23-Year-Old Lineman Electrocuted in North Carolina

FACE 86-20

Introduction:

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) is currently conducting the Fatal Accident Circumstances and Epidemiology (FACE) Project, which is focusing primarily upon selected electrical-related and confined space-related fatalities. The purpose of the FACE program is to identify and rank factors that influence the risk of fatal injuries for selected employees.

On March 21, 1986, a lineman was electrocuted when he contacted a lightning arrestor conductor while working from an aerial bucket. The lineman was attempting to splice a wire cable into a connection box which was attached to the upper cross member of the utility pole.

Contacts/Activities:

Officials of the Occupational Safety and Health Program for the State of North Carolina notified DSR concerning this fatality and requested technical assistance. This case has been included in the FACE Project. A safety specialist and an industrial hygienist from DSR met with company representatives, interviewed comparison workers and next of kin, conducted a site visit, and photographed the accident site.

Overview of Employer’s Safety Program:

The employer is a major electric utility in the southeastern United States and employs 21,000 workers in nine fossil fuel plants, three nuclear plants, and numerous field and administrative offices.

The safety program is structured as a line function within each department (i.e., linemen, construction workers, office workers, etc.). Throughout the company safety responsibilities are implemented by management and supervisory personnel on a collateral-duty basis. Each department conducts its own safety inspections and audits. Training and safety councils are also structured along departmental lines. The company produces and distributes to each employee a written safety manual. The Chief Executive Officer establishes annual goals for the corporation. Of the 11 goals established for 1986 two are safety related. The two corporate safety goals are: 1) no more than one lost work day injury per 1,000,000 hours of work, and 2) no more than 3.5 vehicular accidents per 1,000,000 miles driven.

Synopsis of Events:

The victim (a lineman technician) reported to work at 8:00 a.m. Friday, the day of the accident. The victim had been a lineman technician for three months. As such the victim was permitted to climb poles and make electrical connections. Prior to traveling to the job site, he met with his supervisor who assigned the work crew its activities for the day. The supervisor verified that the crew had the appropriate equipment and materials required to complete the job assigned.

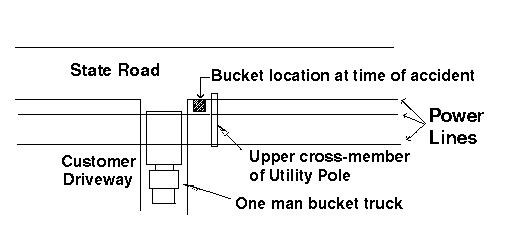

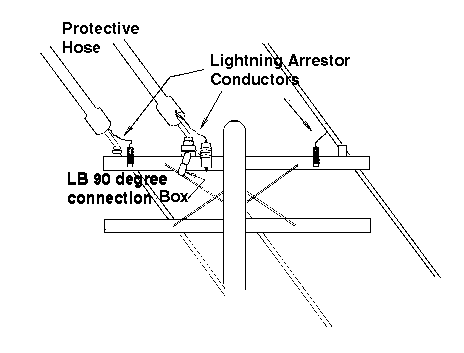

The two-person crew (the victim and a supervising lineman) returned to the location where they had worked earlier in the week. They were to remove and replace a capacitor bank from a utility pole located in a flat rural area. (See Diagram Aimage icon.) The upper cross member supported three 7200 volt conductors and each conductor had attached to it a lightning arrestor. (See Diagram Bimage icon.) The crew’s specific task on the day of the accident was to splice a #16 wire cable into a LB 90o connection box which was attached to the upper cross member of the utility pole. The purpose of the splice was to bring electricity from the conductor to a service meter attached to the pole five feet above the ground.

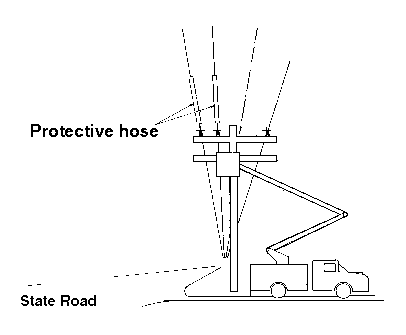

At 8:45 a.m. the victim positioned himself in a one-person articulated, truck-mounted aerial bucket 25 feet above the ground and slightly below the upper cross member of the utility pole. (See Diagram Cimage icon.) Protective insulating hoses were placed over two of the primary conductors; however, the lightning arrestor conductors attached to the primary conductors prevented the hoses from slipping all the way to the cross member on the utility pole. The victim did not use any boots, blankets, or other insulating material to cover the lightning arrestor conductors or other live conductors. The victim’s insulated rubber gloves were in the tool tray located on the floor of the bucket. Immediately before the accident, the victim was in the process of splicing the 3-conductor #16 wire cable into the LB 90o connection box. The victim’s splicing knife was found on the floor of the bucket.

The supervising lineman on the ground did not witness the accident. However, the physical evidence suggests the victim was holding the #16 wire cable with his left hand when his right hand came in contact with the lightning arrestor conductor. The lightning arrestor conductor was located within 11 inches of the LB 90o connection box. The victim cried out when his hand came in contact with the lightning arrestor conductor. The lineman on the ground looked up and saw the victim slumped in the bucket; he then ran to the truck and radioed for assistance.

By using the controls on the truck, the lineman lowered the victim to the ground and removed him from the aerial bucket. Within five minutes a nearby crew from the same utility company responded to the call for help. Finding the victim unconscious, the co-workers began CPR until the local EMS arrived. The victim was transported to a nearby hospital where he was pronounced dead at 9:55 a.m.

Cause of Death:

The cause of death was cardiac arrest due to contact with 7200 volts of electricity. The coroner reported electrical burns on the victim’s right palm (entry wound) and electrical burns on the victim’s left palm (exit wound).

Recommendations/Discussion:

Recommendation #1: When working with electricity, workers should wear appropriate protective equipment and use insulating boots, blankets, and hoses where appropriate.

Discussion: At the time of the accident the victim was not wearing rubber gloves which were provided by the employer. The victim did not cover all exposed electrical parts with blankets, boots, or covers as is required by the company’s safety manual. The victim should have been required to follow the safe job procedure as stated in the company’s safety manual. If the victim had worn protective clothing and covered energized parts, the risk of an electrocution would have been greatly reduced.

Recommendation #2: Corporate safety management should assess the effectiveness of its comprehensive corporate safety program.

Discussion: Corporate management should take an active role in assessing the effectiveness of its safety program. Corporate management should develop an audit instrument designed to assess the adherence to elements of the company’s safety program. At least the following five areas should be included in a safety audit: safety management administration, education and training, safety allied services, supervision, and evaluation.

Recommendation #3: Upon initial hiring and periodically thereafter, all workers and supervisors should receive training in hazard recognition, safe work practices, and emergency response.

Discussion: It was determined during the investigation that, other than on-the-job training and tail-gate meetings, the company has no structured pre-placement training, continuing education, or remedial training of workers. New employees need to know the hazards associated with electricity, and they should be able to recognize electrical hazards and implement effective countermeasures. All workers performing hazardous tasks should be adequately trained to perform all tasks assigned. All field supervisors and workers should be certified in CPR.

Diagram A. Location Sketch

Diagram B. Upper Cross-member of Utility Pole

Diagram C. Location of the Aerial Bucket