Seven Career Fire Fighters Injured at a Metal Recycling Facility Fire - California

Death in the Line of Duty…A summary of a NIOSH fire fighter fatality investigation

Death in the Line of Duty…A summary of a NIOSH fire fighter fatality investigation

F2010-30 Date Released: August 1, 2011

Executive Summary

On July 13, 2010, seven career fire fighters were injured while fighting a fire at a large commercial structure containing recyclable combustible metals. At 2345 hours, 3 engines, 2 trucks, 2 rescue ambulances, an emergency medical service (EMS) officer and a battalion chief responded to a large commercial structure with heavy fire showing. Within minutes, a division chief, 2 battalion chiefs, 3 engines, 3 trucks, 4 rescue ambulances, 2 EMS officers and an urban search and rescue team were also dispatched. An offensive fire attack was initially implemented but because of rapidly deteriorating conditions, operations switched to a defensive attack after about 12 minutes on scene. Ladder pipe operations were established on the 3 street accessible sides of the structure. Approximately 40 minutes into the incident, a large explosion propelled burning shrapnel into the air, causing small fires north and south of structure, injuring 7 fire fighters, and damaging apparatus and equipment. Realizing that combustible metals may be present, the incident commander ordered fire fighters to fight the fire with unmanned ladder pipes while directing the water away from burning metals. Approximately 2 ½ hours later, two small concentrated areas remained burning and a second explosion occurred when water contacted the burning combustible metals. This time no fire fighters were injured.

|

|

Large commercial structure containing combustible metals for recycling |

Contributing Factors

- Unknown building contents

- Unrecognized presence of combustible metals

- Use of traditional fire suppression tactics

- Darkness

Key Recommendations

- Ensure that pre-incident plans are updated and available to responding fire crews

- Ensure that fire fighters are rigorously trained in combustible metal fire recognition and tactics

- Ensure that policies are updated for the proper handling of fires involving combustible metals

- Ensure that first arriving personnel and fire officers look for occupancy hazard placards on commercial structures during size-up

- Ensure that all fire fighters communicate fireground observations to incident command

- Ensure that fire fighters wear all personal protective equipment when operating in an immediately dangerous to life and health environment

- Ensure that an Incident Safety Officer is dispatched on the first alarm of commercial structure fires

- Ensure that collapse/hazards zones are established on the fireground.

|

|

An example of the variety of recyclable combustible |

Introduction

On July 13, 2010, seven career fire fighters were injured while fighting a large commercial structure fire containing recyclable combustible metals. On September 1, 2010, the International Association of Fire Fighters (IAFF), requested that the National Institute for Occupational Safety and Health (NIOSH) investigate this incident. On October 18-22, 2010, a general engineer and a safety and occupational health specialist from the NIOSH Fire Fighter Fatality Investigation and Prevention Program traveled to California to investigate this incident. The NIOSH investigators were accompanied by a fire service technical expert and member of the National Fire Protection Association (NFPA) technical committee on combustible metal fires. In an initial meeting, NIOSH investigators met with the IAFF Local Union President and key union officers. The NIOSH investigators also met with the fire department’s risk management and safety officer and a California Occupational Safety and Health Administration representative at the incident site and conducted interviews with officers and fire fighters who were at the incident scene. The NIOSH investigators reviewed the fire department’s standard operating guidelines (SOGs), officers’ and fire fighters’ training records, dispatch audio tapes, and the arson investigation records.

Fire Department

This career fire department has 106 stations with 3,588 uniformed members which serve a population of more than 4,000,000 within an area of about 470 square miles. The fire department utilizes a modified coverage plan which reduces staffing by 122 positions per shift due to economic constraints. All department members work a 24-hour duty shift for 3 out of 9 days or an average of 56 hours per week. In 2010, the fire department responded to nearly 15,000 actual fire incidents with a less-than 5 minute arrival response time 90% of the time.

The fire department currently has 127 ambulances, 101 engines, 49 trucks, 15 brush apparatus, 4 foam tenders, 4 rehab air tenders, 2 fuel tenders, 1 heavy rescue apparatus, 5 fire boats, 2 emergency lighting units, and 6 helicopters. Specialty units consist of swift water rescue teams, 8 airport companies, 4 hazardous material companies, 6 bicycle medic teams and 6 urban search and rescue companies. All fire department apparatus are maintained by the city’s fleet maintenance division with annual testing of fire apparatus and ambulances conducted by qualified vendors. All advanced life support ambulances are provided by the fire department. The fire department operates 16 battalions in 3 divisions that respond to more than 750,000 incidents annually.

The fire department currently has one designated Occupational Health and Safety Officer (OHSO), who resides in the Risk Management Division. The OHSO is not dispatched until the incident is upgraded to a second alarm for incidents after normal duty hours. The IC will assign an officer as the incident safety officer as part of the fire department’s standard operating guidelines.

The fire department had a comprehensive list of SOGs and policies. However, the policy for the extinguishment of combustible metal fires was out dated. This policy called for copious amounts of water to be put on the combustible metal fire. The SOG for pre-incident planning was followed at this incident. However, due to the constantly changing business environment, the company had submitted a business plan that identified hazards to the city but this information did not get updated in the computer-aided dispatching (CAD) database for the fire department or dispatch.

A month prior to this incident on June 11, 2010, at 11:00 a.m., the same business owner’s metal processing facility located diagonally across the street from this incident, had several small explosions and fire. This incident required 36 fire department companies, 16 rescue ambulances, 1 USAR team, 2 hazardous material teams, 7 BCs, 1 DC, and a DDC, totaling 248 fire department personnel, in addition to mutual aid. Approximately 2 ½ hours of fire suppression operations with water brought the fire under control, which encompassed a 150′ x 100′ area of combustible metal shavings. The company had metal –X (a brand of combustible metal fire extinguishing agent) available, but not enough of it to be effective. No fire fighters were injured. However, a civilian worker was critically injured and a police officer received minor injuries.

Training and Experience

Table 1 lists the training and experience of the command team involved in the incident.

Table 1

|

Fire Fighter

|

Training Courses | Years experience |

|---|---|---|

|

Deputy Department Commander (Incident Commander) |

Fire Fighter I and II, Incident Command courses (IS-100, 200, 300, 400, 700 and 800), Intermediate and Advanced Incident Management Team Training (ICS-320, ICS-420, and L-480), Bachelors Degree in Fire Protection Administration, Rescue Systems 1 and 2, Swift Water 1 and 2, High Angle ropes, Trench Rescue, Confined Space Operational, Fire Operations in the Wildland Urban Interface (S-215), Intermediate Wildland Fire Behavior (S-290), Extended Attack Incident Commander (S-300), Strike Team Leader (S-330), Division/Group Supervisor (S-339), Safety Officer (S-401), Operations Section Chief (S-430), and various other administrative and technical courses |

30 |

|

Division Chief |

Fire Fighter I and II, Incident Command courses (IS-100, 200, 300, 700 and 800), Masters Degree in Public Administration, Certificate in Fire Protection Administration, Rescue Systems 1, Strike Team Leader (S-330), Division/Group Supervisor (S-339), Instructor 1A and 1B, and various other administrative and technical courses. |

26.5 |

|

Battalion Chief 3 (Operations Section Chief; Initial Incident Commander) |

Fire Fighter I and II, Incident Command courses (IS-100, 200, 300, and 400), Fire Instructor 1A and 1B, Fire Command 1A, Unified Command, Fire Operations in the Wildland Urban Interface (S-215), Ignition Operations (S-234), Intermediate Wildland Fire Behavior (S-290), Extended Attack Incident Commander (S-300), Strike Team Leader (S-330), Tactical Decision Making (S-336), Division/Group Supervisor (S-339), Incident Leadership (L-381), and various other administrative and technical courses. |

