Line Mechanic Dies After Falling From Aerial Bucket Truck - Virginia

FACE 9235

SUMMARY

On August 31, 1992, a 35-year-old male line mechanic (the victim) died after falling 37 feet from the bucket of an aerial lift truck. He had been attempting to remove a partially severed tree limb that had fallen onto a powerline. The victim had wrapped the end of a 7/16-inch woven nylon winch line from the boom-mounted winch around the fallen limb in a choker hitch, and was operating the winch from the bucket of the aerial lift truck. Apparently the load conditions exceeded the capacity of the woven nylon winch line causing it to fail. Factors which may have contributed to the line failure included: the method of rigging the load, which may have reduced the line’s capacity; and the fact that the limb was not fully severed from the tree, which could have dramatically increased the load on the line. The winch line suddenly parted under tension allowing the boom of the aerial lift truck to spring upward, throwing the victim out of the bucket. Although fall protection equipment (a safety belt and lanyard secured to an anchor point on the boom adjacent to the man-bucket) was provided in the bucket, the victim was not wearing the safety belt as required by company policy.

NIOSH investigators concluded that, to prevent future similar occurrences, employers should:

- ensure that appropriate fall protection equipment is available and correctly used when working from elevations where there is a danger of falling

- ensure that employees follow standard safe operating procedures for the tasks being performed

- ensure that safe work procedures address the manner in which the load lines of hoisting equipment are attached to the load so that the full strength of the load line is available and that the lifting capacity of the equipment is not exceeded.

INTRODUCTION

On August 31, 1992, a 35-year-old male line mechanic (the victim) died as a result of injuries sustained after falling from the bucket of an aerial lift truck. On September 14, 1992, the Virginia Occupational Safety and Health Administration notified the Division of Safety Research (DSR) of this fatality and requested technical assistance. A DSR safety engineer traveled to the site on September 23, 1992, to conduct an investigation of the incident. During the investigation, the employer’s safety director was interviewed, measurements and photographs of the site and vehicle were taken, and a copy of the death certificate was obtained.

The employer was an electrical utility company that had been in operation for 65 years, employing 5,100 workers, including 216 line mechanics in 9 divisions. The company employed a full-time safety director, as well as divisional human resource managers with part-time safety responsibilities. The company maintained a written safety policy and safety rules, and employees received both formal classroom and on-the-job training. The victim, a journeyman line mechanic, had 15 years experience. The company’s last fatality had occurred four years earlier. This was the first fatality experienced by this division.

INVESTIGATION

The victim and a co-worker had been assigned to remove a broken tree limb from a residential powerline. The tree limb, 9 inches in diameter at its base and tapering to 6 inches at the end of its 15 foot length, weighed an estimated 200 pounds. The limb had partially split from the tree trunk and was leaning against an insulated powerline located at the rear of a residence. A carrier wire strung between wooden poles supported the powerline. The tree stood on the grounds of the local high school, which bordered the residential area. A chain link fence separated the school grounds from the residence and the powerline. The base of the tree was 12 feet and the fence was 9 feet from the powerline.

On the day of the incident, the victim and a co-worker arrived at the site at about 8:15 a.m. in response to a customer request to evaluate the limb on the powerline. They positioned the aerial lift truck on the grounds of the high school approximately 20 feet from the powerline. The truck was equipped with a boom-mounted winch located adjacent to the aerial bucket which the victim intended to use to lift the limb from the powerline. Company standard operating procedure required the use of a sling attached to the end of the winch line for this type of lift.

