Painter Dies After Fall Inside 250,000 Gallon Water TankNorth Carolina

FACE 9323

SUMMARY

A 20-year-old male painter (the victim) died after falling from an undetermined height inside a 250,000 gallon municipal water tank. The victim was part of a four-man crew painting the interior and exterior of the tank. Three painters, including the victim, were sandblasting and priming the exterior of the tank and the steel-grate catwalk around the circumference of the tank. The men were working from the catwalk, 112 feet above ground level. The crew foreman was inside the tank at floor level spraying an epoxy primer on the walls. A worker on the outside of the tank would periodically climb 25 feet to the top of the tank, using a permanently fixed side ladder, to check on the foreman through the 24-inch top opening at the crown of the tank. At approximately 3 p.m., the foreman, wearing a supplied-air respirator hood, heard a nearby noise and turned to see the victim lying on the floor of the tank. The victim was semi-conscious and having difficulty breathing. The foreman called to the outside workers for help. The victim was fitted with a body harness and lowered 85 feet to the ground through the 4-foot-diameter tank riser, located at the bottom of the tank body. The victim was then loaded by co-workers into a van and transported to the local hospital. The victim received no first aid at the site, nor was the EMS summoned. The victim arrived at the hospital at 4:18 p.m., was life flighted to a major trauma center at 5 p.m., and was pronounced dead at 9:13 p.m. NIOSH investigators concluded that, to prevent similar incidents, employers should:

- develop and implement a comprehensive written confined space entry program

- develop and implement a comprehensive written safety program.

- train all workers in the administration of basic first aid

Additionally, property owners should:

- require that all contractors have a written safety program specific to the work to be performed.

INTRODUCTION

On July 2, 1993, a 20-year-old male painter (the victim) died after falling from an undetermined height inside a 250,000 gallon municipal water tank. On July 9, 1993, officials of the North Carolina Occupational Safety and Health Administration (NCOSHA) notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On August 11 and 12, 1993, a safety specialist from DSR conducted an investigation of the incident and reviewed the circumstances of the incident with the NCOSHA district supervisor and health compliance officer assigned to the case, along with employer representatives. NCOSHA photographs of the scene following the incident were reviewed during the investigation.

The employer was a painting contractor that had been in operation for 8 years and employed 6 workers. The contractor specialized in refinishing steel structures such as municipal water tanks. The contractor had a basic confined space entry program; however, workers had not received confined space entry training or training in the proper use of respirators. Workers received training for sandblasting and painting on the job. The victim had worked for the contractor for 2 months. The con- tractor had experienced no previous fatalities.

INVESTIGATION

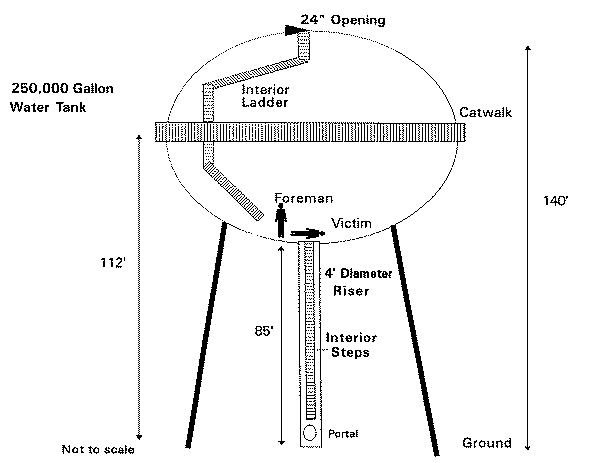

The company had been contracted by a local municipality to sandblast, prime, and paint the interior and exterior of a 250,000 gallon water tank that served as a fresh water reservoir for the municipality. The tank was 140 feet high at its summit, and was encircled by a steel-grate catwalk 112 feet above ground. A 4-foot-diameter riser extended from the tank bottom, 85 feet to the ground. The riser had a 24-inch-diameter portal located 30 inches above the ground (Figure). Both the air lines for the supplied-air respirator hood and the sandblaster, and service ropes, ran from the ground through the riser to the interior of the tank. The men climbed up to the interior entrance of the tank through the riser, by means of fixed steel steps.

The crew had been at the jobsite for 3 weeks. The entire interior and exterior of the tank body had been sandblasted. Three painters (including the victim) were working on the catwalk, sandblasting the exterior surface and applying an epoxy primer. The crew foreman, equipped with an air-line respirator hood, was inside the tank spraying the interior walls with primer. No artificial interior lighting or additional ventilation was used.

