Two Electricians Die When A Bolt Bin Falls 8 Floors At Construction Site

MN FACE Investigation 98MN06301 and 98MN06302

DATE: June 7, 1999

SUMMARY

On the day of the incident, a 46-year-old worker and a 49-year-old worker (victims) died of injuries sustained when a large bolt bin fell at a commercial construction site. The victims worked as electricians for an electrical company that was subcontracted to complete the electrical work on an office tower complex that was under construction. The two victims were working on the sixth floor of a planned 30 story tower when they were struck by an ironworkers’ bolt bin that fell from the eighth floor of the building. The bin was resting directly on steel decking, rather than having its weight distributed over two structural beams which was the usual procedure. Shortly before the incident occurred, a construction crane was used to assist ironworkers who were setting a structural column for the ninth and tenth floors. The column had been previously raised from ground level and placed in a horizontal position on the eighth floor decking. The lower end of the column was near a seam in the decking rather than in a central portion of the decking that provided a safer location for heavy materials. During the lifting process, the lower end of the column slipped off pieces of wood that had been placed on the steel decking to prevent it from slipping. The column punctured the eighth floor decking and dropped approximately seven feet. The column swung from the crane’s cables and bent a structural beam that supported the ends of the decking on which the bolt bin was sitting. The ends of the decking sheets fell from the beam as a result of the beam being bent. The bolt bin and it’s contents fell through the eighth floor decking and continued to slam through each of the lower floors until it reached the first floor. The two victims who were working directly beneath the falling bin were apparently struck by it and also fell to the first floor. Emergency medical personnel were immediately called and pronounced the victims dead at the scene. MN FACE investigators concluded that, in order to reduce the likelihood of similar occurrences, the following guidelines should be followed:

- employers should ensure that heavy items placed on preliminary flooring are placed over structural beams that can adequately support the weight of the items;

- employers should ensure that heavy construction materials, whenever possible, are only raised to elevations as they are needed; and

- employers should ensure that construction materials “such as columns” are placed in the safest locations available if they cannot be stored on the ground.

INTRODUCTION

On December 3, 1998, MN FACE investigators were notified of a work-related fatality that occurred on December 2, 1998. Employer interviews with MN FACE investigators were conducted on January 15, 1999 and on February 22, 1999. During MN FACE investigations, incident information is obtained from a variety of sources such as law enforcement agencies, county coroners and medical examiners, employers, coworkers and family members.

On the day of the incident, two electricians died when an ironworkers bolt bin fell eight floors at a commercial construction site. The electricians were part of a large construction crew of primary contractor workers and various subcontractor workers that were working at the site of an office tower complex in a major metropolitan area. When completed, the planned office complex will consist of a 15 story tower and an adjacent 30 story tower with a total area of approximately one million square feet. Construction of the 3 year project began at the site approximately six months before the incident. The general contractor has been in business for 60 years. The number of employees employed by the general contractor is in the range of 200-499 [1]. In addition to workers employed by the general contractor, up to 150 employees of 25 subcontractors worked at the site. On the day of the incident, 35 employees of the general contractor and 65 workers employed by subcontractors were working at the incident site.

During the past 12 years two ironworkers that were employed by subcontractors of the primary contractor were fatally injured at industrial construction sites. The primary contractor, who has a comprehensive safety program that was developed to exceed federal requirements, was in charge of overall safety at the site of this incident. The general contractor employs a full-time safety coordinator who is responsible for daily monitoring of the site for unsafe conditions.

