Trucker Crushed by Irrigation Pipe

June 23, 2003

Nebraska FACE Investigation 03NE003

SUMMARY:

A 39-year-old male truck driver was killed when a bundle of plastic irrigation pipe he was securing slipped, striking him in the head. A forklift operator placed four bundles of pipe onto the victim’s semi-trailer bed. The victim threw four fabric “gut straps” across the pipe to secure these bundles but did not tighten them. The forklift operator placed four more bundles directly on top of the bottom four and left to load another truck. The victim tightened the first strap closest to the cab on the driver’s side, then moved to the next strap. While using a torque bar to tighten the strap, the movement of the bottom bundle caused the upper bundle to slide off, striking the victim in the head, landing on top of the victim from the waist up. Approximately 15 minutes later the forklift operator noticed the bundle missing and laying on the ground and went to his supervisor’s office and reported the incident. The supervisor ran out to the yard, assessed the situation and ran back into his office to call 911. Local emergency personnel responded and transported the victim to a local hospital where he was pronounced dead.

The Nebraska Workforce Development, Department of Labor’s Investigator concluded that to help prevent future similar occurrences, employers should:

- ensure that all employees are trained according to applicable regulations in the safe use of powered industrial trucks.

- ensure that employees abide by written/verbal policies regarding the proper loading/securing of product.

- ensure that employees are able to communicate required safety information in a language/method understandable to all parties involved.

PROGRAM OBJECTIVE:

The goal of the Fatality Assessment and Control Evaluation (FACE) workplace investigation is to prevent future work-related deaths or injuries, by a study of the working environment, the worker, the task the worker was performing, the tools the worker was using, and the role of management in controlling how these factors interact.

This report is generated and distributed solely for the purpose of providing current, relevant education to employers, their employees and the community on methods to prevent occupational fatalities and injuries.

INTRODUCTION:

On February 27, 2003, at approximately 08:20 a.m., a 39-year-old male truck driver died after being struck and crushed by a load of plastic irrigation pipe he was securing to his semi-trailer. The Nebraska Department of Labor was notified of the fatality the same day by the Occupational Safety and Health Administration (OSHA). The Nebraska FACE Investigator met with the investigating OSHA Compliance Officer (COSHA), company officials and insurance representatives on February 28, 2003 at the mishap location.

The victim’s employer is an over-the-road trucking company (SIC 4213/NAICS 484121). The company has been in business for 26 years. At the time of the incident the company employed approximately 40 “company” over-the-road operators, and 40 more independent owner/operators. The company was in the process of creating a written safety and health program at the time of the incident. The employer had no previous history of fatalities similar to this incident.

The incident occurred at a facility that manufactures plastic piping (SIC 3084/NAICS 326122). The company has been in business since 1968 and now has 500 employees located at six different sites throughout the United States. This site has 86 employees. The production portion operates seven days per week, 24 hours per day. The “yard” would normally load 50 trucks per day, Monday through Friday.

INVESTIGATION:

Victim: The victim was a 39-year-old male. The trucking company had employed him since December 19, 2001 as a driver. He did possess a current commercial driver’s license (CDL). He had hauled this type of pipe before on four occasions, but it could not be confirmed if he had hauled from this particular site. The victim’s primary language was English. The company’s representatives did not believe he spoke Spanish.

Training: The company had both written and video training procedures on how to load and secure different types of pipe. Each driver was required to watch a commercially produced safety video, which included loading techniques and also was given a company handout that detailed company policies of loading, securing and transporting all different types/sizes of pipe. The victim had watched the tape and reviewed the handout. All training was documented and those were provided for the investigation.

Truck: The tractor was a Kenworth conventional unit with a flat bed trailer. Both appeared to be in good mechanical condition.

Forklift Operator: The forklift operator had worked for the pipe company for 8 years, operating forklifts that entire time. His primary language was Spanish, but he could speak some very limited basic English.

Training: All new employees undergo a week’s worth of orientation training, consisting of portions of the OSHA required Powered Industrial Truck training. The operator had received the available training.

Forklift: This was an “Eagle Picker” manufactured by CAT, Model R80, Type D. It had a lift capacity of 8000 pounds with a 24″ depth and 192″ height capacity and was suitable for the task intended.

