Laborer Touching Suspended Cement Bucket Electrocuted When Crane Cable Contacts 7200-Volt Powerline in North Carolina

FACE 90-29

SUMMARY

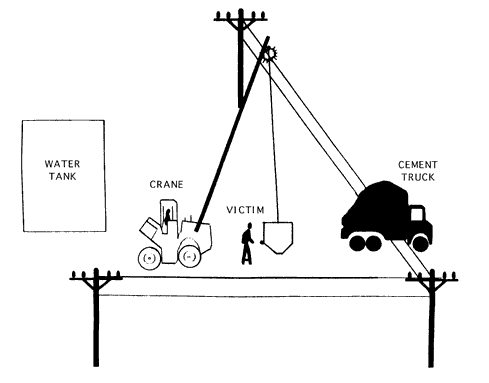

A 29-year-old male laborer was electrocuted when the crane cable suspending a 1-yard cement bucket he was touching contacted a 7200-volt powerline. The victim was a member of a crew that was constructing the back wall of an underground concrete water holding tank at a sewage treatment plant. Before work on the tank was begun, the company safety director, aware of the hazards involved in using a crane near an overhead powerline, requested assistance from the local electrical utility company. As a result, utility company workers placed insulated line hoses over sections of the powerline near the jobsite. The safety director also had markers placed to indicate where arriving cement trucks should stop while the cement bucket was loaded. Loading the bucket at the marked location ensured that the crane boom and cable would remain at least 14 feet from the powerline. (OSHA regulations require that a minimum distance of 10 feet be maintained.) As a result of the precautions taken, the concrete for the wall was poured without incident. However, after the crew had poured the last bucket of concrete to finish the top of the wall, the driver of the cement truck cleaned the loading chute on his truck with a truck-mounted water hose and began to pull away. As he did the crew supervisor yelled to him and asked if the crew could use the water hose to wash out the cement bucket suspended from the crane. The driver stopped the truck under the powerline and the crane operator, not realizing the truck had been moved, swung the boom to position the bucket behind the truck. The victim grasped the handle of the bucket’s door and pushed down to open it, bringing the crane cable into contact with the powerline. The electrical current traveled down the cable and through the bucket and victim to ground, causing the victim’s electrocution. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- ensure that all workers adhere to existing regulations regarding clearance distances between cranes and powerlines, and remain constantly aware of the clearance between the crane and any powerlines that might be present

- evaluate alternative methods of pouring concrete in proximity to overhead powerlines which do not require the use of a crane

- conduct daily jobsite surveys to identify any potential hazards.

INTRODUCTION

On March 1, 1990, a 29-year-old male laborer was electrocuted when the crane cable suspending a 1-yard concrete bucket he was touching contacted a 7200-volt powerline. On March 6, 1990, Officials of the North Carolina Occupational Safety and Health Administration notified the Division of Safety Research of the incident and requested technical assistance. On March 28, 1990, two safety specialists from DSR traveled to the incident site to conduct an investigation. The DSR investigators reviewed the incident with the company safety director, and obtained photographs, diagrams of the incident site, and police reports.

The employer is a heavy construction company that specializes in power station, bridge, and wastewater treatment plant construction. The company employs 600 workers, including a safety director. The company has a comprehensive safety program and provides on-the-job training for all employees. New employees undergo a 6-day orientation period. Each week, a safety meeting is held on site for all company employees. Crew supervisors hold tailgate safety meetings daily at their respective work areas. The tailgate safety meetings include a hazard review for each task that the workers will perform that day. Each employee undergoes a drug test before being hired and is subject to random drug testing thereafter. The victim had received training in crane safety (including the hazards associated with overhead powerlines) on February 12, 1990.