INVESTIGATION

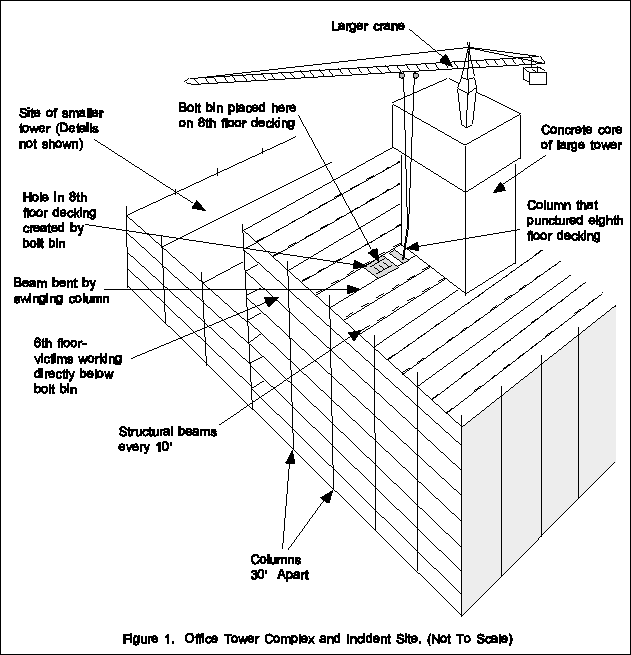

During the months prior to the incident, construction work at the site of a proposed thirty story office tower had progressed from below ground level up to the eighth floor. Above ground construction was completed in accordance with established industry procedures whereby two floors of the tower’s structural steel framing were completed and covered with steel decking before framing was begun on the next two floors of the building. The tower’s basic structural framing consisted of vertical columns spaced 30 feet apart and a grid of horizontal beams every 13 feet to create the floors of the tower (See Figure 1). Structural cross beams for each floor extended the width of the building and were installed every 10 feet beginning at the outer edge of the tower. These cross beams were connected by shorter structural beams to form a non-uniform structural grid versus a uniform 10 foot by 10 foot grid. While the ironworkers continued to successively build the structural framing of each additional two floors of the towers, other workers worked on lower level floors that were protected from falling materials by steel decking installed on floors above them.

Two fixed mast construction cranes were used to lift construction equipment and materials from ground level to the various working levels at the site. One crane was positioned along the outer edge of the smaller tower and a second larger crane was centrally located within a concrete core (Figure 1) of the 30 story tower. Construction of the concrete core progressed ahead of the structural framing for the office towers. At the time of the incident, the core extended 60-70 feet above the eighth floor of the larger tower. The larger crane had a horizontal boom that was capable of being rotated 360 degrees and extended 142 feet from the crane’s mast. It had a lift capacity that ranged from 15,430 pounds at the end of the boom to a maximum of 26,450 pounds at a distance of 85 feet or less from the center of the crane mast. At the time of the incident, the vertical distance from the eighth floor to the boom of the large crane was approximately 100 feet.

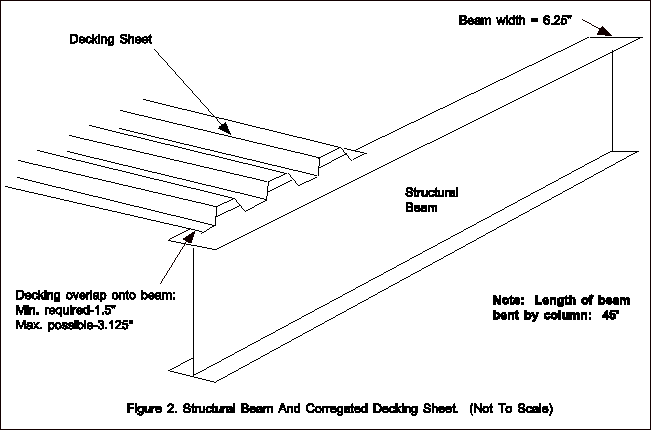

After the horizontal steel beams of the individual floors were assembled, each floor was covered with sheets of corrugated steel decking. Most of the steel decking was comprised of individual sheets that were 30 feet long by 3 feet wide. When installed, the side edges of the sheets overlapped to form the initial working surface for each floor. The decking was delivered to the site in bundles of 15 sheets that were identified by a bundle number and designated for specific areas of specific floors of the towers. When installed, each bundle covered a 30 feet by 45 feet section or area of an individual floor. The sheets of decking were not staggered when they were installed nor was the installation of individual bundles of decking offset in any manner. This resulted in seams at the ends of the decking every 30 feet from the outer edge of the tower with the seams at every third structural beam of each floor. This is a standard method of decking installation used within the construction industry. Although this method results in continuous end seams above certain structural beams versus random seams scattered throughout each floor, it results in 30 feet by 45 feet areas on each floor that do not contain any seams between the ends of the sheets of decking. The central portions of these areas provide safer locations for the placement of heavy materials and equipment than would exist if the sheets were staggered resulting in a random scattering of three foot seams at the ends of the decking sheets. In addition, construction standards do not require the ends of the sheets to extend to the center of the structural beams but are only required to overlap a minimum of 1.5 inches onto the beams (Figure 2).

