Construction Contractor Killed by Fall from a Ladder -- Washington State

|

|

Investigation: #98WA08601

Release Date: March 16, 2000

SUMMARY

On April 21, 1998, a 59-year-old painter/independent contractor (the victim) died of injuries after he fell while working from a metal extension ladder. The victim was working alone on a 90-foot by 20-foot addition to a farm equipment storage building. The building was metal roofed with closed sides and back, and open in the front. The building sat on a concrete slab. The victim was working from an aluminum extension ladder putting the finishing touches around the roof beams near the front of the building. The contractor and the ladder fell backwards to the concrete floor where he suffered massive head trauma. The local emergency medical rescue unit was summoned and responded to the incident scene. The victim was airlifted to a local hospital emergency room. He died two days later from the injuries sustained in the incident.

To help prevent similar occurrences, the Washington Fatality Assessment & Control Evaluation (FACE) Investigative team concluded that persons working from ladders should follow these guidelines:

- Use the type and length of ladder that provides the safest application for the work being done.

- Set up non-self-supporting ladders (e.g. a straight ladder or extension ladder) using the “4 to 1” rule to obtain the most stable working position.

- Use safe working techniques to ensure that the ladder remains stable.

- Secure all non-self-supporting ladders at the top and stabilize them at the bottom.

INTRODUCTION

On May 1, 1998, the Washington FACE Program was notified by CFOI * (Census of Fatal Occupational Injuries) of the April 23, 1998 death of a 59-year-old painter/independent contractor.

The Washington FACE Field Investigators met with the regional WISHA ** (Washington Industrial Safety & Health Administration) representative in whose region the fatal incident occurred. After reviewing the information that WISHA had on the case, they referred us to the County Sheriff’s office in the incident county. The WA FACE team traveled to the incident location where they met with representatives from the County Sheriffs office, the local medical rescue team who had responded to the incident, and workers who were involved with the contract job on which the victim had been working. The incident occurred at a small county museum staffed and operated primarily by community volunteers. It consisted of a variety of buildings that displayed items of historical value set within display themes.

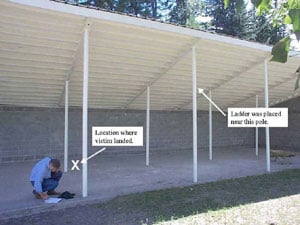

Early in 1998, the museum had advertised for bids to build an addition to their farm equipment building. The building was to be enlarged by constructing a twenty by ninety-foot extension identical to the existing structure. The building was designed to store and exhibit large pieces of farm machinery, in separated, but open equipment stalls (photos 1 and 2). A local painting contractor (the victim in this incident) won the contract to construct the extension.

At the time of the incident, the majority of the new extension had been completed and the victim was in the process of completing the final touches.

The victim was the owner/operator of a small painting/contracting company based in the area. It is unknown how much experience the deceased had in the painting/construction industry.

INVESTIGATION

On April 21, 1998, a Tuesday morning, the victim went to work at the county museum. He was working alone adding an extension to the museum’s farm equipment building. The exact time the victim began work that morning is unknown as the victim did not report in to anyone at the work site.

During our investigation we were told by the museum director that on the day of the incident, the victim had told her that he was going to be doing “some touch-up painting” and applying strapping or banding “tie-downs” on the underside of the extension’s metal roof.

Earlier that day, the victim had been in contact with two of his employees who were performing contract maintenance at a different job site in the area.

Sometime around 2:20 -2:30 PM, the victim’s employees were driving past the museum and attempted to spot their boss working on the farm equipment building.

One of the employees saw the victim lying on the concrete floor of the new building extension (see photo 2). They rushed to the victim to investigate the situation and found him face up on the concrete floor under the ladder.

They immediately called the local emergency service located just a few minutes away in a nearby town.

The victim was transported (airlifted) to a hospital about 50 miles from the incident site. He died two days later from his injuries.

