Mining Product: STOP - Support Technology Optimization Program

Original creation date: April 2010

Authors: NIOSH

Version: 3.4

Pittsburgh, PA: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 2010 Apr

Important note: New issues have been discovered and STOP 4.1 Beta is being taken down until they’re addressed. NIOSH Mining recommends not using STOP 4.1 Beta until these issues have been addressed. Our thanks to the Beta testers for their efforts. In the meantime, the prior version of STOP will be made available. Send any comments or questions to mining@cdc.gov.

STOP (Support Technology Optimization Program) is software to assist in making engineering decisions regarding the selection and placement strategy of various standing roof support technologies.

The software includes a complete database of the support characteristics and loading profiles obtained through safety performance testing of these supports at the NIOSH Safety Structures Testing Laboratory.

The software includes a complete database of the support characteristics and loading profiles obtained through safety performance testing of these supports at the NIOSH Safety Structures Testing Laboratory.

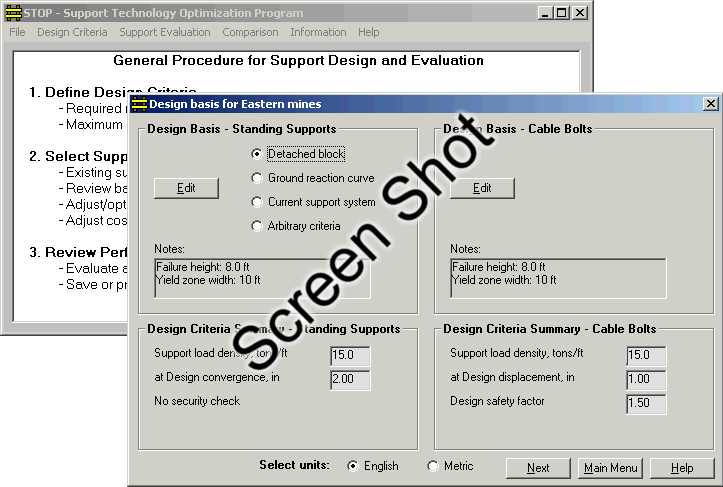

Support design criteria in the form of the required support load density at a specified convergence can be established from four options: (1) a data base of measured ground reaction data from various mines or ground behavior information inputted by the user, (2) determination of loading requirements based on a detached roof block or rock failure height, or (3) criteria based on the current roof support system, and (4) arbitrary criteria set the by user. Using these design criteria, the program will determine the installation requirements for a particular support technology that will provide the necessary support load density and convergence control. Optimization routines are also available to determine the most efficient support design for a user specified support installation. Comparisons among the various support technologies are easily made including graphical analysis of relevant support parameters.

STOP can provide an engineering foundation to ensure that inadequate support designs as well as ultra conservative support applications are avoided. Safety will be improved by proper matching of the support performance to the mine conditions which will reduce the likelihood of roof falls and block escapeways. Material handling injuries associated with support construction are known to account for about 5,000 lost work days per year in underground coal mines. STOP can help to define the material handling advantages of alternative support technologies that use lighter weight materials or systems that can be installed with the aid of mechanical assist. The use of these support technologies can significantly reduce material handling injuries. In addition to these performance and material handling measures, STOP can be used to compare support installation costs.

Audience: Mine operators

Version: 3.4

Pittsburgh, PA: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 2010 Apr

- Diagnosing and Controlling Moisture-Sensitive Roof in Coal Mines

- Effect of the Dip and Excavation Orientation on Roof Stability in Moderately Dipping Stone Mine Workings

- Ground Control Overview

- Optimizing Secondary Roof Support with the NIOSH Support Technology Optimization Program (STOP)

- Overview of Coal Mine Ground Control Issues in the Illinois Basin

- An Overview of Standing Roof Support Practices and Developments in the United States

- Performance Characteristics for Welded Wire Screen Used for Surface Control in Underground Coal Mines

- Pillar and Roof Span Design Guidelines for Underground Stone Mines

- Preventing Falls of Ground in Coal Mines With Exceptionally Low-Strength Roof: Two Case Studies

- Pumpable Roof Supports: Developing Design Criteria by Measurement of the Ground Reaction Curve

- Technology News 482 - Ground Support Safety Training Video

- Technology News 517 - New Updates for NIOSH Coal Mine Ground Control Software

- Tests of Fibre-Reinforced Shotcrete at the Chief Joseph Mine, Butte, Montana

- Updating the NIOSH Support Technology Optimization Program (STOP) With New Support Technologies and Additional Design Features