or chronic medical conditions that render them susceptible to opportunistic infection should discuss with their personal physicians or other qualified authority whether the condition might affect their ability to safely perform their duties. However, under certain circumstances, health-care facility managers might need to exclude DHCP from work or patient contact to prevent further transmission of infection (22). Decisions concerning work restrictions are based on the mode of transmission and the period of infectivity of the disease (5) (Table 1). Exclusion policies should 1) be written, 2) include a statement of authority that defines who can exclude DHCP (e.g., personal physicians), and 3) be clearly communicated through education and training. Policies should also encourage DHCP to report illnesses or exposures without jeopardizing wages, benefits, or job status. With increasing concerns regarding bloodborne pathogens and introduction of universal precautions, use of latex gloves among HCP has increased markedly (7,23). Increased use of these gloves has been accompanied by increased reports of allergic reactions to natural rubber latex among HCP, DHCP, and patients (24--30), as well as increased reports of irritant and allergic contact dermatitis from frequent and repeated use of hand-hygiene products, exposure to chemicals, and glove use. DHCP should be familiar with the signs and symptoms of latex sensitivity (5,31--33). A physician should evaluate DHCP exhibiting symptoms of latex allergy, because further exposure could result in a serious allergic reaction. A diagnosis is made through medical history, physical examination, and diagnostic tests. Procedures should be in place for minimizing latex-related health problems among DHCP and patients while protecting them from infectious materials. These procedures should include 1) reducing exposures to latex-containing materials by using appropriate work practices, 2) training and educating DHCP, 3) monitoring symptoms, and 4) substituting nonlatex products where appropriate (32) (see Contact Dermatitis and Latex Hypersensitivity). Maintenance of Records, Data Management, and Confidentiality The health status of DHCP can be monitored by maintaining records of work-related medical evaluations, screening tests, immunizations, exposures, and postexposure management. Such records must be kept in accordance with all applicable state and federal laws. Examples of laws that might apply include the Privacy Rule of the Health Insurance Portability and Accountability Act (HIPAA) of 1996, 45 CFR 160 and 164, and the OSHA Occupational Exposure to Bloodborne Pathogens; Final Rule 29 CFR 1910.1030(h)(1)(i--iv) (34,13). The HIPAA Privacy Rule applies to covered entities, including certain defined health providers, health-care clearinghouses, and health plans. OSHA requires employers to ensure that certain information contained in employee medical records is 1) kept confidential; 2) not disclosed or reported without the employee's express written consent to any person within or outside the workplace except as required by the OSHA standard; and 3) maintained by the employer for at least the duration of employment plus 30 years. Dental practices that coordinate their infection-control program with off-site providers might consult OSHA's Bloodborne Pathogen standard and employee Access to Medical and Exposure Records standard, as well as other applicable local, state, and federal laws, to determine a location for storing health records (13,35). Preventing Transmission of Bloodborne PathogensAlthough transmission of bloodborne pathogens (e.g., HBV, HCV, and HIV) in dental health-care settings can have serious consequences, such transmission is rare. Exposure to infected blood can result in transmission from patient to DHCP, from DHCP to patient, and from one patient to another. The opportunity for transmission is greatest from patient to DHCP, who frequently encounter patient blood and blood-contaminated saliva during dental procedures. Since 1992, no HIV transmission from DHCP to patients has been reported, and the last HBV transmission from DHCP to patients was reported in 1987. HCV transmission from DHCP to patients has not been reported. The majority of DHCP infected with a bloodborne virus do not pose a risk to patients because they do not perform activities meeting the necessary conditions for transmission. For DHCP to pose a risk for bloodborne virus transmission to patients, DHCP must 1) be viremic (i.e., have infectious virus circulating in the bloodstream); 2) be injured or have a condition (e.g., weeping dermatitis) that allows direct exposure to their blood or other infectious body fluids; and 3) enable their blood or infectious body fluid to gain direct access to a patient's wound, traumatized tissue, mucous membranes, or similar portal of entry. Although an infected DHCP might be viremic, unless the second and third