CAUSE OF DEATH

The medical examiner listed the cause of death as massive head trauma with subdural hematoma.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Use the type and length of ladder that provides the safest application for the work being done.

Discussion: The victim was using an extension ladder to do touch up painting and install roof tie downs along the structural beams and support posts inside the open front of the building. The ceiling/roof sloped substantially from the back of the building up to the open front. The slope went from 10 feet high at the back of the building, to 16 feet high at the open front, a pitch of approximately 4/12.

Because of the roof slope and the fact that the building had no interior walls, it would be very difficult to safely use an extension ladder or straight ladder inside the building. A stepladder may have offered safer access to the work area.

Stepladders are designed to work freestanding, supported by a stable surface. The concrete floor of the interior of the farm equipment building would have provided ideal support. In addition, because stepladders are self-supporting, they are better suited for working in areas where solid secure wall surfaces are not present for supporting the top of non-self-supporting straight or extension ladders. Non-self-supporting ladders require the worker to maintain a three-point contact on the ladder at all times. When properly used, stepladders allow the worker the use of both hands while standing on the ladder. The stepladder is a more appropriate tool to carry out short duration, lightweight work within the effective operating zone/safe reach of the ladder. Typically, those jobs could include activities such as inspection, repair, and painting of small areas of a building or equipment. Stepladders also often have a “paint” shelf that allows the user to place paint and other tools on this small equipment platform.

In addition to the safety guidelines established for non-self-supporting ladders, users of stepladders should:

- Never set up a stepladder as a straight ladder, the legs of the stepladder should be fully extended prior to use;

- Never stand higher up on the ladder than recommended by the manufacturer; and

- Never stand on the paint shelf as it is not designed to carry the weight of a person. 1

Recommendation #2: Set up non-self-supporting ladders (e.g. a straight ladder or extension ladder) using the “4 to 1” rule to obtain the most stable working position.

Discussion: In investigating this ladder-related fatality, the FACE Investigation team determined that the ladder had been positioned at a very steep unstable angle. The ladder had been set up near one of the roof support posts just inside the front of the building. The ladder and victim fell backwards toward the interior of the building, landing close to one of the interior support posts.

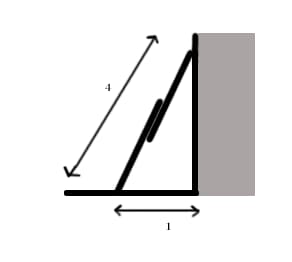

To maintain stability, non-self-supporting ladders should be set up at the appropriate slope or “angle of inclination”. The angle of inclination, that provides the best slip resistance for ladders according to the American National Standards Institute (ANSI), is 75° from the horizontal. This angle of inclination also provides the highest load capacity that can be carried by the ladder and establishes the best balance position for the climber.2 The basic rule for determining the proper angle of inclination is to place the base of the ladder at a distance from the wall (or other support structure upon which the ladder will be resting) equal to one-quarter the effective working length of the ladder. Where the effective working length is defined as the distance along the ladder from the foot to the top support. This is commonly referred to as the “4 to 1” rule. This rule says that for every 4 feet of effective ladder length, the ladder should be 1 foot away from the support structure. For example, using a 12-foot ladder supported by a wall, the base of the ladder should be 3 feet from the wall (if the end of the ladder extends past the structure, as on a gutter, other safety considerations need to be taken into account)3. See Figure 1 for a diagram.

Recommendation #3: Use safe working techniques to ensure that the ladder remains stable.

Discussion: When ladders are used as work platforms, there is a limited area in which a worker can be safely positioned and move. For the ladder to remain stable, the center of the worker’s weight must be kept between the ladder’s side rails and between support contacts at the base and upper supporting surface.

When ascending or descending a ladder, the worker should face the ladder and maintain a 3 point contact (e.g. two feet/one hand or two hands/one foot should be in contact with the ladder at all times) while remaining between the side rails.4 Workers should be trained to keep their belt buckle between the side rails of the ladder.

