Sign Installer Dies After Falling 12 Feet From A Canopy--Tennessee

FACE 9601

SUMMARY

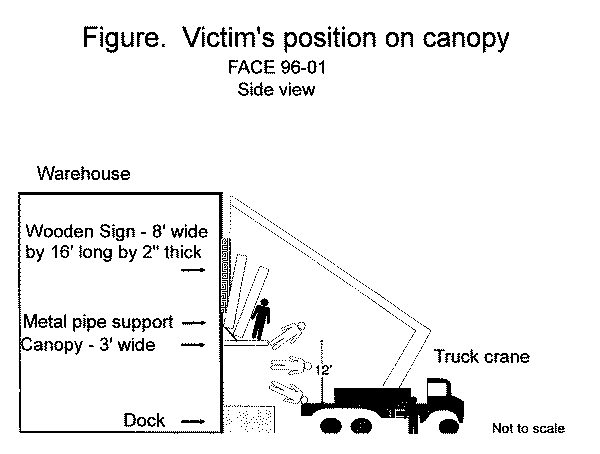

A 22-year-old male sign installer (the victim) died after falling from a canopy located above a loading dock, and striking his head on the bed of a truck crane. The victim and a co-worker had been assigned to remove four wooden signs above a loading dock at a food distribution warehouse. The two workers had removed three signs and were in the process of removing the fourth sign when the incident occurred. While attempting to remove the fourth sign, the victim was standing on a canopy which was about 15 feet above the ground and was not using any personal protective equipment (Note: a safety belt and lanyard were available in the truck crane). The co-worker positioned the truck crane beneath the canopy where the sign was located and extended the boom above the sign. The victim attached the crane’s load line around one of the metal brackets which secured the sign to the building. He then removed five lag screws which secured the sign to the building. As he removed the fifth screw the sign swung free. At that time the lag screw which attached the metal bracket to the wooden sign frame pulled out of the wood. The sign dropped and struck a diagonal canopy pipe support. The sign then slid down the support and struck the victim, knocking him off the canopy. The victim fell about 12 feet and struck his head on the corner of the truck bed. The co-worker, who witnessed the event, ran to aid the victim. He found the victim unresponsive and bleeding profusely. The co-worker then ran inside the warehouse and contacted the warehouse manager, who returned to the incident scene with the co-worker and performed cardiopulmonary resuscitation (CPR) on the victim. In the interim, a passerby in a vehicle equipped with a cellular telephone saw the incident and called 911. An emergency rescue squad arrived in less than 10 minutes, continued CPR, and transported the victim to the local hospital. The victim was removed from life support the following day and died from injuries sustained in the fall. NIOSH investigators concluded that, to prevent similar occurrences, employers should:

- prepare a hazard analysis of each activity involving the installation and/or removal of signs and implement measures to control these hazards

- review and revise, where applicable, the existing written safety program

- routinely conduct scheduled and unscheduled workplace safety inspections

- encourage workers to actively participate in workplace safety.

INTRODUCTION

On September 11, 1995, a 22-year-old male sign installer (the victim) died from injuries he received in a 12-foot fall from a canopy. On September 13, 1995, officials of the Tennessee Occupational Safety and Health Administration (TOSHA) notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On October 18, 1995, a DSR safety and occupational health specialist conducted an investigation of this incident. The incident was reviewed with the employer and TOSHA compliance officer assigned to the case. The sheriff’s report and photographs of the incident site and equipment were obtained during the investigation.

The employer manufactured, installed, and maintained lighted exterior signs. The employer had been in business for 30 years and employed 14 workers, six of whom were sign installers. The employer had a written general safety program that addressed safety procedures for manufacturing workers, but no specific written safety procedures for field workers, which included sign installers. Safety meetings were held on an irregular basis. The victim had worked for the employer for 5 months prior to the incident. This was the first fatality experienced by the employer.

INVESTIGATION

The employer had been contracted to remove four wooden signs attached to the exterior of a food distribution warehouse. The signs would eventually be replaced with new lighted signs. The warehouse was multi-storied, constructed of concrete, and had 14 loading docks. The signs were located on the exterior of the warehouse above a metal 3-foot wide canopy, which extended over the loading docks about 15 feet above ground level. The signs were 8 feet wide by 16 feet long by 2 inches thick and constructed on 2 inch by 4 inch wood frames with 4 feet by 8 feet plywood panels. Each sign was estimated to weigh about 250 lbs. The signs were secured to the warehouse with five ¼-inch by 22-inch-long lag screws and metal “L”-shaped brackets. The screws were screwed through the “L”-shaped metal brackets into the sign’s wooden frame and into the warehouse’s concrete exterior.

