Engineering Technician Run Over and Killed by Backing Dump Truck

Nebraska Case Report: 04NE007

Report Release Date: October 26, 2004

Summary

The victim, a 51-year-old male engineering technician, was killed when he was backed over by a dump truck in a roadway work zone. The victim’s employer had subcontracted with a road construction company to provide engineering services throughout the project. The victim entered the work zone behind a dump truck that was backing towards an asphalt milling machine. He bent down to take measurements on the roadway. The truck’s operator did not see the victim. A lady walking her dogs on an adjacent sidewalk saw the victim behind the truck and heard a noise as the truck struck the victim. She ran into the street to alert the operator. The truck operator stopped, pulled forward a few feet and exited the vehicle. Upon seeing the victim lying in the street the truck operator ran to a nearby supervisor, who then called emergency service personnel. The local fire department responded and pronounced the victim dead at the scene.

The Nebraska Workforce Development, Department of Labor’s Investigator concluded that to help prevent future similar occurrences, employers should:

- establish a system to ensure the area behind and adjacent to vehicles and equipment is clear to safely operate.

- ensure that the company has a policy that requires that site supervisors be notified before sub-contracted employees enter the work zone.

- ensure that all employees are wearing appropriate personal protective equipment (PPE).

- ensure that equipment warning devices are adequate.

Program Objective

The goal of the Fatality Assessment and Control Evaluation (FACE) workplace investigation is to prevent future work-related deaths or injuries, by a study of the working environment, the worker, the task the worker was performing, the tools the worker was using, and the role of management in controlling how these factors interact.

This report is generated and distributed solely for the purpose of providing current, relevant education to employers, their employees and the community on methods to prevent occupational fatalities and injuries.

Introduction

On April 21, 2004, at approximately 7:45 a.m., a 51-year-old senior engineering technician died after he was backed over by a dump truck in a roadway construction zone. The Nebraska Department of Labor received notice of the fatality the same day through local news media coverage. The Nebraska FACE Investigator met with the investigating OSHA Compliance Officer (COSHA), and company officials on April 22 & May 17, 2004. Investigating law enforcement personnel were interviewed on May 26, 2004. The mishap site was visited on April 22 & May 24, 2004.

The victim’s employer is a consulting engineering company, doing consultation work on transportation, geo-technical, environmental and civil engineering projects (SIC Code 8711). The company has been in business since 1944. At the time of the incident the company employed 130 personnel in 5 offices, located in 4 mid-western states. The victim was the only employee of the consulting company on the incident site.

The construction company does general road construction projects (SIC Code 1611) and employed approximately 358 personnel during 2003.

Neither company had a previous history of employee fatalities during the past 20 years.

Investigation

Personnel:

Victim: The victim was a 51-year-old male. He had been employed by this company for 28 years, starting off as an engineering technician/draftsman and working his way up to an associate engineer for the past 10 years. His work hours varied depending on weather, construction schedules, etc. He had worked on this construction project for several days.

Victim training: The company the victim worked for had a generic written safety program that did not include requirements for PPE wear. Employees were instructed to follow the safety requirements of the company they were consulting for. In this case, the victim’s company was contracted with the City, but the City had deferred safety requirements to those of the construction company.

Truck Operator: The operator was a 47-year-old female. She had been employed by the road construction company for approximately 4 weeks. She had previously operated dump trucks for 6 years with another company. She has both a state driver’s license and a commercial driver’s license (CDL).

Truck operator training: The construction company has a Safety & Health program detailed in a safety manual. Each employee is given a copy during new-hire orientation and must sign for their copy. Within this manual is the company’s comprehensive vehicle policy, which states that drivers must complete a “Driver’s Vehicle Inspection Report” each day. Each truck operator is given 30 minutes at the beginning of their shift to inspect their truck for numerous items, including reverse lights, backup alarms and highway horns. This information is documented and turned into the Safety Director and/or maintenance personnel. Company documents indicated that the operator inspected the truck that was involved in the incident that morning.

Equipment: The truck involved in the incident was a 1989 Mack dump truck with an empty weight of 21,880 pounds. It had undergone an annual DOT inspection performed by the owning company April 4 through 10, 2004. Documentation showing this inspection and the repairs that were performed was provided to the investigators. There was written documentation showing that the backup alarm was checked during the DOT inspection and that it was working correctly.