If the worker reaches too far back, the ladder may tip over backward. Workers should be trained to descend the ladder and reposition it if they cannot reach the work area without leaning outside of the side rails or stretching backward.

Over-extending or over reaching, is one of the more prevalent activities conducted on ladders that contribute to many serious injuries and fatalities. 5, 6 Over-extending may have been a factor that led to this fatality.

Recommendation #4: Secure non-self-supporting ladders at the top and stabilize them at the bottom.

Discussion: The ladder the victim was working from, had been set up at a very steep angle allowing a very limited zone in which a worker could move and still maintain balance and ladder stability.

To protect against backward tip over, non-self-supporting ladders should be positioned with both side rails in firm contact with the wall or upper supporting surface. The side rails should be secured to the upper support with lashings, chains or commercial ladder fasteners or clips to maintain firm contact and keep the top of the ladder from sliding or slipping at the top.2

The base of the ladder should be equipped with slip resistant feet made of rubber or metal. Before use, the base should be stabilized on a firm level surface so that there is no possibility of slippage or settling. If footing is on soft ground, additional precautions such as the use of mudsills or planking may be necessary.

If possible, secure the ladder at both the top and bottom. If there are circumstances where the ladder cannot be secured at the top and/or bottom and the positioning of the ladder indicates that it might slip, the assistance of a coworker may be needed to steady the ladder at the bottom.7

If the ladder in this incident had been secured at the top and base, it would not have fallen backwards and serious injuries may have been avoided.

Acknowledgments

In conducting this ladder-related fatality investigation, the Washington State FACE Investigation Program requested that the contents of this report be reviewed by key representatives from ladder manufacturers and distributors, the construction industry, labor organizations and Washington State and Federal agencies, prior to its’ publication. Though we are not able to acknowledge specific individuals for their invaluable input into this document, we would like to recognize the following for their help and support to the FACE process:

- The staff where the incident took place

- The incident County Sheriff’s Department

- The incident location medical response team

- WISHA enforcement

- WISHA Policy & Technical Services staff

- Federal FACE Program Management (NIOSH)

- A ladder equipment manufacturer & distributor

- Ladder accessories distributors

- The Building Industry Association

- Washington State Building & Contractor Trades Council & AFL-CIO

References

- Creighton University Portable Ladder Safety in Accordance with 29 CFR 1910.25/.27. Creighton University Environmental Health & Safety guidelines. Creighton University, Omaha, NE. Publication Date : 1998.

- American National Standard / for ladders – portable metal – safety requirements /ANSI A14.2-1990. American National Standard Institute. Published by the American Society of Safety Engineers, Des Plaines, Il. 1990.

- May, David. Rise and Fall. Occupational Health & Safety, February 1999.

- Ladder Safety Guidelines. Rincon Industries, Inc. website: www.rinconind.com/guide.html (Link no longer valid, 6/14/2006).

- Accident Prevention Manual, For Business and Industry: Engineering and Technology, 11th edition; Chicago: National Safety Council, c1997.

- Injuries Resulting From Falls / Bulletin 2195.Office of Occupational Safety and Health Statistics, Bureau of Labor Statistics, Date: June 1984.

- Ladder – Checklist. U.K. Health and Safety Executive leaflet, website: www.open.gov.uk/hse (Link no longer valid, 6/14/2006).

Other Resources

- Purchase and Use of Ladders. Ohio State University Extension, Columbus, Ohio. Publication Date: June 1992. Document AEX-691.

- Five Rules of Ladder Safety. Agricultural Engineering Department, Agricultural Service, University of Tennessee, Knoxville, Tennessee. Publication Date: April 1986. Document SP288C.

- Ladders, Lifting and Falls. University of Maine Cooperative Service, University of Maine, Orono, ME

- Climb It Safe. American Academy of Orthopedic Surgeons booklet/cover letter, Rosemont, IL. Date: November 1998.

