Field Engineer Struck by Vehicle While Painting Highway Markings

|

|

February 5, 2003

Investigation: # 01-NJ-129

On November 2, 2001, a 43-year-old field engineer was killed when he was struck by a truck as he was marking the shoulder of a major highway. The victim was employed by an engineering firm who oversaw the technical aspects of a highway reconstruction project. The incident occurred along a 12-lane toll road as the victim was examining a planned worksite. He had driven to the site alone, pulled onto the 14-foot-wide shoulder of the highway, and walked on the shoulder ahead of his car. As he used a can of spray paint to mark the pavement near a storm drain, he was stuck by a box truck that had intruded into the shoulder of the highway.

NJ FACE investigators concluded that, to prevent similar incidents in the future, these safety guidelines should be followed:

- Employers should provide protective equipment sufficient to protect individuals working on or near a highway.

- Highway authorities should include contract language to ensure protection for all employees working on the highway.

- Employers should institute a traffic control safety plan as outlined in the NIOSH publication Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment.

INTRODUCTION

On November 8, 2001, a county Medical Examiner’s office notified FACE staff of a highway field engineer who was killed in a motor vehicle accident while working on the shoulder of a highway. FACE investigators contacted the employer and received permission to conduct an investigation, which was done on May 1, 2002. At that time, the investigator interviewed the company health and safety officer who provided documentation and photos of the construction project. Additional information was obtained from the police report, the medical examiner’s report, and the OSHA investigation file.

The victim’s employer was an engineering firm that was overseeing the work of a construction and maintenance contractor along a major state toll road. In business for over 100 years, the company employed approximately 12,000 workers throughout the country. The company had a comprehensive written safety and health program. Safety and health policies were carried out by the regional offices, as well as by a safety and health officer who traveled to the various locations.

INVESTIGATION

The incident occurred on the shoulder of a major toll road that passed through an urban area. In January 2002, the highway authority contracted with a construction company to do repairs and resurfacing along a 39-mile-long stretch of the highway. Work was to consist of bridge deck repairs, joint repairs, resurfacing, and related incidental work on the roadway structures. Most of the work was detailed in the contract and traffic permits, which outlined methods and times to set up the highway work zones to minimize disruption to the traffic flow. The victim’s employer had been contracted by the construction company to do the engineering and technical supervision of the project. A field engineer was usually present at the work zones to help determine what areas were to be repaired. An engineer also surveyed the roadway before the crew arrived to determine if any additional work needed to be done. The survey was done at least a week ahead of time in order to include the additional work in the permit needed to work on the highway.

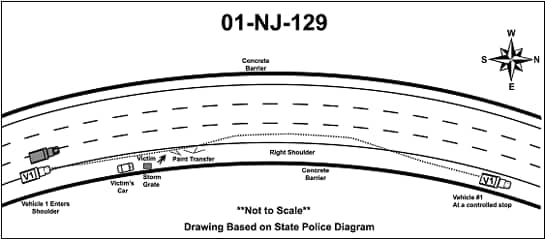

The incident occurred on Friday, November 2, 2001. The weather was sunny and windy with temperature in the 70’s. The victim arrived at 7:00 a.m. for his scheduled shift of 7:00 a.m. to 4:00 p.m. He had worked overtime the night before, supervising a lane closing from 10:00 p.m. to midnight. He spent the morning of the incident with another worker, going on several site inspections and training the employee. He was last seen at lunch before he left on his own to do an inspection of a planned worksite along the highway. The highway he was inspecting was a “dual-dual” design, with two separate roadways going north and two roadways going south. The roadways were arranged so that the two middle (inner) roadways were reserved for cars, while trucks and all other vehicles traveled the outer roadways. Each roadway consisted of a set of three 12-foot-wide traffic lanes with shoulders bordered with concrete barriers. At approximately 1:00 p.m., the victim arrived on site and parked his unmarked white sedan on the 14-foot-wide shoulder of the northbound outer roadway (see diagram). His task was to inspect a planned work site to determine if any additional work was needed. Under the contract, the engineer could authorize additional work “if and where” his inspection found defects requiring repair. The victim left his vehicle wearing a florescent yellow and orange safety vest and walked north, stopping near a storm drain about 30 feet ahead of the vehicle. He then used a can of yellow spray paint to mark the area near a storm grate to instruct the road crew where to start and stop their road milling machine. Except for a flashing amber light in the rear window of his car, the victim did not have any traffic warning devices or other protective equipment at the site.