conditions are also met, transmission cannot occur. The risk of occupational exposure to bloodborne viruses is largely determined by their prevalence in the patient population and the nature and frequency of contact with blood and body fluids through percutaneous or permucosal routes of exposure. The risk of infection after exposure to a bloodborne virus is influenced by inoculum size, route of exposure, and susceptibility of the exposed HCP (12). The majority of attention has been placed on the bloodborne pathogens HBV, HCV, and HIV, and these pathogens present different levels of risk to DHCP. Hepatitis B Virus HBV is a well-recognized occupational risk for HCP (36,37). HBV is transmitted by percutaneous or mucosal exposure to blood or body fluids of a person with either acute or chronic HBV infection. Persons infected with HBV can transmit the virus for as long as they are HBsAg-positive. The risk of HBV transmission is highly related to the HBeAg status of the source person. In studies of HCP who sustained injuries from needles contaminated with blood containing HBV, the risk of developing clinical hepatitis if the blood was positive for both HBsAg and HBeAg was 22%--31%; the risk of developing serologic evidence of HBV infection was 37%--62% (19). By comparison, the risk of developing clinical hepatitis from a needle contaminated with HBsAg-positive, HBeAg-negative blood was 1%--6%, and the risk of developing serologic evidence of HBV infection, 23%--37% (38). Blood contains the greatest proportion of HBV infectious particle titers of all body fluids and is the most critical vehicle of transmission in the health-care setting. HBsAg is also found in multiple other body fluids, including breast milk, bile, cerebrospinal fluid, feces, nasopharyngeal washings, saliva, semen, sweat, and synovial fluid. However, the majority of body fluids are not efficient vehicles for transmission because they contain low quantities of infectious HBV, despite the presence of HBsAg (19). The concentration of HBsAg in body fluids can be 100--1,000-fold greater than the concentration of infectious HBV particles (39). Although percutaneous injuries are among the most efficient modes of HBV transmission, these exposures probably account for only a minority of HBV infections among HCP. In multiple investigations of nosocomial hepatitis B outbreaks, the majority of infected HCP could not recall an overt percutaneous injury (40,41), although in certain studies, approximately one third of infected HCP recalled caring for a patient who was HBsAg-positive (42,43). In addition, HBV has been demonstrated to survive in dried blood at room temperature on environmental surfaces for <1 week (44). Thus, HBV infections that occur in HCP with no history of nonoccupational exposure or occupational percutaneous injury might have resulted from direct or indirect blood or body fluid exposures that inoculated HBV into cutaneous scratches, abrasions, burns, other lesions, or on mucosal surfaces (45--47). The potential for HBV transmission through contact with environmental surfaces has been demonstrated in investigations of HBV outbreaks among patients and HCP in hemodialysis units (48--50). Since the early 1980s, occupational infections among HCP have declined because of vaccine use and adherence to universal precautions (51). Among U.S. dentists, >90% have been vaccinated, and serologic evidence of past HBV infection decreased from prevaccine levels of 14% in 1972 to approximately 9% in 1992 (52). During 1993--2001, levels remained relatively unchanged (Chakwan Siew, Ph.D., American Dental Association, Chicago, Illinois, personal communication, June 2003). Infection rates can be expected to decline further as vaccination rates remain high among young dentists and as older dentists with lower vaccination rates and higher rates of infection retire. Although the potential for transmission of bloodborne infections from DHCP to patients is considered limited (53--55), precise risks have not been quantified by carefully designed epidemiologic studies (53,56,57). Reports published during 1970--1987 describe nine clusters in which patients were thought to be infected with HBV through treatment by an infected DHCP (58--67). However, transmission of HBV from dentist to patient has not been reported since 1987, possibly reflecting such factors as 1) adoption of universal precautions, 2) routine glove use, 3) increased levels of immunity as a result of hepatitis B vaccination of DHCP, 4) implementation of the 1991 OSHA bloodborne pathogen standard (68), and 5) incomplete ascertainment and reporting. Only one case of patient-to-patient transmission of HBV in the dental setting has been documented (CDC, unpublished data, 2003). In this case, appropriate office infection-control procedures were being followed, and the exact mechanism of transmission was undetermined. Because of the high risk of HBV infection among