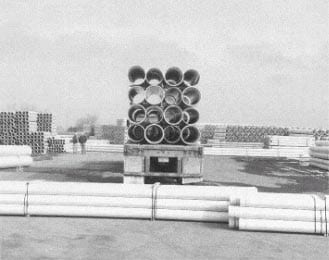

Pipe: The incident pipe was 21″ in diameter. Each section was 20′ 10″ long and weighed approximately 260 pounds each. Each pipe has a “wide” end and a “tapered” end. The “wide” end is slightly larger in diameter than the tapered end but both are perfectly round. For this size diameter, four pipes are placed together to form a “bundle”. Two pipes (wide & narrow end side-by-side) are laid on hardwood dunnage that is rounded out on top so the pipes fit exactly. Two more pieces of dunnage are placed on top of the bottom two pipes and the third and fourth pipes set on these (wide & narrow ends exactly opposite of the pipes below). The four are then wrapped on each end with metal banding/strapping tape. The entire four-pipe bundle weighs approximately 1100 lbs. when assembled and is four feet wide by four feet high.

ANALYSIS/SYNOPSIS:

On the morning of the incident the victim was waiting to load at 07:15 a.m. along with two other trucks when the storage yard personnel arrived. Two forklift operators checked their industrial trucks out, then proceeded to pick up load orders.

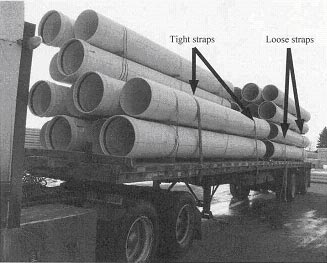

The forklift operator loaded four bundles of pipe on the victim’s flat bed trailer. There had been recent snowstorms that had moved through the area. While interviewing the forklift operator using a company provided interpreter, the operator stated that the bottom layer of pipes did not have any snow or frost accumulation. Pictures taken the same day of the incident show that the bottom layer still had snow on top of the pipes. (See attachment #1). When the operator left to get the fifth bundle from a nearby pile, the victim threw four restraining straps over the bundles.

The pipe company teaches proper loading/securing techniques for different sized pipe/load configurations during their forklift operator’s initial training. This size of pipe required the first four bundles be loaded, then the truck driver must throw the “gut straps” over the bundles and “hand tighten” them before the next load is placed on top. This is intended to prevent the bottom bundle from sliding or shifting during placement of the top bundle. Once the top four bundles are in place, four more straps would have been thrown across the upper layer and securely tightened down. After tightly securing the top layer, the bottom layer that had been “hand tightened” would be securely re-tightened.

The truck driver had thrown the four straps across the bottom bundles, but did not “hand tighten” them before the operator returned with the next load. Pipe company training for the forklift operators require the operator to not place the next load on top prior to ensuring the driver has “hand tightened” the gut straps, which he did not. Instead of informing the truck driver to hand tighten the straps he proceeded to place that first upper bundle, leave and return three more times before exiting the area to load another truck. He stated during the initial interview that all of the bundles had their retaining/banding straps in place.

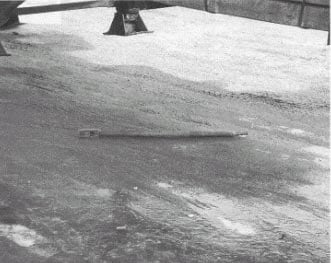

Evidence indicates that once all eight bundles were in place, the victim began to tighten the bottom gut straps, starting with the one closest to the cab. As the strap tightened, it was being pulled towards the victim. The first strap was cinched down extremely tight using a three foot “torque bar”. As the victim tightened the bundle, it caused the pipe closest to him to “oval out” slightly (see attachment #2). During the investigation the outside pipe, driver’s side of the trailer on the front bundle was measured. It showed that the pipe, due to the tension of the front “gut strap”, now measured 22″ horizontally and 20″ vertically at dead center. The victim proceeded to tighten the second strap on the forward bundle. As he did, this again caused the bottom bundle to pull slightly downward and toward him.

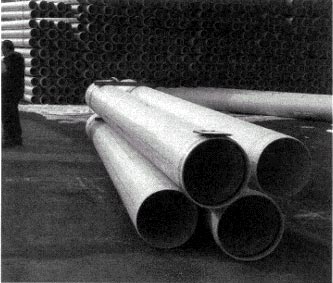

It is believed that this motion and change in shape of the bottom bundle, along with the metal strapping acting similar to a sled runner, allowed the unsecured top bundle to slide off, striking the victim in the head. The victim fell, landing on his back beside the truck. As the bundle fell to the ground, it rotated half way over, landing on the victim from his waist up.