21 |

|

Battalion Chief 1 (Division A Chief) |

Fire Fighter I and II, Fire Investigator 1A, Fire Management 1, Fire Command 1A and 1B, Fire Prevention 1A and 1B, Fire Instructor 1A and 1B, Emergency Medical Technician, Incident Command courses (IS-300 and 400), Trench Rescue, Strike Team Leader (S-330), Division/Group Supervisor (S-339), Basic and Advanced Wildland Fire Behavior Calculations (S-390 and 490), Management Operations and Techniques, Company Officer Management Operations, Confined Space Rescue, Hazardous Materials First Responder Training, Hazardous Materials Terrorist Training, and various other administrative and technical courses. |

33 |

|

Battalion Chief 14 (Division B Chief) |

Fire Fighter I and II, Incident Command courses (IS-100, 200, 300, and 400), Hazardous Materials First Responder, Engine Boss (S-290), Strike Team Leader (S-330), Division/Group Supervisor (S-339), Instructor 1A and 1B, and various other administrative and technical courses. |

30 |

|

Battalion Chief 13 (Division C Chief) |

Fire Fighter I and II, Incident Command courses (IS-100, 200, 300, and 400), Hazardous Materials Terrorist Training, First Responder and Hazardous Materials First Responder Training, Division/Group Supervisor (S-339), Wildland Fire Behavior Calculations (S-390), Advanced Fire Behavior Calculations (S-490), Confined Space Rescue, Confined Space and Rope Training, Major Disaster Case Studies, Multiple Casualty Training, and various other administrative and technical courses. |

32 |

|

Battalion Chief 11 (Division D Chief) |

Fire Fighter I and II, Fire Instructor, Fire Officer, Incident Command courses (IS-100, 200, 300, 400, 700 and 800), Associate of Arts Degree in Fire Science, Heavy Rescue Systems, Swift Water 1 and 2, High Angle Ropes, Trench Rescue, Confined Space Operational, Fire Operations in the Wildland Urban Interface (S-215), Intermediate Wildland Fire Behavior (S-290), Strike Team Leader (S-330), Unified Command Instructor/Facilitator, West Point Leadership, Company Officer’s Management and Operations Course, and various other administrative and technical courses. |

23 |

|

Battalion Chief 7 (Incident Safety Officer) |

Fire Fighter I and II, Incident Command courses (IS-100, 200, 700 and 800), Fire Control 3, Fire Command, Fire Instructor 1A and 1B, Intermediate Wildland Fire Behavior (S-290), Strike Team Leader (S-330), Division/Group Supervisor (S-339), Leadership I, Weapons of Mass Destruction, and various other administrative and technical courses. |

32 |

Note: Fire Fighter 1 and 2 training meet the criteria for National Fire Protection Association (NFPA) 1001, Standard for Fire Fighter Professional Qualifications, Fire Fighter I and Fire Fighter II. 1

Equipment and Personnel

At 2343 hours, the initial 911 call came in as a commercial building fire in the rear of the building. The first alarm dispatch was a Battalion Chief, 3 engines, 2 trucks, 2 rescue ambulances, and an emergency medical service officer. Four minutes later, after confirming a large one story commercial structure with heavy fire showing, additional companies were dispatched. This incident involved 41 fire department companies, 21 rescue ambulances, 8 battalion chief officer command teams, 1 division chief officer command team, 1 deputy chief, 2 bulldozers, 3 arson units, 1 urban search and rescue unit, 1 rehab unit, 1 hazardous materials team, and 2 automatic mutual aid engine companies. Table 2 identifies the first alarm and specific additional apparatus and staff dispatched, along with their approximate arrival times (rounded to the nearest minute). Note: NIOSH investigators did not interview all companies that were on scene due to the large number of personnel. The lack of mention of any fire department companies is not meant to take away from their importance and duties at this incident.

Table 2. Equipment and Personnel Dispatched

|

Resource

Designation |

Staffing | Dispatched (rounded to minute) |

On-Scene (rounded to minute) |

|---|---|---|---|

|

Rescue 833 (R833) |

2 Fire fighters |

2345 hrs |

2347 hrs |

|

Engine 14 (E14) |

Captain |

2345 hrs |

2349 hrs |

|

Truck 14 (T14) |

Captain |

2345 hrs |

2350 hrs |

|

Engine 46 (E46) |

Captain |

2345 hrs |

2350 hrs |

|

Battalion Chief 3 (BC3; Initial IC) |

Battalion Chief |

2345 hrs |

2350 hrs |

|

Emergency Medical Service 3 (EMS3) |

Captain |

2345 hrs |

2351 hrs |

|

Truck 33 (T33) |

Captain |

2345 hrs |

2351 hrs |

|

Engine 21 (E21) |

Captain |

2345 hrs |

2352 hrs |

|

Rescue 21 (R21) |

2 Fire fighter/Paramedics |

2345 hrs |

0002 hrs |

|

Division Chief 2 |

Division Assistant Chief |

2349 hrs |

2354 hrs |

|

Battalion Chief 13 (BC13) |

Battalion Chief |

2349 hrs |

2354 hrs |

|

Engine 66 (E66) |

Captain |

2349 hrs |

2354 hrs |

|

Truck 66 (T66) |

Captain |

2349 hrs |

2355 hrs |

|

Truck 10 (T10) |

Captain (injured) |

2349 hrs |

2357 hrs |

|

Battalion Chief 1 (BC1) |

Battalion Chief |

2349 hrs |

0001 hrs |

|

Squad 4 (SQ4) |

Captain |

2349 hrs |

0001 hrs |

|

Rescue 33 (R33) |

2 Fire fighter/Paramedics |

2349 hrs |

0006 hrs |

|

Urban Search And Rescue 88 |

Captain |

2349 hrs |

0015 hrs |

|

Truck 3 (T3) |

Captain |

2349 hrs |

0002 hrs |

|

Engine 3 (E3) |

Captain |

2349 hrs |

0002 hrs |

|

Rescue 803 (R803) |

2 Fire fighters |

2349 hrs |

0002 hrs |

|

Rescue 3 (R3) |

2 Fire fighter/Paramedics |

2349 hrs |

0003 hrs |

|

Battalion Chief 11 (BC11) |

Battalion Chief |

2358 hrs |

0011 hrs |

|

Battalion Chief 7 (BC7) |

Battalion Chief |

2358 hrs |

0018 hrs |

|

Mutual Aid Engine 9 (E9) |

Captain |

2358 hrs |

0016 hrs |

|

Mutual Aid Battalion Chief |

Battalion Chief |

2358 hrs |

0016 hrs |

|

Deputy Department Commander (DDC; IC after 1st explosion) |

Deputy Chief |

0003 hrs |

0030 hrs |

|

Battalion Chief 14 (BC14) |

Battalion Chief |

0025 hrs |

0035 hrs |

|

Engine 5 (E5) |

Captain |

0025 hrs |

0032 hrs |

|

Truck 29 (T29) |

Captain |

0038 hrs |

0046 hrs |

Personal Protective Equipment

The injured fire fighters were wearing their structural fire coat and pants, boots, structural fire fighting helmet with eye protection, and self-contained breathing apparatus (SCBA) with an integrated personal alert safety system (PASS). The fire fighter that was operating the ladder pipe on T66 was the only injured fire fighter that had on his full personal protective equipment (PPE) ensemble and was on air with an activated PASS at the time of the explosion.

