Temporary Laborer Crushed by Dump Truck at Landfill -- South Carolina

FACE 9810

SUMMARY

On March 9, 1998, a 38-year-old temporary laborer (the victim) was run over and crushed by an off-road dump truck while he was working at a sanitary landfill. The victim had been assigned to pick up litter which fell from refuse collection vehicles traveling the landfill access road. He performed this task for about 2½ hours and was then assigned to act as a traffic guide, directing trucks to the proper dumping location along the landfill working face. Approximately 45 minutes after the victim began this assignment, co-workers noticed he was no longer in visual or audible contact with them and began a search. A loader operator saw the victim lying near a stockpile of cover-dirt and notified the foreman, who contacted the local emergency services. A local rescue squad, sheriff’s department, and the coroner responded. The victim was pronounced dead at the scene.

NIOSH investigators concluded that, to prevent similar incidents, employers should:

- ensure that workers follow procedures that minimize or eliminate pedestrian exposure to hazards from moving vehicles and mobile equipment

- consider the use of electronic signaling devices or sensors to warn equipment operators of the presence of pedestrians in the blind spots of mobile equipment

- ensure that routes of pedestrian travel are located to minimize worker exposure to hazards of vehicle movement during access and egress from rest rooms and similar facilities.

INTRODUCTION

On March 9, 1998, a 38-year-old temporary laborer (the victim) at a landfill was run over and crushed by an off-road dump truck. On May 4, 1998, officials of the South Carolina Occupational Safety and Health Administration (SCOSHA) notified the Division of Safety Research (DSR) of the occurrence and requested technical assistance. On May 12, 1998, a DSR safety engineer reviewed the SCOSHA case file and visited the incident site. The safety engineer interviewed the landfill operator’s Director of Safety/Human Resources, the landfill manager, and the landfill foreman.

The incident occurred at a landfill operated by a private refuse collection and disposal company, in business for over 20 years. The multi-state company employed over 500 employees, 9 of whom worked at the landfill. The company had been operating the landfill for 3 months prior to the incident. Prior to that, the landfill had been operated by the county. The landfill serviced 95 to 100 refuse-collection vehicles per day.

The company has a written safety policy and program which includes monthly safety meetings, regular job site inspections, disciplinary action for violations of the safety policy, and use of appropriate personal protective equipment. Training was conducted on-the-job under the direction of the foreman.

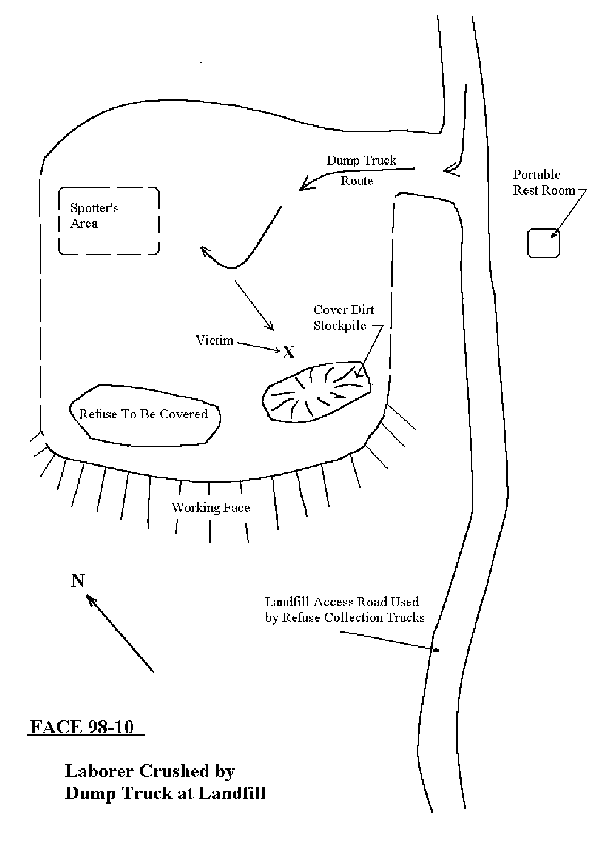

The victim had been hired from a temporary agency and was starting his second week on the job. He had been assigned to pick up litter refuse which spilled from the trucks along the access road or was wind-blown from the landfill’s working face He had been instructed about vehicle hazards and had been observed throughout the week safely performing this task by the landfill foreman. When re-assigned duties as a traffic guide, the foreman had instructed him where to stand in relation to truck movement (see Figure) while signaling to the truck’s driver. The victim had been furnished a hard hat, high visibility vest, and was wearing yellow rain pants at the time of the incident.

INVESTIGATION

The landfill was operated using a compactor/wheel dozer to spread and compact the refuse, two 6-wheeled off-road dump trucks to haul cover dirt to a temporary stockpile, a track-type loader to haul the cover dirt from the stockpile to the working face, and a bulldozer to spread and grade the cover dirt. At the time of the incident, the landfill was approximately 100 feet wide and 500 feet long. The victim reported for work at the normal start time of 7:00 a.m. He was assigned his usual task of picking up litter along the access road to the landfill and along the wind screens near the working face.

