A Road Construction Worker Was Killed When He Was Run Over by an Asphalt Dump Truck

Oklahoma Case Report: 03-OK-047-01

Summary

A 20-year old road construction worker died on June 20, 2003 from multiple injuries received when a dump truck fully loaded with asphalt backed over him. Five dump trucks loaded with asphalt were preparing to transfer their loads into the asphalt paver. As the first truck unloaded its asphalt, the victim was sent to repair a break in the string line used to guide the paver. The victim was kneeling down to nail the string to the road surface. He was about 10 feet behind the second dump truck, in the driver’s blind spot, and had his back to the truck. As the truck began backing up to the unloading position, at least one other worker in the area heard the back up warning signal. He and another worker saw the hazard, and although they tried to warn the victim, he was run over by the truck’s dual rear tires.

Oklahoma Fatality Assessment and Control Evaluation (OKFACE) investigators concluded that to prevent similar occurrences, employers should:

- Develop and implement a written program that includes policies and procedures regarding the positioning of employees during all phases of the asphalt laying process.

- Employers should consider the use of a spotter to direct vehicles that are backing up in a work zone.

- Employers should implement the use of effective warning devices in work zone areas.

Introduction

A 20-year old road construction worker died on June 20, 2003 from multiple crushing injuries received when a fully loaded asphalt dump truck backed over him. OKFACE investigators reviewed the Occupational Safety and Health Administration (OSHA) Fatality/Catastrophe Report, the death certificate, the Medical Examiner’s report, the Official Oklahoma Traffic Collision Report, and news clippings from local news services. A site visit was conducted on August 22, 2003. OKFACE investigators interviewed the company safety director and the investigating law enforcement officer.

The road construction company had been in business for 31 years and employed 100 people. The victim had worked for the company for a month and a half prior to the incident. There were approximately 20 employees at the site when the incident occurred. The company and the victim had been working at this site for two weeks.

|

| Figure 1. Photo of the Back of the Asphalt Truck |

The company had a comprehensive safety and health program in place, which was administered by the safety officer. Safety meetings were held weekly and attendance was mandatory in order to receive paychecks. On-the-job training was conducted with all new employees, with constant monitoring for compliance with policies and procedures. There was specific on-the-job training conducted on the processes involved in the job the victim was performing at the time of the incident. Monitoring was done by the supervisors at the work site and randomly by the safety officer, either at the site or from a distance by the use of binoculars.

Investigation

On the day of the incident, the weather was clear, the temperature was 90 degrees Fahrenheit, and all working surfaces were dry. The victim had arrived at work late that day, and he had not put on his required orange vest before starting to work. He was not wearing any type of hearing protection.

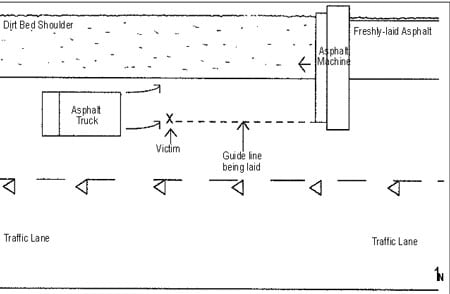

The road construction company was in the process of paving the shoulder of the westbound lane of a recently repaved two lane rural highway (Figure 2). The shoulder was being paved over a dirt surface. The shoulder area was 8 feet wide, and the asphalt paver was 12 feet wide. Thus, the paver guide string, which was necessary for the asphalt paver to use as a guide to maintain a straight path for applying fresh asphalt, had to be nailed 4 feet into the westbound driving lane of the highway. The westbound driving lane was closed, and all traffic was directed to the eastbound lane of the highway using pilot cars and flaggers. Cones were used to separate the redirected traffic lane from the work zone area.

