Truck Driver Dies After the Off-Highway Truck He was Operating Rolled Over an Embankment and Came to Rest on Its Top - Pennsylvania

NIOSH In-house FACE Report 2000-05

Summary

A 48-year-old male truck driver (the victim) died after the off-highway truck he was operating rolled 49 feet over an embankment and came to rest on its top in 4 feet of water. The victim was hauling dirt that was being cut from a bank to clear ground for a 3-mile stretch of a new freeway project. As the victim was traveling up a haulage road, a road grader that was scraping mud from the road was traveling toward him from the opposite direction. The victim steered the truck to the right to allow the grader to pass. As he did, a portion of the built-up haulage road gave way under the truck’s right-side tires, causing the truck to overturn. The truck rolled over twice while traveling 49 feet down the embankment, and came to rest on its top in 4 feet of water. The grader operator immediately ran to the truck and pulled the victim clear. With the help of two flaggers, they placed the victim on the bottom of the truck cab. The two flaggers initiated cardiopulmonary resuscitation (CPR) on the victim while the emergency medical service (EMS) was called from a company truck. The EMS arrived at the scene within 8 minutes and summoned the county coroner, who pronounced the victim dead at the scene.

NIOSH investigators concluded that, to prevent similar incidents, employers should:

- ensure that employees adhere to established standard operating procedures

- ensure that heavy-equipment operators are properly trained and proficient in the operation of the equipment they are assigned to operate

Additionally, employers and manufacturers should:

- evaluate the possibility of installing video equipment in the cabs of heavy equipment or installing hood-mounted mirrors that would allow operators to clearly see how close their equipment is to road edges.

Introduction

On December 1, 1999, a 48-year-old male truck driver (the victim) died after the off-highway truck he was operating rolled 49 feet over an embankment and came to rest on its top in 4 feet of water. On December 3, 1999, the Division of Safety Research was alerted of the incident by a newspaper article, contacted the Occupational Safety and Health Administration (OSHA) compliance officer assigned to the case, and initiated an investigation. On December 6, 1999, two DSR Occupational Health and Safety Specialists traveled to the incident site to conduct an investigation. The incident was reviewed with the OSHA compliance officer, the company’s corporate safety director, and two company safety department personnel who were on site.

The company specialized in site clearance and preparation for highway/street construction. The company had been in operation for 75 years and employed 850 workers in their construction division. The company had a written safety policy, a comprehensive written safety program, and a drug screening program. Training was provided in the classroom and on the job. When the company purchased a new piece of heavy equipment, manufacturers’ representatives were brought to the site to train operators. During the previous summer, representatives from two manufacturers were on site to train operators of their off-highway trucks. Since the victim’s usual job was driving the water truck, he had not attended the training. Weekly safety meetings were conducted on site by safety department personnel. Every 2 years, workers’ yearly audiograms were scheduled to coincide with the company safety expo. During the safety expo, workers can be trained by manufacturers’ representatives or company representatives for jobs other than those they usually perform. The victim had worked for the company for 3½ years and had operated off-highway trucks on previous occasions; however, the amount of experience the victim had operating these trucks could not be determined. This was the fifth fatality experienced by the company in the past 9 years.

Back to Top

Investigation

The company had been contracted for site clearance and land preparation for a new 3-mile section of a four-lane expressway. Eight and one half million cubic yards of earth had to be moved for the project. Much of the roadway had to be built up well above ground level and much of the earth moved was used for that purpose.

The portion of the project where the incident occurred was thought to be completed; however, when company engineers surveyed the site, it was discovered that a corner of a hillside, containing approximately 50 cubic yards of earth, still had to be removed.

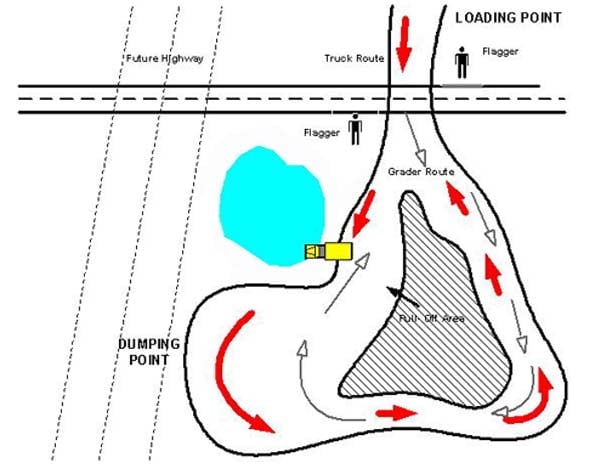

On the day of the incident, the victim, whose usual occupation was water truck driver, was asked by his supervisor to operate an off-highway truck to haul earth from the loading area to a dumping point approximately ¼ mile away. The entire trip was approximately ½ mile. The route was laid out in an oval configuration. The operators would take on their load, travel down a slight grade and across a two-lane state road, then up a built-up hill to the dumping point. They would then travel back down the return route, across the state road and back to the loading point. The built-up road leading up to the loading point was 25 feet wide and had a 49-foot-high bank on its right side. Approximately halfway up the hill was a large turnaround area on the left side of the haulage road. Flaggers were positioned on each side of the state road.

