Roofing Mechanic Trainee Electrocuted in South Carolina

FACE 92-06

SUMMARY

A 19-year-old roofing mechanic trainee (victim) was electrocuted after he inadvertently contacted an energized service entrance conductor. At the time of the incident, a crew of six workers, including the victim, was performing various tasks on the roof of a warehouse. The victim, in preparing to apply aluminum flashing around the perimeter of the roof, was kneeling on the corner of the roof, taking measurements along the roof’s perimeter. Two electrical service entrances were located on the corner of the roof where the victim was working. When the victim completed his measurements and stood up, he contacted one of the energized electrical service entrance conductors (240-volts phase-to-phase) at his chest area. At the same time, his right forearm contacted the grounding wire for the service entrance which provided a path for the electrical current across the victim’s chest through his right forearm to ground. Two co-workers knocked the victim away from the service entrance conductors and, without training, attempted CPR care until the local emergency medical service (EMS) arrived. The victim was pronounced dead at the emergency room of the local hospital approximately 25 minutes after the incident occurred. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- conduct initial jobsite surveys to identify all hazards associated with each specific jobsite, and develop specific methods of controlling the identified hazards

- establish procedures for the protection of employees exposed to electrical hazards and provide worker training in the recognition and avoidance of such hazards

- ensure that electrical service entrance conductors are insulated

- develop, implement, and enforce a written safety program which includes worker training in recognizing and avoiding hazards, especially electrical hazards

- train/certify workers in the use of cardiopulmonary resuscitation (CPR)

- contact the local utility company to de-energize or insulate energized conductors before the start of work.

INTRODUCTION

On September 30, 1991, a 19-year-old roofing mechanic trainee was electrocuted after contacting an energized electrical conductor. On October 3, 1991, officials of the South Carolina Occupational Safety and Health Administration notified the Division of Safety Research (DSR) of the fatality, and requested technical assistance. On December 19, 1991, a DSR safety specialist traveled to the incident site to conduct an investigation. The incident was reviewed with the owner of the company and with the SCOSHA compliance officer assigned to the case. Photographs of the incident site were taken, and copies of the medical examiner’s report and police report were obtained.

The employer in this incident was a residential and commercial roofing contractor who had been in operation for 18 years. The contractor employed seven workers, including two roofing mechanic trainees. The employer had no written safety program. General discussion of safety procedures was provided on an as-needed basis by the company owner, and the jobsite foreman was responsible for jobsite safety. The employer provided on-the-job training. The victim had worked for the employer for 3 months prior to the incident.

INVESTIGATION

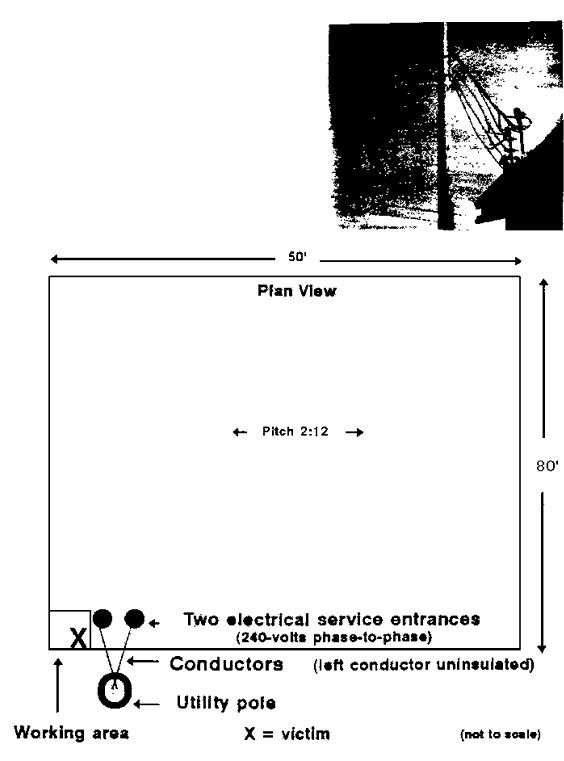

A roofing company had been contracted to remove old roofing materials from the roof of a warehouse and to install a new roof system including roofing felt, rubber membrane, and aluminum flashing. The incident occurred on the first day at the site. At the time of the incident, the old roofing material had been removed, the roof’s wooden deck had been repaired in several areas, and base roof felt had been installed on the roof deck. The roof was 50 feet wide by 80 feet long. Two electrical service entrances were located on the corner of the roof. One of the electrical service entrances had insulated conductors while the other did not. The roof had a 2:12 pitch (i.e., the roof rose 2 feet for every 12 feet in width.) (Figure).