Approximately 15 minutes later the forklift operator stated he noticed there was a bundle missing from the top of the load, and went towards the truck to investigate. He stated he saw the pipe lying on the ground and went to the yard supervisor to ask why. The yard supervisor stated that he couldn’t make out what the operator was saying for sure, but knew it was about pipe and the victim’s load. He went out into the yard and got within 100 feet of the incident site and saw the victim covered with pipe.

He ran back inside the office and called 911. He told both forklift operators to get back to the site and get the pipe removed from the victim so they could perform first aid. Company personnel along with another truck driver performed first aid until local emergency personnel arrived on scene and transported the victim to a local hospital where he was pronounced dead.

There were no witnesses to this incident.

CAUSE OF DEATH:

According to the death certificate, the cause of death was: Closed head injury.

RECOMMENDATIONS/DISCUSSION:

Recommendation #1: ensure that all employees are trained according to applicable regulations in the safe use of powered industrial trucks.

Discussion: Effective March 1, 1999 OSHA changed the training requirements as they pertain to industrial truck operators. This training is very specific, requiring training on 13 separate items pertaining to truck-related topics and 9 separate items that pertain to workplace-related topics. The composition of loads to be carried and load stability, load manipulation, stacking and unstacking and unique hazardous conditions that could affect safe operation must be trained, that training verified by a competent trainer, and the training documented. Initial re-training of the operator should have been completed by December 1, 1999.

Suggestion: The company needs to evaluate its current industrial truck training program, make those changes necessary to re-train all present and future operators, and ensure that re-evaluation of operator’s qualifications meet the written OSHA requirements.

(Ref. 29 CFR 1910.178)

Recommendation #2: ensure that employees abide by written/verbal policies regarding the proper loading/securing of product.

Discussion: The forklift operator had been verbally trained to ensure that all truck drivers, when loading this configuration of pipe, must “hand tighten” the bottom layer down prior to the next layer being laid on top. Interviews conducted with other company employees indicated that this was not an uncommon event to have top bundles of pipe slip off, even when no moisture was present. During initial training, forklift operators, when starting to load trucks in the yard, start with the simpler loads and work their way up to the more complex, although the flexibility of this type of pipe makes all loading somewhat difficult, even for the more skilled.

Recommendation #3: ensure that employees are able to communicate required safety information in a language/method understandable to all parties involved.

Discussion: The victim had hauled this type of pipe at least four times before from this company, but it could not be confirmed if it was from this site. During interviews with the victim’s company safety representatives, they stated the video and written handouts that the victim trained on covered many different types/sizes of pipe. The handout did show a basic plastic pipe load configuration similar to the incident pipe, and showed the bottom gut straps being placed across the load prior to placing any top load. It did not state in writing that the bottom should be “hand tightened” prior to placement of the top load.

Suggestion: The trucking company needs to ensure the step of “hand tightening” is included (in writing) in all training materials and that all drivers are briefed on the new proper procedures.

The forklift operator spoke very limited basic English, and the truck driver spoke no Spanish. The operator, during the interview the day after the incident, could not remember which side he loaded the first top bundle from, so may not have seen the unsecured bottom bundles while placing the first and/or second top bundles. However, when he loaded the two bundles on the driver’s side of the trailer, he should have seen the unsecured straps and stopped loading until they were secured. If communication between an operator and driver is an issue, especially when it relates to safety, a method should be developed to ensure proper safe loading procedures are followed by both.

Suggestion: The pipe company needs to develop a single page handout with diagram(s) showing proper tie-down procedures for different load configurations that could be given to truck drivers when they first arrive at the yard. Retrain all forklift operators to ensure they are familiar with proper tie-down procedures to ensure unsafe loads are not created.

ATTACHMENTS:

Picture #1 taken day of incident showing snow on top of pipes.

Picture #2 taken day after incident showing four gut straps.

Picture #3 taken day of incident showing victim’s approximate location when found.

Picture #4 taken day after incident showing torque bar used on gut straps.

Picture #5 taken day after incident showing rear view of pipe configuration.

Picture #6 taken day after incident showing bundle that struck victim.

To contact Nebraska State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.