As the victim was working, a small box-style rental truck with a single occupant approached the site in the right lane of the highway. The police interviewed the truck driver who stated that he saw the victim’s car parked on the shoulder of the road. As he approached the vehicle, the driver reported that a second truck in the center lane began to move into his lane, and he moved right onto the shoulder to avoid it. He saw the victim only a moment before the mirror on the passenger side of his truck struck him. He traveled an additional 1,170 feet (0.22 mile) before pulling onto the shoulder and stopping. He called 911 on his cell phone, and the police arrived within a minute to find the victim unresponsive. Damage was noted to the truck’s passenger side bumper and the extended mirror that struck the victim’s head and upper torso. EMS units arrived and pronounced the victim dead at the scene at 1:45 p.m.

Figure 1: Diagram of Incident Site

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should provide protective equipment sufficient to protect individuals working on or near a highway.

Discussion: This was not a typical highway work zone incident because the short time the victim was in the area did not require setting up signage or other highway warning devices. However, it demonstrates the extreme danger of working on or near a highway, even for a short time. To avoid similar incidents, FACE recommends providing equipment that would protect an individual worker at all times while on the highway. The best option is to use a dump truck equipped with an impact attenuator, flashing arrow or signboard, and clearly visible flashing lights. The employee would work ahead of the truck, which would provide protection from a vehicle intrusion. Other recommendations include:

- Providing a police escort in the area,

- Providing vehicle warning lights that can be easily seen during daylight hours,

- Ensuring the worker is wearing high-visibility clothing,

- Providing signage and traffic control devices if the employees will be working near the traffic lanes, and,

- Having a second employee available to spot traffic problems.

These recommendations only apply in instances when the worker will only be present on the highway for a few minutes. Any extended work requires setting up a highway work zone as described in the US Department of Transportation (USDT) Manual on Uniform Traffic Control Devices. It should be noted that, since this incident, the employer and contractor now require a truck-mounted impact attenuator while engineers are doing field inspections.

Recommendation #2: Highway authorities should include contract language to ensure protection for all employees working on the highway.

Discussion: The highway authority had extensive requirements for working on the highway, including a permit system with specific hours and chores. FACE recommends that the contractors and highway authorities include specific written contractual procedures for protecting employees whenever they are on the highway outside of a marked work zone.

Recommendation #3: Employers should institute a traffic control plan as outlined in the NIOSH publication Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment.

Discussion: NIOSH has recently published a booklet describing a number of highway work zone fatalities and recommendations for reducing injuries in work zones. Designed to be used with the latest edition of the USDT Manual on Uniform Traffic Control Devices, the booklet outlines a number of additional methods to prevent injuries. One measure is a traffic control plan to coordinate the flow of construction vehicles within the work zone. Specific information on the plan can be found in the attached NIOSH publication, Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment, pages 16 to19.

REFERENCES

- Manual on Uniform Traffic Control Devices, Part IV: Standards and Guides for Traffic Controls for Street and Highway Construction, Maintenance, Utility, and Incident Management Operations. US Department of Transportation, 1998. American Traffic Safety Services Association, Fredericksburg, VA (540) 898-5400.

- Building Safer Highway Work Zones: Measures to Prevent Worker Injuries From Vehicles and Equipment. DHSS (NIOSH) publication 2001-128, NIOSH Publications Dissemination, Cincinnati, OH (800) 356-4674. www.cdc.gov/niosh/docs/2001-128/ (Link updated 3/25/2013)

To contact New Jersey State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

|

NJ Department of Health & Senior Services

Occupational Health Service PO Box 360, Trenton NJ 08625-0360 (609) 984-1863

|

|

Back to New Jersey FACE reports

Back to NIOSH FACE Web