Maryland Steelworker Electrocuted When He Contacted Energized Toaster Oven Casing in Employee Lunchroom

FACE 90-37

SUMMARY

A 53-year-old male steelworker was electrocuted when he contacted the energized case of a toaster oven. While taking a break from his normal work routine, the victim sat upon a wooden bench and rested his right forearm on a floor model air conditioner upon which the 120-volt toaster oven was setting. The victim’s right arm contacted the energized casing of the toaster oven while his right calf contacted the grounded air-conditioning unit. The victim received an electrical shock and went into cardiac arrest. The victim was treated by the local emergency medical service and transported to the local hospital where he was pronounced dead on arrival. NIOSH investigators concluded that, in order to prevent future occurrences, employers should:

- periodically inspect all areas of the facility for electrical hazards and implement appropriate controls

- adopt a policy requiring that all appliances brought into their facility be tested for electrical integrity by qualified persons before they are used

- periodically re-evaluate safety programs and reinforce training related to worker recognition, avoidance, and reporting of hazards

- provide cardiopulmonary resuscitation (CPR) training to all workers, both management and labor.

INTRODUCTION

On August 17, 1990, a 53-year-old male steelworker (caster attendant) was electrocuted when he contacted the energized case of a toaster oven in the employee lunchroom at a steel manufacturing plant. On August 27, 1990, officials of the Maryland Occupational Safety and Health Administration notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On September 20, 1990, a safety specialist from DSR traveled to the worksite and conducted an investigation. The investigator reviewed the incident with a company safety supervisor and a safety engineer, interviewed the OSHA compliance officer assigned to the case, and gathered further data. Photographs of the incident site and an autopsy report were obtained after the investigation.

The victim’s employer is a major steel company that has been in operation for 74 years and employs 8000 workers. The company has a written safety policy and a comprehensive safety program. The safety department is comprised of a superintendent, two supervisors, two engineers, one industrial hygienist, and two union safety personnel. On-the-job and classroom training are provided to all employees, as well as training videos and safety manuals. Additionally, weekly safety contacts are made and documented. Pre-employment physicals are required of all new employees. The victim worked for this employer for 26 years prior to this incident.

INVESTIGATION

On the day of the incident, the day shift (7:00 a.m. to 3:00 p.m.) of the steel-making department in which the victim worked, was conducting normal daily operations. A crew of 4 workers including the victim, had been performing maintenance on a tundish (i.e., an intermediate pouring vessel which is used to control the pouring of molten steel into molds). At about 9:50 a.m., the crew decided to take a break. The crew took a 15-minute break once an hour due to the hot working environment.

The victim walked to the lunch room and sat on a wooden bench next to a floor-model air conditioner, which was approximately 30 inches tall. The toaster oven was on top of the air conditioner and plugged into a 120-volt electrical circuit.

The victim, who was sweating profusely and wearing a short sleeved shirt, rested his right forearm on top of the air conditioner. The victim’s right arm contacted the energized casing of the toaster oven while his right calf was in contact with the grounded air-conditioning unit. The victim began to shake which attracted the attention of the co-workers. A co-worker, suspecting the victim was being shocked, knocked the toaster oven off the air conditioner, disconnecting the plug from the receptacle. Current had traveled through the victim and exited at the point of contact between the victim’s right leg and the grounded casing of the air conditioner.

A co-worker laid the victim on the wooden bench, positioned a jacket beneath his head, and began pushing on the victim’s chest. Another co-worker contacted the foreman, who called the plant emergency medical service. The plant EMS team responded in 15-20 minutes and provided advanced cardiac life support. The victim received additional treatment from the local emergency medical service which transported him to the local hospital where he was pronounced dead on arrival.

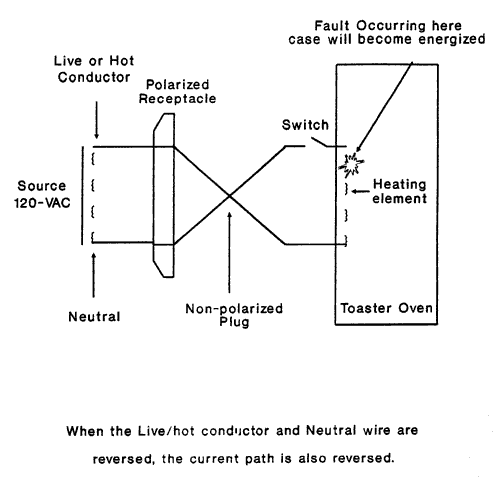

Investigators learned that the toaster oven’s power cord had a non-polarized plug which, sometime prior to the incident, had been inversely inserted into a polarized receptacle.1 The heating element in the toaster oven had been previously damaged and was in contact with the oven casing. Reverse insertion of the plug in the polarized receptacle created a condition known as reversed polarity. Electrical current flowed through the heating element without the switch being turned to the ON position and energized the toaster oven casing (Figureimage icon).

CAUSE OF DEATH

The autopsy report listed the cause of death as arteriosclerotic cardiovascular disease complicated by electrocution.

RECOMMENDATIONS/DISCUSSION:

Recommendation #1: Employers should periodically inspect all areas of their facility for electrical hazards and apply appropriate control measures.

Discussion: Employers should periodically inspect all areas of their facilities, especially non-production areas, lunch rooms, break rooms, rest rooms, etc., to identify non-polarized plugs, improper grounding, and any other electrical hazards that may be present, and then apply appropriate measures to eliminate the hazard. Additional information pertaining to electrical hazards can be found in the NIOSH Alert “Request for Assistance in Preventing Fatalities of Workers Who Contact Electrical Energy (1).”

Recommendation #2: Employers should require that all appliances brought into their facility be tested for electrical integrity by a qualified person before they are used.

Discussion: Employers should not only require such testing, but also ensure that all supervisors and workers are aware of the testing policy. [Note: The employer in this incident has adopted such a policy.]

Recommendation #3: Employers should periodically re-evaluate safety programs and reinforce training related to worker recognition, avoidance, and reporting of hazards.

Discussion: A subsequent interview of the witnesses revealed that the victim and his co-workers were aware that a problem existed with the oven. On a number of occasions the workers, including the victim, had received electrical shocks from the oven. Employers should periodically re-evaluate existing safety programs and reinforce worker training related to recognizing, avoiding, and reporting hazards, especially electrical hazards.

Recommendation #4: Employers should provide CPR training to all workers, both management and labor.

Discussion: Employers should ensure that all workers are provided with CPR training to support circulation and ventilation until trained medical personnel arrive. To optimize results, CPR should begin within 4 minutes (in accordance with American Heart Association guidelines). (2) Initial CPR was administered by a co-worker whose last CPR training occurred about 15 years previous to this incident. CPR training should be repeated at least annually to ensure that employees retain knowledge, and keep up with advances in life support techniques.

1 Note: On a polarized plug, the neutral terminal is wider than the hot terminal. Therefore, a polarized plug can be inserted into a polarized receptacle in one way only. On a non-polarized plug, the neutral and hot terminals are the same width. Therefore, the non-polarized plug can be inserted two ways.

REFERENCES

1. NIOSH [1986]. Request for Assistance in Preventing Fatalities of Workers Who Contact Electrical Energy. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 87-103.

2. 1985 National Conference on Cardiopulmonary Resuscitation (CPR) and Emergency Cardiac Care (ECC). Standards and Guidelines for Cardiopulmonary Resuscitation (CPR) and Emergency Cardiac Care (ECC). JAMA 255(21):2905-2989 (June 1986).

Figure. Reversed Polarity