|

| Figure 2. Diagram of Work Zone (not drawn to scale) |

Shortly before 1:00 p.m. on the day of the incident, five dump trucks loaded with asphalt were lined up on the westbound driving lane, waiting to unload into the paver. As the first dump truck unloaded its asphalt into the paver, the victim was sent to repair a break in the paver guide string. The break was located approximately 10 feet behind the second dump truck. The victim was kneeling down, approximately 90 feet west of the paver. Although the company’s safety officer reported training the victim to face the fastest moving vehicle in the work zone (the dump trucks in this case) and to stay outside the string line, he had his back to the dump trucks and was inside the string line as he repaired it. His supervisor was in another area of the work zone, operating another piece of equipment. When the first dump truck moved clear of the work site, the second dump truck driver, who had 10 years of experience, began to back up into position for unloading. The asphalt truck’s back up warning signal was in full operation at 97 decibels, and at least one other person in the work zone reported hearing it. The victim was behind the inside rear dual wheel of the truck in a blind spot that the driver’s mirrors did not cover. One co-worker who noticed the hazard ran toward the victim and yelled to him. The paver operator also yelled and beeped his horn to try to warn the victim. Despite their efforts, the victim was run over by the truck, which was estimated to weigh 27 tons. Employees called emergency medical services immediately.

Cause of Death

The Medical Examiner listed the cause of death as crushing injuries to the head, chest, and abdomen.

Back to Top

Recommendations/Discussion

Recommendation # 1: Employers should develop and implement a written program that includes policies and procedures regarding the positioning of employees during all phases of the asphalt laying process.

Discussion: Employers should establish written training programs, policies, and procedures, including job safety analysis, on all jobs where there is a potential for employees to be exposed to a work-related hazard. In work zone areas, workers on foot should be separated from equipment as much as possible. The work space for dump trucks should be identified and workers on foot should be kept out of this space until the dump trucks have cleared the area. In this incident, the worker was repairing the paver guide string in an area where dump trucks were backing up. This incident may have been prevented if the worker repaired the string when the dump trucks had cleared the work zone area.

Recommendation #2: Employers should consider the use of a spotter to direct vehicles that are backing up in a work zone.

Discussion: OSHA regulations prohibit the use of motor vehicle equipment that has an obstructed view to the rear unless 1) the vehicle has a reverse signal alarm that can be heard above the surrounding noise level; or 2) the vehicle is backed up only when a spotter indicates that it is safe to do so. The vehicle may be used if either of these conditions is met. In this incident, the dump truck did have a reverse signal alarm; however, the alarm alone was not sufficient to warn the victim. In addition to the reverse signal alarm, using a spotter to guide the dump truck as it backed up may have prevented this incident.

Recommendation # 3: Employers should implement the use of effective warning devices in work zone areas.

Discussion: Noise levels at work zone sites where asphalt is being laid are very high, and workers can become desensitized to some of the noises, including back up warning alarms. Effective emergency warning devices that are accessible to all employees and are identifiable above all of the other potential noises in and around a work zone could prevent injury incidents. The emergency warning device could be some type of audible alarm, hand held air horn, or siren. Two-way portable radio communication may also be helpful. Other safety options include equipping vehicles with devices to detect persons or objects behind the vehicle, such as electromagnetic signal detection systems, infrared detection systems, ultrasonic systems, or video cameras to monitor blind spots.

References

- O.S.H.A, 29 CFR 1910.95 Noise Exposure

- O.S.H.A. 20 CFR 1926.601 (b)(4) General Requirements

- O.S.H.A., 29 CFR 1926.602(a)(9) Alarms: Audible

- Manual on Uniform Traffic Control Devices (MUTCD)

- National Safety Council Publication 16001-0000, Controlling and Abating Hazards in Highway Construction.

- National Safety Council Publication 14800-0000, Driving and Work Zone Worker Safety.

- Road Crew Safety, Vista Training, Inc.

- Pratt SG, Fosbroke DE, Marsh SM. Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health (Pub. No. 2001-128).

- National Institute for Occupational Safety and Health. Roadway Construction Worker Dies From Crushing Injuries When Backed Over by a Dump Truck – Virginia. Fatality Assessment and Control Evaluation (FACE) Report Number: 2002-06.

Oklahoma FACE Program

The Oklahoma Fatality Assessment and Control Evaluation (OKFACE) is an occupational fatality surveillance project to determine the epidemiology of all fatal work-related injuries and identify and recommend prevention strategies. FACE is a research program of the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research.

These fatality investigations serve to prevent fatal work-related injuries in the future by studying the work environment, the worker, the task the worker was performing, the tools the worker was using, the energy exchange resulting in injury, and the role of management in controlling how these factors interact.

To contact Oklahoma State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE website. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.