A Farm Worker on a Family Run Farm in Texas Died When He was Crushed by the Basket of a Cotton Stripper as He Stood in the Engine Compartment of the Cotton Stripper.

Investigation: #99TX02001

Release Date: January 18, 2001

SUMMARY:

On November 11, 1998 a 49 year-old farm worker (the victim) died in Texas when he was crushed by the basket of a cotton stripper as he stood in the engine compartment of the cotton stripper. The victim, who was operating the cotton stripper, had just dumped his load of cotton into a module packer, when, for an unknown reason, he entered the engine compartment beneath the basket. As he stood in the engine compartment, the basket slowly descended, due to a hydraulic leak, and crushed the victim. When the owner arrived, he did not immediately see the victim. The cotton stripper’s engine was still running. As he was about to leave, he decided to take one more look. He then saw the victim’s leg extending between frame members surrounding the engine compartment. After raising the basket, he called Emergency Medical Services (EMS).

The Texas FACE investigator concluded that to reduce the likelihood of similar occurrences, employers should:

- Ensure workers never enter the top of the engine compartment unless the basket is raised over center

- Ensure machinery is checked periodically for leaks or other mechanical defects

- Additionally, the manufacturer should include cautions in the operator’s manual warning operators not to enter the engine compartment unless the basket is in the full over-center position

INTRODUCTION

On November 11, 1998 a 49 year-old farm worker (the victim) in Texas died when the basket of a cotton stripper crushed him as he stood in the engine compartment of the cotton stripper. The regional OSHA office notified the Texas FACE program officer about this fatality. On January 19, 1999, the Texas FACE program officer visited the job site and met with the owner of the farm, where he took pictures of the cotton stripper. He obtained copies of the sheriff’s department report. He also contacted the justice of the peace and obtained a copy of the autopsy report.

The employer was a family-owned farm that employed one worker. The employer had been operating a farm for 50 years. The victim had been employed for 18 years. According to all accounts, the victim was well trained in the operation of the cotton stripper.

The cotton stripper used by the victim was a used machine when purchased by the employer. It did not come with an operator’s manual, but the employer later obtained a manual for use by those operating the machine.

INVESTIGATION

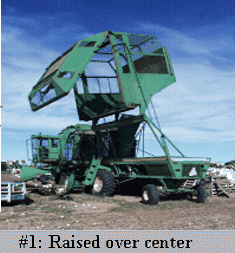

The victim was using a cotton stripper manufactured in 1984. On this particular model the operator’s compartment is located at the front of the machine and the basket is located behind the operator’s compartment, above the engine compartment and fuel tank. The right side of the basket is connected to two hydraulic arms, and the left side of the basket is hinged. The basket is emptied by extending the hydraulic arms which push the right side of the basket upward. The arms are designed to push the basket up and over to where the basket’s center of balance has been transferred to the left side of the machine or the over-center position (see photo #1). When the basket is in the raised position, the top of the engine compartment and the fuel tank are exposed.

The victim started to strip cotton from one of the fields. When he had a full basket, he proceeded to a module builder to dump his load. A module builder packs the cotton down and prepares it to be transported by truck to a cotton gin. After he dumped his load, he exited the operator’s compartment and for an unknown reason stepped into the area above the engine compartment. He was able to get into this area because the basket was still in the raised position but not over center (see photo #2)

While he was in this area, the basket of the cotton stripper slowly descended due to a hydraulic leak. (When the basket is not raised to the over-center position, the weight of the basket is not transferred to a safe position. When the basket is pushed over center, it requires use of the hydraulic system to pull it back and lower it.)

The victim was unaware the basket was slowly descending. Before he could move from beneath the basket, he was pinned between the bottom of the basket and the top of the engine compartment (see photo #3)

When the owner arrived, he did not immediately see the victim. The cotton stripper’s engine was still running. As he was about to leave, he decided to take one more look. He then saw the victim’s leg extending between frame members surrounding the engine compartment. After raising the basket, he called Emergency Medical Services (EMS).

CAUSE OF DEATH

The Justice of the Peace report stated the victim died from suffocation resulting from the tremendous pressure put on his chest from the weight of the cotton basket.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure workers never enter the top of the engine compartment unless the basket is raised over center.

Discussion: According to page 20 of the operator’s manual for this cotton stripper, operators are instructed to “Perform periodic service after every basket dump.” Item 2 on page 34 instructs the operators to clean the engine hood area. Page 36 mentions the necessity for checking the coolant level. In order to perform each of these tasks, the basket must be raised. It is possible for a tall person to perform these tasks without entering the area beneath a raised basket. However, since the side of the stripper is approximately six feet high, a short person would not be able to perform these tasks while standing on the ground. The victim in this incident was 5′ 5″ tall. It is not known why the victim entered the area beneath a raised basket.

Recommendation #2: Employers should ensure that machinery is checked periodically for leaks or other mechanical defects

Discussion: It is unlikely that this incident would have occurred had the leak been repaired. The victim was the sole operator and he performed maintenance as required. It is unknown if he was aware there was a hydraulic leak. The operator’s manual requires the hydraulic oil level be checked every 10 hours. Checking the hydraulic oil level at regular intervals would alert the operator to a possible leak. Also, any hydraulically elevated components without locking detents must be supported by jacks or heavy timber supports.

Recommendation #3: The manufacturer should include cautions in the operator’s manual warning operators not to enter the engine compartment unless the basket is in the full over-center position.

Discussion: When the basket is in the raised position, it is supported by hydraulic pressure. In this incident, the basket was not fully raised and a hydraulic leak allowed the basket to slowly descend. Another possibility that would cause the basket to lower would be a ruptured hydraulic line. Since there are no locks installed or available for this particular model of cotton stripper, the operators must ensure the basket is in the full over-center position before they enter the area beneath the raised basket. Placing the basket in the full over-center position transfers the weight to the opposite side of the engine compartment. In order to lower the basket, the hydraulic system must be used.

The following cautionary measures should be incorporated into the operator’s manual:

- In the lubrication and maintenance section on page 34, under item number 2. Clean engine hood area: “The engine hood area should be cleaned while the operator is standing on the ground. If the area below the basket must be entered while the basket is in the raised position, ensure the basket has been raised to the full over-center position.”

- In the sections on “Operating the Engine” on page 11, item 3 and on “lubrication and maintenance” on page 36, item 7. “The coolant level should be checked and/or coolant added while the operator is standing on the ground. If the check/fill point cannot be reached from ground level, ensure the basket has been raised to the full over-center position before entering the area beneath the raised basket.”

REFERENCES

- Cotton stripper operators manual

ILLUSTRATIONS

Please use information listed on the Contact Sheet on the NIOSH FACE web site to contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Back to NIOSH FACE Web