Analysis/Synopsis

At 6:30 a.m. the morning of the incident, the truck operator arrived at the company’s vehicle parking area and started her pre-operation checklist. She left the parking area at 7:00 a.m. en route to the job site, arriving at approximately 7:35 a.m.

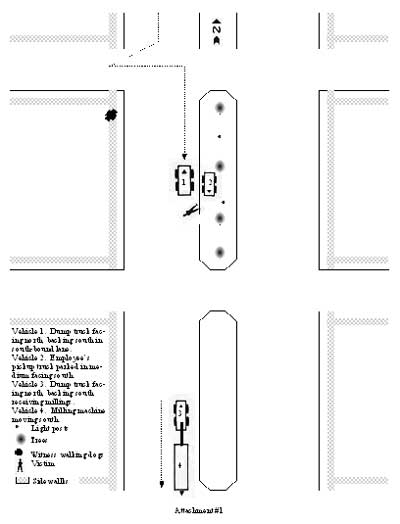

The job site was an inner-city two-lane tree-lined boulevard running basically north and south. Each lane is extremely wide and could accommodate side-by-side traffic if needed. The lanes are separated by a wide grassy median with mature trees and shrubs throughout its length. The old asphalt was being removed by a milling machine moving south in the southbound lane. There was a dump truck being loaded by the milling machine approximately one block south. Both the dump truck and milling machine were in a slow, continual southbound motion. The milling machine operators are the designated spotters for the operation but they only have control over the truck being loaded with asphalt millings, and the next truck in line for loading. (The milling operator would not have been observing the area where the victim and truck driver were located.)

The victim arrived at the job site at approximately the same time the female truck driver arrived. He parked his vehicle on a side street, crossed the southbound lane into the median and walked north, away from the milling machine operation, towards the backing dump truck. He was wearing blue jeans, a dark blue shirt covered by a dark blue lightweight jacket. He was not wearing a hard hat or any type of high visibility clothing. There was an employee’s personal pickup truck facing south parked along the south bound lane’s inner curb in the medium. As the victim reached the front of the employee’s truck he re-entered the southbound lane to perform some measurements. The victim was bent over, using a three foot level and a wooden folding ruler to measure the amount of asphalt that had been removed.

The dump truck operator pulled into the job site approximately one block north of the milling machine, made a three-point turn and started to back towards the milling machine to wait her turn to be loaded. A skid steer operator approached her and had her stop at the intersection so he could dump a bucket of asphalt millings into her truck. She left the truck in reverse while the bucket was dumped. As the skid steer pulled away, she honked her horn and continued to back towards the milling machine. While in reverse, the white reverse lights and the reverse audible signal were activated, and a witness verified later that she could hear the alarm. The truck backs at approximately 5 mph, which equals 7 feet per second. Measurement taken from the intersection to the site where the victim was working was approximately 129 feet. Using this calculation it should have taken approximately 18 seconds to reach the victim.

A lady walking her dogs south along the boulevard’s southbound lane just north of the dump truck witnessed the incident. She noticed the victim step from the median into the area directly behind the dump truck and bend over. She also noticed that the dump truck was backing towards the victim, but assumed he either heard or saw the approaching danger, as his head kept moving up and down, as though he was looking at the approaching truck.

The witness heard a noise as the truck struck the victim. She realized that the truck operator didn’t know she’d hit the victim. The witness ran into the roadway, yelling at the truck driver to stop. The truck driver’s windows were rolled up and she couldn’t hear the witness, but did see her running towards the truck. She stopped and rolled her window down. The witness told her she thought she just ran over someone. The truck driver pulled the truck forward a few feet, exited the truck’s cab and went towards the rear. She saw the victim lying in the street and turned back to the north where she knew a supervisor was located. She was able to flag him down. The supervisor came to the scene, saw the victim, and notified local rescue personnel by calling 911.

Rescue personnel arrived within minutes and pronounced the victim dead at the scene. The truck’s operator was transported to a local hospital for a blood draw as per Department of Transportation guidelines, with negative results. The dump truck was impounded by the investigating law enforcement personnel and the State’s Carrier Enforcement Division was called. The dump truck was examined, with no discrepancies noted that would have affected this incident. Both the reverse lights and reverse audible signal were operating, and it was released back to the construction company.

