|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

||||

| ||||||||||

|

|

|

|

|

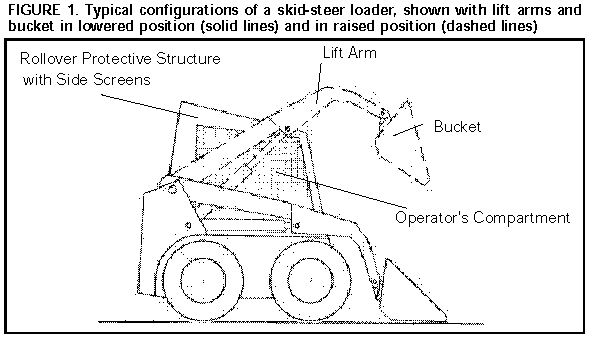

Persons using assistive technology might not be able to fully access information in this file. For assistance, please send e-mail to: mmwrq@cdc.gov. Type 508 Accommodation and the title of the report in the subject line of e-mail. Skid-Steer Loader-Related Fatalities in the Workplace -- United States, 1992-1995The skid-steer loader is a specialized type of wheel loader that is small, compact, and versatile and is readily adaptable to a variety of work settings (Figure_1); it is commonly used in agriculture, construction, and general industry. Recent injury surveillance findings of and investigations by the state component of CDC's National Institute for Occupational Safety and Health (NIOSH) Fatality Assessment and Control Evaluation (FACE) program * underscore the potential for preventing incidents in which workers are pinned between the bucket and frame or the lift arms and frame of skid-steer loaders. This report describes the results of FACE program investigations of four skid-steer loader-related fatalities, summarizes surveillance data for 1980-1995, and provides recommendations for the prevention of such incidents. Case Reports Incident 1. On October 16, 1993, a 26-year-old hog farmer in Minnesota was using a skid-steer loader to pile manure inside a hog containment building. The protective cage enclosing the operator's compartment had been removed to allow operating clearance inside the building. The machine stalled while the bucket was raised, and the farmer attempted to dismount by climbing over the left side of the loader. While dismounting, he inadvertently struck the lift control lever; as a result, the lift arms lowered on him. He died from respiratory arrest caused by crush injury to the chest wall. Incident 2. On March 1, 1994, a 26-year-old sawmill operator in Wyoming was transporting stockpiled logs to a bin area of the mill. He was using a reconditioned skid-steer loader on which the safety belt and protective screens on the sides of the cab had been removed. While operating the machine, he leaned out of the cab and was pinned between the moving lift arms and the side of the cab. The cause of death was listed as massive crush injuries to the head. Incident 3. On February 7, 1995, a 37-year-old farmer in Iowa was cleaning the foot-pedal control linkage of a skid-steer loader while the bucket was raised. The loader's safety-belt interlock control system ** had been bypassed by jamming a glove in the linkage. Because the loader controls had frozen in the lift position, the bucket rose when the farmer started the engine. The farmer shut down the engine and dismounted; however, because there was insufficient clearance to completely raise the bucket, the manufacturer-provided lift-arm support device *** was not set in place. While the farmer was beneath the bucket cleaning the pedals, he inadvertently activated the foot-operated lift control and caused the bucket to descend. He sustained fatal crush injuries to the chest. Incident 4. On May 25, 1995, a 30-year-old carpenter in Nebraska was preparing to use a skid-steer loader to back-fill dirt around a newly constructed house. While standing in front of the machine under the raised bucket, he activated the foot-operated lift control and the bucket dropped on him. He died from internal injuries. FACE investigators determined that the safety-belt interlock had been deactivated. Surveillance for Skid-Steer Loader-Related Fatalities During 1992-1995, FACE received 22 reports of skid-steer loader-related fatalities from eight states (Wisconsin {six}, Iowa {four}, Minnesota {four}, Nebraska {three}, Colorado {two}, California {one}, Massachusetts {one}, and Wyoming {one}). All the decedents were males; ages ranged from 21 to 68 years (mean: 40 years). The decedents were employed in agriculture (13), construction (four), services (two), retail trade (one), manufacturing (one), and wholesale trade (one); their occupations were classified as farmer (10), laborer (four), business owner (three), machine operator (two), landscaper (two), and carpenter (one). In 10 of the 22 cases, the decedent had been working or standing under a raised bucket. Five incidents occurred because the decedent had leaned out of the operator's compartment into the path of ascending or descending lift arms and was crushed against the frame by the lift arm. In the other incidents, the decedents were crushed between the bucket and machine frame while dismounting or mounting (four) or were caught between the bucket and frame (three). Additional cases were identified through two other surveillance systems for work-related fatal injuries: the NIOSH National Traumatic Occupational Fatalities (NTOF) surveillance system **** and the Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries (CFOI). ***** During 1980-1992, NTOF identified 25 work-related fatalities that resulted when the worker was pinned between the bucket and frame or the lift arms and frame of a skid-steer loader; 15 (60%) occurred during 1988-1992. NTOF data include 65 additional case narratives describing similar injuries but do not specify the loader type; some of these deaths may have been skid-steer loader related. CFOI identified 20 such incidents during 1992-1994. Overlap in the identification of cases was limited: one fatality in 1992 was recorded by NTOF and by FACE, and two fatalities (one each in 1992 and 1993) were reported in both FACE and CFOI. Incidence rates were not calculated because denominator data for exposure to skid-steer loaders were not available. Reported by: DL Parker, MD, DJ Boyle, DVM, G Wahl, MS, Minnesota Dept of Health. JS Murray, JW Rolf, Wyoming Dept of Health. JA Merchant, MD, R Rautiainen, MScAgr, W Johnson, MD, Dept of Preventive Medicine and Environmental Health, Univ of Iowa, Iowa City. GL Hirsh, WE Hetzler, MA, Nebraska Dept of Labor. Div of Safety Research, National Institute for Occupational Safety and Health, CDC. Editorial NoteEditorial Note: Skid-steer loaders are particularly adaptable to use in agriculture and construction because their small size and method of steering ****** permit exceptional maneuverability. The machine is compact, in part because the operator's seat and controls are placed in front of the engine between the loader lift arms and in front of the lift-arm pivot points, which requires the operator to mount and dismount the machine from the front by climbing over the bucket. Skid-steer loaders incorporate hand-lever controls or foot-pedal controls for the lift arms and bucket tilt functions; the operator can inadvertently activate these controls by failing to follow proper safety procedures during mounting and dismounting. Specifications of currently manufactured skid-steer loaders conform to recommendations issued in June 1985 by the Society of Automotive Engineers (2). To protect against inadvertent activation, manufacturers have equipped the loaders with skid-resistant steps, grab handles, and specific warning and instructional signs. In the early 1980s, manufacturers introduced interlock control systems that require the safety belt and/or safety bar to be engaged before the loader's controls can be activated. However, these interlock control systems can be bypassed by operators and rendered inoperative. Rollover protective structures (ROPSs) with side screens and use of safety belts provide additional protection by preventing the operator from leaning into the path of moving lift arms. Finally, an approved lift-arm support device can prevent serious injury from inadvertent lowering of the lift arms when the lift arms are raised for service procedures. The risk for inadvertent lowering is increased if the loader's interlock control systems are bypassed or inoperative. Because of the variety of industries and circumstances in which skid-steer loaders are used (estimates of the number of these machines in use during 1991 ranged from 140,000 to 178,000 {3}) and the limitations inherent in current surveillance for fatal occupational injuries, the data in this report probably underestimate the number of fatal injuries associated with skid-steer loaders. The state component of FACE receives reports of work-related fatalities from only 14 states. In addition, death certificate-based systems like NTOF identify approximately 80% of work-related fatalities (4,5). Finally, because of the limited nature of injury descriptions in NTOF and CFOI when compared with FACE, these systems are less likely to specify the exact type of loader associated with a fatality, constraining ascertainment of specific circumstances. Despite these underestimates, the cases in this report suggest a recurrent pattern of preventable injuries. To protect against lift arm- or bucket-related injuries while using skid-steer loaders, NIOSH and equipment manufacturers recommend the following precautions:

