Two Workers Electrocuted by 23,000 Volt Power Line While Erecting a Steel Support Structure

FACE 85-07

Introduction

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR), is currently conducting the Fatal Accident Circumstances and Epidemiology (FACE) Project, which is focusing primarily upon selected electrically-related fatal injuries and confined space fatalities. By scientifically collecting data from a sample of fatal accidents, it will be possible to identify and rank factors which influence the risk of fatal injury for selected employees.

On December 11, 1984, at approximately 8:00 a.m., a co-owner and three employees of a steel erection company were using a telescoping boom crane to move a section of steel framing member at the construction site of a commercial storage shed. As this section was moved, it contacted one phase of a 23.000 KVA overhead power line. Two of the three employees who were in direct contact with the steel section were electrocuted while the third received serious electrical burn injuries.

Contacts/Activities

The Tennessee Department of Labor, Occupational Safety Division invited a DSR team, consisting of an epidemiologist and consulting engineer, to collect research information. On January 7, 1985, this team visited the office of the area director who had conducted the State’s investigation. At this time, the area director informed the team that the co-owners who employed the victims, had dissolved their company, sold their equipment, and could not be contacted by telephone. Consequently, the team’s field activities were limited to ascertaining what was learned and concluded by the area director during his investigation and conducting a site survey of the accident location. The majority of this report’s content resulted from the latter activity.

Synopsis of Events

The company employing the victims was established in July, 1984 and owned by two men who had numerous years’ experience as ironworkers. This construction project represented the first major job for the company who was serving as the subcontractor for steel erection. This project consisted of the erection of a 40′ X 180′ materials storage shed (consisting of a structural steel framework enclosed with a sheet metal roof and sides) at a warehouse facility. The 180′ side was in a north-south direction and the 40′ side was in an east-west direction.

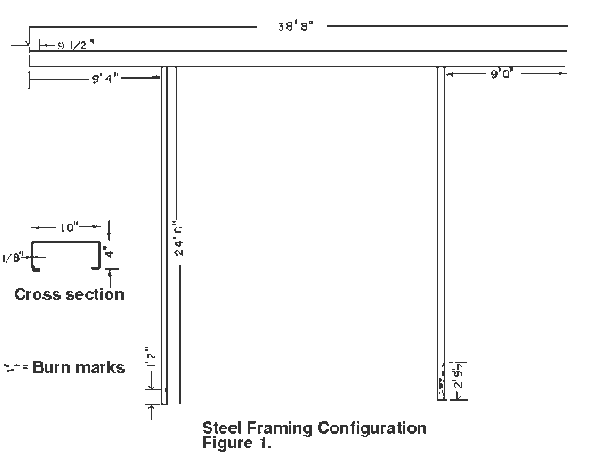

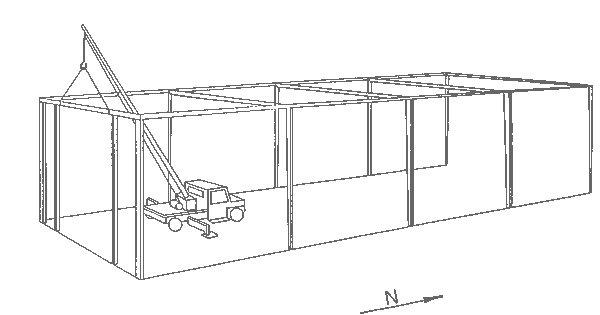

At the time of the accident, the major steel framework had been erected except for the end sections. After the south end was erected, the workers discovered that an incorrect roof beam had been installed (Figure 1). To replace this beam, a decision was made to use a crane to lower the south section to the slab (Figure 2). The incorrect beam was unbolted from the two corner columns, but was left connected to the two intermediate columns. These intermediate columns were disconnected from the anchor bolts on the slab. A lifting sling was placed around the incorrect beam with the intention of raising the whole assembly (beam and support columns) off the anchor bolts, tipping it in a northward direction, and laying the whole assembly on the slab. Then the columns would be unbolted and the correct beam installed.

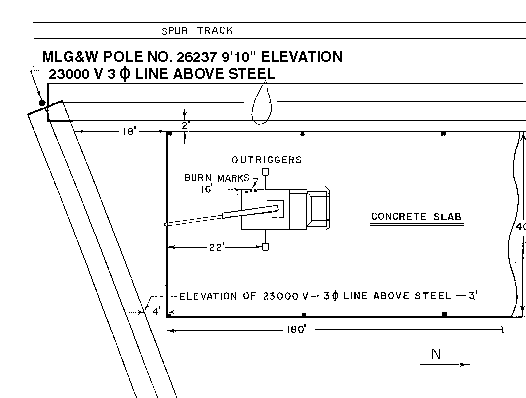

A plan view of the building layout and the proximity of the two sets of 23 KVA overhead power lines to the work area are shown in Figure 3. One set of power lines ran in an east-west direction. This set came from a corner pole (outside the fence) on the west side of the slab and steel uprights. These powerlines fed a transformer bank consisting of 3, single phase, 23 KVA transformers which supplied power to the facility. One of these lines was approximately a five foot diagonal distance from the structural section which was to be lowered. The second set of power lines ran on the west side of the structure along its entire 180′ length. The inside phase of this set appeared to be approximately 10 feet diagonally from the upright columns of the structure’s west side.

As the co-owner (standing on the running board and operating the hydraulic crane controls) raised the steel section, two workers attempted to pull the base of the west column towards the north while the third worker tried to pull the east column likewise. Due to unbalanced forces, the east end of the incorrect beam rotated and/or tipped into the inside phase of the east-west powerlines. The phase to ground voltage was approximately 13.200 KVA. Two workers (one on each of the support columns) were electrocuted. The remaining worker, pulling the west column, sustained extensive electrical burn injuries on his left hand, left arm, and both feet and was in the burn unit of a local hospital when the field activities were conducted. It is surmised that he was still alive because he had only one hand in contact with the column. The electrocuted workers had both hands on the columns and this probably facilitated the path of current through vital organs. The co-owner who was operating the crane was not injured.

Subsequent to the accident, the city building inspector issued a “cease work” order which will not be removed until the utility company adjusts the location of the power lines.

Conclusion/Recommendations

Various factors contributed to the occurrence of this fatal accident. Some of these factors are:

1. Initial approval for construction was granted by the city building inspector. It is recommended that in the future, the issuing body of construction permits should incorporate rules and regulations requiring all known electrical lines (both overhead and underground) be referenced on building application drawings.

2. Apparent insufficient safety awareness by the general contractor prior to issuing a subcontract and during steel erection.

3. The electrical lines were neither de-energized, insulated, nor moved away from the construction activity.

4. The apparent insufficient recognition, knowledge, and appreciation of the dangers of electrical energy, as demonstrated by the employees of the steel erection company.

5. The incorrect beam was installed.

6. Failure to use nonconductive taglines in performing the task of lowering the steel structure. One existing guideline suggests using nonconductive tagline to control all loads being moving in the proximity of powerlines. (Dickie DE [1975]. Crane Handbook, Ontario: Construction Safety Association of Ontario.)

7. The subcontractor had no written safety program nor standardized procedures for working around power lines.

The cooperation and assistance of the State OSHA and their area director are greatly appreciated.

Figure. 1 Steel Framing Configuration

Figure 2.

Figure 3.