Structure

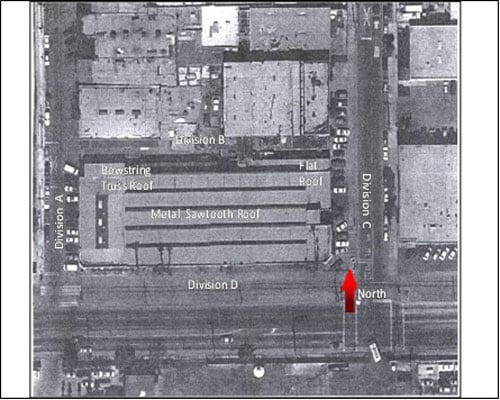

The incident involved a 45,000 square foot multiple business commercial structure that measured approximately 300′ x 150′ and was built in 1939 (see Photo 1). The commercial structure was divided into 3 sections with both Type III and Type V (metal clad) construction. The A-side (west) of the structure measured 60′ x 100′ under a heavy timber bowstring truss roof and exterior block walls covered with a stucco finish. This section of the structure contained denim fabric altering machinery. The larger 210′ x 150′ open warehouse middle section of the structure was under a metal sawtooth roof (a roof composed of a series of small parallel roofs of triangular cross section, usually asymmetrical with the vertical slope glazed or windowed to allow for light) with concrete reinforced metal beam exterior walls covered with an exterior stucco finish. This section of the structure contained bins, bales, and piles of recyclable metals. The C-side of the structure was an office area that measured approximately 30′ x 150′. It was comprised of two stories with a conventional flat roof, wood framed interior walls, and concrete reinforced metal beam exterior walls covered with an exterior stucco finish.

|

|

Photo 1: Aerial view of commercial structure prior to fire. |

Occupancy hazard placards existed at the A and C/D corner of the structure. The placards had a 3 health rating (a serious hazard) in the blue quadrant, a 4 flammability rating (flammable gases, violate liquids, pyrophoric materials) in the red quadrant, a 2 instability rating (a violent chemical change possible at elevated temperatures and pressure) in the yellow quadrant, and an OX (material is an oxidizer) in the white quadrant.

The commercial structure had been recently acquired, within the past year or two, by a local metal recycling company. The company had submitted the annual business plan to the city, which identified potential hazards, but this information had not been updated in the computer-aided dispatch (CAD) database for the dispatch center or fire department. The construction features of the occupancy such as the bowstring trusses, presence of combustible metals, and access restrictions would have been critical information to the fire department for fighting a fire at this location. The fire department had pre-planned the structure prior to the metal recycling company acquiring the commercial structure.

Weather

The weather was clear with an approximate temperature of 71°F. The relative humidity was 55% and the wind was from the west at 2 miles per hour. 2 There were no dramatic changes in the weather over the course of the incident. The weather did not play a role in the incident.

Investigation

On July 13, 2010, at 2343 hours, a 911 call came into dispatch for a commercial structure fire in the rear of the building. At 2345 hours, 3 engines (E14, E46, and E21), 2 trucks (T14 and T33), 2 rescue ambulances (R833 and R21), an emergency medical service (EMS3) officer and a battalion chief (BC3) were dispatched. At 2347 hours, R833 was the first on scene and reported a large one story commercial structure with fire in the rear. Minutes later, T33 arrived on scene, assumed incident command and called for an offensive attack. T33 reported heavy fire showing through the roof with heavy black smoke from a large primarily one story commercial structure. T33’s aerial was raised to the roof on the East side of the structure which was 2 stories with a flat roof. BC3 arrived on scene, staged on the southwest side of the structure, and assumed incident command (IC). The IC established the West side of the structure as Division A, the North as Division B, the East as Division C, and the South as Division D. The IC requested additional resources due to the size of the structure. E21 and E14 were assigned to fire attack on the west side of the structure. T14 was assigned to the roof. At 2349 hours, dispatch added a division chief (DC2), 2 battalion chiefs (BC13 and BC1), 3 engines (E57, E66, and E3), 3 trucks (T66, T10, and T3), a squad (SQ4), 4 rescue ambulances (R14, R803, R3, and R33), 2 EMS officers (EMS13 and EMS1) and an urban search and rescue team (USAR88) pre-assigned as the rapid intervention crew (RIC). At 2355 hours, the additional truck resources started arriving. The IC assigned T10 and T66 to Division D, T14 to Division A, and T33 to Division C.

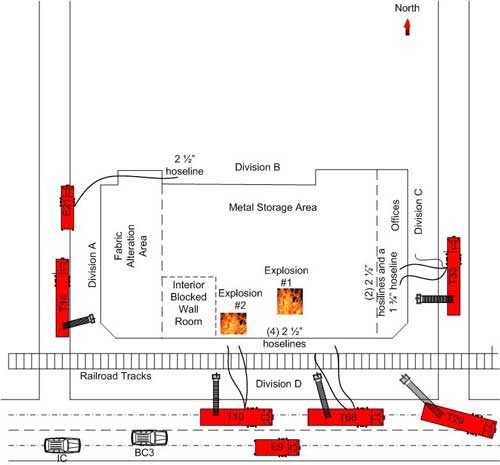

At 2356 hours, DC2 assumed IC. Ladder pipe operations were established on the 3 street accessible sides of the structure (see Diagram 1). T14, T33, T10, and T66’s ladderpipes were flowing 750 gallons of water per minute. On Division A, BC1 was assigned as the division supervisor and was in the breezeway unloading area with SQ4 cutting 3 holes in the metal wall panels along the B-side to access fire inside the storage area. E21’s crew had a 2 ½” hoseline and flowed water through the holes after they were cut. On Division C, two 2 ½” hoselines and a back-up 1 ¾” hoseline were flowing water inside the office area on the ground floor. BC13 was assigned to Division C as the division supervisor. On Division D, four 2 ½” hoselines (2 off T10 and 2 off T66) were flowing water to help protect the fire fighters on the trucks (see Diagram). Note: Numerous fire fighters reported seeing bright white flames with hues of green and blue but this was not communicated to command. At 0011 hours, BC11 arrived on scene and was assigned Division D as the division supervisor. Conditions had rapidly deteriorated forcing T33 and E66 crews to leave the roof. Seven minutes later, the IC ordered a defensive attack. At 0015 hours, USAR88 arrived on scene as the rapid intervention crew. At 0018 hours, BC7 arrived on scene and was assigned as the safety officer.

|

|

Diagram 1: Approximate Placement of Key Fireground Apparatus, Hoselines and Explosion Areas Relative to Commercial Fire Structure. |

BC11 left the command post and was walking towards T10 and T66 when an upper section of wall on the D-side near the C/D corner collapsed followed by a larger upper midsection of wall on the D-side. BC11 recalled seeing white hot metal and was about to instruct the trucks to direct water away from the white burning metals. Seconds later, approximately 40 minutes into the incident, at 0026 hours, a large explosion propelled burning shrapnel into the air and caused small fires north and south of the structure. T33 and E66’s hoseline crews were blown backwards by the blast. T10 and mutual aid E9 were hit with flaming debris which broke through E9’s driver-side door window and ignited the seat. T10 received several large dents and wooden ground ladders were ignited. Approximately 10 feet away, T10’s hoseline crew was blown approximately 20′ back and off the 2 ½” hoseline by the explosion. T10’s captain was backing up the nozzleman and was hit with burning debris causing serious burns on his hand and ear. T66’s captain jumped on the hoseline to stop it from whipping around. T10’s fire fighter operating the ladderpipe had seen 2 white flashes and greenish plumes just prior to explosion. When the explosion occurred he turned his head to the left causing pain and ringing in his right ear as white hot debris went all around him. Multiple hose beds and hoses on the ground were burned through. The explosion was reported to have been broadcast up and out in all directions (see Photo 2).

