Four Members of a Maintenance Crew Electrocuted in California at a Major Naval Installation

FACE 87-12

Introduction

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) is currently conducting the Fatal Accident Circumstances and Epidemiology (FACE) Project, which is focusing primarily upon selected electrical-related and confined space-related fatalities. The purpose of the FACE program is to identify and rank factors that influence the risk of fatal injuries for selected employees.

On October 31, 1986, four members of a maintenance crew at a major naval installation were electrocuted and one crew member was critically injured when a scaffold they were moving contacted a 12,000 volt power line. The men were using the 30-foot high scaffold while painting a three story building.

Contacts/Activities

The National Institute for Occupational Safety and Health provided assistance to the Naval Public Works Center concerning this fatality. This case has been included in the FACE Project. On November 17, 1986, the DSR research team (consisting of two safety specialists) conducted a site visit, met with representatives of the base safety and compensation offices, interviewed comparison workers, interviewed surrogates for the victims, and photographed the accident site.

Overview of Employer’s Safety Program

The maintenance crew of the major installation consists of 1100 workers, who are assigned to work in one of the five zones of the naval installation. The victims were painters in the 400 man crew of zone three.

The safety function at the naval base is managed by the safety office on a full-time basis. A written safety policy and a comprehensive safety program exist at the base. The safety office publishes safety bulletins to be used by supervisors for their bi-monthly workplace safety meetings.

Workers are required to sign statements as evidence that they have attended these safety meetings. A safety committee of supervisors meets monthly to discuss safety issues. First line supervisors receive eight hours of annual supervisor training. Hazard recognition is stressed at these training sessions. The safety officer personally conducts training in respiratory protection, back injury prevention, handling of hazardous materials, and confined space entry.

Synopsis of Events

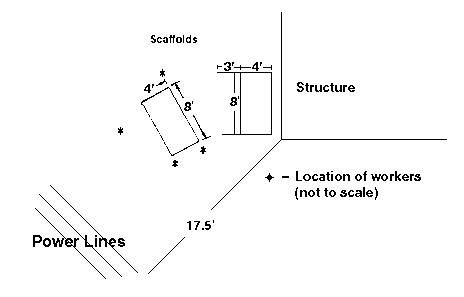

The crew (a crew chief and four painters) was painting a three story structure that housed offices for base personnel. The crew was using tubular welded frame scaffolding, approximately 4 feet wide by 8 feet long. The scaffold was five tiers high (approximately 28.5 feet) and was mounted on five-inch rubber-clad, aluminum wheels. The crew had completed painting the left side of the office building and was preparing to paint the front of the building. Although time was allocated on the work order to dismantle and rebuild the scaffold, the crew began to push the five-tier high scaffold to the front of the structure. A three-phase 12,000 volt power line was located 27.5 feet above the ground and 17.5 feet away from the left front corner of the building (See Figure).

A second scaffold was located at the left front corner of the structure. This three-tier high scaffold was also constructed from tubular welded frame scaffolding. However, the base dimensions were increased an additional three feet because the outriggers were extended. The crew had to maneuver the five-tier scaffold between the extended outriggers of the second scaffold and the 12,000 volt power line to reach the front of the building. Naval personnel estimated that less than four feet of clearance existed between the 12,000 volt power line and the five-tier scaffolding.

As the crew was maneuvering the five-tier scaffold around the extended outriggers of the second scaffold, the five-tier scaffold contacted the 12,000 volt power line. The four painters remained in contact with the scaffold while the crew chief received a severe electrical shock and was knocked backwards away from the scaffold. As naval personnel and civilians tried to approach the victims they received electrical shocks through their feet from the current running through the scaffolding to ground. The crew chief was able to grasp a board held by a rescuer and was pulled to safety. He was flown by helicopter to a local hospital where he was listed in critical condition. Rescuers tried to separate the victims from the scaffold, but were unable to do so until the power lines were de-energized.

Cause of Death

The cause of the four deaths was listed as electrocution.

Recommendations/Discussion

Recommendation #1: Supervisory personnel trained in hazard recognition should make a job site survey prior to the start of work at a site.

Discussion:Hazard recognition is stressed during yearly first line supervisor training sessions. The first line supervisor in this case (the crew chief) should have made a job site inspection to identify potential safety hazards. Once a safety hazard (in this case the power line) is identified, measures can be taken to control it.

Recommendation #2: Supervisors should utilize all allocated time to safely accomplish job assignments.

Discussion: Sufficient time to dismantle and re-assemble the scaffolding for moves was allocated on the work order. Had the scaffolding been even partially dismantled prior to the move, it would have made the scaffold much more maneuverable and would have eliminated the potential hazard presented by the power line.

Recommendation #3: Safe working distances should be maintained between scaffolding and power lines.

Discussion: California OSHA regulations require that six feet of clearance be maintained between power lines and scaffolding. Although California OSHA does not have jurisdiction in the case, it is smart and safe work practice to maintain at least a six foot distance as clearance. Additionally, when scaffolding is being moved in the vicinity of power lines a person should be appointed to constantly monitor the clearance between the power lines and the scaffolding.

Figure. Top View of Accident Site