Lineman at Hydroelectric Utility was Asphyxiated when the Safety Rope Attached to his Harness Became Entangled in a Revolving Turbine Shaft

Wisconsin Case Report 99WI075

Summary

A 34-year-old male lineman (the victim) died of asphyxiation when the safety rope attached to his harness became entangled in a revolving turbine shaft. The victim was employed as a lineman for the city’s hydroelectric utility, and was inspecting a 75-year-old turbine that was idle following replacement of a dam. He was working with a co-worker in the enclosed flume that channeled river water through the turbine. The victim donned a fall protection harness and entered the flume via a ladder lowered from a floor opening in the platform above the flume. His safety rope was held by a co-worker standing on the platform. Another co-worker held the safety rope of the co-worker who was working in the flume with the victim. Although the major portion of the water flow had been blocked off , a small steady stream of water leaked through the control gates and flowed through the area. The knee-high, flowing water struck the turbine vanes which caused the 4 1/4-inch diameter shaft to rotate about 20 rpm. The turbine was tagged out at the utility station, but there was no lockout device to stop the revolution caused by the leaking water stream. After inspecting the area around the turbine, the victim noted that many of the turbine vanes were “frozen” in place, rather than swinging on the bolts which held them in place. He and the co-worker in the flume began striking the vanes with a maul, to break the crust that prevented them from moving. After several strikes, the victim apparently slipped in the water and fell toward the spinning shaft. His safety rope got caught on a shaft coupling, and his harness was pulled tight to the shaft. The victim’s body stopped the rotation of the turbine shaft. The co-worker cut the rope after he realized what happened, and called for help up to the two co-workers. The co-workers secured the generator wheel so the victim could be cut loose without the wheel restarting. Emergency services responded, and cut the victim free of the shaft. He was transported to the hospital, where he was pronounced dead. The FACE investigator concluded that, to prevent similar occurrences, employers should:

- install a locking brake which stops the rotation of hydroelectric turbines when maintenance and repair is necessary.

- develop and implement a written hazardous energy control program that includes specific procedures for all machines that could result in a release of hazardous energy

- provide training in the recognition and avoidance of unsafe conditions to workers who are assigned tasks outside their normal duties.

|

|

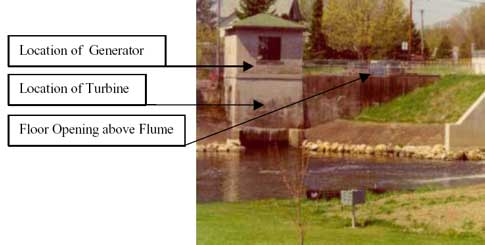

Figure 1. View of Dam and Turbine Building

|

Introduction

On October 21, 1999, a 34-year-old male lineman was asphyxiated when a safety rope became entangled on a turbine shaft and pulled him tight to the rotating shaft. The Wisconsin FACE field investigator learned of the incident from the Workers’ Compensation Division of the Department of Workforce Development on November 30, 1999. On May 3, 2000, the field investigator visited the incident site and interviewed the utility manager. The FACE investigator also obtained the death certificate, and the sheriff’s and coroner’s reports. No photos were taken of the scene at the time of the incident, but the investigator reviewed a videotape that had been made about four months before the incident which displayed the turbine as it may have appeared at the incident.

The employer in this incident was a city light and water department that had been in existence about 100 years. The department also managed the portion of the facility that sold electricity to a regional electric utility. A dam across a river controlled water flow through multiple turbines that provided mechanical energy to generators that produced hydro-electrical energy for sale. A separate turbine and generator produced electric energy that powered the utilities’ operations. The turbine and generator had been installed 75 years before the incident, and continued to operate with few interruptions since that time. The generator operation could be tagged out at the main utilities office, but the generator and turbine did not have energy isolating devices that could completely halt the revolution of the turbine shaft.

The department had five employees, including one office manager. New employees were trained by a combination of formal training and on-the-job training, depending on their background and the needs of the department. Task-specific safety training was provided verbally during orientation and at monthly safety meetings in the department. The department maintained records of all formal training provided to employees. A written safety program was in place, but did not include task-specific safe work procedures for all tasks, including the activity being performed at the time of the incident.

The victim had worked for the city light and water department as a lineman for ten years prior to the incident. He sought and accepted work assignments that were identified as having high-risk safety hazards. He had not been formally cited for violating personnel safety policies.

