ESPnano Characterizes Hazardous Airborne Particles in the Workplace

Summary

The commercially available ESPnano particle sampler allows industrial hygienists and safety professionals to easily take air samples that can be used to attain detailed particle information via micro-analytical techniques such as transmission electron microscopy (TEM), scanning electron microscopy (SEM), and energy dispersive spectrometry (EDS). The ESPnano collects representative samples of inhalable, respirable, and submicron particles for offline analyses. The instrument is being used worldwide for both research and workplace assessments of airborne hazards.

By Arthur Miller and Grant King

Need for Airborne Particle Sampling

Mine workers are exposed to a variety of hazardous airborne particles that can lead to respiratory illness, and researchers from the National Institute for Occupational Safety and Health (NIOSH) study ways to mitigate exposures to such particulate matter. Due to rapid advances in nano-technology, researchers have recently focused on the role of airborne ultrafine and nano-sized particles in harming workers’ health. The smallest of these particles are easily inhaled and not effectively filtered by the nose or upper respiratory system, allowing them to deeply penetrate the lungs. Inhalation of these particles can be associated with respiratory illness, cardiovascular disease, and lung cancer, which can have a long latency period, extending into decades. Further, these illnesses and diseases may be asymptomatic, with negative physical effects remaining hidden until diagnosed, and can thus affect a person’s quality of life and reduce their life span. Respiratory disease therefore continues to be one of the single biggest occupational health hazards in mining.

By definition, research on airborne hazards involves detailed particle analyses, and while many devices exist to measure airborne particle concentrations, a technology gap existed when taking samples for detailed physico-chemical characterization and particle speciation (e.g., differentiating between welding fume and dust particles). NIOSH researchers identified the need for a device to collect representative samples of airborne nanoparticles for the purpose of conducting microanalyses such as TEM and EDS. NIOSH mine safety researchers therefore collaborated with colleagues at the NIOSH Nanotechnology Research Center to develop an electrostatic precipitator (ESP) nanoparticle sampler [Miller et al. 2010a].

ESP Nanoparticle Technology

Figure 1. Inserting a "sampling key" into the ESPnano model 100 particle sampler. During operation, particles enter the device via the white inlet tube at the top of the sampler. Photo by NIOSH. (Click for larger image.)

The handheld ESPnano (Figure 1) is battery-powered and encased in a rugged enclosure. It comes with “sampling keys” onto which various types of sampling media can be loaded. To take a sample, the user slides a key into the device and selects a sampling time from the menu. Sampling time selection is aided by a table (Table 1) on the back of the ESPnano and is dependent on airborne particle concentration, with approximate number concentrations measured in particles per cubic centimeter (cc). When the user selects “run” from the menu, the device begins sampling, and within seconds collects particles as large as tens of microns and as small as ten nanometers, providing representative samples over a wide range of particle sizes. The capability of collecting such a wide range of particle sizes in a very short time makes this device advantageous for research purposes or when doing air quality surveys at field sites. Such a wide size range is often not possible with other techniques, especially ones that are field-portable.

Table 1. Reference sampling time information (approximated)