On the day of the incident, the victim and a co-worker arrived at work and were instructed to proceed to a food distribution warehouse to remove four wooden signs and bring the signs back to the shop. The two workers arrived at the jobsite about 8:30 a.m., and commenced work. They removed two signs without incident. In removing the third sign, the sign reportedly broke into pieces, due to wood deterioration, while it was being lowered to the ground via the truck crane. In attempting to remove the fourth sign, the victim positioned himself on a canopy (Figure) above loading dock number 13 and did not use any personal protective equipment. The canopy was 3 feet wide, 2 to 3 feet below the sign, and about 15 feet above ground level. The co-worker moved the truck crane into position below the sign, extended the boom tip above the sign, and lowered the boom cable down to the top of the sign. The victim secured the boom cable around a corner metal “L” bracket on the sign and the co-worker took up the slack in the boom cable. The victim then removed the five lag screws. When the last screw was removed, the sign swung free of the building. The weight and deteriorated condition of the wooden frame caused the screw to pull out of the wooden sign frame, allowing the sign to drop. As it dropped, the sign struck a metal pipe canopy support which was at a 45-degree angle to the canopy and warehouse wall. The sign then slid down the support and outward toward the victim, striking him and knocking him off the canopy. The victim fell about 12 feet and struck his head on the corner of the truck bed. The co-worker, who witnessed the event, ran to aid the victim. He found the victim unresponsive and bleeding profusely. The co-worker then ran inside the warehouse and contacted the warehouse manager, who returned to the incident scene with the co-worker and performed cardiopulmonary resuscitation on the victim. In the interim, a passerby in a vehicle equipped with a cellular telephone saw the incident and called 911. An emergency rescue squad arrived in less than 10 minutes, continued CPR, and transported the victim to the local hospital. The victim was removed from life support the following day and died from injuries sustained in the fall.

CAUSE OF DEATH

The official cause of death was listed as severe brain stem trauma.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should conduct job hazard analysis of each activity involving the installation and/or removal of signs and implement measures to control these hazards.

Discussion: As sign installation and/or removal tasks vary widely from location to location, a job-hazards analysis and subsequent implementation of control measures should be performed prior to the commencement of any work task. A proper hazard analysis involves three distinct steps: (1) outlining each step of a task or activity, (2) identifying all potential hazards associated with each step, and (3) developing measures for controlling each hazard. If a hazard analysis had been performed, the employer may have identified the dangers associated with working from an elevated work surface and the deteriorated condition of the sign, and could have subsequently taken measures to prevent this incident (e.g., ensure the use of safety belts and lanyards by employees who work from elevated work surfaces).

Recommendation #2: Employers should review and revise, where applicable, the existing written safety program.

Discussion: Although the employer had a written safety program, the program did not address safety procedures regarding work performed by field personnel, which included sign installers. The implementation and enforcement of a written comprehensive safety program should reduce and/or eliminate worker exposures to hazardous situations. The safety program should include, but not be limited to, the recognition and avoidance of fall hazards, and the use of appropriate safety equipment such as safety belts and harnesses. Note: A safety belt and harness was available on the truck crane, but was not used by the victim, possibly due to the unrecognized hazard of falling or being knocked off the canopy. Also, the employer is working with TOSHA to design and implement a comprehensive written safety program that encompasses all employees.

Recommendation #3: Employers should routinely conduct scheduled and unscheduled workplace safety inspections.

Discussion: Employers should be cognizant of the hazardous conditions at jobsites and take an active role to eliminate them. Additionally, scheduled and unscheduled safety inspections should be conducted by a competent person to ensure that jobsites are free of hazardous conditions. Even though these inspections do not guarantee the elimination of occupational injury, they do demonstrate the employer’s commitment to the enforcement of the safety program and to the prevention of occupational injury.

Recommendation #4: Employers should encourage workers to actively participate in workplace safety.

Discussion: Employers should encourage all workers to actively participate in workplace safety and ensure that all workers understand the role they play in the prevention of occupational injury. In this instance, the victim was working from an elevated work surface without the use of personal protective equipment. Workers and co-workers should look out for one another’s safety and remind each other of the proper way to perform their tasks. Employers must instruct workers of their responsibility to participate in making the workplace safer. Increased worker participation will aid in the prevention of occupational injury.

Figure.

Return to In-house FACE reports