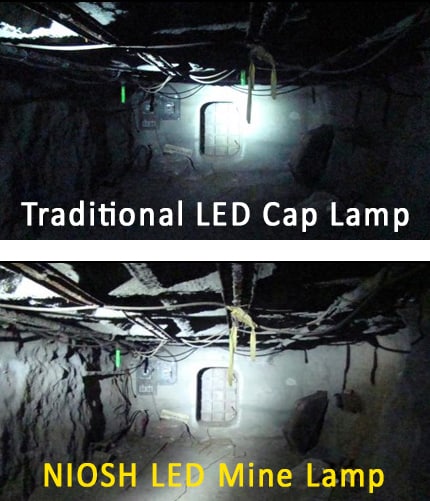

Improved LED Mine Lamp Designs

Years of successful illumination research by NIOSH scientists have led to advances in the functionality of cap lamps and mine lamps worn by mineworkers. Manufacturers of cap lamps and mine lamps can use the documents and design packages from the research offered below to build cap lamp and mine lamp equipment that will illuminate more effectively and operate more efficiently than products currently on the market. These downloadable packages include descriptions and specifications of the newly modified lamp features, the necessary programming software, and all of the diagrams and schematics needed to make the circuit boards. Using the design packages, as well as some off-the-shelf components, manufacturers can improve upon existing designs or produce an altogether new lamp with the same specifications as the four prototypes described below.

GEN 4 and GEN 5 Models

The GEN 4 model is MSHA-approved for use in underground mines. It uses the battery, battery cable, and headpiece of an existing MSHA-approved cap lamp that is commercially available. This existing cap lamp was retrofitted with new optics, three LEDs, an LED mounting plate, a printed circuit board (PCB) that provides programmable functional control of the mine lamp, and a single integrated circuit (IC) driver with three constant current sources for the LEDs.

NIOSH developed a second LED mine lamp, model GEN 5, to better suit the visual tasks performed in underground metal/nonmetal mines. The primary difference from the GEN 4 is that a more intense spot beam is available for illuminating objects or mine areas that are 40 feet or greater from the lamp. NIOSH achieved this by changing the LED and optic used for the spot beam as well as modifying the PCB to have dual IC drivers that enable the spot beam to operate at a greater range of current. NIOSH did not seek MSHA approval of the GEN 5 model, given its similarities to the GEN 4 model.

Both the GEN 4 and GEN 5 will last up to 50 hours with the use of a six-cell battery pack, and they include low, medium, and high settings that the user can activate at the push of a button depending on the specific illumination needs at the time and the desirability of power consumption savings.

GEN 4E and GEN 5E Models

The GEN 4E and GEN 5E models (the "E" stands for "energy-saving") are reduced-power versions of the GEN 4 and GEN 5 with both hardware and software changes. Rather than operating via a battery pack, these reduced-power models can operate using a single lithium-ion battery cell. Both the GEN 4E and GEN 5E can provide at least 11 hours of operation at the highest lamp intensity, and both employ a "smart light" technology - when battery power is getting low, the lamp automatically switches to a lower output setting to save battery power and alert the user of the need for a battery change. NIOSH did not seek MSHA approval of the GEN 4E and GEN 5E models, given their similarities to the GEN 4 model.

Downloading the Files

The organization of the four downloadable ZIP files is by model type as described above - GEN 4, GEN 4E, GEN 5, GEN 5E. Each set of files includes a PDF describing a functional overview of all four models, a README file, and numerous individual software and schematic files created by NIOSH or NIOSH partners in this research. The CDC's Technology Transfer Office has approved the public release of these files. Note that the ZIP files contain information for the LEDs, PCBs, mounting plates, optics, and software. Manufacturers will need to provide their own designs for the lamp headpiece enclosure and battery.

For further information about NIOSH illumination research or working with the downloaded files, contact NIOSH Electrical Engineer John Sammarco at 412-386-4507 or ZIA4@cdc.gov.