- Fall Protection in Construction, Publication 3146. U.S. Department of Labor, Occupational Safety and Health Administration. 1995.

- Chapter 9 – Portable Ladders (PL-1). Department of Energy (DOE) OSH Technical Reference (OTR). Date: September 1998.

Photo #1. The exterior of the building under construction.

Photo #2. The interior of the building under construction.

Figure 1 Schematic of the “4 to 1” rule for optimal angle of inclination.

APPENDICES

for Construction Contractor Killed by Fall from a Ladder — Washington State.

Investigation: #98WA08601

Release Date: March 16, 2000

SHARP Report: #52-4-2000In reviewing this ladder-related fatality, the WA FACE investigation team conducted research to identify potential root cause issues related to the incident and a variety of different ideas and safety applications that are currently available or under development, but not be widely used within the industry. Some of that research is shared in these appendices.

Appendix A

Medications and “at Risk” Medical Conditions when Working at Heights. In the process of conducting a root-cause investigation, speculation regarding coincident factors associated with this event were considered. Several defined aspects of the case led to this speculation:

- The ladder fell directly backwards,

- The victim was still positioned at his working level on the ladder,

- Both of the victims hands were still clutching tightly to the ladder rungs,

- The ladder was found laying directly on top of the victim on the concrete surface where he landed,

- The victim did not apparently try to jump or maneuver clear of the ladder as it was falling, and

- The victim did not apparently try to break his fall using his hands, arms, or legs which would be a normal reaction for person falling from this short height.

One hypothesis is that, witness recollection of injury incidents is sometimes faulty given the stress and anxiety associated with discovery of a trauma scene.

Another hypothesis is the possibility of a medical event preceding the ladder fall. It was noted during the course of the investigation that the deceased had a medical history of a minor stroke, cardiac problems and used therapeutic medications. With limited medical knowledge in hand, the case was reviewed with a physician at the Washington State Department of Labor and Industries (L&I), members of the WA Dept. of L&I Safety & Health Assessment & Research for Prevention Program (SHARP), and the WA FACE investigator. This review suggested a possible contribution of a medical condition or medication to this ladder fall.

In raising this question, a search of available literature was conducted related to falls, working at heights, and work restrictions for persons with specific medications and/or medical conditions. Very little information found was applicable to this FACE research question. Most studies focused on the act of driving motor vehicles in work and private situations.

Some literature was found in the following categories that provides information and general recommendations/guidelines related to a few hazardous and moderately hazardous occupations:

- Fitness for the job,

- Physical ability to do the job,

- History of dizziness, fainting spells, heart problems or other impairments that could make climbing dangerous, and

- Taking medications that could alter the first three items on this list.

The question that the FACE Investigation team poses is, what if any specific guidelines should be in place for persons working at heights with specific medical conditions and/or taking certain medications?

Given the lack of specific guidelines, an important action that both the worker/patient and the physician need to take, is to have a clear and open channel of communication. The worker/patient needs to make sure that the treating physician is aware of, and understands the type of work, and specific aspects of the work that the individual performs, such as working on ladders, roofs, scaffolding and heights in general.

The worker/patient should ask the physician specific questions regarding precautions to take in relation to his/her medical condition and medications that he or she is taking. The physician in identifying the worker’s occupation should outline the risks and benefits of continued employment in potentially hazardous occupations and how medications may place a worker at increased risk for injury.

Another communication link in this chain could be the worker/patient’s pharmacist. Even without knowing the prescription owner’s occupation, there are defined precautions posted by the pharmaceutical company that the pharmacist should relay to the patient.

Appendix B

Specialty Ladders and Ladder Accessories

In researching this ladder-related fatality, the FACE Field Investigator visited a ladder manufacturer, a ladder accessories manufacturer and several commercial ladder sales companies to better understand the state-of-the-art in ladder safety. A few of those ideas/safety applications are outlined in this appendix below.