The IC called for a personnel accountability report (PAR) which accounted for all personnel and indentified 2 injured fire fighters and a captain. Note: The other 4 fire fighters injuries were not made apparent until after the incident. Minutes later, the Division C chief (BC13) reported to the IC that he identified a National Fire Protection Association 704 placard above the entrance door on the C/D corner of the structure. BC13 relayed to command the placard classifications of Health – 3, Flammability – 4, Reactivity – 2, and Special Hazards – OXIDIZER. The command team discussed the current fire department policy of using copious amounts of water on combustible metals and decided to alter the tactical plan based on information learned through the 704 placard and the fire conditions. The IC called for aerial ladderpipe personnel to move from the tip of the aerial to the aerial turntable. Note: When the decision is made to go defensive, ladderpipe personnel should be removed from the tip of the aerial to minimize any risk associated with being at an elevated height, such as explosions or falling. On Division C, two monitors and a 2 ½” hoseline were directed on the office area of the structure.

|

|

Photo 2: The first explosion sent shrapnel up and out in all directions. A fire fighter can be seen on T10’s ladderpipe to the right of the palm trees. (Courtesy of Fire Department’s Arson Section)

|

At approximately 0030 hours, the Deputy Department Commander (DDC) arrived on scene and assumed command. The DDC assigned DC2 as the deputy IC and BC3 remained as the operations section chief. The IC associated this incident with the incident that occurred a month earlier just down the street. The command team continued a defensive strategy and instructed the ladderpipes and hoselines to be directed away from what they now believed was burning combustible metals, to knock down fire surrounding those areas, and to protect exposures. Command spoke to the business owner who confirmed that titanium products were stored in the structure and the division supervisors were advised. At 0032 hours, E5 arrived on scene and was assigned to the USAR group which staged rapid intervention crews at the A/D and D/C corners of the structure. At approximately 0035 hrs, BC14 arrived on scene and was assigned to Division B to protect the exposures to the North. see Photo 3).

|

|

Photo 3: Defensive mode prior to second explosion. |

At approximately 0258 hours, a second explosion occurred, which sent debris into the air (see Photo 4). T66’s crew was blown off the turntable, but they were not injured. T66’s back cab window was blown out and the crew seats were riddled with holes from debris. The second explosion which blew out toward personnel and apparatus on Division D was reported by BC11 as being essentially a shaped charge containing large pieces of concrete and metal (see Photo 5). A PAR was immediately performed and the IC received reports that all fire fighters were accounted for and safe. The ladderpipes were redirected off the burning combustible metals, to allow the metals to burn out. A few minutes past 0400 hours, the incident was declared under control.

|

|

Photo 4: Second explosion |

|

|

Photo 5: Explosion #2 debris contained large pieces of concrete and metal. (Courtesy of Fire Department’s Arson Section) |

Contributing Factors

Occupational injuries and fatalities are often the result of one or more contributing factors or key events in a larger sequence of events that ultimately result in the injury or fatality. NIOSH investigators identified the following items as key contributing factors in this incident that ultimately led to the injuries:

- Unknown building contents

- Unrecognized presence of combustible metals

- Use of traditional fire suppression tactics

- Darkness

Cause and Origin

Per the fire department’s arson investigation report, the fire originated on the north side of the one-story commercial building and traveled throughout the entire structure over a period of several hours. Titanium products were involved with 2 major explosions. The cause of the fire was undetermined.3

Cause of Injuries

Impact from flaming airborne shrapnel and percussion from sound waves were the primary causes of the fire fighters injuries. Seven personnel sustained injuries consisting of: a captain had burns on the left hand and right ear, a fire fighter/paramedic had burns on the left hand, a fire fighter/paramedic had discomfort in the right eye, a fire fighter twisted the left ankle avoiding shrapnel, a fire fighter had pain and ringing to the right ear, a fire fighter/paramedic had ringing in the ears, and a fire fighter had a right foot injury from a steel gate falling on to him.

Recommendations

Recommendation #1: Fire departments should ensure that pre-incident plans are updated and available to responding fire crews.

Discussion: NFPA 1620 Standard for Pre-Incident Planning, states “The purpose of this document shall be to develop pre-incident plans to assist responding personnel in effectively managing emergencies for the protection of occupants, responding personnel, property, and the environment.” 4 A pre-incident plan identifies deviations from normal operations and can be complex and formal, or simply a notation about a particular problem such as the presence of flammable liquids, explosive hazards, modifications to structural building components, or structural damage from a previous fire.4, 5, 6

Building characteristics including type (or more importantly risk) of construction, materials used, occupancy, fuel load, roof and floor design, and unusual or distinguishing characteristics should be recorded, shared with other departments who provide mutual aid, and if possible, entered into the dispatcher’s computer so that the information is readily available if an incident is reported at the noted address.4 Since many fire departments have thousands to hundreds of thousands of structures within their jurisdiction, it is a challenge to establish an effective preplanning system that addresses all structures and hazards. Priority should be given to those locations having elevated or unusual fire hazards and life safety considerations.

Written SOGs enable individual fire department members an opportunity to read and maintain a level of assumed understanding of operational procedures. Conversely, fire departments can suffer when there is an absence of well developed SOGs. The NIOSH Alert: “Preventing Injuries and Deaths of Fire Fighters” identifies the need to establish and follow fire fighting policies and procedures.4 Guidelines and procedures should be developed, fully implemented and enforced to be effective. Periodic refresher training should also be provided to ensure fire fighters know and understand departmental guidelines and procedures.

One tool for fire departments to use in assessing their risks for structures within their jurisdictions is the mnemonic, BECOME SAFE:

- Building

- Evaluation

- Construction/occupancy

- Operational hazards

- Manage time and elements

- Engagement

- Situational awareness

- Assessment and risk analysis

- Fire behavior and effects

- Evaluate and execute 7

A pre-planning process should integrate the BECOME SAFE concepts and include updated information from the annually submitted business plans and any other pertinent fire safety information needs to be developed by involving fire department personnel, dispatch center personnel, and building and fire code officials. NFPA 1, Fire Code, Annex Q, Fire Fighter Safety Building Marking System, makes direct reference to potential resolution towards identifying structures and contents. 8 It contains a standard symbol that integrates information about building construction features, content hazards, life safety systems and NFPA 704 placards into one placard. High hazard and life safety considerations for the storage, handling, and manufacturing of chemicals should be indicators to prioritize processing of the information and expediting it to the CAD system.

Current and correct information is needed to adequately address risk management issues and to comply with NFPA 1500, Standard on Fire Department Occupational Safety and Health Program, Annex A, Section 8, that addresses guidelines for the IC to consider when evaluating risk versus gain.9

In this incident, the construction features of the occupancy, such as the bowstring trusses, presence of combustible metals, and access restrictions, would have been critical information to the fire department for fighting a fire at this location. A more complete pre-planning process and/or business plan updating process, involving fire department personnel, dispatch center personnel, and building code officials could have noted this information which may have aided the IC in developing a safer and more effective offensive or defensive strategy. In order to facilitate open communication, fire department personnel, dispatch center personnel, and building and fire code officials should develop a process to effectively update building information and to share this information in a timely manner. The relay of this information could be used to facilitate dynamic risk management and enhanced command and control. (Note: The fire department did a business survey following this incident and found 68 business sites that had combustible metals.)