On the day of the incident, six workers–two roof mechanic trainees (including the victim), foreman, laborer, and two roof mechanics–arrived at the job site to install a new roofing system. About 3:30 p.m. all work had been completed except for installing the flashing around the roof’s perimeter and placing the membrane over the roof felt. The victim and a co-worker were instructed to measure the perimeter of the roof and to cut aluminum flashing to size. The victim, working on the corner of the roof, was cautioned by the foreman to be aware of the electrical conductors in that area. The victim knelt between the corner edge of the roof and the electrical service entrances (approximately a 2-feet by 2-feet working area) to take the measurement around the perimeter of the roof’s corner. After taking the measurement, the victim stood up.

Upon standing upright, the victim either lost his balance and stepped into the electrical conductor, or misjudged his position in relation to the electrical conductors’ location and stood upright into a conductor. The victim’s chest contacted one of the uninsulated energized conductors and his right forearm simultaneously contacted the grounding wire for the electrical service entrance. Although no one saw the victim make contact with the conductor, the co-worker looked up and saw the victim in contact with the conductor and shaking violently. The co-worker shouted to the foreman for assistance.

The foreman and co-worker used a wooden board to push the victim away from the conductor, lowered him to the ground in the bucket of an aerial lift truck, and without formal training, attempted to administer CPR. In the interim, the foreman telephoned the local emergency medical service (EMS) for assistance. The EMS arrived in less than 5 minutes, continued CPR, and transported the victim to the emergency room of a local hospital where he was pronounced dead approximately 25 minutes after the incident occurred.

CAUSE OF DEATH

The medical examiner’s report listed the cause of death as ventricular arrhythmia from electrical shock.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should conduct initial jobsite surveys to identify all hazards associated with each specific jobsite and develop specific methods of controlling the identified hazards.

Discussion: The surface of the roof, 50 feet by 80 feet, contained at least two identifiable hazards (i.e., two electrical service entrances located on the corner of the roof creating a tripping hazard, and exposed electrical conductors creating an electrical hazard). Before the start of any work, employers should comply with OSHA construction safety standard 29 CFR 1926.416 (a)(3) [1] by conducting initial jobsite surveys to identify potential situations for employee contact with energized electrical circuits. Employers should also comply with OSHA construction safety standard 29 CFR 1926.416 (a)(3) [1] by providing subsequent employee notification about protective measures (i.e., identification, testing, de-energization, locking/tagging of energized conductors, verification, posting and maintaining proper warning signs, or avoidance of that area of the roof) to be implemented to control the hazards.

Recommendation #2: Employers should establish required procedures for the protection of employees exposed to electrical hazards and provide worker training in the recognition and avoidance of such hazards.

Discussion: Employers should comply with OSHA construction safety standard 29 CFR 1926.416 (a)(1)[2] by prohibiting employees from working in close proximity to energized electrical circuits where employees could make contact in the course of work, unless employees are protected against electric shock by de-energizing and grounding the circuit and/or by effective guarding. Employers should provide worker training in the recognition of electrical hazards and in safe work procedures, including identifying circuits, testing circuits, de-energizing circuits, locking/tagging de-energized circuits, and verifying de-energization.

Recommendation #3: Employers should ensure that service entrance conductors are insulated.

Discussion: Two electrical service entrance conductors were attached to the service head and conduit located at the corner of the warehouse roof. One set of conductors was insulated while the other was not. Employers should comply with the National Electrical Code Article 230-41 which states that service entrance conductors entering or on the exterior of buildings or other structures shall be insulated.

Recommendation #4: Employers should develop, implement, and enforce a written safety program which includes worker training in recognizing and avoiding hazards, especially electrical hazards.

Discussion: In this incident, the victim had just completed taking a measurement along the perimeter of the roof. He stood up, contacted an energized conductor, and was electrocuted. Employers should evaluate tasks performed by workers; identify all potential hazards; and then develop, implement, and enforce a written safety program addressing these issues as required by OSHA standard 1926.21(b)(2) [3]. This safety program should include, but not be limited to, worker training in electrical hazard recognition.

Recommendation #5: Employees who work around electrical circuits/conductors should be trained in cardiopulmonary resuscitation (CPR).

Discussion: To optimize results, CPR should begin within 4 minutes (in accordance with American Heart Association guidelines). To meet this criterion, workers should be trained to support circulation and ventilation until trained medical personnel arrive. Because neither the co-workers nor the foreman were trained in CPR, potentially critical care could not be provided in a timely manner. All employees working on or in proximity to powerlines, electrical circuits, and electrical equipment should be trained in CPR.

Recommendation #6: When circumstances offer no alternative to working in close proximity to energized conductors, employers should contact the local utility company to de-energize or insulate the conductors before the start of any work.

Discussion: De-energizing or insulating electrical conductors in working areas provides a passive measure of protection to workers who might contact the conductors. When there is no alternative to working in close proximity to energized conductors, de-energizing or insulating provides a viable option.

REFERENCE

Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. p.162. July 1, 1990.

Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. p.162. July 1, 1990.

Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. p.20. July 1, 1990.

National Fire Protection Association 70: National Electrical Code 230-41. p.70. 1990.

Figure. Warehouse Roof and Utility Pole with Service Entrances