Back to Top

Investigation

During the year before the incident, the dam had been replaced and modifications were made to the structures that housed the separate flume, turbine and generator. Modifications included re-design and replacement of the gates that were dropped in place to divert river flow from the flume, and maintenance to the turbine and generator that were inactive while the dam was being replaced. While the turbine was inactive, minerals and organic deposits dried and crusted on the vanes, making many of them inoperable.

On the day of the incident, the department crew, consisting of the victim, the utilities manager (co-worker #1), a utility worker and an additional linesman (co-workers #2 and #3) drove about 1/4 mile from the department office to the dam to work on the turbine vanes. They came equipped with two fall protection harnesses, safety ropes, pulleys, hard hats, waders, and tools to work on the turbine. The workers lowered the new wooden gates to block the river from the flume, but noted enough water continued to flow through to keep the level at about two feet. The weather forecast predicted rain and cold weather for the next day, so they decided to proceed to avoid worse conditions. They lowered a ladder from an opening in the cement platform 12 feet above the floor of the flume where the turbine was located. The victim and co-worker #3 each donned waders, safety harness, and a hard hat. Separate safety ropes were attached to each harness, then run through pulleys on the rails surrounding the platform. Co-workers #1 and 2 held the ends of the ropes while the victim and co-worker #3 descended the ladder. The workers below walked through the water toward the turbine, while the workers above maintained visual contact with them and held the ropes taught. Co-worker #1 warned the workers below to always stay in front of the ropes. After some inspection time, the workers below decided to free the crusted vanes by pounding on them with a maul. The turbine shaft was rotating at about 20 rpm at this time, propelled by the water that continued to flow through the gates. Co-worker #2 handed the safety rope he was holding to Co-worker #1, and went into the generator room to try to work the turbine vanes to see if they would break free, to no avail (Figure 2). Meanwhile, the victim tried to free the vanes with the maul. During one swing, the maul missed the turbine and hit the water. The victim apparently lost his balance and fell toward the rotating shaft. His safety rope was caught by a coupling on the shaft, and his harness was pulled tight. Co-worker #3 saw the victim being pulled tight, and yelled for help to the workers above. He cut the safety rope, and started up the ladder to get help. One of the co-workers called for emergency assistance, while the others jammed the generator to prevent additional rotation. Emergency medical and rescue services arrived, and removed the victim from the shaft. He was transported to the hospital, where he was pronounced dead.

|

|

Figure 2. View of Turbine

|

Cause of Death

The death certificate listed the cause of death as traumatic asphyxiation as a consequence of compression of the chest and neck by a harness.

Recommendations/Discussion

Recommendation #1: Employers should install a locking brake which stops the rotation of hydroelectric turbines when maintenance and repair is necessary.

Discussion: The generator and turbine had been installed about 75 years before the incident, and was not equipped with a braking mechanism that could completely stop the rotation of the turbine vanes during repair activities. Therefore, the turbine shaft continued to rotate while the victim was attempting to free the vanes.

Note: The utility company has installed a brake on the generator that could stop the rotation of the turbine. The brake was in place at the time of the on-site investigation.

Recommendation #2: Employers should develop and implement a written hazardous energy control program that includes specific procedures for all machines that could result in a release of hazardous energy.

Discussion: The utility company’s lockout/tagout policy did not include specific procedures for locking out the generator and turbine during repair activities. The absence of a braking mechanism made lockout of the generator and turbine infeasible, but development of a specific lockout procedure for the repair activity would have spotlighted this deficiency.

Recommendation #3: Employers should provide training in the recognition and avoidance of unsafe conditions to workers who are assigned tasks outside their normal duties.

Discussion: The victims primary job responsibilities were as a lineman for the electric utility. Loosening the vanes on a water turbine was outside of his normal duties, and presented hazards that may not have been immediately evident to the worker. When workers are expected to perform additional duties that place the worker at risk, the employer should instruct the worker on those risks and how to avoid them.

Wisconsin Fatality Assessment and Control Evaluation (FACE) Program

Staff members of the FACE Project of the Wisconsin Division of Health, Bureau of Public Health, do FACE investigations when a work-related fatal machine-related, youth worker or road construction work-zone death is reported. The goal of these investigations is to prevent fatal work injuries in the future by studying: the working environment, the worker, the task the worker was performing, the tools the worker was using, the energy exchange resulting in fatal injury and the role of management in controlling how these factors interact.

To contact Wisconsin State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.