Step 7: Maintain Management Commitment and Employee Involvement

‹View Table of Contents

Communicate with management

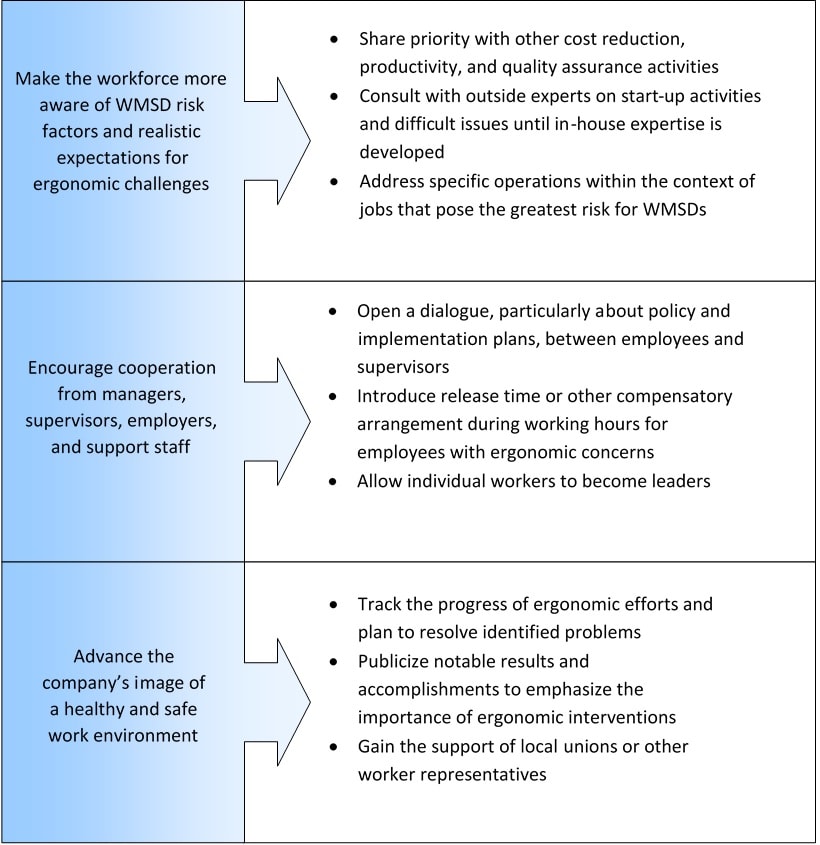

Occupational safety and health research shows that management commitment is crucial to the success of musculoskeletal health awareness training and WMSD interventions. Management is responsible for encouraging worker input on real or suspected job hazards, ways to control these hazards, and how best to implement interventions. Management should follow the objectives of a good ergonomics program, outlined in the figure below.

Figure 7.1: Management Objectives

Get People Involved

Ergonomics programs typically require input from worker and management representatives, safety personnel, health care providers, ergonomics specialists, human resources, maintenance, engineering, and purchasing. These groups conduct job analyses, identify hazards, review injury records and symptoms surveys, develop control measures, and install new equipment specifically for ergonomics programs.

Workers involved in ergonomics programs are trained to recognize physical risk factors and should report potential hazards, changes in workplace conditions, and suggestions for improvements. They are more motivated, have higher job satisfaction, are better at problem-solving, are less resistant to changes in the workplace, and are more knowledgeable about their work and about the organization for which they work. The nature of the WMSD problem, the skills and abilities of those involved, and the company’s practices in resolving workplace issues all factor into worker involvement.

Table 6.2: Types of Worker Input

| Type of input | What it looks like | Example |

|---|---|---|

| Direct input | Individuals communicate their ergonomic concerns to responsible officials | NIOSH evaluated MSD complaints from supermarket cashiers who attributed their pains to certain design characteristics of the checkout counters. Management and workers collectively decided to place a barrier at the far corner of each checkout counter and install adjustable keyboards. The barrier reduced the need for workers to reach and bend for groceries, and the keyboard relieved static stress and shoulder flexion. Reports of MSD symptoms declined after these ergonomic changes were implemented. |

| Department-wide input | Seven to fifteen supervisors, maintenance workers, engineering staff and other members of the department form a ‘work group’ or ‘ergonomics team’ to address issues affecting specific department operations | Team members share information related to the MSD interventions(s) among themselves and with the affected workforce. This is the most popular method of addressing MSD problems. |

| Company-wide input (committee) | Union leaders, worker representatives, department heads, and key figures from various areas of the organization discuss ways to resolve safety and health issues, make recommendations for working groups, and approve resources for specific actions | NIOSH assisted an ergonomics committee comprised of one worker and one supervisor from each department, one industrial engineer, three manufacturing engineers, three department superintendents, one secretary, and the plant manager. First, committee members were given literature and videos on ergonomics. Then, the committee examined safety logs, talked with equipment operators, and observed job operations to identify problem areas. Injury patterns, operator reports, and observations indicated specific priorities for intervention. |

Supervisors may need training on how to avoid dominating discussions or intimidating workers when collecting direct, department-wide, and/or company-wide input.

Learn More on Prevention through Involvement:

Pages in this Report

- Step 1: Identify Risk Factors

- Step 2: Train Management and Workers

- Step 3: Collect Health and Medical Evidence

- Step 4: Implement your Ergonomic Program

- Step 5: Evaluate Ergonomic Program

- Step 6: Promote Worker Recovery through Health Care Management and Return-to-Work

- ›Step 7: Maintain Management Commitment and Employee Involvement