Laborer Killed While Inflating a Tire Mounted on a Multi-piece Rim Wheel

Massachusetts Case Report: 03-MA-057-01

Release Date: December 22, 2004

Summary

On October 16, 2003, a 42-year-old male laborer (the victim) was fatally injured while inflating a front-end loader’s tire mounted on a multi-piece rim. The loader’s front left tire had gone completely flat preventing the loader from being moved out of the garage location where it was parked. The victim was sitting in a chair approximately 12 inches from the tire’s sidewall while inflating the tire when increased air pressure caused the tire tube to explode. The explosion knocked the victim backwards. A tractor-trailer driver, waiting to access the garage, heard the explosion, found the victim on the ground, and informed the company of the incident. A 911 call was placed and a company employee ran to a neighboring building that housed the Ambulance Response Headquarters. Several employees of the Ambulance Response Headquarters immediately responded to the scene and attended to the victim. Emergency Medical Services (EMS) from the 911 call responded to the incident site within minutes and transported the victim to a local hospital where he was pronounced dead. The Massachusetts FACE Program concluded that to prevent similar occurrences in the future, employers should:

- ensure that tires mounted on multi-piece rims that are flat or under inflated (the tire has less than 80% of recommended pressure) are never re-inflated while the wheel is on the vehicle. Once the wheel is off of the vehicle, the rim should be disassembled, inspected, reassembled, re-inflated and placed back on the vehicle.

- ensure that employees never position themselves in front of or over tires mounted on multi-piece rims during tire inflation.

- develop standard operating procedures (SOP) for servicing multi-piece rims and provide training on these procedures.

- develop, implement and enforce equipment maintenance programs that include inspecting all equipment for defects and having only trained workers service multi-piece rim wheels when problems are identified.

Introduction

On October 20, 2003, the Massachusetts FACE Program was notified by the Occupational Safety and Health Administration (OSHA) through the 24-hour Occupational Fatality Hotline, that on October 16, 2003, a 42-year-old male was fatally injured when the tire he was inflating exploded. An investigation was immediately initiated. On October 27, 2003, the Massachusetts FACE Program Director traveled to the incident location, a cement product manufacturer, to discuss the incident with one of the two company owners and an employee. The death certificate, corporate information, police incident report, and the OSHA fatality and catastrophe report were reviewed. The front-end loader involved in the incident was photographed during the course of the site visit.

The employer, a concrete products manufacturer, had been in business for approximately 54 years at the time of the incident. The current owners, two brothers, manage the family business. The company employed approximately ten people on a regular basis. The victim had worked at the company for approximately four years, during which he worked as a laborer / yardman. His main task consisted of operating a forklift.

The company did not have a designated person in charge of employee safety and health nor did it have a safety and health program. Employee training was provided on-the-job by more experienced employees. The victim did not have an operating license for forklifts. In Massachusetts these licenses are required and issued by the Massachusetts Department of Public Safety. The victim was not part of a union collective bargaining unit.

Investigation

The company’s main manufactured product was concrete blocks. The machine involved in the incident was a wheeled front end loader (Figure 1). This was the only front end loader owned by the company. The loader was used to fill the hoppers on the kilns with materials, such as sand and stone, during the cement block manufacturing process. The company had purchased the loader approximately ten years prior to the incident. The employer was unsure of the exact year the loader was manufactured but estimated that it was around 1985. The loader had a diesel engine and was equipped with a two cubic yard bucket. The tires had been originally manufactured as tubeless, but at some point, tubes had been place inside of them. The loader’s wheels were multi-piece rims each consisting of a rim base, a continuous side ring, and a lock ring (Figure 2). The function of the rim base and continuous side ring is to support the tire. The function of the lock ring is to hold the continuous side ring on the rim.

