Electrical Technician Electrocuted after Contacting a 800-volt Conductor in South Carolina

FACE 92-07

SUMMARY

An electrical technician (victim) was electrocuted while he and another worker were performing electrical testing inside a control panel cabinet. The victim was assisting a company service representative with testing the voltage regulating unit on a new high-temperature, steel-alloy rolling mill. After meeting at the new plant, the two men tested voltages on several low-voltage wires and determined that the unit was not regulating the correct amount of voltage. While the victim retrieved the equipment service manual, the service representative opened the panel cover for the voltage regulating control cabinet in preparation to trace the low-voltage wiring in question, as the wiring was not color-coded. The service representative climbed onto an adjacent cabinet in order to view the wires. The victim worked inside the control cabinet near exposed energized electrical conductors, tugging at the low-voltage wires as the service representative tried to identify them from above. The representative heard the victim making a gurgling sound, and looked down to see the victim shaking as though he were being shocked. Cardiopulmonary resuscitation (CPR) was administered to the victim approximately 10 minutes after the incident occurred. He was pronounced dead approximately one hour and forty-five minutes later as a result of his contact with an energized electrical conductor. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- review and revise, where applicable, the safe job procedure governing access into electrical control cabinets

- re-emphasize and reinforce the importance of following safe job procedures related to de-energizing electrical systems prior to performing repairs

- equip voltage regulating equipment with color-coded wiring

- train employees in cardiopulmonary resuscitation techniques.

INTRODUCTION

On September 19, 1991, a 30-year-old male electrical technician was electrocuted when he inadvertently contacted an energized conductor inside a control panel cabinet. On September 20, 1991, officials of the South Carolina Occupational Safety and Health Administration (SCOSHA) notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On December 19, 1991, a safety specialist from DSR conducted an investigation of this incident. The safety specialist reviewed the incident with the company representative, and the SCOSHA compliance officer assigned to the case. A schematic of the equipment and the medical examiner’s report were obtained.

The employer in this incident was a steel-alloy rolling mill that had been in business for 19 months. The company was in the process of starting-up a new plant where 35 personnel were employed which included 5 electrical technicians who installed and maintained the plant’s electrical equipment. The company had a written safety policy, and comprehensive safety program including written safety procedures, and a full-time director of safety. The victim had worked for this employer for 16 months prior to the incident.

INVESTIGATION

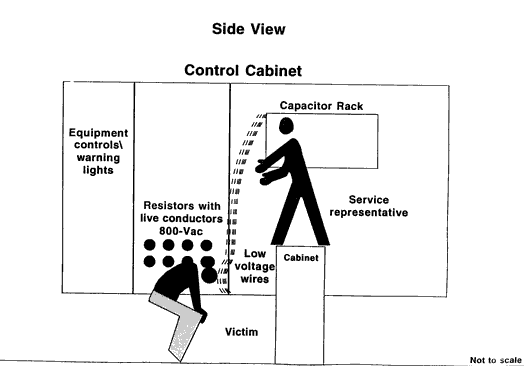

The high-temperature, steel-alloy rolling mill was in the start-up mode at the time of the incident. The plant’s buildings had been erected, rolling machines and all related equipment had been installed, and the employees were in the process of testing all equipment prior to the actual start-up of the rolling mill. On the day of the incident, the victim had been instructed to meet with and assist a service representative from the company that manufactured a piece of voltage regulating equipment. The equipment (a Mini-Comp system) was being used to control voltage surges and regulate voltages to different pieces of equipment throughout the plant (Figure).

On the day of the incident, the victim met the service representative and proceeded to the building within the plant that contained the Mini-Comp system. The two men discussed what had to be done, then began checking the voltages on the low-voltage (15-volts) wiring from the Mini-Comp system. They determined a problem existed within the equipment, as the correct amount of voltage was not being detected. The victim left the area to get the service manual for the equipment. Without de-energizing the Mini-Comp system, the service representative opened the panel cover on the system’s control cabinet in preparation to trace out the low-voltage wires in question. The wires were not color-coded. He then climbed onto the compartment adjacent to the capacitor rack in order to view the wiring.