Cause of Death

According to the death certificate, the cause of death was: Extreme head injuries due to truck-pedestrian accident.

Recommendations/Discussion

Recommendation #1: Establish a system to ensure the area behind and adjacent to vehicles and equipment is clear to safely operate.

Discussion: No employer shall use any motor vehicle equipment having an obstructed view to the rear unless the vehicle has a reverse signal alarm audible above the surrounding noise level, or the vehicle is backed up only when an observer signals that it is safe to do so.

Ref: 29 CFR 1926.601(4)(i-ii)

Workers in highway work zones are exposed to risk of injury from the movement of construction vehicles and equipment within the work zones, as well as from passing motor vehicle traffic.1 Data from the Census of Fatal Occupational Injuries (CFOI) indicate that of the 841 work-related fatalities in the U.S. highway construction industry between 1992 and 1998, 465 (55%) were vehicle or equipment-related incidents that occurred in a work zone. The primary injury source for fatalities of workers on foot struck by a construction vehicle within the work zone were trucks (61%).2

Separate workers on foot from equipment as much as possible by:

- Scheduling work tasks to keep workers on foot out of areas where heavy equipment is in use.

- Channelizing dump trucks leaving the work space and keeping workers on foot out of that channel. Use flexible, colored poles (as used for snow plow markers) or temporary pavement marking inside the work space to mark pedestrian-free areas or flow-of-traffic lines. These delineators should be installed so that the public will not notice or respond to them, but the workers will recognize them as guideposts.

- Train subcontractors, crews, operators, and truck drivers to understand any symbols, markers, and colors used to separate workers on foot from equipment within the work space.

- Design the work space to eliminate or decrease backing and blind spots; when feasible pull trucks in and let the operation catch up to them.

- Train workers on foot and equipment operators in appropriate communication methods (e.g., using hand signals and maintaining visual contact) to be used when workers on foot are required to be in the same area as equipment.

- Train equipment operators never to move equipment without making positive visual contact with any workers on foot near the equipment.

Whenever practical, equipment, worker’s private vehicles, materials, and debris should be stored in such a manner so it will not impede a vehicle operator’s line-of-sight while operating construction equipment. The employee’s personal vehicle that was parked in the median along the inner southbound curb may have hindered the dump truck operator from seeing the victim walking towards her in the median. She was only able to see behind her truck through the use of the door-mounted mirrors, as the dump box obscured her rear vision through the cab’s rear glass.

Recommendation #2: Ensure that the company has a policy that requires that site supervisors be notified before sub-contracted employees enter the work zone.

Discussion: When personnel, especially those that are subcontracted to the project, arrive on the site, the site supervisor needs to be made aware of their presence. This could occur through radio or cell phone communication. This would allow for the discussion of safety related items, such as new site hazards, PPE requirements, etc. Requiring this mandatory “check in” could be a requirement on all future job contracts. Make it part of the company’s safety & health manual, and a mandatory requirement for all sub-contractors. In this incident, the site supervisor was unaware that the victim had arrived at the job site that morning

Recommendation #3: Ensure that all employees are wearing appropriate personal protective equipment (PPE).

Discussion: The employer is responsible for requiring the wearing of appropriate personal protective equipment in all operations where there is an exposure to hazardous conditions.

Ref: 29 CFR 1926.28(a)

All workers exposed to the risks of moving roadway traffic or construction equipment should wear high-visibility safety apparel meeting the requirements of ISEA “American National Standard for High-Visibility Safety Apparel (section 1A.11), or equivalent revisions, and labeled as ANSI 107-1999 standard performance for Class 1, 2, or 3 risk exposure.3

A competent person designated by the employer to be responsible for the worker safety plan within the activity area of the job site should make the selection of the appropriate class of garment and ensure its usage.4

All workers, especially those on foot, need to wear high-visibility safety apparel, i.e. vests, arm bands, hard hat covers, etc. The site supervisor must ensure each employee on the job site, prior to commencing work, is in compliance with both OSHA and company policy.