INVESTIGATION

The company was contracted in 1988 to construct a large addition that would upgrade an existing wastewater treatment plant. The victim’s crew was pouring concrete for the back wall of an underground water holding tank that measured 20 feet long by 29 feet wide by 23 feet high. Prior to the start of construction on the holding tank, the company safety director contacted the local electrical utility and requested that they relocate a 7200-volt powerline at the site. The powerline presented a serious hazard, since a crane would be used to position a 1-yard bucket during the pouring of the concrete. Electrical utility engineers determined that the powerline could not be relocated because the adjacent swampy ground would not permit the proper anchoring of the utility poles. Instead, the powerline was covered with insulated line hoses in the vicinity of the worksite. In order to comply with OSHA regulations pertaining to clearances between cranes and powerlines, the safety director had markers placed in the ground that identified the spot where truck drivers would back the cement trucks for the unloading of the bucket. This action ensured that the crane boom would come no closer than 14 feet to the powerline, greater than OSHA’s required minimum clearance distance of 10 feet. Because of subsequent damage caused by Hurricane Hugo, the insulated hoses were removed from the powerline so that the slack in the powerline could be adjusted. The insulated hoses were not replaced by electrical utility workers after the slack in the powerlines was adjusted.

On the day of the incident, the victim was working on the floor of the holding tank cleaning up spilled concrete. After the last bucket was poured, the truck driver cleaned the loading chute on the truck with a truck-mounted water hose. The victim joined the rest of the crew at ground level. When the driver finished cleaning the truck, he began to pull away. The supervisor called for him to stop and asked if the crew could use the water hose to clean the concrete bucket. The driver stopped the truck under the powerline. The supervisor signaled the crane operator to swing the bucket around to the truck. Without realizing the truck had been moved, the crane operator positioned the bucket behind the cement truck. The victim grasped the door handle on the bucket and pushed down to open it, causing the crane cable to contact the powerline. The electrical current traveled down the cable and through the bucket and victim to ground, causing his electrocution. The supervisor detected a pulse, but the victim was not breathing. The supervisor immediately began mouth-to-mouth resuscitation while one of the crew members summoned the emergency medical squad (EMS). The EMS transported the victim to the hospital where he was pronounced dead-on-arrival by the attending physician.

CAUSE OF DEATH

The coroner listed the cause of death as electrocution. No autopsy was performed.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure adherence to existing OSHA regulations concerning crane operations.

Discussion: OSHA standards 1926.550 (a)(15) and 1910.180 (j) require that the minimum clearance between electrical lines rated 50 kV or below and any part of the crane or load shall be 10 feet, unless the electrical lines have been “de-energized and visibly grounded” at the point of work or physical contact between the lines, equipment, or machines is “prevented” by the erection of insulating barriers which cannot be part of the crane. Additionally, 29 CFR 1926.550 (a)(15)(iv) requires that a person be designated to observe clearance of the equipment and to give timely warning for “all” operations where it is difficult for the operator to maintain desired clearances by visual means.

Recommendation #2: Employers should ensure that all crew members remain constantly aware of the clearance between a crane and any powerline that may be present.

Discussion: In this instance, the powerline had been identified as an overhead hazard. Measures were developed to control this hazard and crew members may have become complacent with the procedure of loading the bucket behind the cement truck. When the crane operator received the signal from the supervisor, he automatically positioned the bucket behind the truck, not knowing that it had moved toward the powerline. All crew members must remain constantly aware of the hazards associated with overhead powerlines.

Recommendation #3: Employers should evaluate alternative methods of pouring concrete in proximity to overhead powerlines.

Discussion: One alternative way to pour concrete in proximity to overhead powerlines would be to use a concrete pumping truck. The truck could be positioned in a manner that would avoid the hazard of overhead powerlines. A truck-mounted flexible hose could be used to dispense the concrete.

Recommendation #4: Employers should conduct daily jobsite surveys to identify all potential hazards.

Discussion: It could not be determined exactly when the insulated hoses had been removed by the utility company. A daily jobsite survey might have identified that the line hoses had been removed. The utility company could then have been contacted to replace the insulative hoses.

References

1. 29 CFR 1926.550 (a)(15) Code of Federal Regulations, Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

2. 29 CFR 1910.180 (j) Code of Federal Regulations, Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

3. 29 CFR 1926.550(a)(15)(IV) Code of Federal Regulations, Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

Figure.