Recommendation #2: Fire departments should ensure that fire fighters are rigorously trained in combustible metal fire recognition and tactics.

Discussion: Fire departments often respond to complex or unique hazards which require specialized/advanced knowledge and/or training in dealing with that hazard. Combustible metal fires present unique and dangerous hazards to fire fighters which are not commonly encountered in conventional structure fire fighting operations. The temperatures encountered in a combustible metal fire far exceed those of a structure fire.10 A block wall near the first explosion had an appearance of brown and black glass, suggesting that temperatures exceeded 3000 degrees F (see Photo 6). 11

|

|

Photo 6: In order to change the sand in the cement block to a smooth brown and black glass as depicted in this photo, the block wall would have had to sustain temperatures over 3000 degrees. Molten flow marks and indentations can be seen in the photo. |

The National Fire Protection Association (NFPA) 484, Standard for Combustible Metals, states that it is extremely important to conduct a good size-up by identifying the combustible metals involved, the physical state of the metals (e.g., shavings, chips, fine dust, etc.), the location relative to other combustible materials, and the quantity of the product involved. NFPA 484, A.13.3.3.10.3, states that the application of a wet extinguishing agent (particularly water hose streams) accelerates a combustible metal fire and could result in an explosion.12 This is due to the water reacting with the combustible metal and giving off highly flammable hydrogen gas and oxygen. This conversion of water into hydrogen has a heat value (British Thermal Units per pound (Btu/lb)) of about 2.8 times that of gasoline, assuming 100 percent conversion of the hydrogen in the water. This equates to flowing 42.8 gallons per minute (gpm) of gasoline on the fire for every 100 gpm of water. NFPA 484, A.13.3.3.5, states that the following agents shall not be used as extinguishing agents on a combustible metal fire because of adverse reactions or ineffectiveness: water, foams, halon, carbon dioxide, nitrogen (except on iron, steel, and alkali metals, excluding lithium), and halon replacement agents. 12 Thus, in lieu of using a wet extinguishing agent, primarily water, it is recommended that a bulk dry extinguishing agent compatible with the product involved, such as dry sand, dry soda ash, or dry sodium chloride, be used. In most cases for large fires beyond the incipient stage, the application of a dry agent is not feasible. In these cases the best approach is to isolate the material as much as possible, protect exposures, and allow the fire to burn out naturally. Thorough training is a must to properly identify and handle these unique fires. Businesses that manufacture, use or store combustible metals, and fire departments with combustible metals in their jurisdiction, should review Chapter 13 of the National Fire Protection Association (NFPA) 484: Standard on Combustible Metals.12

Combustible metal fire training should only occur in the classroom since combustible metals are not a practical substance to use for live exercises. The excessive temperatures and the unstable nature of combustible metals when burning would put fire fighters in an unnecessary and dangerous situation, if used in live exercises.

In this incident, several fire fighters noticed the unusually bright white hot fire, white sparks, bluish green hues of the fire, and white smoke but did not recognize that this could be indicative of burning combustible metals. The fire department did not suspect that combustible metals were present until after the first explosion and the discovery of the placard indicating oxidizers were in the structure. Once identified, command directed water away from areas of suspected burning combustible metals. Later in the incident, a few concentrated areas remained burning, and copious amounts of water were directed on these areas to extinguish them. This caused a second explosion, in which no one was hurt. The titanium that was involved in the second explosion had developed a protective crust during the fire which was over 2 feet thick and contributed to the shaped charge effect when the molten metal under the protective crust came in contact with the water being applied by the ladderpipes and exploded. The development of the protective crust is a normal occurrence in combustible metal fires which actually limits open burning of the combustible metal and will result in control and extinguishment of the fire, if no actions are taken which disturb the protective crust. 10

In June, an incident had occurred diagonally across the street at different structure, owned by the same company, where the fire department had a combustible metal fire and was informed by employees not to use water. The fire department updated their training bulletin addressing tactics for combustible metals and removed the use of copious amounts of water.

Recommendation #3: Fire departments should ensure that policies are updated for the proper handling of fires involving combustible metals.

Discussion: The fire department had an outdated policy on the handling of combustible metal fires which primarily called for copious amounts of water to be put on a metal fire. The policy had been based on a training scenario in which burning magnesium Volkswagen engine blocks, when hit with water, would spark, but the water cooled the large mass of magnesium enough to put the fire out. Numerous fire departments across the country remember this training scenario and have not kept up with the increasing and varied uses of combustible metals in everyday products. Manufacturing and recycling facilities for these combustible metal products have been on the rise. This poses a new and different hazard for fire fighters. Combustible metals in smaller pieces and particle sizes burn at much higher temperatures, 5000 degrees F for magnesium to 8500 degrees F for zirconium, and present an explosion hazard when water comes into contact with these burning metals. When applied to burning combustible metals, water and carbon dioxide will disassociate into their base chemical elements. For example, water disassociates into hydrogen and oxygen. The added fuel and oxygen increases burning and causes extreme reactions, such as explosions. An example standard operating procedure (SOP) for the proper handling of combustible metal fires that reflects modern day hazards is provided in Attachment 1.

Recommendation #4: Fire departments should ensure that first arriving personnel and fire officers look for occupancy hazard placards on commercial structures during size-up.

Discussion: NFPA 704, Identification of the Hazards of Materials for Emergency Response, states that all buildings or areas storing, using, or handling hazardous materials should be marked by use of a standardized placard system. The placard system identifies hazard categories for health, flammability, reactivity and special hazards, including water reactivity and oxidizers.13 When conducting a size-up at commercial structures, fire officers should look for such placards. Placard locations should be located at or near entrances and unobstructed by landscaping, fencing, etc.

In this incident, placards existed at the A and C/D corner of the structure. However, they were not identified until after the explosion. The late night hour, poor lighting, angled corners of structure, and fire attack from doorways other than the front entrance may have contributed to first arriving personnel and fire officers not seeing and acting upon the information on the placard (see Photo 7).

|

|

Photo 7: NFPA 704 Placard located on top left corner of barred entry door. (Courtesy of Fire Department’s Arson Section) |

Recommendation #5: Fire departments should ensure that all fire fighters communicate fireground observations to incident command.

Discussion: National Fire Protection Association (NFPA) 1561, Standard on Emergency Services Incident Management System, Section 6.3 Emergency Traffic states: To enable responders to be notified of an emergency condition or situation when they are assigned to an area designated as immediately dangerous to life or health (IDLH), at least one responder on each crew or company shall be equipped with a portable radio and each responder on the crew or company shall be equipped with either a portable radio or another means of electronic communication.14 The U.S. Fire Administration report, Voice Radio Communications Guide for the Fire Service, 15 provides an overview of radio communication issues involving the fire service. Effective fireground radio communication is an important tool to ensure fireground command and control as well as helping to enhance fire fighter safety and health. It is every fire fighter and company officer’s responsibility to ensure radios are properly used. Ensuring appropriate radio use involves both taking personal responsibility (to have your radio, having it on, and on the correct channel) and a crew-based responsibility to ensure that the other members of your crew (subordinates, peers, and supervisor) are doing so as well.

Receiving interior/exterior status updates is critical to the safety of fire fighters on the incident, rescue/recovery efforts, and overall control of the incident. The decision to commit interior fire fighting personnel or establishing a collapse/hazard zone for exterior fire fighting personnel should be made on a case-by-case basis with proper risk-benefit decisions being made by the incident commander.16, 17The fireground is very dynamic, and conditions can either improve or deteriorate based on fire suppression activities, and available resources, and most importantly assessments/size-ups of the incident are necessary to detect a change on the fireground.