HCP, DHCP who perform tasks that might involve contact with blood, blood-contaminated body substances, other body fluids, or sharps should be vaccinated (2,13,17,19,69). Vaccination can protect both DHCP and patients from HBV infection and, whenever possible, should be completed when dentists or other DHCP are in training and before they have contact with blood. Prevaccination serological testing for previous infection is not indicated, although it can be cost-effective where prevalence of infection is expected to be high in a group of potential vacinees (e.g., persons who have emigrated from areas with high rates of HBV infection). DHCP should be tested for anti-HBs 1--2 months after completion of the 3-dose vaccination series (17). DHCP who do not develop an adequate antibody response (i.e., anti-HBs <10 mIU/mL) to the primary vaccine series should complete a second 3-dose vaccine series or be evaluated to determine if they are HBsAg-positive (17). Revaccinated persons should be retested for anti-HBs at the completion of the second vaccine series. Approximately half of nonresponders to the primary series will respond to a second 3-dose series. If no antibody response occurs after the second series, testing for HBsAg should be performed (17). Persons who prove to be HBsAg-positive should be counseled regarding how to prevent HBV transmission to others and regarding the need for medical evaluation. Nonresponders to vaccination who are HBsAg-negative should be considered susceptible to HBV infection and should be counseled regarding precautions to prevent HBV infection and the need to obtain HBIG prophylaxis for any known or probable parenteral exposure to HBsAg-positive blood. Vaccine-induced antibodies decline gradually over time, and 60% of persons who initially respond to vaccination will lose detectable antibodies over 12 years. Even so, immunity continues to prevent clinical disease or detectable viral infection (17). Booster doses of vaccine and periodic serologic testing to monitor antibody concentrations after completion of the vaccine series are not necessary for vaccine responders (17). Hepatitis D Virus An estimated 4% of persons with acute HBV infection are also infected with hepatitis Delta virus (HDV). Discovered in 1977, HDV is a defective bloodborne virus requiring the presence of HBV to replicate. Patients coinfected with HBV and HDV have substantially higher mortality rates than those infected with HBV alone. Because HDV infection is dependent on HBV for replication, immunization to prevent HBV infection, through either pre- or postexposure prophylaxis, can also prevent HDV infection (70). Hepatitis C Virus Hepatitis C virus appears not to be transmitted efficiently through occupational exposures to blood. Follow-up studies of HCP exposed to HCV-infected blood through percutaneous or other sharps injuries have determined a low incidence of seroconversion (mean: 1.8%; range, 0%--7%) (71--74). One study determined transmission occurred from hollow-bore needles but not other sharps (72). Although these studies have not documented seroconversion associated with mucous membrane or nonintact skin exposure, at least two cases of HCV transmission from a blood splash to the conjunctiva (75,76) and one case of simultaneous transmission of HCV and HIV after nonintact skin exposure have been reported (77). Data are insufficient to estimate the occupational risk of HCV infection among HCP, but the majority of studies indicate the prevalence of HCV infection among dentists, surgeons, and hospital-based HCP is similar to that among the general population, approximately 1%--2% (78--86). In a study that evaluated risk factors for infection, a history of unintentional needlesticks was the only occupational risk factor independently associated with HCV infection (80). No studies of transmission from HCV-infected DHCP to patients have been reported, and the risk for such transmission appears limited. Multiple reports have been published describing transmission from HCV-infected surgeons, which apparently occurred during performance of invasive procedures; the overall risk for infection averaged 0.17% (87--90). Human Immunodeficiency Virus In the United States, the risk of HIV transmission in dental settings is extremely low. As of December 2001, a total of 57 cases of HIV seroconversion had been documented among HCP, but none among DHCP, after occupational exposure to a known HIV-infected source (91). Transmission of HIV to six patients of a single dentist with AIDS has been reported, but the mode of transmission could not be determined (2,92,93). As of September 30, 1993, CDC had information regarding test results of >22,000 patients of 63 HIV-infected HCP, including 33 dentists or dental students (55,93). No additional cases of transmission were documented. Prospective studies worldwide indicate the average risk of HIV infection after a single percutaneous