Note: Neither SHARP/Washington State Department of Labor ∓ Industries nor the NIOSH FACE program endorse the items or products listed in this appendix. The items are primarily presented in this appendix to stimulate discussion within the industry. Prior to the purchase of any device, the buyer should carefully investigate the claims made by the seller, and ensure that the products provide an extra measure of safety to the user and not create an additional hazard. All products must meet all regulatory guidelines.

Specialty Ladders:

There are several “combination” type ladders and “articulated” ladders currently on the market that might help in dealing with the issue of not having the “right” ladder for the job. The combination and the articulated ladders are designed to function as many types of ladders, in essence as an “all in one ladder”.

Combination/Articulated Ladders:

There is a variety of combination ladders on the market. An example of this type ladder is the “5-way” combination ladder. This ladder can convert to any of five configurations such as:

- a step ladder;

- a double stepladder (where two persons can climb the ladder, one from each side);

- a stairway ladder;

- 2 single ladders;

- or an extension ladder.

Articulated ladders also provide similar flexibility as combination ladders with a few additional features. The articulated ladder works using a locking hinge system (which varies depending on the manufacturer) that allows the ladder to be maneuvered into a variety of configurations depending on the work need.

Some of the articulated ladders have a telescoping capability that allows the ladder to be height adjusted in relatively small increments. This makes positioning and locating the ladder much easier for a variety of job heights.

Key features of articulated ladders are; they have the ability to fold into a very compact profile, they are easily transported, and some can even fit in the trunk of a moderately sized vehicle.

Folding Utility/Platform Ladders

There are many styles of folding utility/platform ladders currently being manufactured. The folding utility/platform ladder is essentially a cross between a step ladder and a large kitchen utility step stool ladder.

This type of ladder provides a more stable and more comfortable work platform for the individual to stand on. This type of ladder is a good choice for jobs that are going to take an extended time in one position. It allows a person a greater degree of movement while working on the platform portion of the ladder.

One manufacturer’s utility ladder has extra wide steps on all of its levels. When folded, this utility ladder has wheels, located at an angle, which engage for easy movement of the ladder. This helps with transport, so that the ladder does not have to be lifted and carried to each work location. The ladder has an optional safety bar located near the top, for added work stability and security. In the authors opinion the safety bar should not be an option but be a standard part of this ladder due to it’s important added safety benefits.

Ladder Accessories:

There are many types of accessories commercially available that can make working with ladders a much safer venture. Just a few of the large variety of ladder accessories are described in the section below.

Ladder Levelers

Ladder levelers are devices that can be attached to most straight and extension ladders to help level the ladder on uneven ground or for use on steps. There is a variety of design mechanisms available that either manually or automatically adjust and generally bolt to each leg of the ladder.

In using ladder levelers, caution must be taken that the ladder is placed on a solid, stable surface. The ladder levelers are not designed to adjust for soft ground or loose or slippery surfaces.

When choosing ladder levelers, one should take a close look at the structural integrity and design of the leveler. It should match the ladder’s duty type, rating and grade, so that the leveler holds up to the use, and capacity of the ladder to which it is attached. One needs to also look closely at the ladder leveler’s locking mechanism. The locking mechanism needs to be designed so that it is easy for the user to observe that leveler is locked in place. The locking mechanism ensures that the ladder does not slip when weight is applied.

Ladder Stabilizers and Stand-Offs

Ladder stabilizers attach near the top rung of extension ladders or straight ladders and provide additional width stability to the top of the ladder. Both fixed and adjustable span stabilizers are available from ladder sales and distribution sources.

Stand-offs can be used in conjunction with ladder stabilizers. Some units even function in both capacities. Stand-offs move the ladder anywhere from a few inches to 28 inches from the support surface and allows the user to work on overhangs and other extended surfaces. Ladders equipped with stand-offs, can be placed directly over a window to allow the ladder to be centered over the work area. In this way, the worker would not have a need to try to over extend to complete the job and/or would not have to move the ladder to complete the job.