In this incident, several fire fighters noticed the unusually bright white hot fire, white sparks, bluish green hues of the fire, and white smoke (all potential signs of combustible metal involvement), but did not communicate it to command.

Recommendation #6: Fire departments should ensure that fire fighters wear all personal protective equipment when operating in an immediately dangerous to life and health environment.

Discussion: NFPA 1500 Standard on Fire Department Occupational Safety and Health Program states, “the fire department shall provide each member with protective clothing and protective equipment that is designed to provide protection from the hazards to which the member is likely to be exposed and is suitable for the tasks that the member is expected to perform…protective clothing and protective equipment shall be used whenever a member is exposed or potentially exposed to the hazards for which the protective clothing (and equipment) is provided.”9

NFPA 1971 Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting has established minimum requirements for structural fire fighting protective ensembles and ensemble elements designed to provide fire fighting personnel limited protection from thermal, physical, environmental, and bloodborne pathogen hazards encountered during structural fire fighting operations.18 These requirements will assist in protecting firefighters, but only if they wear the PPE as recommended by the manufacturer. The potential for injury at all incidents exists when fire fighters do not wear the full PPE ensemble, including gloves.

In this incident, numerous fire fighters did not don their facepiece and/or wear hoods or gloves. The potential for unknown toxic gases and flying debris as evidenced by the 2 explosions makes wearing full PPE critical for protecting fire fighters from immediate and chronic hazards. If gloves and hoods had been worn, the hand and ear burn injuries would have been less severe or perhaps totally eliminated.

Recommendation #7: Fire departments should ensure that an Incident Safety Officer is dispatched on first alarm of commercial structure fires.

Discussion: According to NFPA 1561 Standard on Emergency Services Incident Management System, “The incident commander shall have overall authority for management of the incident and the incident commander shall ensure that adequate safety measures are in place.” This shall include overall responsibility for the safety and health of all personnel and for other persons operating within the incident management system. While the incident commander is in overall command at the scene, certain functions must be delegated to ensure adequate scene management is accomplished.14 According to NFPA 1500 Standard on Fire Department Occupational Safety and Health Program, 9 “as incidents escalate in size and complexity, the incident commander shall divide the incident into tactical-level management units and assign an incident safety officer (ISO) to assess the incident scene for hazards or potential hazards.” These standards indicate that the incident commander is in overall command at the scene, but acknowledge that oversight of all operations is difficult. On-scene fire fighter health and safety is best preserved by delegating the function of safety and health oversight to the ISO. Additionally, the incident commander relies upon fire fighters and the ISO to relay feedback on fireground conditions in order to make timely, informed decisions regarding risk versus gain and offensive-versus-defensive operations. The safety of all personnel on the fireground is directly impacted by clear, concise, and timely communications among mutual aid fire departments, sector command, the ISO, and the incident commander. NFPA 1521 Standard for Fire Department Safety Officer defines the role of the ISO at an incident scene and identifies duties such as recon of the fireground and reporting pertinent information back to the incident commander; ensuring the department’s accountability system is in place and operational; monitoring radio transmissions and identifying barriers to effective communications; and ensuring established safety zones, collapse zones, hot zones, and other designated hazard areas are communicated to all members on scene.19 Larger fire departments may assign one or more full-time staff officers as incident safety officers who respond to working fires. In smaller departments, every officer should be prepared to function as the ISO when assigned by the incident commander. The presence of an incident safety officer does not diminish the responsibility of individual fire fighters and fire officers for their own safety and the safety of others. The ISO adds a higher level of attention and expertise to help the fire fighters and fire officers. The ISO must have particular expertise in analyzing safety hazards and must know the particular uses and limitations of protective equipment. 20

In this incident, for the size of the fire department and responsible coverage area, there is an insufficient number of incident safety officers (ISO) and/or qualified personnel (certified to NFPA 1521) to act as an ISO. The ISO should be of a rank worthy of the significant responsibility.

Recommendation #8: Fire departments should ensure that collapse/hazard zones are established on the fireground.

Discussion: During fire operations, two rules exist about structural collapse: (1) the potential for structural failure always exists during and after a fire, and (2) a collapse danger zone must be established.6,17,21 A collapse zone is an area around and away from a structure in which debris might land if a structure fails. The collapse zone area should be at least 1½ times the height of the building—the height of the building plus an additional allowance for debris scatter.22 For example, if the wall was 20 feet high, the collapse zone would be established at least 30 feet away from the wall. In this incident, the structure was approximately 18 feet high at the top of the parapet wall, and the collapse zone extended at least 27 feet from the structure.

Fire fighters must recognize the dangers and take immediate safety precautions if factors indicate the potential for a building collapse. An external load—such as a parapet wall, steeple, overhanging porch, awning, sign, or large electrical service connections—reacting on a wall weakened by fire conditions may cause the wall to collapse. Other factors include fuel loads, building damage, renovation work, pre-existing deterioration as well as deterioration caused by the fire, support systems, and truss construction.21 Whenever these contributing factors are identified, all persons operating inside the structure must be evacuated immediately and a collapse zone should be established around the perimeter. Once a collapse zone has been established, the area should be clearly marked and monitored to make certain that no fire fighters enter the danger zone. Positioning companies at the corners of the building is usually safer than a frontal attack.7 In this incident, a collapse zone should have been established given the age of the structure and deteriorating fire conditions.

Recommendation #9: Vendors/Training Organizations should develop and offer a training program on combustible metal fires.

Discussion: There are a limited amount of training materials/programs that exist on combustible metal fires. There have been a small number of presentations and workshops conducted at fire conferences over the years but nothing offered by outside training organizations that pertains to what the fire service needs to know. Programs should be developed to highlight the characteristics of a combustible metal fire, tactics, and strategies for handling them.

References

- NFPA [2008]. NFPA 1001: Standard for Fire Fighter Professional Qualifications. 2008 ed. Quincy, MA: National Fire Protection Association.

- Weather Undergroundexternal icon [2010]. http://www.wunderground.com/history/airport/KCQT/2010/7/13/DailyHistory.html?req_city=NA&req_state=NA&req_statename=NA. Date accessed: June 2011.

- Arson Report [2010]. Report number: 2010-07-0133.

- NFPA [2010]. NFPA 1620. Standard for pre-incident planning. 2010 ed. Quincy, MA: National Fire Protection Association.

- Dunn V [1998]. Risk management and lightweight truss construction. New York: WNYF, Official training publication of the New York City Fire Department. 1st issue.

- Brannigan FL [1999]. Building construction for the fire service. 3rd ed. Quincy, MA: National Fire Protection Association.

- CommandSafety.com [2009]. “Building Knowledge = Firefighter Safety”, Know Your District and its Risk.external icon http://www.commandsafety.com/2009/06/16/fireems-safety-health-and-survival-week-day-two-building-knowledge-firefighter-safety-know-your-district-and-its-risk/ (Link Updated 5/13/2015). Date accessed: June 2011.

- NFPA [2009]. NFPA 1: Fire Code. Quincy, MA: National Fire Protection Association.

- NFPA [2007]. NFPA 1500 Standard on Fire Department Occupational Safety and Health Program. 2007 ed. Quincy, MA: National Fire Protection Association.

- Fire Engineering [2008]. Proper Handling of Combustible Metal Firesexternal icon. http://www.fireengineering.com/articles/print/volume-161/issue-2/features/proper-handling-of-combustible-metal-fires.html Date accessed: June 2011. (Link update 9/19/2011)

- Utah Department of Natural Resourcesexternal icon [2005]. http://geology.utah.gov/surveynotes/gladasked/gladfulgurites.htm. Date accessed: June 2011.