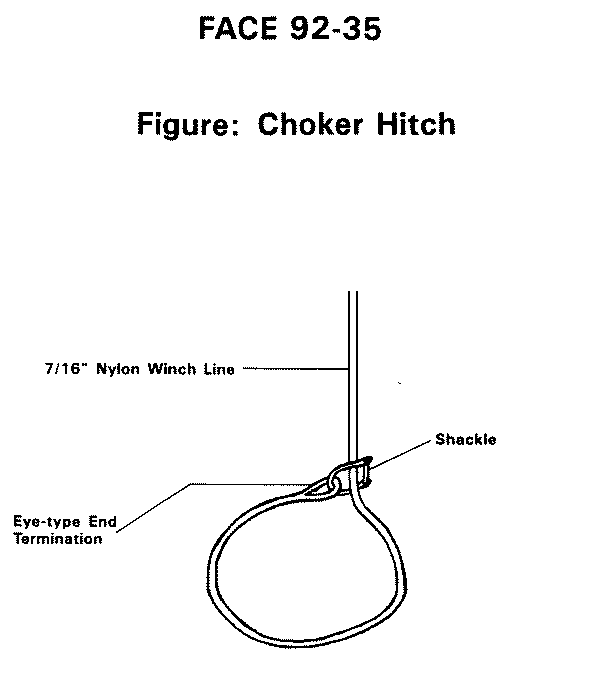

The victim, without wearing the fall protection equipment provided (a safety belt and lanyard secured to a boom anchor point adjacent to the man-bucket), entered the bucket and positioned the end of the truck boom next to the tree limb. Instead of following company procedure and using a sling, he passed the end of the 7/16-inch woven nylon winch line around the limb and formed a choker hitch by attaching the line’s eye-type end termination to the line with a shackle (Figure), and attempted to lift the partially split limb (using the winch).

The attempt was unsuccessful, and at about 8:30 a.m., the victim indicated to his co-worker on the ground that he was going to reposition the boom to change the direction of lift. The winch line suddenly parted, allowing the loaded boom to spring upward. The victim was thrown out of the bucket and he fell 37 feet to the ground. Although the victim was wearing fall protection equipment (a safety belt and lanyard) he had not attached the lanyard to the anchor point on the boom adjacent to the aerial bucket as required by company policy. The local emergency medical squad (EMS) responded 15 minutes after notification by a school employee who had witnessed the incident. The victim was transported by the EMS to a local hospital where he was pronounced dead at 10:28 a.m.

CAUSE OF DEATH

The medical examiner determined death to be due to multiple chest and abdominal injuries.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that appropriate fall protection equipment is available and correctly used when working from elevations where there is danger of falling.

Discussion: The victim had been provided with appropriate fall protection equipment, a safety belt and lanyard secured to the boom anchor point. However, the victim was not wearing the safety belt while inside the bucket. Employers should ensure that workers follow established procedures for wearing fall protection equipment. Use of fall protection equipment may not have prevented the victim from being catapulted out of the bucket, but it could have prevented his falling to ground.

Recommendation #2: Employers should ensure that employees follow standard safe operating procedures for the tasks being performed.

Discussion: According to the company safety director, standard operating procedures prohibit using the winch line itself as the means of attachment to the load and require the use of a fabricated sling which is then attached with a shackle to the eye-type end termination of the winch line. A properly sized sling could have increased the load carrying capacity of the winch line.

Recommendation #3: Employers should ensure that safe work procedures address the manner in which load lines of hoisting equipment are attached to the load so that the full strength of the load line is available and the lifting capacity of the equipment is not exceeded.

Discussion: The winch line, a 7/16-inch woven nylon rope, had been attached to the tree limb as a choker by looping the line around the limb. The loop was closed by connecting the eye of the end termination to the line with a shackle. This method of rigging may have jeopardized the strength of the rope by concentrating excessive rope stresses at the point where the end termination was connected to the line, or by severing the rope fibers through contact with metal fittings (shackles). Either of these conditions could effectively decrease the working capacity of the rope and cause it to fail suddenly. The rope had a manufacturer’s rated working capacity of 1,500 pounds and a breaking strength of 7,500 pounds. However, because of the sharp bends in a rope rigged in a choker hitch, the working capacity of a rope can be reduced by 30%. After the incident, the employer load tested the remaining line to 3,000 pounds without damage. The employer’s standard operating procedures prohibit the use of winch lines for loads over 1,000 pounds, and require the use of separate slings appropriate for the type of lift being performed. Use of fabricated slings allows the selection of rope sizes larger than the winch line, thereby compensating for the decrease in effective strength from rigging in a choker hitch. Larger size ropes also decrease the severity of the rope bends used in fashioning a choker hitch, further protecting the integrity of the rope. It is not known what load the rope experienced on the day of the incident. The tree limb was 9 inches in diameter at the base, tapering to 6 inches in diameter at the end of its 15 foot length not including the minor branches. It is estimated that the limb weighed 200 pounds. Since the tree limb was only partially split from the tree trunk, it is possible that, because of the location of the winch line attachment to the limb and the angle of the pull, the victim was unintentionally attempting to lift the entire tree, not just the limb. If this was the case, then the winch line would have been subjected not only to the weight of the tree, but also to the resistance of the tree roots. This could have significantly overloaded the winch line, resulting in failure.