Lineman Trainee Electrocuted after Contacting an Energized Pickup Truck in South Carolina

FACE 91-20

SUMMARY

A 21-year-old male lineman trainee (victim) was electrocuted after he contacted an energized pickup truck. The victim was part of a four-man crew assigned to convert a single-phase 7,200-volt overhead powerline to a three-phase 7,200-volt overhead powerline system, and remove the single-phase powerline. An aerial bucket truck was being used to provide access to the overhead powerlines, while a pickup truck was being used as a utility vehicle. At the time of the incident, the conversion had been completed and the crew was removing the de-energized single-phase powerline from the utility poles. The bucket truck crew, consisting of the foreman and victim, had cut the single-phase powerline and dropped one end to the ground without incident. When the other end of the powerline with attached come-along was dropped, it contacted the ground and the front of the pickup truck. The line recoiled when dropped causing it to contact an energized jumper wire on a utility pole one span away. This contact energized the single phase-powerline, which in turn energized the pickup truck. The victim, in an apparent attempt to move the pickup truck, jumped down from the bucket truck, removed his protective rubber glove from his right hand, and grasped the energized truck door handle. Contact with the handle provided a path to ground for the electrical current and the victim was electrocuted. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers and utility companies should:

- enforce compliance with established safe work procedures for covering or insulating all energized powerlines and jumper wires

- investigate alternative methods for lowering de-energized powerlines to ground level

- ensure that worksites are free of non-essential equipment

- retrofit utility/service vehicles used in the vicinity of energized powerlines with chassis/frame-energization alarm systems

- test, and instruct employees to inspect, personal protective equipment on a regular basis

- evaluate training programs to ensure that emergency situations and appropriate worker responses are addressed.

INTRODUCTION

On June 18, 1991, a 21-year-old male lineman trainee was electrocuted when he touched an energized pickup truck. On June 20, 1991, officials of the South Carolina Occupational Safety and Health Administration notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On July 10, 1991, a safety specialist from DSR conducted an investigation of this incident. The investigator reviewed the incident with company representatives, company employees, and the OSHA compliance officer assigned to the case. Photographs of the incident site and equipment, and a copy of the corresponding medical examiner’s report, were obtained.

The employer in this incident was an electrical contracting company that had been in operation for 46 years and employed 2,100 workers, including approximately 300 lineman trainees. The company had a written safety policy and written safety rules and procedures which were administered by the safety officer, company owners, and jobsite foremen. The safety department was comprised of a safety director, three safety supervisors, a safety training supervisor, equipment testing supervisor, and related clerical staff. Monthly safety meetings were held and documented, and the company promoted safety through the use of safety evaluations, communications, and incentive programs. The victim had worked for this employer for 19 months before this incident.

INVESTIGATION

The company had been contracted by an electric utility company to convert a single-phase 7,200-volt overhead distribution powerline to a three-phase 7,200-volt overhead distribution system, and to remove the single-phase powerline. Work had been completed on the conversion of the powerlines and the crew was in the process of removing the de-energized single-phase powerline from the utility poles.

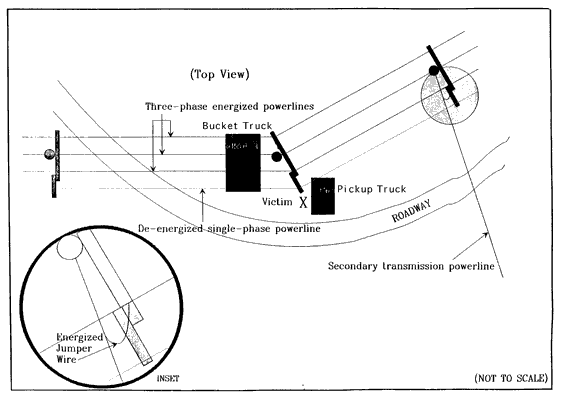

On the day of the incident, a four-man crew consisting of a jobsite foreman, truck operator, lineman, and lineman trainee, arrived at the jobsite to remove the single-phase de-energized powerline from the utility poles. The single-phase de-energized powerline had been previously offset away from the energized powerlines by mounting an additional section of crossarm to the permanent crossarm on the utility pole, and attaching the de-energized powerline to an insulator on its end. Two of the crew members were working as a team, four spans away. The victim and jobsite foreman were working as a team at the incident site. An aerial bucket truck was being used to provide access to the overhead powerlines, while a pickup truck was being used as a utility vehicle. The trucks were parked close to the utility pole, and beneath the overhead powerlines (Figure).

The foreman, working from the elevated bucket, had cut the de-energized single-phase powerline and lowered both sections, still connected by a hand winch (come-along), to the victim standing on the back of the bucket truck. The foreman continued to maneuver the bucket into its resting position over the truck cab thus placing his back to the victim.

Apparently, the victim released the grip on the left side of the come-along and dropped the left section of the de-energized powerline to the ground. When the victim dropped the right section of powerline, including the come-along, they both contacted a winch attached to the front of the pickup truck and the ground. The powerline recoiled and contacted a bare jumper wire on the three phase system at a utility pole one span away. This contact energized the single-phase powerline, which in turn energized the pickup truck. The victim, positioned on the back of the bucket truck, possibly saw electrical arcing between the powerline and the ground, and/or saw grass burning around the powerline. The victim jumped down from the bucket truck in an apparent attempt to move the pickup truck away from the area. The victim removed a protective rubber glove from his right hand and grasped the door handle of the energized pickup truck. This contact provided a path to ground for the electrical current and the victim was electrocuted.