This clothing should be inspected regularly to ensure that color has not faded and that retro-reflective properties have not been lost. So that workers do not blend into the background, consider seasonal variations in landscape and foliage when choosing colors for worker apparel. Consider using fluorescent garments with retro-reflective material when working under poor lighting conditions. Also consider increasing visibility by using high-visibility arm bands and hats, and vests with strobes.5

The victim was required to follow the written safety rules of the construction company. Although the victim was not wearing high-visibility apparel at the time of the incident, he had been seen wearing a reflective vest the previous evening at the job site. Investigators found two reflective vests in the victim’s company truck after the incident Why he did not wear it this particular day could not be determined.

Recommendation #4: Ensure that equipment warning devices are adequate.

Discussion: All vehicles in use shall be checked at the beginning of each shift to assure that the following parts, equipment, and accessories are in safe operating condition and free of apparent damage that could cause failure while in use: service brakes, including trailer brake connections; parking system (hand brake); emergency stopping system (brakes); tires; horn; steering mechanism; coupling devices; seat belts; operating controls; and safety devices.6

Ref: 29 CFR 1926.601(14)

The dump truck had passed the required annual DOT inspection conducted just prior to this incident. All safety related items were checked and were in working order. The operator conducted the pre-operational checklist prior to moving the truck from its parking location to the job site. Again, all lights and audible signals were working. Witnesses stated that they heard the back up alarms working on the dump truck just prior to the incident, and when Carrier Enforcement inspected it shortly after the incident, all were operating properly.

It can not be determined why the victim did not move away from the approaching dump truck. One possible scenario is that he may have become complacent to the warning devices in use, being exposed to the same warning signals/tones every day.

There are other options available for construction equipment, vehicles and employees. Some of these are:

- Hard hat mounted mirrors. These are similar to those worn by bicyclists. They allow the worker to have some rear vision to possibly see approaching hazards.

- Changing the audible tone on equipment. This can be done using either mechanical or electrical warning devices. Workers that are exposed to the same warning tones every day may tend to become complacent when these audible signals are used. Changes every so often may help to alleviate this.

- Parabolic mirrors. The use of parabolic mirrors on construction equipment and vehicles, similar to those used on school buses, allows the operator to view what is directly behind their vehicle. These mirrors normally produce a “fish-eye” type view, which must be taken into consideration when judging distances between a vehicle and the obstacle.

- Ultrasonic backup sensing system. These devices attach to the left and right rear of trucks, and wired to either the left or right back up light, allowing it to only function when the vehicle is in reverse. The device emits an audio warning and sends a wireless signal to a video display to indicate in feet and in tenths of feet how close the vehicle is getting to the obstacle. The audio alerts and the red-flashing video display warning begin at about 6 feet and continue as the distance decreases to the obstacle. The audio warning becomes continuous when the video display indicates the distance to be one foot and/or less from the obstacle.

- Reverse camera systems. These are normally mounted near a rear license plate and have a wide angle lens (up to 120 degrees cone of vision), and a visibility range of 165 feet. These are similar to ones used on larger recreational vehicles.

References

- National Institute For Occupational Safety & Health, Building Safety Highway Work Zones – Measures to Prevent Worker Injuries from Vehicles and Equipment, April 2001, pg. ix.

- National Institute For Occupational Safety & Health, Building Safety Highway Work Zones – Measures to Prevent Worker Injuries from Vehicles and Equipment, April 2001, pg. 5.

- National Institute For Occupational Safety & Health, Building Safety Highway Work Zones – Measures to Prevent Worker Injuries from Vehicles and Equipment, April 2001, pg. 22.

- U.S. Department of Transportation Federal Highway Administration, Uniform Traffic Control Devices (MUTCD), Section 6D.03, Worker Safety Considerations, November 20, 2003 edition.

- National Institute For Occupational Safety & Health, Building Safety Highway Work Zones – Measures to Prevent Worker Injuries from Vehicles and Equipment, April 2001, pgs. 12-13.

- 29 CFR 1926, Occupational Safety and Health Standards for The Construction Industry, 2003 Edition.

Attachments

|

|

Site diagram (not to scale).

|

|

| Mishap site looking south. Note dotted line showing location of parked pickup truck and arrow indicating victim’s location when struck. |

|

|

Milling machine discharging asphalt residue into waiting dump truck.

|

|

|

Side view of incident dump truck.

|

|

|

Rear view of incident dump truck.

|

To contact Nebraska State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.