On the day of the incident, the victim had started work at his usual time, 7:00 a.m. The loader involved in the incident had been parked in its normal location inside one of the garage bays (Figure 3). A truck had arrived with a delivery that was to be dropped off inside the garage bay where the loader was parked. The truck driver walked into the garage looking for someone to move the loader and noticed that the front left tire was fully deflated. The truck driver informed the victim that the loader had to be moved and that it had a flat tire. The truck driver went back to the cab of his truck to fill out paperwork.

The victim decided to inflate the loader’s front left tire (Figure 2) using an air chuck attached to an air line and a compressor. The victim was sitting on a chair that was positioned approximately 12 inches away from, and directly in front of the tire’s sidewall during this task. The police report noted that at one point, the victim had asked a coworker about noise made by the tire / wheel during inflation. The coworker responded that to the best of his knowledge, some noise was normal when adding air to a tire.

When the tire had fully deflated, it appears the rim’s lock ring had become partially unseated. The air compressor being used by the victim to inflate the tire had a faulty pressure gauge, consequently the victim could not measure the tire’s increasing air pressure. Evidence indicates that the increase in air pressure caused the tube to explode, which caused the unseated lock ring and the tire to dislodge from the rim. The release of air pressure when the tube exploded knocked the victim backward with the chair.

The truck driver heard a loud noise and exited his cab to see what happened. He walked into the garage and discovered the victim and the chair approximately six feet away from the loader’s front left wheel. The truck driver notified the victim’s coworkers of the incident and a 911 call was placed for Emergency Medical Services (EMS). Another coworker ran to a neighboring building that housed the local Ambulance Response Headquarters. Several employees of the Ambulance Response Headquarters immediately responded to the scene and attended to the victim. Local police and EMS from the 911 call responded to the incident site within minutes and transported the victim to a local hospital where he was pronounced dead.

It had been reported the loader’s front left tire had been partially deflating on a daily basis, and that this was the first time the tire had completely deflated. No defects were found during an inspection of the wheel (rim and tire) after the incident. In addition, one of the company’s owners reported that they used a local tire company for servicing the loader’s rims and tires.

Cause of Death

The medical examiner listed the cause of death as head trauma.

Recommendations/Discussion

Recommendation #1: Employers should ensure that tires mounted on multi-piece rims that are flat or under inflated (the tire has less than 80% of recommended pressure) are never re-inflated while the wheel is on the vehicle. Once the wheel is off of the vehicle, the rim should be disassembled, inspected, reassembled, re-inflated and placed back on the vehicle.

Discussion: In this case, the victim attempted to inflate the fully deflated tire while the wheel was still mounted on the vehicle. As required by OSHA, when tires that are mounted on multi-piece rims have less than 80% of the manufacturer’s recommended pressure, the tire should be inspected prior to reinflation. First, the tire should be completely deflated by removing the valve core. Then the wheel should be removed from the vehicle, the tire demounted from the rim, the rim disassembled and inspected. If no problems are found, then the rim can be reassembled, the tire remounted on to the rim and reinflated. When reinflating the tire, employees should use a restraining device for the tire such as a safety cage or cable restraints. Only workers trained in servicing multi-piece rim wheels should service these wheels.

Recommendation #2: Employers should ensure that employees never position themselves in front of or over tires mounted on multi-piece rims during tire inflation.

Discussion: A tire mounted on a multi-piece rim that is under inflated, but has more than 80% of the recommended pressure, can be inflated without an inspection and with the wheel mounted on the vehicle. OSHA requires that the employee inflate the tire from a distance standing behind the tire tread, to be out of the trajectory, using a long air line with a clip-on chuck, and an in-line valve with a pressure gauge. If the same under inflated tire mounted on a multi-piece rim is not mounted on a vehicle, the employee still can inflate the tire without an inspection, but must use a restraining device such as a safety cage or cable restraints while inflating. Only workers trained in servicing multi-piece rims should inflate tires mounted on these rims.