Approximately every 30 minutes, one of the painters would climb a fixed ladder approximately 25 feet to the top of the tank to look through the 24-inch-diameter opening and check on the foreman. At approximately 3 p.m. the victim, without notifying the other workers, climbed to the top of the tank and entered. The foreman, spraying the epoxy primer, heard a noise and turned to see the victim lying on the tank floor. The foreman went to the victim and found him unconscious and breathing with some difficulty. The foreman yelled to the other workers, who entered the tank to help assist the victim. The men placed a full body harness on the victim, then placed him on the foreman’s back. The foreman climbed down the fixed steps in the tank riser, assisted by the two other workers, who lowered the victim with a rope attached to the body harness. When the foreman reached the ground, he pulled the victim through the portal at the base of the riser. When the other workers reached the ground, the victim was loaded into a van. The victim was given no first aid at the site and the emergency medical service (EMS) was not summoned. The three men drove the victim to the hospital, arriving at 4:18 p.m. At 5:00 p.m., the victim was life flighted to a major trauma center where he died at 9:13 p.m.

The event was unwitnessed; however, it is possible that the victim entered the tank and either slipped or tripped and fell from the fixed ladder inside the tank. It is also possible that the victim entered the tank and was affected by epoxy vapors, causing him to become dizzy and fall.

The Material Safety Data Sheet (MSDS) for the epoxy primer warned against inhalation of the vapors, stating that inhalation of vapors would affect the brain or nervous system, causing dizziness. The MSDS also advised the epoxy primer be applied in a well-ventilated area with workers wearing airline respirators. An atmospheric testing meter was on-site; however the oxygen sensor was not functioning.

CAUSE OF DEATH

The coroner listed the cause of death as excessive pooling of blood in the brainstem. The victim had also sustained fractures of the fifth and sixth cervical vertebrae.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should develop and implement a comprehensive written confined space entry program.

Discussion: Employers should develop and implement a written confined space entry program to address all provisions outlined in the following NIOSH publications: Working in Confined Spaces: Criteria for a Recommended Standard [Pub. No. 80-106]; NIOSH Alert, Request for Assistance in Preventing Occupational Fatalities in Confined Spaces [Pub. No. 86-110]; A Guide to Safety in Confined Spaces [Pub. No. 87-113]; and NIOSH Guide to Respiratory Protection [Pub. No. 87-116].

A confined space entry program should contain the following:

- written confined space entry procedures

- evaluation to determine whether entry is necessary

- issuance of a confined space entry permit

- evaluation of the confined space by a qualified person

- testing and monitoring the air quality in the confined space to ensure:

– oxygen level is at least 19.5 %

– flammable range is less than 10% of the LFL (lower flammable limit)

– absence of toxic air contaminants

- training of workers and supervisors in the selection and use of:

– safe entry procedures

– respiratory protection

– environmental test equipment

– lifelines and retrieval systems

– protective clothing

- training of employees in safe work procedures in and around confined spaces

- training of employees in confined space rescue procedures

- conducting regular safety meetings to discuss confined space safety

- availability and use of proper ventilation equipment

- monitoring of the air quality while workers are in the confined space.

Recommendation #2: Employers should develop and implement a comprehensive written safety program.

Discussion: The safety program should include, but not be limited to, the recognition and avoidance of fall hazards. When employees are required to work from elevations, employers should provide appropriate fall protection equipment and include appropriate worker training in the proper selection and use of fall protection equipment.

Recommendation #3: Employers should ensure that supervisors and workers are aware of the potential hazards of all substances with which they are required to work.

Employers should ensure that Material Safety Data Sheets (MSDS) are available for all chemicals, paints, solvents and other substances that are used, and that supervisors and workers are aware of their potential hazards and appropriate protective measures. It is unclear whether the workers were familiar with the hazards associated with the epoxy primer that was being sprayed inside the tank.

Recommendation #4: Employers should train all workers in the administration of basic first aid.

Discussion: All workers should be trained in the administration of basic first aid, and instructed to summon the Emergency Medical Service (EMS) prior to moving an injured person if the possibility of serious injury exists.

Recommendation #5: Employers should require that all contractors have a written safety program specific to the work to be performed.

Discussion: Although the contractor had a basic confined space entry program, the contractor was not required to have a written safety program or confined space entry procedures specific to the work being performed in the water tank. The contract language should address specific safety and health requirements for any contractors. Additionally, worker safety and health issues should be included as one of the evaluation criteria for selecting the appropriate contractor.

REFERENCES

National Institute for Occupational Safety and Health, Working in Confined Spaces: Criteria for a Recommended Standard. DHHS (NIOSH) Publication No. 80-106, December 1979.

National Institute for Occupational Safety and Health Alert, Request for Assistance in Preventing Occupational Fatalities in Confined Spaces. DHHS (NIOSH) Publication No. 86-110, January 1986.

National Institute for Occupational Safety and Health, A Guide to Safety in Confined Spaces. DHHS (NIOSH) Publication No. 87-113, July 1987.

National Institute for Occupational Safety and Health, Guide to Respiratory Protection. DHHS (NIOSH) Publication No. 87-116, September 1987.

Figure.