|

Example Source |

Approximate Number Concentrations |

Suggested Cycle Time |

|---|---|---|

|

Diesel - undiluted emissions |

108 particles/cc | 1 second |

|

Industrial process emissions |

107 particles/cc | 1 second |

|

Factory/production area |

106 particles/cc | 2-5 seconds |

|

Warehouse/shipping dock |

105 particles/cc | 20-50 seconds |

| Office air | 104 particles/cc | 200-500 seconds |

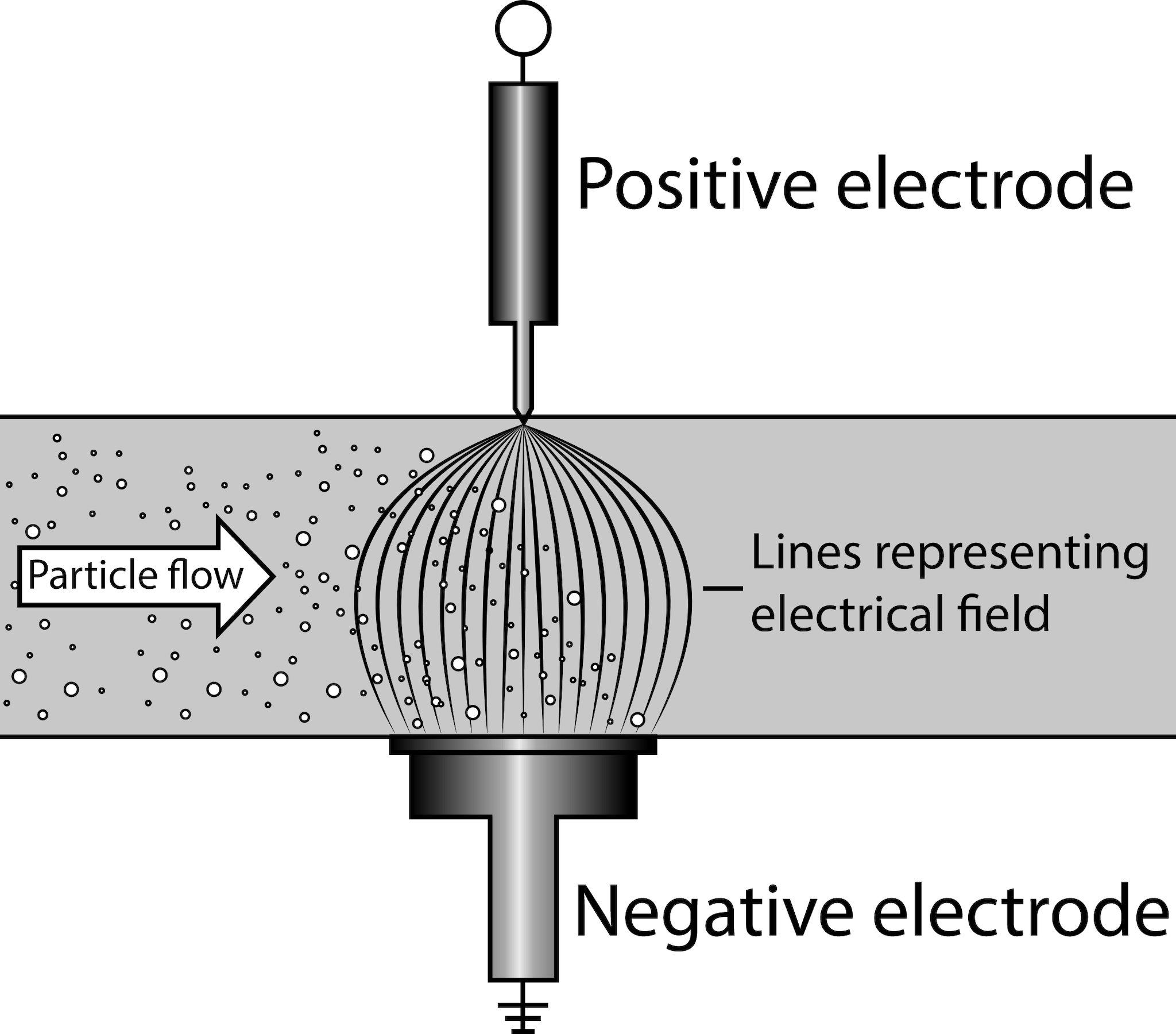

Figure 2. Particles entering the ESPnano inlet pass through a high-voltage electrical field inside the device that simultaneously charges and collects them onto media that rests on the negative electrode plate. Illustration by NIOSH. (Click for larger image.)

The operating principle for the ESPnano entails using high voltage to generate an intense electrical field in which particles are charged, causing them to migrate toward a negative electrode to which collection media has been attached (Figure 2). This allows all sizes and types of particles to be deposited by electrostatic deposition onto a variety of different sampling media, which can then be sent to a lab for offline analyses by TEM, SEM, and EDS.

Future Use

Since the original 2010 publication describing the ESP technology and the subsequent licensing and commercialization of the ESPnano, this nanoparticle sampler has become an important tool for industrial hygienists and air quality researchers. This technology fills a unique gap in air quality monitoring, and its worldwide use is evidenced by many citations of the original work as well as published references to its application for the characterization of hazardous airborne particulate matter [Barone et al. 2012; Jung et al. 2013] and in occupational exposure studies [Miller et al. 2010b; Bugarski et al. 2016]. This device will be an important component in future work aimed at methods for characterizing and assessing nanoaerosols and other airborne hazards in the workplace.

References

Barone TL, Storey JME, Youngquist AD, Szybist JP [2012]. An analysis of direct-injection spark-ignition (DISI) soot morphology. Atmos Environ 49:268–274.

Bugarski AD, Hummer JA, Stachulak JS, Miller AL, Patts LD, Cauda EG [2016]. Emissions from a diesel engine using Fe-based fuel additives and a sintered metafiltration system. Annals of Occup Hygiene 60(2):252–262.

Jung HS, Miller AL, Park K, Kittelson DB [2013]. Carbon nanotubes among diesel exhaust particles: real samples or contaminants? J Air Waste Man Assoc 63(10):1199–1204.

Miller AL, Frey G, King G, Sunderman C [2010a]. A handheld electrostatic precipitator for sampling airborne particles and nanoparticles. Aerosol Sci and Tech 44(6):417–427.

Miller AL, Drake PL, Hintz P, Habjan M [2010b]. Characterizing exposures to airborne metals and nanoparticle emissions in a refinery. Annals of Occup Hygiene 54(5):504–513.

For More Information

For more information on the ESPnano particle sampler, contact the NIOSH Mining Program (mining@cdc.gov).

DHHS (NIOSH) Publication No. 2020-111

DOI: https://doi.org/10.26616/NIOSHPUB2020111

- Benchmarking Longwall Dust Control Technology and Practices

- Determining the Spatial Variability of Personal Sampler Inlet Locations

- A Handheld Electrostatic Precipitator for Sampling Airborne Particles and Nanoparticles

- Instrumentation for Diesel Particulate Matter Emissions Research

- Observations of Post-Explosion Dust Samples From an Experimental Mine

- Performance of a Light Scattering Dust Monitor at Various Air Velocities: Results of Sampling in the Active Versus the Passive Mode

- Respirable Quartz Hazard Associated with Coal Mine Roof Bolter Dust

- Rock Dusting Considerations in Underground Coal Mines

- Sonic Anemometer Airflow Monitoring Technique for Use in Underground Mines

- Use of Vacutainers for Collection of Mine Atmosphere Samples