exposure to HIV-infected blood is 0.3% (range: 0.2%--0.5%) (94). After an exposure of mucous membranes in the eye, nose, or mouth, the risk is approximately 0.1% (76). The precise risk of transmission after skin exposure remains unknown but is believed to be even smaller than that for mucous membrane exposure. Certain factors affect the risk of HIV transmission after an occupational exposure. Laboratory studies have determined if needles that pass through latex gloves are solid rather than hollow-bore, or are of small gauge (e.g., anesthetic needles commonly used in dentistry), they transfer less blood (36). In a retrospective case-control study of HCP, an increased risk for HIV infection was associated with exposure to a relatively large volume of blood, as indicated by a deep injury with a device that was visibly contaminated with the patient's blood, or a procedure that involved a needle placed in a vein or artery (95). The risk was also increased if the exposure was to blood from patients with terminal illnesses, possibly reflecting the higher titer of HIV in late-stage AIDS. Exposure Prevention Methods Avoiding occupational exposures to blood is the primary way to prevent transmission of HBV, HCV, and HIV, to HCP in health-care settings (19,96,97). Exposures occur through percutaneous injury (e.g., a needlestick or cut with a sharp object), as well as through contact between potentially infectious blood, tissues, or other body fluids and mucous membranes of the eye, nose, mouth, or nonintact skin (e.g., exposed skin that is chapped, abraded, or shows signs of dermatitis). Observational studies and surveys indicate that percutaneous injuries among general dentists and oral surgeons occur less frequently than among general and orthopedic surgeons and have decreased in frequency since the mid-1980s (98--102). This decline has been attributed to safer work practices, safer instrumentation or design, and continued DHCP education (103,104). Percutaneous injuries among DHCP usually 1) occur outside the patient's mouth, thereby posing less risk for recontact with patient tissues; 2) involve limited amounts of blood; and 3) are caused by burs, syringe needles, laboratory knives, and other sharp instruments (99--102,105,106). Injuries among oral surgeons might occur more frequently during fracture reductions using wires (104,107). Experience, as measured by years in practice, does not appear to affect the risk of injury among general dentists or oral surgeons (100,104,107). The majority of exposures in dentistry are preventable, and methods to reduce the risk of blood contacts have included use of standard precautions, use of devices with features engineered to prevent sharp injuries, and modifications of work practices. These approaches might have contributed to the decrease in percutaneous injuries among dentists during recent years (98--100,103). However, needlesticks and other blood contacts continue to occur, which is a concern because percutaneous injuries pose the greatest risk of transmission. Standard precautions include use of PPE (e.g., gloves, masks, protective eyewear or face shield, and gowns) intended to prevent skin and mucous membrane exposures. Other protective equipment (e.g., finger guards while suturing) might also reduce injuries during dental procedures (104). Engineering controls are the primary method to reduce exposures to blood and OPIM from sharp instruments and needles. These controls are frequently technology-based and often incorporate safer designs of instruments and devices (e.g., self-sheathing anesthetic needles and dental units designed to shield burs in handpieces) to reduce percutaneous injuries (101,103,108). Work-practice controls establish practices to protect DHCP whose responsibilities include handling, using, assembling, or processing sharp devices (e.g., needles, scalers, laboratory utility knives, burs, explorers, and endodontic files) or sharps disposal containers. Work-practice controls can include removing burs before disassembling the handpiece from the dental unit, restricting use of fingers in tissue retraction or palpation during suturing and administration of anesthesia, and minimizing potentially uncontrolled movements of such instruments as scalers or laboratory knives (101,105). As indicated, needles are a substantial source of percutaneous injury in dental practice, and engineering and work-practice controls for needle handling are of particular importance. In 2001, revisions to OSHA's bloodborne pathogens standard as mandated by the Needlestick Safety and Prevention Act of 2000 became effective. These revisions clarify the need for employers to consider safer needle devices as they become available and to involve employees directly responsible for patient care (e.g., dentists, hygienists, and dental assistants) in identifying and choosing such devices (109). Safer versions of sharp devices used in hospital