Two off-highway trucks were used. The load capacity of each truck was 5 cubic yards. The victim asked to operate a specific truck (Photo 1) since he had operated it previously. It could not be determined at the time of the investigation how much experience or training the victim had operating off-highway trucks; however, he had not operated an off-highway truck recently, nor had he attended the most recent training session conducted by manufacturer representatives for this type of equipment.

|

|

Photo 1. Truck involved in the incident

|

It had snowed the night prior to the incident and there was a light dusting of snow on the already wet ground. The first driver to use the haulage road told the supervisor that the portion of the road from the loading point up the hill to the dumping point was particularly “greasy” and slick and that the entire haulage road needed to be scraped. The supervisor directed the grader operator to scrape the haulage road. The grader operator started at the loading point and began scraping the haulage road up the hill to the dumping point. Standard operating procedures called for one-way traffic on the haulage road; however, when the grader operator reached the dumping point, he turned the grader around and started scraping the remainder of the haulage road coming back down the hill. The victim was hauling his load up the hill as the grader was traveling back down the hill. The two pieces of machinery approached each other approximately halfway up the hill at the turnaround area. The victim steered the off-highway truck toward the right-side embankment to allow the grader to pass. As he did, a portion of the right side of the haulage road gave way, causing the off-highway truck to overturn (Figure 1). The truck rolled over twice, coming to rest on its top in approximately 4 feet of water that had gathered at the bottom of the embankment (Photo 2).

|

|

|

Photo 2. Truck rollover

|

The grader operator, the two flaggers, and a safety consultant for the state department of transportation immediately ran to the victim’s aid. The grader operator waded through the water, reached into the cab of the truck, and pulled the victim free. The victim’s head was submerged and he was not belted in when he was pulled from the cab. The grader operator and the flaggers placed the victim on the bottom of the truck’s cab and the flaggers immediately initiated cardiopulmonary resuscitation (CPR) while the emergency medical service (EMS) was summoned by phone from a company truck. The EMS arrived at the scene within 8 minutes and summoned the county coroner, who pronounced the victim dead at the scene.

During the investigation the seatbelt was examined and found to be operational. A NIOSH investigator also sat in the operator’s seat and looked through the side mirror on the truck’s right side. The investigator could only see about halfway down the truck’s 6-foot-high rear tires. The area around the base of the tires could not be seen. It is likely that the victim could not determine how close he was to the right-side edge of the road.

Back to Top

Cause of Death

The coroner listed the cause of death as multiple skull fractures. Autopsy results identified no water in the lungs.

Recommendations and Discussion

Recommendation #1: Employers should ensure that employees adhere to established standard operating procedures.

Discussion: Standard operating procedures called for one-way traffic flow on the haulage road. Employers should ensure that one-way traffic flow is maintained on haulage roads, particularly on built-up roads. If for some reason it is necessary for a piece of equipment to travel against the established flow of traffic, all other traffic should be removed from the road until that piece of equipment completes its run.

Recommendation #2: Employers should ensure that heavy-equipment operators are properly trained and proficient in the operation of the equipment they are assigned to operate.

Discussion: The amount of experience the victim had operating the off-highway truck could not be determined during the investigation. The victim’s usual job was driving the water truck, a truck with a water tank mounted on it that was used to wet down haulage. The two trucks were different in design and mechanical operation. Because the area around the base of the off-highway truck’s tires could not be seen by an operator, it is unlikely the victim knew how close he was to the right-side edge of the haulage road. Workers should be adequately trained to operate equipment and should demonstrate proficiency in operating that equipment prior to operating it in a work situation.

Recommendation #3: Employers and manufacturers should evaluate the possibility of installing video equipment in the cabs of heavy equipment or installing hood-mounted mirrors that would allow operators to clearly see how close their equipment is to road edges.

Discussion: During the investigation, a NIOSH investigator sat in the operator’s seat of the truck and looked through the mirrors mounted on the sides of the truck. The investigator could not see the area around or underneath the 6-foot high rear tires. This suggests that an operator could not accurately determine how close he was to the side or edge of a road. Employers should evaluate the feasibility of installing surround-view camera systems on large heavy equipment. The monitor in the operator’s cab would allow equipment operators a clear view of the area surrounding the equipment and allow them to determine if they were approaching a dangerous area. Such surround-view systems are available. Additionally, mirrors could be mounted on a truck’s hood in a manner that would assist the operator in determining where a truck’s tires were in reference to a road’s edge.