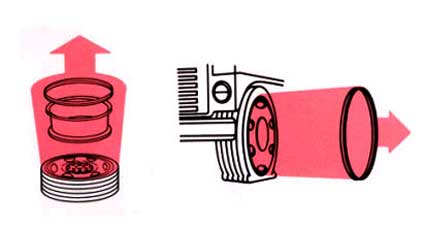

OSHA’s definition of trajectory: any potential path or route that a rim wheel component may travel during an explosive separation, or the sudden release of the pressurized air (Figure 4).

Recommendation #3: Employers should develop standard operating procedures (SOP) for servicing multi-piece rims and provide training on these procedures.

Discussion: Employers should develop standard operating procedures (SOP) for servicing multi-piece rims and should train employees who will service multi-piece rims in these procedures. All employees should be cautioned of the potential hazards of multi-piece rims. Employees that are not assigned to service these rims should not to attempt to inflate these tires. Only employees who are assigned to service multi-piece rim wheels and have been trained on the proper servicing of these rim wheels, including demounting, inspecting, inflating and mounting procedures, should be allowed to service them. The SOP should also include both the multi-piece rim manufacturer’s and the tire manufacturer’s instructions and recommendations and applicable OSHA’s standards.

OSHA has outlined safe operating procedures for multi-piece rim wheels in their 29CFR1910.177 standard, Servicing multi-piece and single piece rim wheels. In addition to the above two recommendations, other required procedures for servicing multi-piece rim wheels are listed below. The full text of this standard can be found at https://www.osha.govexternal icon.

- Whenever a rim wheel is in a restraining device the employee shall not rest or lean any part of his body or equipment on or against the restraining device.

- After tire inflation, the tire and wheel components shall be inspected while still within the restraining device to make sure that they are properly seated and locked. If further adjustment to the tire or wheel components is necessary, the tire shall be deflated by removal of the valve core before the adjustment is made.

- No attempt shall be made to correct the seating of side and lock rings by hammering, striking or forcing the components while the tire is pressurized.

- Cracked, broken, bent or otherwise damaged rim components shall not be reworked, welded, brazed, or otherwise heated.

- No heat shall be applied to a multi-piece wheel or wheel component.

Recommendation #4: Employers should develop, implement and enforce equipment maintenance programs that include inspecting all equipment for defects and having only trained workers service multi-piece rim wheels when problems are identified.

Discussion: Employers should develop, implement and enforce equipment maintenance programs that include both scheduled preventive maintenance and immediate maintenance to equipment when problems arise. In this incident, the air compressor had a faulty pressure gauge that prohibited the victim from knowing how much air pressure was being added to the loader’s tire, which had been routinely losing air. The air compressor should have been taken out of service until the pressure gauge was replaced and when the loader’s tire first starting losing air the company should have had a trained worker or the local tire company address the problem.

In this case, the maintenance program should also include a warning for all employees of the potential hazards associated with multi-piece rims (as mentioned in recommendation #3) and a current manual containing the manufacturer’s instructions for mounting, demounting, maintenance and safety precautions relating to the multi-piece rim wheels. In addition, the maintenance program should state that only trained workers and the local tire company should service multi-piece rim wheels.

The victim, whose main task was operating a forklift, was apparently unaware of the hazards associated with inflating under inflated tires mounted on multi-piece rims and the company’s procedure of using a local tire company for any servicing of these wheels. If the victim knew it was a standard procedure to call the local tire company instead of attempting to inflate the tire himself, his injuries might have been prevented.

References

- Code of Federal Regulations, 29 CFR 1910.177, Servicing multi-piece and single piece rim wheels, Motor vehicles, U.S. Government Printing Office

- Equipment Manufacturers Institute, 1991, Wheel loader / tractor, Form # WLT70-1

Illustrations

|

|

Figure 1 – Front-end loader involved in the incident

|

|

|

Figure 2 – Front left multi-piece rim wheel

|

|

|

Figure 3 – Garage where the front end loader was parked

|

|

|

Figure 4 – Trajectory of multi-piece rim parts both mounted on a vehicle and placed on the ground

|

To contact Massachusetts State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.