It is important that ladder stabilizers and stand-offs meet the ladder manufacturers guidelines. Most ladder stabilizers and standoffs are made of metal so caution must be taken so that they are not used in areas where electrical hazards exist.

Note: Stabilizers should not be used on ladders longer than 40 feet or in conjunction with ladder jacks. When using stand-offs or stabilizers with stand-offs, extra caution needs to be taken when determining the angle of inclination for the ladder.

Pole, Tree and other Round Object, Ladder Accessories

When there is need to set up a ladder against round or irregular objects there are a variety of ladder accessories that can make working on the ladder much safer.

Fixed V-Rung devices also known as pole grips, are steel bands with a “v” indent in the center of the steel band. Most have a rubber pad riveted to the steel band. Padded fixed v-rung devices are installed at the top of the ladder where the top rung would be located.

This device’s padded section helps provide a slip resistant material to help better grip the pole or round object. V-Rung devices are generally good for poles or round objects that are less than 10 inches in diameter.

Pole Straps, Pole Lashes and Ladder-Cinches are other devices that can be used for varied size poles and round objects.

Pole Straps are similar to the V-Rung devices except they are made of material such as nylon and can be adjusted to fit the circumference of most poles. Pole Straps attach to the ladder just above the top rung and generally have slip-resistant rubber stitched to the strap to reduce movement while resting on a pole.

Pole Lashes are designed for most diameter poles. They attach to the very top of the ladder and wrap totally around the pole, securing the ladder tightly with little chance for movement.

Ladder-Cinches are essentially long, adjustable straps that can be used with almost any ladder and can be attached to poles and other awkward ladder support surfaces. The Ladder-Cinches help keep straight and extension ladders from sliding off or rotating around utility poles or other posts. Ladder-Cinches can be used as tie downs at the top and lower sections of straight and extension ladders.

Conclusions

There are many more types of specialty ladders and ladder accessories than have been described in this Appendix. The goal of all of these tools and accessories is to make ladder-related jobs easier and most of all, safer.

It is very important to remember to check with the ladder manufacturer and/or distributor before adding accessories to any ladder.

Appendix C

Applicable Regulations

Although this particular case was not in WISHA or OSHA’s jurisdiction, (because the victim was the owner of the business involved), there are good safety practices defined by federal and state regulations that are applicable to working at heights and for the use of portable ladders.

In reviewing the WISHA standards, listed below are a few of the standards that could apply to this case:

- Non-self-supporting ladders shall be used at an angle such that the horizontal distance from the top support to the foot of the ladder is approximately one-quarter of the working length of the ladder (the distance along the ladder between the foot and the top support). WAC 296-155-480(2)(e)(i) and;

- Ladders shall not be used on slippery surfaces unless secured or provided with slip-resistant feet to prevent accidental displacement. Slip-resistant feet shall not be used as a substitute for care in placing, lashing, or holding a ladder that is used upon slippery surfaces including, but not limited to, flat metal or concrete surfaces that are constructed so they cannot be prevented from becoming slippery. WAC 296-155-480(2)(g) and;

- Ladders shall be used only on stable and level surfaces unless secured to prevent accidental displacement. WAC 296-155-480(2)(f) and:

- Employees shall not ascend or descend ladders while carrying tools or materials that might interfere with the free use of both hands. WAC 296-155-480(2)(v) and:

- When working from a ladder, the ladder shall be secured at both top and bottom. WAC 296-155-480(2)(v)

* CFOI is a BLS (Bureau of Labor Statistics) cooperative federal/state system to collect information on all fatal occupational injuries of public and private sector workers.

** The OSHA State Plan program in Washington State.

To contact Washington State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Back to Washington FACE reports

Back to NIOSH FACE Web