At that time the victim returned, kneeled in front of the opened control cabinet, and positioned his head and shoulders inside the 800-volt resistor compartment. As he began tugging on the wires inside the compartment, he was told by the service representative to be careful around the conductors. The service representative was watching to see which wire moved when he heard the victim making a gurgling noise. When he looked down he saw the victim shaking as though he were being shocked. He jumped down from the cabinet and although receiving a shock himself, knocked the victim away from contact with the energized conductor.

The service representative ran to his truck and called the plant’s main office for assistance. Personnel from the main office called the emergency medical service (EMS) and proceeded to the incident site where cardiopulmonary resuscitation (CPR) was administered by one of the plant’s managers. The EMS arrived approximately 15 minutes after being notified, continued CPR, and transported the victim to the local hospital’s emergency room where he was pronounced dead one hour and forty-five minutes after the incident occurred.

CAUSE OF DEATH

The medical examiner’s office reported the cause of death as electrocution.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should review and revise, where applicable, the safe job procedures associated with accessing electrical control panel cabinets.

Discussion: The control panel cabinet was located inside a building accessible only through a locked gate, but the cabinet itself was unlocked and accessible to anyone within the building. When the control panel was opened by an unauthorized person (the service representative), the returning victim may have assumed the incoming power had been shut off, and started work within the cabinet without first verifying de-energization. Cabinets of this nature should be locked and the key held only by persons authorized to enter. Workers should be trained to never enter into electrical cabinets without first determining which areas and equipment are de-energized and which are energized. Also, consultants and manufacturers representatives should be trained in company standard operating procedures before entrance into controlled access areas and servicing of electrical equipment is permitted.

Recommendation #2: Employers should re-emphasize and reinforce the importance of following established safe work procedures especially de-energizing electrical systems prior to any work being performed on them.

Discussion: Although the circuits had to remain energized during testing to determine if the circuits were sensing the proper voltage, it was not necessary to leave the circuits energized while tracing wiring. In spite of company safe work procedures requiring the de-energization of the control panel, the circuits were not de-energized as required by 29 CFR 1910.333 (a). For these procedures to be effective, they must be clearly communicated and fully understood by the effected employees and supervisors. The employees and supervisors must believe the company genuinely expects compliance with the guidelines, even if it means sacrificing production or other company goals.

Recommendation #3: Voltage regulating equipment should be wired with color-coded conductors.

Discussion: The victim was in the process of trying to identify non-color-coded wiring in the regulating unit when he contacted an energized conductor and was electrocuted. Color-coded insulation covering the wiring is unique to specific conductors, and can be readily identified and separated from all others in the same wiring harness or conduit. Voltage regulating equipment should be designed and manufactured with unique color-coded conductors for each separate circuit in the cabinet or compartment of electrical equipment. Also, electrical equipment purchase orders should require voltage regulating equipment conductors be color-coded, and electrical equipment deliveries should be inspected for compliance before delivery acceptance and before equipment installation.

Recommendation #4: Employers should train workers in cardiopulmonary resuscitation (CPR).

Discussion: Approximately 7-10 minutes lapsed before potentially critical CPR techniques were initiated. CPR was attempted after the incident by one of the plant managers from the main office located about 3 minutes from the incident site. To optimize results, CPR should begin within four minutes in accordance with American Heart Association guidelines. To meet this criteria, all workers should be trained to support circulation and ventilation until trained medical personnel arrive.

REFERENCES

Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. July 1, 1989.

1985 National Conference on Cardiopulmonary Resuscitation (CPR) and Emergency Cardiac Care (ECC). Standards and Guidelines for Cardiopulmonary Resuscitation (CPR) and Emergency Cardiac Care (ECC). JAMA 255(21):2905-2989 (June 1986).

Figure. Mini-Comp System