- NFPA [2009]. NFPA 484: Standard on Combustible Metals. Quincy, MA: National Fire Protection Association.

- NFPA [2007]. NFPA 704: Identification of the Hazards of Materials for Emergency Response. Quincy, MA: National Fire Protection Association.

- NFPA [2008]. NFPA 1561: Standard on Emergency Services Incident Management System. 2008 edition. Quincy, MA: National Fire Protection Association.

- USFA [2008]. Voice Radio Communications Guide for the Fire Service. U.S. Fire Administration, Federal Emergency Management Agency, U.S. Department of Homeland Security. Emmitsburg, Maryland. October 2008.

- Jones J [2001]. No empty threat.external icon Fire Chief Nov 1. [http://firechief.com/mag/firefighting_no_empty_threat]. Date accessed: June 2011. (Link Updated 1/28/2013)

- NIOSH [1999]. NIOSH alert: preventing injuries and deaths of fire fighters due to structural collapse. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 99-146.

- NFPA [2007]. NFPA 1971 Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting. 2007 ed. Quincy, MA: National Fire Protection Association.

- NFPA [2008]. NFPA 1521 Standard for Fire Department Safety Officer. 2008 ed. Quincy, MA: National Fire Protection Association.

- Dunn V [2000]. Command and control of fires and emergencies. Saddle Brook, NJ: Fire Engineering Book and Videos.

- Klaene BJ, Sanders RE [2000]. Structural fire fighting. Quincy, MA: National Fire Protection Association.

- International Fire Service Training Association [2008]. Essentials of fire fighting and fire department operations, 5th ed. Stillwater, OK: Fire Protection Publications, Oklahoma State University.

- Kreitman, K [2010]. Standard Operating Procedure Combustible Metal Fires. Redding, CA.: Redding Fire Department.

Investigator Information

This investigation was conducted by Matt E. Bowyer, General Engineer, and Jay Tarley, Safety and Occupational Health Specialist, with the Fire Fighter Fatality Investigation and Prevention Program, Fatality Investigations Team, Surveillance and Field Investigations Branch, Division of Safety Research, NIOSH located in Morgantown, WV. Fire Chief Kevin Kreitman, Redding Fire Department, Redding, CA, assisted in the investigation as a fire service technical expert. This report was authored by Matt E. Bowyer. An expert technical review was provided by John J. Salka, Jr., Battalion Chief, New York City Fire Department. A technical review was also provided by the National Fire Protection Association, Public Fire Protection Division.

Additional Information

NFPA Journal, January/February 2001, Dangers of Combustible Metalsexternal icon, by Rivkin, Carl, http://findarticles.com/p/articles/mi_qa3737/is_200101/ai_n8938247/, Date accessed: May 2011..

STANDARD OPERATING PROCEDURE #

COMBUSTIBLE METAL FIRES 23

DATE: September 2010

SUBJECT: Combustible Metal Fires

PURPOSE: To provide operational guidelines on appropriate fire control methods when dealing with combustible metal fires involving metals such as alkali metals – lithium, sodium and potassium; alkali earth metals – magnesium, beryllium and calcium; transitional metals – hafnium, niobium, tantalum, titanium and zirconium; and other metals – aluminum. In addition, metals such as iron, etc. in a fine enough form and/or powders may also present a fire hazard to responders.

PROCEDURE:

Combustible metals involved in a fire create extreme hazards for responders if not properly handled. Burning combustible metals will produce extreme heat as compared to normal combustible materials with possible temperatures of 5000oF (2760oC) (magnesium) to 8500oF (4700oC) (zirconium).

Water and carbon dioxide when applied to burning metals will result in disassociation to their base components. Water will create a subsequent release of hydrogen and oxygen when applied to burning metal. Water in contact with molten metal will result in extreme reactions and explosions and increase burning intensity.

Combustible metals are seeing an increase use in everyday products including automobiles, and aircraft. We are also seeing more of the materials showing up in recycling facilities. Some common locations on vehicles for combustible metals include engines, wheels, steering columns, seat frames, transfer cases, and dash components. It is extremely important to recognize the potential for combustible metals to be involved in a fire.

Full structural personnel protective equipment ensembles and SCBA should be worn when dealing with Combustible Metal Fires. It should be noted however, the extreme thermal risks that are presented with Combustible Metal fires and the explosion potential when water comes in contact with a burning metal.

The following general guidelines are to be taken into account when dealing with a combustible metal fire.

A. Unusual Hazards of Combustible Metal Fires

- Water applied to a burning combustible metal will result in an increase in burning intensity. Water applied to alkali metals not involved in fire will result in hazardous decomposition and ignition and/or explosion.

- Application of carbon dioxide has similar effects as water; the carbon dioxide adds to the intensity of the burning. Most combustible metals will ignite and burn in 100-percent carbon dioxide atmospheres.

- Dry chemical extinguishers used on alkali metal fires will react and intensify the fire. Extinguishers utilized on non-alkali fires are ineffective.

- Halogenated extinguishing agents used on alkali metals can result in an explosion and will have a detrimental effect on other combustible metal fires, with the decomposition of products producing hazardous by-products.

- A fire primarily involving metals displays intense orange-to-white flame and may be associated with a heavy/large production of white/gray smoke. Reactions from water in contact with a metals fire may result in popping sounds and bright flashes similar to an electrical arc; and/or violent explosions.

- When water is applied to material, it actually disassociates to basic elements of oxygen and hydrogen. Similar results occur with carbon dioxide.

B. Conversion of Water into Hydrogen

The table below is based on the assumption that 100 percent of the hydrogen in the water is converted into the basic hydrogen element when it reacts with a combustible metal. The percent conversion will vary from metal to metal based on the specific reactions taking place. Even if there is a relatively small conversion percentage, there is the possibility of releasing large amounts of hydrogen.

Hydrogen has a heat value (BTU/lb) of about 2.8 times that of gasoline. For example, 1000 gal/min of water would convert to 2.8 x 917.4 lb/min of hydrogen = 2569 lb/min of gasoline.

|

Gal/Min |

Density of Water (lb/gal) |

Lb of Water/Min. |

Fraction Hydrogen |

Lb/Min of Hydrogen |

Lb/Min of Gasoline |

Gal/Min of Gasoline 2 Density of |

|---|---|---|---|---|---|---|

|

1 |

8.34 |

8.34 |

0.11 |

0.9174 |

2.56872 |

0.42812 |

|

100 |

8.34 |

834 |

0.11 |

91.74 |

256.872 |

42.812 |

|

1000 |

8.34 |

8340 |

0.11 |

917.4 |

2568.72 |

428.12 |

- Fires involving combustible metals that contain moisture will exhibit more intense burning characteristics than dry product.

- Dusts, fines, and powders of combustible metals present an explosion hazard, especially in confined spaces.

- Dust, fines, and powders of titanium and zirconium present extreme hazards; zirconium powders having ignition temperatures as low as 68oF (20<sup>o</sup>C). Static electric charges can ignite some dusts and powders of titanium and zirconium.

- Titanium and zirconium powders can exhibit pyrophoric characteristics.

- Turnings and chips of combustible metals can ignite and burn with intensity, especially if coated with petroleum-based oil, with some spontaneous combustion having been observed.

- The larger the product, the lower the likelihood of ignition. Bars, ingots, heavy castings, and thick plate/sheets are virtually impossible to ignite and, in most cases, will self-extinguish when the heat source is removed.