References

* Through cooperative agreements with NIOSH, 14 states maintain multiple-source surveillance networks for identification of all traumatic occupational fatalities; conduct site investigations of selected categories of cases (including fatal falls from elevations and machinery-related incidents); and disseminate injury-prevention information. ** An interlock is a device or mechanism used to connect individual components so that the action of one part of the equipment is constrained by, or dependent on, another (1); in general, its purpose is to prevent the operation of machine components under specified conditions, usually when a hazard is present. As applied to skid-steer loaders, the interlock prevents movement of the lift-arm controls unless safety belts or safety bars are correctly engaged. *** A lift-arm support device is a mechanical device used to prevent inadvertent lowering of the lift arms when the bucket is required to be in the elevated position for maintenance, service, or similar purpose other than loader operation (2). **** Based on death certificates obtained from the 50 states, the District of Columbia, and New York City, NTOF contains data for persons aged greater than or equal to 16 years for whom there was a work-related external cause of death. Data are available for 1980-1992. ***** CFOI is a multiple-source reporting system for occupational fatalities implemented nationwide by BLS in 1992. ****** Vehicles steer by varying the speed and/or direction of the wheel rotation on opposite sides of the machine (i.e., skidding). Figure_1  Return to top. Disclaimer All MMWR HTML versions of articles are electronic conversions from ASCII text into HTML. This conversion may have resulted in character translation or format errors in the HTML version. Users should not rely on this HTML document, but are referred to the electronic PDF version and/or the original MMWR paper copy for the official text, figures, and tables. An original paper copy of this issue can be obtained from the Superintendent of Documents, U.S. Government Printing Office (GPO), Washington, DC 20402-9371; telephone: (202) 512-1800. Contact GPO for current prices. **Questions or messages regarding errors in formatting should be addressed to mmwrq@cdc.gov.Page converted: 09/19/98 |

|||||||||

This page last reviewed 5/2/01

|