The foreman saw the victim fall to the ground, and immediately ran to him, suspecting he had been shocked. After realizing the victim was unconscious, he ran back to the bucket truck and radioed the electric utility company to call for an ambulance. The foreman then contacted the other crew members for additional assistance, and returned to the victim to initiate cardiopulmonary resuscitation (CPR). An ambulance arrived about 9 minutes after being contacted. Ambulance personnel continued CPR and transported the victim to the hospital where he was pronounced dead on arrival.

CAUSE OF DEATH

The medical examiner’s certificate listed the cause of death as electrocution.

RECOMMENDATIONS/DISCUSSION

:

Recommendation #1: Employers should enforce compliance with established safe work procedures for covering or insulating energized powerlines and jumper wires.

Discussion: Safe job procedures covering the work being performed at the incident site were specific (i.e., all secondary transmission lines and jumper wires were to be covered with line hose). Although the secondary transmission lines were covered with line hose, the jumper wires were not. When the de-energized powerline was dropped, kinetic energy caused the de-energized powerline to recoil into contact with an energized jumper wire, which ultimately resulted in an electrocution. Employers should enforce compliance with established work procedures for covering or insulating energized powerlines and jumper wires through the periodic monitoring of worksites to evaluate field compliance with company safety rules and procedures. To be effective, a safety program must be enforced at the worksite. Regular company safety inspections show workers that the company is committed to enforcing its safety policies and procedures. Any violations of safety rules should be corrected immediately.

Recommendation #2: Employers should investigate alternative methods of lowering de-energized powerlines to the ground.

Discussion: The de-energized powerline was handed down to the victim standing on the back of the bucket truck; from that position the powerline was dropped to the ground. The uncontrolled release of kinetic energy caused the line to recoil unpredictably, and ultimately resulted in a fatality. Employers should consider alternative methods of lowering powerlines to the ground (e.g., possibly attaching non-conductive ropes to control the powerline and eliminate the risk of recoil caused by dropping the powerline from a height).

Recommendation #3: Employers should ensure that worksites are free of non-essential equipment.

Discussion: A utility pickup truck had been parked adjacent to the utility pole and bucket truck, and beneath the overhead powerlines. When the powerline was dropped from the bucket truck, the come-along and powerline contacted the winch attached to the front of the pickup truck. The victim may have seen the arcing between the powerline and ground, and without noticing the come-along and powerline contacting the winch, attempted to move the pickup truck. Employers should ensure that worksites are free of non-essential equipment (e.g., the utility pickup truck), that may interfere with the safe completion of tasks.

Recommendation #4: Employers should retrofit utility/service vehicles used in the vicinity of energized powerlines with chassis/frame-energization alarm systems, and provide periodic testing to ensure alarms are operational.

Discussion: When the energized powerline contacted the winch attached to the front of the pickup truck, the truck became energized and an electrocution resulted. Prior to the incident, the victim was on the back of the bucket truck, which was parked adjacent to, and partially in front of, the pickup truck. The position of the vehicles may have obstructed the victim’s line of sight such that he could not see the powerline in contact with the winch. Vehicles should be equipped with alarm systems that warn workers when the frames of vehicles become energized. Such an alarm system would signal all employees that a vehicle is energized. Employers should ensure that workers understand the meaning of the alarm, and specific procedures they should follow to avoid contact with the vehicle, and correct the problem. Additionally, the alarm systems should be tested on a periodic basis.

Recommendation #5: Employers should test, and instruct employees to inspect, personal protective equipment on a regular basis.

Discussion: The victim was wearing insulated rubber gloves in accordance with the employer’s safety program. Additionally, the victim was issued, and was wearing, insulated rubber overshoes as an added measure of safety. However, the overshoes were not required to be worn, nor were they tested for electrical integrity. When the overshoes were tested after the incident at the rubber goods testing laboratory, the left shoe was found to have three holes in the sole which allowed electrical current (50 milliamperes) to pass through to ground at 5,400-volts. It is not known, but when the victim removed his rubber glove to open the truck door, he may have relied on the rubber overshoes to protect him. Employers should periodically test all personal protective equipment provided to employees. Employees provided rubber overshoes as an added measure of protection should be instructed to routinely inspect for holes, cuts, tears, etc., and not to rely upon rubber overshoes for primary protection from electrical hazards.

Recommendation #6: Employers should evaluate training programs to ensure that workers know and practice appropriate responses to emergency situations.

Discussion: The energized powerline contacting the ground and pickup truck should have indicated to any employee that there was an emergency situation and that contacting the truck was unsafe and a dangerously inappropriate response. An appropriate countermeasure may have been to use a “hot stick” to remove the energized powerline from the pickup truck, rather than trying to move the pickup truck from the area. Employers should evaluate the training programs to ensure that workers know appropriate response measures to emergency situations, and are drilled to respond properly under simulated emergency conditions.

Figure. Conversion of Single-phase Powerline to Three-phase Powerlines