About 9:15 a.m., the landfill foreman assigned him to work as a spotter (traffic guide), directing loaded refuse trucks to the proper dumping locations along the working face. The regular spotter was absent this day and spotting duties were being performed by another man who had to leave. The victim arrived at the spotter area and was given a radio by the co-worker he was relieving. He began to direct traffic and reportedly was in radio contact with the bulldozer operator. He performed this task until about 10:00 a.m. when he left the designated spotter’s area and went to the cover dirt stockpile, engaging in conversation for a few minutes with the bulldozer operator and one of the dump truck drivers near the stockpile. About 10 minutes later, the bulldozer operator heard co-workers inquiring over the radio whether or not anyone knew where the victim was. The bulldozer operator checked an area of the landfill where the victim had been known to take a break. He was not there. The supervisor began to search for the victim. After about 45 minutes, the loader operator found the victim lying face up in the tire tracks of the dump truck near the cover-dirt stockpile. He radioed to the foreman who notified the local rescue squad. The rescue squad responded and notified the coroner who pronounced the victim dead shortly after he arrived at the scene.

CAUSE OF DEATH

The coroner determined the cause of death to be multiple trauma.

RECOMMENDATIONS/DISCUSSIONS

Recommendation #1: Employers should ensure that workers follow procedures that minimize or eliminate pedestrian exposure to hazards from moving vehicles and mobile equipment.

Discussion: Directing traffic was a new assignment for the victim. The procedure for this task was to remain in a designated though unmarked area of the landfill and signal to the drivers of the arriving refuse-collection vehicles where they should position trucks for dumping. This designated area had been chosen such that the spotter was able to perform all assigned tasks while remaining in front of the collection vehicles and out of the blind spot. Traffic was guided to the proper location by hand signals between the spotter and the vehicle’s driver. Communication between the spotter and the operator’s of the landfill’s mobile equipment was provided by radio. It is known that the victim left this area during a slack period shortly before the incident to converse with one of the dump-truck drivers and the bulldozer operator, near the stockpile of cover dirt, about 100 feet from the designated spotter area. The victim was not seen again until after the incident. During the investigation it was theorized that the victim may have gone to the portable rest room facilities and passed through the area while the truck was backing up to the cover dirt stockpile. Had the victim remained in the designated area, the likelihood of the incident occurring would have been diminished.

Recommendation #2: Employers should consider the use of electronic signaling devices or sensors to warn equipment operators of the presence of pedestrians in the blind spots of mobile equipment.

Discussion: The dump truck involved in the incident was a 1995 Caterpillar D-250E off-road hauler. It was equipped with a functioning backup alarm and rear view mirrors in good condition. While these devices are designed to prevent incidents such as occurred, there are limitations to their effectiveness. To be effective, audible alarms depend on the pedestrian’s ability to hear the alarm and to remove themselves from the path of the backing vehicles; no action is taken by the vehicle operator. Also, while the mirrors on the truck were effective in providing a view to the rear from the driver’s seat, there still exists a blind spot approximately 21 feet in length behind the vehicle which cannot be viewed from the seat. The driver of the truck involved in the incident had followed the employer’s policy of visually scanning the area while approaching the cover-dirt stockpile and turning to begin backing, however he did not see the victim.

There are several devices which could offer increased protection for pedestrians working near vehicle traffic.

- Working under a grant from the Federal Highway Administration (FHA), the Laborers’ Health and Safety Fund of North America (LHSFNA) developed two pedestrian-activated devices. The Spot Alarm allows workers who are within 100 feet of a vehicle to signal the operator to stop. The pedestrian worker carries a small key-chain sized radio transmitter on his/her belt, and when the transmitter button is pushed, the signal is detected by a receiver in the truck and a buzzer sounds to alert the driver of the worker’s presence. Prototypes of the device have worked well in field testing, providing pedestrian workers with a non-visual means of signaling operators to stop their vehicles. The Truck Stop expands the concept to incorporate automatic application of the truck’s brakes while in reverse at the detection of the pedestrian’s signal.

It should be noted, however, that the victim in this incident was equipped with a functioning radio yet none of the landfill equipment operators heard any transmission from him. After the incident, the radio was checked and found to be operating.

- Object and motion sensing devices using electromagnetic waves might be employed to passively detect pedestrians behind reversing vehicles. These devices are being used successfully on school buses to alert drivers to children who enter the blind spots in front of the buses and the devices have been used on residential refuse collection vehicles.

- Consideration could also be given to equipping pedestrians with a radio transmitter which would remain activated for the entire work shift. Vehicles could be equipped with shielded antennas so that only signals within the blind spot of the vehicle would be received.

These devices have good potential for preventing pedestrian fatalities, and their use should be evaluated for work environments which place pedestrian workers near vehicle traffic.

Recommendation #3: Employers should ensure that routes of pedestrian travel are located to minimize worker exposure to hazards of vehicle movement during access and egress from rest rooms and similar facilities.

Discussion: As stated previously, the reason for the victim’s location near the cover dirt stockpile could not be determined. The location was at least 100 feet away from the area in which he had been instructed to remain while spotting for the refuse collection trucks. It is possible that he may have crossed through the area of truck travel to access or return from the portable rest room at the time that the truck was backing. Whether this occurred or not, a rest room could have been located in the North corner of the landfill nearer to the spotter’s location.

REFERENCES

Hoffner K [1997]. A training program for the spotter to operator alarm system-the spot alarm. Laborers’ Health and Safety Fund of North America. Unpublished Report for FHWA Grant DTFH-93-X-00024.

Hoffner K [1997]. A training program for the ribbon switch/radio control truck stopping system-the truck stop. Laborers’ Health and Safety Fund of North America. Unpublished Report for FHWA Grant DTFH-93-X-00024.

NIOSH [1998]. Program of Mining Research, Navigation and Warning Aids for Mobile Equipment, pg 20. DHHS (NIOSH) Publication No. 98-114.

Figure.