settings have become available (e.g., blunt suture needles, phlebotomy devices, and butterfly needles), and their impact on reducing injuries has been documented (110--112). Aspirating anesthetic syringes that incorporate safety features have been developed for dental procedures, but the low injury rates in dentistry limit assessment of their effect on reducing injuries among DHCP. Work-practice controls for needles and other sharps include placing used disposable syringes and needles, scalpel blades, and other sharp items in appropriate puncture-resistant containers located as close as feasible to where the items were used (2,7,13,113--115). In addition, used needles should never be recapped or otherwise manipulated by using both hands, or any other technique that involves directing the point of a needle toward any part of the body (2,7,13,97,113,114). A one-handed scoop technique, a mechanical device designed for holding the needle cap to facilitate one-handed recapping, or an engineered sharps injury protection device (e.g., needles with resheathing mechanisms) should be employed for recapping needles between uses and before disposal (2,7,13,113,114). DHCP should never bend or break needles before disposal because this practice requires unnecessary manipulation. Before attempting to remove needles from nondisposable aspirating syringes, DHCP should recap them to prevent injuries. For procedures involving multiple injections with a single needle, the practitioner should recap the needle between injections by using a one-handed technique or use a device with a needle-resheathing mechanism. Passing a syringe with an unsheathed needle should be avoided because of the potential for injury. Additional information for developing a safety program and for identifying and evaluating safer dental devices is available at

Postexposure Management and Prophylaxis Postexposure management is an integral component of a complete program to prevent infection after an occupational exposure to blood. During dental procedures, saliva is predictably contaminated with blood (7,114). Even when blood is not visible, it can still be present in limited quantities and therefore is considered a potentially infectious material by OSHA (13,19). A qualified health-care professional should evaluate any occupational exposure incident to blood or OPIM, including saliva, regardless of whether blood is visible, in dental settings (13). Dental practices and laboratories should establish written, comprehensive programs that include hepatitis B vaccination and postexposure management protocols that 1) describe the types of contact with blood or OPIM that can place DHCP at risk for infection; 2) describe procedures for promptly reporting and evaluating such exposures; and 3) identify a health-care professional who is qualified to provide counseling and perform all medical evaluations and procedures in accordance with current recommendations of the U.S. Public Health Service (PHS), including PEP with chemotherapeutic drugs when indicated. DHCP, including students, who might reasonably be considered at risk for occupational exposure to blood or OPIM should be taught strategies to prevent contact with blood or OPIM and the principles of postexposure management, including PEP options, as part of their job orientation and training. Educational programs for DHCP and students should emphasize reporting all exposures to blood or OPIM as soon as possible, because certain interventions have to be initiated promptly to be effective. Policies should be consistent with the practices and procedures for worker protection required by OSHA and with current PHS recommendations for managing occupational exposures to blood (13,19). After an occupational blood exposure, first aid should be administered as necessary. Puncture wounds and other injuries to the skin should be washed with soap and water; mucous membranes should be flushed with water. No evidence exists that using antiseptics for wound care or expressing fluid by squeezing the wound further reduces the risk of bloodborne pathogen transmission; however, use of antiseptics is not contraindicated. The application of caustic agents (e.g., bleach) or the injection of antiseptics or disinfectants into the wound is not recommended (19). Exposed DHCP should immediately report the exposure to the infection-control coordinator or other designated person, who should initiate referral to the qualified health-care professional and complete necessary reports. Because multiple factors contribute to the risk of infection after an occupational exposure to blood, the following information should be included in the exposure report, recorded in the exposed person's confidential medical record, and provided to the qualified health-care professional:

Each occupational exposure should be evaluated individually for its potential to transmit HBV, HCV, and HIV, based on the following: