Roof Collapse Injures Four Career Fire Fighters at a Church Fire - Arkansas

Death in the Line of Duty…A summary of a NIOSH fire fighter fatality investigation

Death in the Line of Duty…A summary of a NIOSH fire fighter fatality investigation

F2001-03 Date Released: October 30, 2001

SUMMARY

On December 28, 2000, at 0724 hours, fire fighters from a career fire department responded to a structural fire at a local church. A 49-year-old captain (Injured Fire Fighter #1), a 28-year-old fire fighter/engine operator (Injured Fire Fighter #2) assigned to drive an air service truck (Air Service 1), and two 27-year-old fire fighters (Injured Fire Fighters #3 and #4) were injured while performing interior suppression activities when a section of the roof collapsed, trapping them inside the structure. At 0728 hours, the Chief arrived on the scene, assumed incident command (IC), and reported that he had a fire in a large church, which was not heavily involved. The IC radioed a hydrant position and asked central dispatch to tone out a second alarm. At 0730 hours, Fire Fighter #1 pulled a 1¾-inch preconnect off Engine 4 and advanced to the double doors, where he met up with his crew. The IC ordered this crew (the Captain from Engine 4 and Fire Fighters #1 and #2) to enter the structure for an aggressive fire attack; however, the IC instructed them not to enter the structure very far. At 0732 hours, Air Service 1 (a captain and Injured Fire Fighter #2) arrived on the scene and pulled a second 1¾-inch preconnect off Engine 4 and advanced it to the front doors of the structure. At 0734 hours, Engine 5 arrived on the scene with Injured Fire Fighters #1 and #4 and an engine operator. Upon arrival, the IC ordered them to pull a third 1¾-inch preconnect from Engine 4 and advance into the structure. At approximately 0737 hours, the crew from Engine 5 (Injured Fire Fighters #1, #3, and #4) and the crew from Air Service 1 (Captain and Injured Fire Fighter #2) met up in a classroom. They noticed intense fire in the ceiling/truss void area where a small piece of ceiling in the northeast corner of the classroom had fallen. At approximately 0740 hours, as the crew from Truck 1 made their way to the front of the structure, the roof collapsed in the classroom area, trapping and injuring Fire Fighters #1, #2, #3, and #4. They began frantically searching for an exit. Injured Fire Fighter #4 located a section of the wall that felt different from the other walls in the room. He began to bang his helmet, still on his head, against this section of the wall. After approximately six blows, he heard glass break and realized that he had located a window. The Captain from Air Service 1 helped clear the remaining section of the window and assisted Injured Fire Fighters #4, #2, and #3 exit the classroom through the window. Injured Fire Fighter #1 was able to locate the classroom door, and the IC led him out of the classroom, into the hallway, and out of the structure. NIOSH investigators concluded that to minimize the risk of similar occurrences, fire departments should

- ensure that the department’s standard operating procedures (SOPs) are developed, followed, and refresher training is provided

- ensure that fire command always maintains close accountability for all personnel at the fire scene

- ensure that incident command conducts an initial size-up of the incident before initiating fire-fighting efforts and continually evaluates the risk versus gain during operations at an incident

- ensure that fire fighters use extreme caution when operating on or under a lightweight truss roof and develop standard operating procedures for buildings constructed with lightweight roof trusses

- ensure that fire fighters performing fire-fighting operations under or above trusses are evacuated as soon as it is determined that the trusses are exposed to fire

- explore using a thermal imaging camera as a part of the exterior size-up

- ensure that the assigned rapid intervention team(s) (RIT) complete search-and-rescue operations and are properly trained and equipped

- ensure that fire fighters are equipped with a radio that does not bleed over, cause interference, or lose communication under field conditions

- ensure consistent use of personal alert safety system (PASS) devices at all incidents and consider providing fire fighters with a PASS integrated into their self-contained breathing apparatus which provides for automatic activation

- establish written standard operating procedures, record keeping, and conduct annual evaluations to monitor and evaluate the effectiveness of their overall SCBA respirator maintenance program

INTRODUCTION

On December 28, 2000, four fighters from a career fire department responded to a structural fire at a local church. The fire was started by electrical wiring in the truss void at approximately 0715 hours. A 49-year-old captain (Injured Fire Fighter #1), a 28-year-old fire fighter/engine operator (Injured Fire Fighter #2), and two 27-year-old fire fighters (Injured Fire Fighters #3 and #4) were injured while performing interior suppression activities when a section of the roof collapsed, trapping the four fire fighters.

On January 2, 2001, the International Association of Fire Fighters (IAFF), notified the National Institute for Occupational Safety and Health (NIOSH) of this incident and requested an investigation. On January 22-24, 2001, two safety and occupational health specialists investigated this incident. Interviews and meetings were conducted with the chief, fire fighters from the department who were on the scene of this incident, the president of the Local IAFF, and representatives from the Fire Marshal’s Office. The incident site was visited and the scene was photographed. Copies of witness statements, training records, standard operating procedures (SOPs), dispatch logs, the fire/arson investigation report, building blueprints, video footage, and a map of the fire scene were reviewed.

This career department consists of 78 uniformed fire fighters and a chief. The department serves a population of 68,000 in an area of approximately 53 square miles. The department operates on a three-shift rotation with 26 fire fighters per shift.

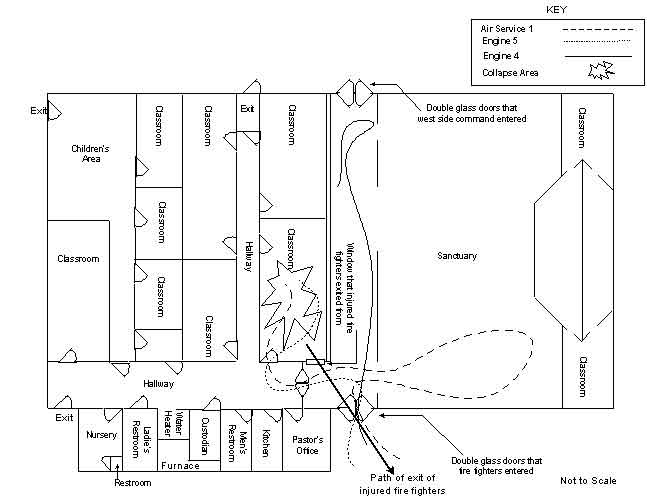

The structure involved in this incident was initially constructed in 1973, and an addition was added to the structure in 1975. The structure was one story, formed on a concrete slab. The primary structure measured 68 feet by 72 feet. The secondary structure measured 43 feet by 72 feet (see Diagram). The wall systems consisted of 2- by 4-inch wood studs, with 3 ½-inch insulation,½-inch drywall, ½-inch plywood, and exterior masonry brick. The roof system was formed using lightweight wood trusses, consisting of 2- by 4-inch and 2- by 6-inch lumber connected with metal and wood gusset plates (Photo 1). The roof system sheathing consisted of 5/8-inch interior plywood covered by felt paper and asphalt shingles. The interior ceiling consisted of ½-inch drywall attached to the trusses. The truss system incorporated both metal and plywood gusset plates. Two different truss systems were utilized due to the different dates that construction and renovations occurred.

The department requires all fire fighters to complete a 2-week orientation followed by an 8-week minimum standards school at the Arkansas State Fire Academy. The department requires all fire fighters to attain their Fire Fighter I and II certifications. In addition, all fire fighters must complete the following courses: arson detection for first responders, hazmat, wildland fire suppression, emergency vehicle operations, emergency medical technician, and cardiopulmonary resuscitation. All fire fighters are placed on 1-year probation. Injured #1 had 27 years of experience, Injured #2 had 6 years of experience, Injured #3 had 1 year of experience, and Injured #4 had 2 years of experience.

At the time of the incident, Injured Fire Fighters #2, #3, and #4 were wearing their full array of personal protective clothing and equipment, consisting of turnout gear (coat and pants), helmet, Nomex ® hoods, gloves, boots, a self-contained breathing apparatus (SCBA), and a manual personal alert safety system (PASS) device secured to each fire fighter’s SCBA harness. Injured Fire Fighter #1 was wearing the same personal protective clothing and equipment except his Nomex ® hood. When the roof collapsed in this area, Injured Fire Fighters #1, #2, #3, and #4 were pinned and trapped by fallen debris. Injured Fire Fighter #1 received severe burns (third-degree) to his hands, and was transported to a regional burn center for treatment for his burns. Injured Fire Fighters #2, #3, and #4 were treated at a local hospital for injuries received when struck by the falling roof section, for minor burns, and for smoke inhalation.

The weather conditions at the time of this fire included a relative humidity of 96%, an ambient air temperature of 28″F, a wind speed of 5 mph, and barometric pressure of 30.08 in Hg. The roadways and grounds were covered with ice from freezing rains.

INVESTIGATION

On December 28, 2000, at 0724 hours, Central Dispatch received the report of a structure fire at a local church. Central Dispatch toned out the first alarm and immediately dispatched the following units: Car 1 (Chief), Battalion 1 (Captain), Engine 4 (Captain, an Engine Operator and Fire Fighters #1 and #2), Engine 11 (Injured Fire Fighter #3 and an Engine Operator), and Air Service 1 (Captain and Injured Fire Fighter #2).

At 0728 hours, the Chief arrived on the scene and assumed incident command (IC). The IC reported to Central Dispatch that he had a large church with brick veneer not heavily involved. The IC radioed a hydrant position to Engine 4 and asked Central Dispatch to tone out a second alarm. The following units were dispatched as second-alarm companies: Engine 5 consisting of a captain (Injured Fire Fighter #1), a fire fighter (Injured Fire Fighter #4) and an engine operator and Truck 1 (captain, Fire Fighter #3, and an engine operator). The IC then radioed Engine 4 reporting that the main body of the fire was located in the middle of the structure and asked Engine 4 to approach the structure from the east side and enter through the double doors located in the center of the structure (Photo 2). At 0729 hours, Engine 4 arrived on the scene. The IC radioed Central Dispatch requesting that Truck 1 respond to the scene. Note: Truck 1 was not originally toned out on the first alarm due to weather conditions on the day of this incident. It is department policy that when weather conditions make the roadways hazardous, only engine companies respond. Upon arrival, the engine operator from Engine 4 connected to the hydrant and the Captain and Fire Fighter #2 proceeded to the double doors located in the center of the structure. The Captain from Engine 4 made forcible entry to the doors by pulling them open and breaking free the locking mechanism. At this time Fire Fighter #1 pulled 200 feet of a 1¾-inch preconnect hoseline off Engine 4 and advanced to the double doors where he met up with his crew. The IC ordered this crew (the captain from Engine 4 and Fire Fighters #1 and 2) to enter the structure; however, he instructed them not to advance into the structure very far. At 0732 hours, Battalion 1 (battalion chief) arrived on the scene and was assigned as west sector command. Also at this time, Air Service 1 (a captain and Injured Fire Fighter #2) arrived on the scene and pulled a second preconnect (a 200-foot section of 1¾-inch hoseline) off Engine 4 and advanced it to the front doors of the structure where they met up with the crew from Engine 4. They determined that the crew from Engine 4 would enter and go straight to the west side of the structure, and the crew from Air Service 1 would go right into the sanctuary area (see Diagram). The Battalion Chief proceeded from the east to the west side of the structure. During his walk around the structure, the Battalion Chief forced open a door on the southeast corner that led into a closet and noticed that there was no visible fire and very little smoke. Arriving on the west side, the Battalion Chief forced open a set of double doors and propped them open with an object inside the structure. He entered the structure approximately 5 feet and heard fire fighters inside. Note: The Battalion Chief was not wearing his self-contained breathing apparatus (SCBA), bunker pants, or fire boots . At this time the Captain and Fire Fighters #1 and #2 from Engine 4 made their way to the west side of the structure following a hallway that led from the east-side double doors to the west-side double doors. As they approached the west-side doors, they noticed heavy smoke but no fire showing. At 0734 hours, Engine 5 arrived on the scene with Injured Fire Fighters #1, #4, and an engine operator. Upon arrival the IC ordered them to pull a third preconnect (a 250-foot section of 1¾-inch hoseline) from Engine 4 and advance into the structure. At this time Engine 11 (Injured Fire Fighter #3 and an engine operator) arrived on the scene. Note: At 0735 hours a fire marshal from the department arrived on the scene and began photographing the structure and conducting his preliminary investigation. Injured Fire Fighters #1, #3, and #4 entered the structure and made their way left into the classroom area. Injured Fire Fighter #3 stayed at the door and pulled line for his crew until they made their way into the classroom area and then proceeded into the structure, following the line, and met up with his crew. While the crew from Engine 4 was near the west side of the structure, a piece of the ceiling fell, knocking the crew to the ground. At this time they noticed heavy fire in the ceiling/truss void area and sprayed water into this area to suppress the fire. The crew from Air Service 1 made their way out of the sanctuary into the classroom area, where they met up with the crew from Engine 5. At approximately 0737 hours, the crew from Engine 5 ( Injured Fire Fighters #1, #3 and #4) and the crew from Air Service 1 (Captain and Injured Fire Fighter #2) met up in the classroom. They noticed intense fire in the ceiling/truss void area where a small piece of ceiling in the northeast corner of the classroom had fallen. At approximately 0738 hours, while the crews in the classroom area were hitting the fire in the ceiling/truss void area, the IC gave the order to switch from the fireground/ tactical channel to the talk-around channel, due to interrupted communications with fireground personnel. Note: Most of the fireground personnel have radios which require the fire fighters to scroll through a menu using push buttons on the radios to switch from the fireground/tactical channel to the talk-around channel. At 0739 hours, Truck 1 (a captain, Fire Fighter #3 and an engine operator) arrived on the scene and were instructed by Battalion 1 to stage on the road to the east of the structure. As the Captain and Fire Fighter #3 approached the structure, they made their way to the IC, who was not at the command post. During this time the crew from Engine 5, Air Service 1, and Engine 4 were continuing fire suppression inside the structure. Injured Fire Fighter #3 ( the nozzleman) and Injured Fire Fighter #1 (backup) in the southwest portion of the classroom, and Injured Fire Fighter #2 (the nozzleman) and Injured Fire Fighter #4 (backup) in the northeast portion of the classroom were pulling ceiling and hitting the ceiling and attic areas in efforts to control the fire. Note: At this time the crews reported that debris was falling on them. Due to lack of visibility, they were not sure if it was dropping down from the ceiling or small parts of the truss system. The Captain from Air Service 1 was in the hallway assisting with the hoseline as the IC made his way inside the structure to the classroom area. Note: The IC was not wearing his SCBA or Nomex ® Hood. At this time, approximately 0740 hours, as the crew from Truck 1 made their way to the front of the structure, the roof collapsed in the classroom area, trapping and injuring Fire Fighters #1, #2, #3, and #4 (Photo 3). Also at this time, the crew from Engine 4 (a captain and Fire Fighters #1 and #2), approximately 10 feet from the east-side doors, made their way to the east-side doors, due to concerns of structural integrity expressed by the Captain. The Crew from Engine 4 left their line inside the hallway and followed it out to the east-side doors. When the Captain and his crew reached the east-side doors, the Captain told his fire fighters to stay by the door, while he went to tell the IC that all fire fighters should exit the structure. When the collapse occurred, the classroom began to fill with heavy fire and intense heat. At the time of the collapse, all four injured fire fighters were knocked to the ground by falling debris. They began frantically searching for an exit. Injured Fire Fighter #4, who was in the southeast corner of the room, located a section of the wall that felt different from the other walls in the room. He began to bang his helmet, still on his head, against this section of the wall. After approximately six blows, he heard glass break and realized that he had located a window. The Captain from Air Service 1 helped clear the remaining section of the window and assisted Injured Fire Fighters #2, #3, and #4 out of the classroom. Injured Fire Fighter #4 was first to exit the classroom through the window. After Injured Fire Fighter #4 exited, crews in the east doors of the structure began spraying water into the classroom to protect the remaining three fire fighters. Injured Fire Fighters #2 and #3 heard glass break and saw the water spraying into the classroom, giving them the direction they needed to travel to exit the classroom. Injured Fire Fighters #2 and #3 ran through the heavy fire and debris and bailed out of the window. Injured Fire Fighter #1 was able to locate the classroom door and was led down the hallway to the east-side doors by the IC. He was then taken to an emergency medical service (EMS) unit that was on the scene. At this time the safety officer arrived on the scene. Also at this time the Battalion Chief assigned to the west-side of the structure ran into the hallway and grabbed the line left in the hallway by the crew from Engine 4, and began hitting the fire in the ceiling/truss void area for approximately 1 minute. He then exited through the west-side doors and made his way around the structure to the east side. At approximately 0741 hours, all injured fire fighters were outside the structure and being taken to EMS units for medical treatment. The Captain from Air Service 1 inside the east doors, received confirmation from the IC that all four injured fire fighters had exited the structure. As the remaining fire fighters were exiting the structure and the IC confirmed that no additional fire fighters were inside, he gave the order to hit the roof with the deck gun from Engine 4. Injured Fire Fighter #1 was taken to a regional burn center for third-degree burns to his hands. Injured Fire Fighters #2, #3, and #4 were taken to the local hospital for minor burns and smoke inhalation and were treated and released.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Fire departments should ensure that the department’s standard operating procedures (SOPs) are developed, followed, and refresher training is provided.1,2

Discussion: Fire departments should develop and ensure that companies perform their duties as described in the department’s standard operating procedures (SOPs) unless directed or approved by the incident commander to do otherwise.

Command Procedures

As stated in Incident Management for the Street-Smart Fire Officer2, the incident commander (IC) determines the location of the command post. It is extremely important that the incident commander remain at the command post for the majority of the incident so that he/she will be easy to locate.

Truss Roof Systems

- Departments should develop standard operating procedures for buildings constructed with lightweight roof trusses.

Discussion: Standard operating procedures should be developed and implemented for buildings constructed with lightweight roof trusses. The SOPs should be provided to all fire fighters and training should take place to identify buildings constructed of lightweight roof trusses.

- Departments should ensure that fire fighters are trained to identify truss roof systems.3,4

Discussion: Trusses come in many sizes, shapes, and design. It is important that fire fighters are able to identify them and the dangers they may pose. Trusses generally consist of wood but may also be constructed with other types of metals. All the materials may act differently under fire conditions, but all are subject to failure. Fire fighters should be provided with training to identify the different types of truss systems and their potential hazards in a fire.

Recommendation #2: Fire departments should ensure that fire command always maintains close accountability for all personnel at the fire scene.5,6,7

Discussion: Accountability on the fireground is paramount and may be accomplished by several methods. It is the responsibility of every officer to account for every fire fighter assigned to his or her company and relay this information to the incident commander. Fire fighters should not work beyond the sight or sound of the supervising officer unless equipped with a portable radio. The crew leader should communicate with the supervising officer by portable radio to ensure accountability and indicate completion of assignments and duties. When the assigned duties are completed, the crew should radio this information to the supervisor then return to the supervisor for additional duties. As a fire escalates and additional fire companies respond, a communication assistant with a command board should assist the incident commander with accounting for all fire fighter companies at the fire, at the staging area and at rehabilitation. One of the most important aids for accountability at an incident is an incident management system (IMS). The IMS is a management tool that defines the roles and responsibilities of all units responding to an incident. It enables one individual to better control the incident. This system works on an understanding among the crew that the person in charge will be “standing back” from the incident, focusing on the entire scene.

Recommendation #3: Fire departments should ensure that incident command conducts an initial size-up of the incident before initiating fire-fighting efforts and continually evaluates the risk versus gain during operations at an incident.6, 8-14

Discussion: One of the most important size-up duties of the first-in officers is locating the fire and determining its severity. This information lays the foundation for the entire operation. It determines the number of fire fighters and the amount of apparatus and equipment needed to control the blaze, assists in determining the most effective point of fire extinguishment attack, and the most effective method of venting heat and smoke. A proper size-up begins from the moment the alarm is received, and it continues until the fire is under control. Several factors must be evaluated in conducting the size-up: type of structure, time of day, contents of the structure, potential hazards, etc. The size-up should also include risk versus gain during incident operations. The following factors are important considerations:

- Occupancy type involved. The type of occupancy can have a great effect on the aspects of the fire attack. The type of occupancy could assist in determining the structure’s layout, hazardous materials, and the possibility of civilians (e.g., civilians will be present in a hospital around the clock).

- Smoke conditions. The smoke conditions can provide the incident commander with additional information about the fire. For example, if the fire is in the roof and burning roofing materials, the smoke would probably appear to be thick and black.

- Type of construction. The type of construction will be one of the most important areas to identify. The type of structure could provide the incident commander information such as how the building may hold up under fire conditions, or if the building is generally subject to collapse under fire conditions.

- Type of roof system. The roof system should be one of the first things that is determined before fire fighters enter a burning structure. One type of roof system is the lightweight truss roof. It is generally formed by 2- by 4-inch or 2- by 6-inch lumber, attached together with metal gusset plates. The structural idea of the lightweight truss is to distribute loads over a large area. The National Engineered Lightweight Construction Fire Research Project published test results which support that unprotected steel trusses have shown failure from 4 to 6 minutes and the wood trusses have shown failure from 6 to 13 minutes. Typically, fire fighters will rely on warning signs such as sagging roofs or floors to determine that the integrity of the truss systems has deteriorated to the point that the truss systems will no longer support any load. Quite often, those warning signs are not a good predictor of truss system failures.15

- Age of structure. The incident commander should ascertain the age of the building when determining strategy or tactics. The age of the structure can provide the incident commander with information to help determine the building’s integrity or other vital information such as construction methods or construction materials.

- Exposures. The incident commander should evaluate the entire fireground. The protection of exposures near or connected to a burning building should be included in the strategic plan.

- Time considerations. Information such as time of incident, time fire was burning before arrival, time fire was burning after arrival, and type of attack, is some of the most important information the incident commander could have.

Additionally, departments should ensure that the first officer or fire fighter inside evaluates interior conditions and reports them immediately to the incident commander. Interior size-up is just as important as exterior size-up. Since the IC is staged at the command post (outside), the interior conditions should be communicated as soon as possible to the IC. Interior conditions could change the IC’s strategy or tactics. For example, if heavy smoke is emitting from the exterior roof system, but fire fighters cannot find any fire in the interior, it is a good possibility that the fire is above them in the roof system. It is important for the incident commander to immediately obtain this type of information to help make the proper decisions.

Recommendation #4: Fire departments should ensure that fire fighters use extreme caution when operating on or under a lightweight truss roof and should develop standard operating procedures for buildings constructed with lightweight roof trusses.10,16

Discussion: The lightweight wood truss incorporates wooden members which can be as small as 2- by 4-inch timber connected with metal gusset plates.

The trusses are designed according to specified load amounts. The loads are generally heating, ventilation, and air conditioning (HVAC) units, compressors, air ducts, cooling lines, rest room ventilation fans, grease exhaust ducts and exhaust fans, snow, and ice. Additional loads, which could be applied after the truss is in place, are antennas, satellite dishes, flags, banners, large air-filled advertisements with air blowers, and improperly stored items. The trusses are designed to distribute the loads throughout the roof system and can span large openings without interior load-bearing walls. Since the trusses are tied together and are designed to distribute the load, if one of the trusses fails, it places an additional load on the others, which could cause a chain reaction of failure leading up to a collapse. The document, Building Construction for the Fire Service, states that “the metal gusset plates can also be weakened or destroyed by fire by acting as a heat collector, delivering the heat to the metal gusset plate teeth, which can pyrolytically destroy the tensioned wood fibers, which had been gripping the metal teeth. Sometimes trusses are set in multiples to cope with a concentrated load. This does not suffice in a fire because all the trusses can be exposed to the same fire conditions. An additional load not incorporated into the design can shorten the time to failure in a fire. When a fire occurs in this type of truss, it generally travels rapidly throughout them reducing their structural integrity.”3

Additional hazards that exist with truss systems are “truss voids” or “trussloft.” It is described as the void of space between the ceiling and roof, which is not high enough to be called an attic. The lightweight trusses are designed in a series of triangles which create the trusses’ structural integrity. The area from the top chord of the truss to the bottom chord is known as the “truss void” or “trussloft,” which creates a path for rapid fire spread. Even if firestops are placed in the voids, openings for duct work, appliance lines, electrical lines, conduit, or additional utility installations create a path for fire to spread. Building Construction for the Fire Service notes that no tests exist which demonstrate the effectiveness of firestopping or draftstopping for its intended purpose:

“All personnel at a fire scene should be alert to exterior conditions. Fire or heavy smoke from the roof indicates that the trusses are on or have been exposed to fire. The truss voids in the ceiling may harbor a well-concealed fire that is ready to burst out with almost an unbelievable fury when oxygen is admitted to a void containing heated carbon monoxide. The reaction can range from a deflagration to a detonation, from a backdraft or flashover to an explosion capable of blowing a building apart. Any ceiling below a truss void should be pulled and examined by disciplined fire fighters under control, standing near a doorway for rapid escape. If there is a fire barrier in the void, the same procedure should take place on the opposite side.”3

A well-known cautionary phrase within the fire service bears repeating – “Beware of the Truss!”3

An article authored by Vincent Dunn, retired Deputy Chief, New York Fire Department, states that if fire fighters arrive at a structure fire involving the burning of the truss structure, a defensive fire-fighting strategy should be employed: Remove people from the building and attack the fire from the exterior.16 Over the past 4 years, approximately 10 fire fighter fatalities have occurred due to truss-related incidents.

Recommendation #5: Fire departments should ensure that fire fighters performing fire-fighting operations under or above trusses are evacuated as soon as it is determined that the trusses are exposed to fire.3

Discussion: There is no specific time limit on how long fire fighters should operate under or on truss roofs that are exposed to fire. A time limit is often used by fire departments as a guide for operation under or on truss roofs. Even though standard fire engineering calculations show that lightweight trusses may be expected to collapse after about 10 minutes in a fully developed fire, it is not recommended to set a time limit. “Under fire conditions, truss failure is unpredictable.”3 When fire fighters arrive on the scene of a building with trusses exposed to fire, it is virtually impossible to identify how long the trusses have been exposed to fire and set a time limit for fire suppression. When it is determined that the building’s trusses have been exposed to fire, any fire fighters operating under or above them should be immediately evacuated. If it is not clear that the building’s trusses have been exposed to fire, a defensive attack should take place until the conditions can be verified.

Fire fighters may have difficulty finding the exact location of fire in a building, even though heavy smoke makes it clear that fire is present. The fire could be in a void or concealed area. For example, fire-rated suspended-ceiling panels create a space between them and the top chord of the roof truss. The void creates a path for rapid fire spread and can shield the fire from the fire fighter’s sight. The term “fire-rated” should not be misinterpreted. It does not provide any fire resistance, but merely meets fire code requirements for rate of flame spread. The design of suspended-ceiling panels provides a void to hide the fire and store carbon monoxide. If the suspended ceiling were to collapse while fire fighters were under it, the fire fighters could become entangled in the steel supporting grid. Additionally, fire fighters could become entangled in wire and other loose debris falling from the suspended ceiling and could be trapped in the building.

Recommendation #6: Fire departments should explore using a thermal imaging camera as a part of the exterior size-up.4,11, 17-19

Discussion: Thermal imaging cameras are being used more frequently by the fire service. One function of the cameras is to locate the fire or heat source. Additionally, “infrared thermal imagers assist fire fighters in quickly getting crucial information about the location of the source (seat) of the fire from the exterior of the structure, so they can plan an effective and rapid response with the entire emergency team. Knowing the location of the most dangerous and hottest part of the fire helps fire fighters determine a safe approach and avoid structural damage in a building that might otherwise have been undetectable. Ceilings and floors that have become dangerously weakened by fire damage and threaten to collapse can be spotted with a thermal imaging camera. A fire fighter about to enter a room filled with flames and smoke can judge whether or not it will be safe from falling beams, walls, or other dangers.”4 The use of a thermal imaging camera may provide additional information the incident commander can use during the initial size-up.

Recommendation #7: Fire departments should ensure that the assigned rapid intervention team(s) (RIT) complete search-and-rescue operations and are properly trained and equipped.5

Discussion: A RIT should consist of at least two fire fighters and should be available for rescue of a fire fighter or a team if the need arises. The RIT should be fully equipped with the appropriate protective clothing, protective equipment, SCBA, and any specialized rescue equipment that might be needed, given the specifics of the operation under way. Once the RIT is established, they should remain the RIT throughout the operation. They should constantly survey the fireground operations and be in communication at all times with the IC and companies on the fireground. As fireground operations continue, the RIT team should observe the following: where fire fighters are entering and exiting, how many fire fighters are inside, where the fire fighters are operating, what operations are taking place, the layout of the structure, the structure (i.e., trussed roof, metal roof, etc.) and hazards that could exist with the structure (i.e., possible collapse areas, etc.), hazards they might encounter (i.e., chemicals, tanks, etc.), the fire’s condition (i.e., fire spread, fire in the roof, etc.), if an emergency occurs, what will be their best route to enter or exit, and what equipment they will need if an emergency occurs (i.e., airbags, hydraulic jacks, additional air bottles, etc.).

Each incident is different and additional concerns should also be taken into consideration. There are many functions expected from the RIT members during an incident. If an emergency occurs, the RIT should be rested, have full air bottles, a good understanding of the overall situation, and be able to respond in a safe manner to perform the search or rescue. If the RIT is used for an emergency operation, a second RIT should be put in place in case an additional emergency should occur. Note: Fire departments should ensure that they assess all risk factors when making the decision to send a RIT into a structure that has already been the scene of an emergency evacuation, search, or rescue. When a RIT enters a structure, they generally will use a rope or some type of guide to enter and exit. When more than one RIT enters at the same time, more than one rope would be taken into the structure. If multiple ropes are taken into the structure, they could get entangled and cause confusion. If multiple ropes are used for search and rescue, a plan of action should be put into place to avoid confusion or to prevent the ropes from being entangled.

Recommendation #8: Fire departments should ensure that fire fighters are equipped with a radio that does not bleed over, cause interference, or lose communication under field conditions.20

Discussion: Radio communication is one of the most important functions on the fireground. When situations arise on the fireground, radio transmissions need to be clear and timely. Radios need to be reliable, in good working condition, fully charged, ready to use, and free of any interference or bleedover. Fire departments should also take into consideration the frequency on which the radio communication system will operate. The National Fire Protection Association (NFPA) recommends that frequency bands should be separated by 15 kHz in the VHF high band. The separation in the frequencies is to avoid possible interference. Although the department’s radios met the NFPA recommended standard for separation of frequencies, there still remains the possibility of bleedover, interference, or loss of communication in certain types of fireground conditions. In this incident there were problems with radio communications coming through clearly or without being walked over. If the department operated with a standard radio throughout the entire department, this would ensure that all fire fighters are familiar with radio functions, such as emergency signal buttons, switching of channels, and general function of the radio.

Recommendation #9: Fire departments should ensure consistent use of personal alert safety system (PASS) devices at all incidents and consider providing fire fighters with a PASS integrated into their self-contained breathing apparatus which provides for automatic activation.21

Discussion: PASS devices are electronic devices worn by the fire fighter, which will emit a loud and distinctive alarm if the fire fighter becomes motionless for more than 30 seconds. Fire fighters entering hazardous areas should be equipped with a PASS device. There are several types of PASS devices available. One device that could be used is a PASS that is integrated into the SCBA. “Such automatic activation shall be permitted to be, but not limited to, linked to activation of SCBA, linked to removal from storage or transportation positions, by pull-away tether to a fixed position, or by remote activation.” Manual PASS devices are also used throughout the fire service. These devices require fire fighters to manually turn on the device each time they use it.

Recommendation #10: Fire departments should establish various written standard operating procedures, ensure record keeping, and conduct annual evaluations to monitor and evaluate the effectiveness of their overall SCBA respirator maintenance program.22

Discussion: Fire departments should ensure that SCBAs are serviced, perform properly, and are reliable. To monitor and enforce the service and maintenance of SCBAs, fire departments should establish written standard operating procedures, ensure record keeping, and conduct annual evaluations. Although there were no SCBA problems noted in this investigation, the fire department requested that NIOSH evaluate their SCBA maintenance program (see Attachment).

REFERENCES

1. City Fire Department [1999]. Manual of operations, Fayetteville, AR.

2. Coleman, J [1997]. Incident management for the street-smart fire officer. Saddle Brook, NJ: Fire Engineering Books and Videos.

3. Brannigan FL [1999]. Building construction for the fire service. Quincy, MA: National Fire Protection Association.

4. Brannigan FL [2000]. A call for fire chiefs. Saddle Brook, NJ: Fire Engineering, May Issue.

5. NFPA [1997]. NFPA 1500: Standard on fire department occupational safety and health program. Quincy, MA: National Fire Protection Association.

6. Dunn V [1992]. Safety and survival on the fireground. Saddle Brook, NJ: Fire Engineering Books & Videos.

7. NFPA [1995]. NFPA 1561: Standard on fire department incident management system. Quincy, MA: National Fire Protection Association.

8. National Institute for Occupational Safety and Health [1999]. Preventing injuries and deaths of fire fighters due to structural collapse. Publication No. 99-146. Division of Safety Research, Morgantown, WV.

9. International Fire Service Training Association [1995]. Essentials of fire fighting, 3rd ed. Fire Protection Publications.

10. Kipp JD, Loflin ME [1996]. Emergency incident risk management: a safety & health perspective. New York: Van Nostrand Reinhold Publishing.

11. Norman J [1998]. Fire officer’s handbook of tactics. Saddle Brook, NJ: Fire Engineering Books and Videos.

12. Dunn V [1988]. Collapse of burning buildings: a guide to fireground safety. Saddle Brook, NJ: Fire Engineering Books and Videos.

13. Dunn V [1996]. Systems analysis, size-up: Part 1. Firehouse, October Issue.

14. Brunacini A [1985]. Fire command, Quincy, MA: National Fire Protection Association.

15. Grundahl, K [1991]. Fire Performance of Trusses Reference Guide. [http://sbcindustry.com/sites/default/files/uploads/attachments/node/128/fireperf_kg.pdfpdf iconexternal icon]. Date accessed: January, 2006. (Link Updated 11/12/2013)

16. Dunn V [1998]. Risk management and lightweight truss construction. New York, NY: WNYF, Official training publication of the New York City Fire Department, 1st issue.

17. Brannigan FL [2000]. Professional review of NIOSH FACE report F2000-13, September 18, 2000.

18. Corbin DE [2000]. Seeing is believing. Dallas, TX: Occupational Safety and Health, August issue.

19. Colley K [1999]. Eyes wide open. Industrial Fire World, March-April issue.

20. NFPA [1995]. NFPA 297: Guide on principles and practices for communication systems. Quincy, MA: National Fire Protection Association.

21. NFPA [1998]. NFPA 1982, Personal Alert Safety System. Quincy, MA: National Fire Protection Association.

22. National Institute for Occupational Safety and Health (NIOSH) [2000]. Self-contained breathing apparatus (SCBA) maintenance program evaluation, NIOSH Reference: TN-11399. Division of Respiratory Disease Studies, Respirator Branch, NIOSH, Morgantown, WV.

INVESTIGATOR INFORMATION

This incident was investigated by Thomas P. Mezzanotte and Frank C. Washenitz II, Safety and Occupational Health Specialists, Division of Safety Research, Surveillance and Field Investigations Branch.

Photo courtesy of the Fire Department.

Photo 1. Truss and Gusset Plates

Photo courtesy of the Fire Department.

Photo 2. Doors where crews entered and fire venting over collapse area

Photo courtesy of the Fire Department.

Photo 3. Collapsed Area

Diagram. Overview of Incident Site

ATTACHMENT

The following is a summary of NIOSH Task No. TN-11838. For a full report, including photos, tables, and diagrams, contact NIOSH, Division of Respiratory Disease Studies, Respirator Branch at (304) 285-5907.

Department of Health & Human Services

Public Health ServiceNIOSH Reference: TN-11399

Phone: (304) 285-5907

Fax: (304) 285-6030

July 6, 2000Dear Chief:

The National Institute for Occupational Safety and Health (NIOSH or the Institute) has concluded its investigation conducted under NIOSH Task Number TN-11838. This investigation consisted of the inspection and performance-testing of three self-contained breathing apparatus (SCBA) shipped to NIOSH by your department. The three SCBA, each secured in its own black carrying case, were shipped to the NIOSH Appalachian Laboratory for Occupational Safety and Health (ALOSH). The three packages were received by NIOSH on February 7, 2001. The cases were stored under lock in the Firefighter SCBA Evaluation Lab (room 1520) until the time of the evaluations.

The primary purpose of this investigation was to determine the SCBA’s conformance to the NIOSH certification requirements of Title 42, Code of Federal Regulations, Part 84 (42 CFR 84). Six selected performance tests were conducted in accordance with these NIOSH approval requirements. In order to provide you with additional information about the SCBA’s performance, the National Fire Protection Association (NFPA) Air Flow Performance test was also conducted. The NFPA Air Flow Performance test was conducted in accordance with NFPA 1981, Standard on Open-Circuit Self-Contained Breathing Apparatus for the Fire Service – 1997 Edition. Our inspection report and results of all tests are contained in a detailed SCBA Status Investigation Report which is enclosed.

SCBA Inspections

I inspected the contents of each SCBA carrying case. Each case contained one complete Scott Air-Pak® 2.2 SCBA. The SCBA were examined individually, component by component, in the condition as received to determine their conformance to the NIOSH-approved configuration. The entire inspection process was videotaped.

The first case from the Fayetteville Fire Department was opened on February 9, 2001, in room 1520 of the ALOSH Building. The inspection of the first SCBA (referred to as Unit #1) was completed on February 13, 2001. The second case was opened on February 14, 2001. The inspection of Unit #2 was completed that day. The third unit was removed from its case and inspected on March 8, 2001.

The SCBA inspections are summarized in Appendix I of the enclosed report. The condition of each major component was also photographed with a digital camera. Images of the three units are contained in Appendix IV of the report.

SCBA Testing

Testing of the three SCBA was initiated on May 8, 2001, and was completed on May 11, 2001. The three SCBA were tested in the conditions as received from the Fayetteville Fire Department with one exception. The compressed air cylinders on Units #1 and #2 were found to have expired requalification test dates. The cylinder on Unit #3 was found to have a valid test date. Therefore, the cylinder from Unit #3 was used during the performance testing of all three units.

The following performance tests were conducted:

NIOSH SCBA Certification Tests (in accordance with the performance requirements of 42 CFR 84):

- Positive Pressure Test [42 CFR 84.70(a)(2)(ii)]

- Rated Service Time Test (duration) [42 CFR 84.95]

- Gas Flow Test [42 CFR 84.93]

- Exhalation Breathing Resistance Test [42 CFR 84.91(c)]

- Static Facepiece Pressure Test [42 CFR 84.91(d)]

- Remaining Service Life Indicator Test (low-air alarm) [42 CFR 84.83(f)]

National Fire Protection Association (NFPA) Tests (in accordance with NFPA 1981, 1997 Edition):

7. Air Flow Performance Test [NFPA 1981, Chapter 6, 6-1]

SCBA Test Results

Units #1 and #2 met the requirements of all six selected NIOSH tests performed. Unit #3 failed to meet the requirements of the Remaining Service Life Indicator Test. The low-air alarm on Unit #3 consistently activated at a higher pressure than is acceptable per the regulations. This test failure is indicative of an SCBA alarm that is out of adjustment. Because the alarm is adjusted too high, it would sound earlier than required and give the user additional time to exit. Therefore, this failure mode does not pose a health or safety risk. All three SCBA met the facepiece pressure requirements of the NFPA Air Flow Performance Test.

Appendix II of the enclosed report contains the complete NIOSH and NFPA test reports for the three SCBA. Tables One, Three, and Five summarize the NIOSH test results. Tables Two, Four, and Six summarize the NFPA test results.

SCBA Compressed Air Cylinder Contents Analyses

During the inspections, it was noted that the compressed air cylinders on Units #1 and #3 were partially pressurized. In order to provide information regarding the quality of the compressed air contained in these two cylinders, air samples were collected from the cylinders and forwarded to a certified laboratory for analyses. The laboratory, Dräger Lab Services, used gas chromatography, calorimetric and gravimetric analyses in accordance with the standards and methodologies found in the American National Standards Institute/Compressed Gas Association ANSI/CGA G-7.1 – Commodity Specification for Air. The test reports from Dräger Lab Services indicate that both samples met the requirements for Grade D air.

Appendix III of the enclosed report contains the complete test reports for the analyses of the air samples taken from Units #1 and #3.

Personal Alert Safety System (PASS) Device

A Personal Alert Safety System (PASS) device was attached to the waist belt of Unit #1. During the SCBA inspection, the PASS device was activated both manually and automatically. The device appeared to function properly in both modes. Because NIOSH does not test or certify PASS devices, no further testing or evaluations were conducted on the PASS unit. There were no PASS devices shipped with Units #2 or #3.

Recommendations

It is strongly recommended that these SCBA be inspected and serviced by an authorized Scott service technician and all necessary overhaul and repair work be completed before placing the units back into service. It is also recommended that all SCBA inspection, handling, use, and maintenance procedures be reviewed with regard to activities and practices that could impact the safe use of all SCBA. It should be noted that the compressed air cylinders on Units #1 and #2 have expired requalification dates. These cylinders should be submitted to a U.S. Department of Transportation (DOT)-certified cylinder retest facility for requalification prior to their return to service.

No further action will be taken by NIOSH and the investigation of Task Number TN-11838 will be considered closed. The SCBA will be stored under lock in room 1520 of the NIOSH ALOSH building pending return to your department.

I trust this information is satisfactory to meet your needs. If you require further assistance, please feel free to contact me at (304) 285-6337.

Sincerely yours,

Thomas W. McDowell,

General Engineer

Quality Assurance Team

Respirator Branch

National Personal Protective Technologies LaboratoryThis page was last updated on 10/30/01

- Departments should ensure that fire fighters are trained to identify truss roof systems.3,4