Product Specialist/Service Manager Dies After Falling 4½ Feet During Machine Assembly

Minnesota FACE 93MN076

SUMMARY

A 57-year-old male product specialist/service manager (victim) died as a result of head injuries received after falling 4½ feet during machine assembly. He and three other workers were engaged in assembling a large, stationary, rotary mining drill. Drill assembly took place outdoors and was about one-third to one-half complete; the temperature was in the mid-20’s. The victim was fit testing a pin in a hole about 11 feet off the ground. He climbed on to a 6-inch wide, painted, steel girder at a height of 4½ feet, then stood and reached above his head to place the pin in the hole. The incident was unwitnessed, but apparently he slipped and fell to the ground, striking his head either on a protruding metal bracket or the ground itself. He died three days later as a result of his head injuries. MN FACE investigators concluded that, in order to minimize the occurrence of similar incidents, the following guidelines should be followed:

- use appropriate equipment, such as ladders, scaffolds, or lifts, to achieve work heights.

INTRODUCTION

MN FACE was notified of a November 22, 1993, work-related death on November 24, 1993. The incident occurred on November 19, 1993. MN OSHA and the county coroner were contacted, and releasable information was obtained. The victim’s employer was interviewed via telephone on December 15, 1993. A site investigation was not conducted by MN FACE.

The victim had been employed for three years by a mining and construction equipment sales company as a product specialist/service manager for a large rotary mining drill they distributed. He was the company’s “factory trained” drill specialist and had assembled drills for 10-12 years before being hired by his present employer.

INVESTIGATION

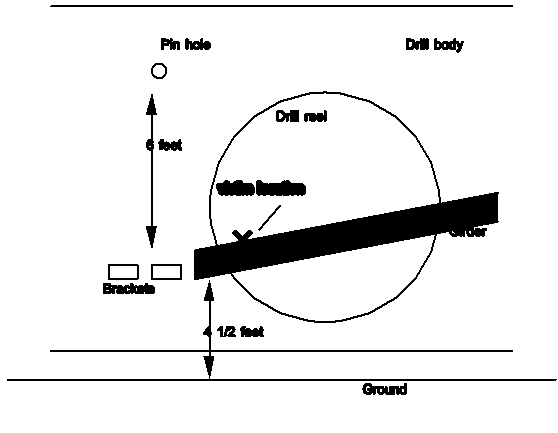

A 57-year-old male product specialist/service manager (victim) died as a result of head injuries received after falling 4½ feet during machine assembly. He and three other workers, whom he was supervising, were engaged in assembling a large, stationary, rotary mining drill. They were assembling the drill outdoors; the temperature was in the mid-20’s, and it was windy on the day of the incident. There was snow on the ground, but the area surrounding the drill had been plowed and sand had been spread in the area for traction. The workers were wearing insulated coveralls, boots, hard hats with liners, and gloves or mittens. The ground surrounding the drill was frozen. s had completed one-third to one-half of the assembly. Complete assembly took three weeks, at which time the drill would weigh 130 tons and have a total mast height of 130 feet. The drill was assembled in a horizontal versus an upright position, and the workers were installing pins for connecting hydraulic rods above a drill reel. The reel was approximately 10 feet in diameter and was secured to the drill on either side with a 6-inch wide, painted, steel girder. The girder was about 4½ feet above the ground and slightly angled. See Figure 1.

Figure 1. Portion of drill where fall took place. Not to scale.

The incident occurred at about 2:30 p.m. The victim took a pin to install or fit test it in a hydraulic rod hole at approximately 11 feet above the ground. He climbed on the 4½-foot high girder, stood, and reached above and to his left to fit the pin in the hole. Though unwitnessed, he apparently slipped or lost his balance and fell to the frozen ground. Investigators could not determine if he struck his head on a protruding metal bracket located next to the girder or the ground itself, but he sustained severe head injuries as a result of the fall.

A 911 call was placed from a cellular phone, and first responders arrived promptly. The victim was transported to a local medical center and later that same day transferred to a larger facility for surgery. He died, however, three days after the incident as a result of his head injuries.

CAUSE OF DEATH

The cause of death listed on the death certificate was cardiorespiratory arrest due to or as a consequence of severe intracranial injury secondary to a head injury sustained when he fell while at work.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Use appropriate equipment, such as ladders, scaffolds, or lifts, to achieve work heights.

Discussion: Standing on the drill itself to achieve his work height created hazards for the victim. He was standing on a narrow ledge, reaching above his head, and had little to grasp to help maintain his balance except the reel itself. Painted steel can also be slippery; any snow or water on the victim’s boots would probably increase this hazard. Ladders were available on site and, when work at elevations is performed under these conditions, their proper use to attain work height is a safer alternative.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.