- Sponge product of most combustible metals will burn at a slower rate, but will still produce tremendous heat.

- Burning combustible metals can extract moisture from concrete and similar products that can intensify burning and cause spalling and explosion of the products. Burning metal will destroy asphalt and extract moisture from rock.

- Fires involving large quantities of combustible metals cannot be extinguished unless they are placed in an inert atmosphere of argon or helium; they can only be controlled. Fires involving large quantities should be allowed to cool for at least 24 hours prior to being disturbed to prevent re-ignition. Fires will oxidize the metal.

- Combustible metal fines and powders that are stored and contain moisture can produce hydrogen gas.

- Combustible metal fines and dusts that are not oxidized and come in contact with iron oxides can result in thermite reactions.

C. Proper Handling of Combustible Metal Fires

- A good size-up and identification of involved materials; the physical state of the product, e.g. chips, powder, fines, dust, etc.; and the quantity of product involved and/or potentially involved in the fire are extremely important factors for emergency responders.

- Ensure control of utilities (water, gas, power) to affected areas.

- Obtain Material Safety Data Sheets for the involved products and, if available, contact those familiar with the product and hazards.

- Fires involving large quantities of product within structures can result in rapid heat build-up and smoke generation, beyond that which is normally encountered in fires involving ordinary combustibles. Fires beyond the incipient stage within structures can place personnel at risk. Extreme caution should be taken.

- If fires can be safely isolated, the best course of action is to allow them to burn out.

- Uninvolved product and exposures can be protected by hose streams if adequate precautions are taken. It is extremely important that care is taken to prevent runoff from hose streams coming in contact with burning material or molten product; and in the case of alkali metals any product in the area even if not involved in the fire.

- If a fire is burning in a closed container, such as a dust collection system, and an adequate delivery system is available and consideration is taken for personnel safety, argon or helium may be effective in controlling the fire by placing an inert blanket over it. Evaluation of explosion potential should also be considered.

- Extreme caution needs to be taken for fires involving combustible metal powders, dusts, and fines. Explosions are possible with these products, especially if the product becomes airborne in the presence of an available ignition source.

- Thin layers of dust can be enough to produce an explosive atmosphere for products under 420 µm (microns), which is equivalent in size to the cross section of a standard staple.

- Small and incipient fires may be contained utilizing Class D extinguishing agents, dry sand, or dry salt (see appendix “A” for a chart on acceptable agents for a given metal).

- Most fires involving combustible metals cannot be extinguished other than by providing an inert atmosphere of argon or helium if the product is dry. In most cases, the fire is controlled by application of one of the above products or the development of an oxide crust. The temperature of the material involved can remain extremely hot, and the fire can flare up again if the product is disturbed prior to the oxidation of the product and self-extinguishment.

- Water in contact with molten combustible metals will result in violent steam and hydrogen explosions and reactions. Control of domestic and fire protection water systems should be considered in fires involving a structure to prevent water contact with burning material.

- Large fires are impossible to extinguish. The best approach is to isolate material as much as possible if it can be done safely. Protect exposures with water streams if adequate drainage is present to prevent contact of water with the burning material. Let the fire burn out naturally to minimize hazards to personnel and losses to exposures.

D. Vehicle Fires Involving Combustible Metals

- Extreme caution should be exercised when approaching a vehicle fire. It is not uncommon for well-involved interior fires on newer vehicles to have combustible metals involved. Observe burning characteristics for signs of metal involvement. Extreme caution should be utilized on initial application of water from a safe distance with full protective equipment in place. In all cases, if a reaction is observed cease water application.

- If combustible metals are suspected, protect exposures and allow the metals to burn out prior to attempting further extinguishment. The greatest potential for molten product is in the interior components of the vehicle; this can result in severe reactions and explosions as the smaller components are much more prone to melting and becoming involved in the fire versus larger components of metal such as engine blocks and wheels.

- If a determination is made that the fire cannot be allowed to safely burn out; remote heavy streams can be considered if appropriate safety precautions are taken. Consideration should be given to potential impacts due to the explosion potential of the molten product, and the potential for projectiles from the explosion impacting personnel and/or bystanders.

Author: Kevin L. Kreitman

Fire Chief, Redding Fire Department

Redding, CA

NFPA 484 Technical Committee Fire Service Member

Revisions: February 2004

January 2009

September 2010

Appendix A

Combustible Metal Fire-Extinguishing Agents Quick Reference Chart

|

Extinguishing |

Alkali Metals |

Alkali Metals |

Aluminum |

Magnesium |

Niobium |

Tantalum |

Titanium |

Zirconium |

|---|---|---|---|---|---|---|---|---|

| Coke (Carbon Microspheroids) |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

| Met-L-X |

YES |

NO |

YES |

YES |

YES |

YES |

YES |

YES |

| Lith-X |

YES |

YES |

NO |

NO |

NO |

NO |

NO |

NO |

| Copper Powder |

YES |

YES |

YES* |

NO |

NO |

NO |

NO |

NO |

| Dry Flux |

YES |

YES |

YES |

YES |

NO |

NO |

NO |

NO |

| Dry Sand |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

| Dry Lithium Chloride |

YES |

YES |

NO |

NO |

NO |

NO |

YES |

YES |

| Dry Soda Ash |

YES |

YES |

YES |

YES |

NO |

NO |

YES |

YES |

| Dry Sodium Chloride |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

| Water |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

| Foam |

NO |

NO |

NO** |

NO |

NO |

NO |

NO |

NO |

| Argon |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

| CO2 |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

| Nitrogen |

YES |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

| Halon |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

| Halon Replacements |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

NO |

NOTES: When combustible metals are blended with other materials, the extinguishing agent should be compatible with the combustible metal.

- Green text indicates the preferred extinguishing agents.

*Copper powder can be utilized on Aluminum fires but requires large quantities to be effective.

**Aqueous Film Forming Foam (AFFF) has been shown to be effective on aluminum paste fires in the incipient stage where a class B solvent is the primary fuel.

Disclaimer

Mention of any company or product does not constitute endorsement by the National Institute for Occupational Safety and Health (NIOSH). In addition, citations to Web sites external to NIOSH do not constitute NIOSH endorsement of the sponsoring organizations or their programs or products. Furthermore, NIOSH is not responsible for the content of these Web sites.

|

The National Institute for Occupational Safety and Health (NIOSH), an institute within the Centers for Disease Control and Prevention (CDC), is the federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. In 1998, Congress appropriated funds to NIOSH to conduct a fire fighter initiative that resulted in the NIOSH “Fire Fighter Fatality Investigation and Prevention Program” which examines line-of-duty-deaths or on duty deaths of fire fighters to assist fire departments, fire fighters, the fire service and others to prevent similar fire fighter deaths in the future. The agency does not enforce compliance with State or Federal occupational safety and health standards and does not determine fault or assign blame. Participation of fire departments and individuals in NIOSH investigations is voluntary. Under its program, NIOSH investigators interview persons with knowledge of the incident who agree to be interviewed and review available records to develop a description of the conditions and circumstances leading to the death(s). Interviewees are not asked to sign sworn statements and interviews are not recorded. The agency’s reports do not name the victim, the fire department or those interviewed. The NIOSH report’s summary of the conditions and circumstances surrounding the fatality is intended to provide context to the agency’s recommendations and is not intended to be definitive for purposes of determining any claim or benefit.

|

For further information, visit the program Web site at www.cdc.gov/niosh/fire or call toll free 1-800-CDC-INFO (1-800-232-4636).

This page was last updated on 08/08/2011.