During construction, as the ironworkers completed the structural portions of each additional pair of floors, equipment and structural materials were raised from lower floors or the ground and placed on the top most floor. Structural columns for the next two floors were routinely placed horizontally at various locations on the decking of the top floor. The decking was protected from damage by the heavy columns by pieces of 2 inch and 4 inch thick wood known as dunnage in the construction industry. Before columns were laid on the decking, pieces of wood were placed in the grooves of the decking. Additional pieces of lumber were then laid perpendicular across the wood in the grooves of the decking. When the ironworkers were ready to begin framing the next two floors, the crane was used to lift one end of the structural columns to attain a vertical orientation for each individual column. After being raised vertically, each column was connected to an existing column of the completed framing of the lower floors. As the columns were raised to a vertical position, the wood (dunnage) prevented the lower end of the columns from slipping until the column was completely lifted from the floor and suspended by the crane.

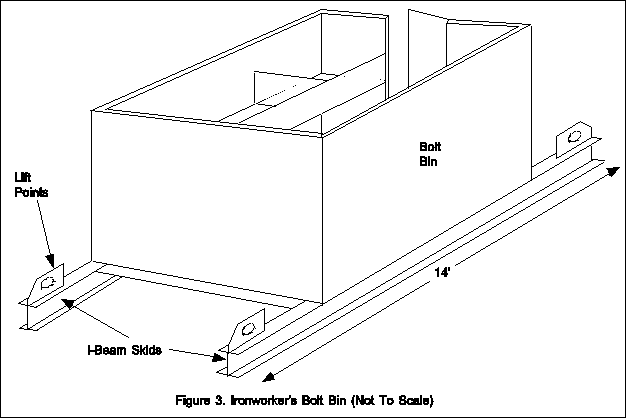

On the day of the incident, an ironworker’s bolt bin had been placed on the eighth floor of the planned thirty story tower. The bolt bin (Figure 3) had been fabricated for the construction project to provide bolts and other small items that the ironworkers used to assemble the steel framing of the office towers.

The bin was 8 feet long and was mounted on two I-beam skids that were approximately 14 feet long. The skids were long enough so that when the bin was placed on a floor of the office towers, the skids would extend across two of the parallel structural beams that were spaced 10 feet apart on each floor. On the top side of each end of both skids, a steel plate containing a circular hole was welded to provide four lift points. The bin was periodically filled with bolts at ground level and lifted by the crane to the floor where the ironworkers were working. The bin and it’s contents weighed approximately 9000 pounds when it was full. At the time of the incident, the combined weight of the bin and it’s contents was approximately 6000 pounds.

During each day of construction, the bolt bin was routinely moved several times to various locations to accommodate specific work being done by the ironworkers. When it was last moved prior to the incident, it was not placed with its I-beam skids extending across two of the 10 feet apart parallel structural beams but instead was rotated 90 degrees and placed on the eighth floor decking with it’s skids parallel to the beams. This resulted in the entire weight of the bin and it’s contents resting “directly” on only the steel decking and not directly over two structural beams. In addition, the bin was placed near a 45 foot long seam in the steel decking (See Figure 1).

Shortly after 9:00 a.m. on the day of the incident, ironworkers on the eighth floor of the large tower prepared to set one of the structural I-beam columns for the ninth and tenth floors. The column was 26 feet long, had a cross section 18 inches square and weighed 10, 800 pounds. The column had previously been placed on the eight floor decking near one side of the concrete building core. One end of the column was near a 45 foot long seam in the steel decking and nearly directly above one of the eighth floor structural beams (See Figure 1). The crane operator, via radio instructions from ironworkers on the eighth floor, positioned the crane’s lift hook above the other end of the column and the ironworkers hooked the column to the crane. The crane operator could not see the column as it was raised to a vertical position and relied on instructions via radio communication from the ironworkers to operate the crane during the lift. While the column was lifted, the crane operator slowly rotated the crane boom to his right and extended or trolleyed out the lift cables along the crane boom. These two movements were necessary to maintain the lift cables nearly vertical as the column was lifted. Normally, during the lifting of the columns, direct contact between the lower end of the column and the wooden dunnage prevented the column from slipping.

When the column approached a nearly vertical position, the lower end of it slipped from the dunnage and the column punched through the decking (See Figure 1) near one of the parallel eighth floor beams. The column dropped approximately seven feet before the attached cables stopped it’s fall. It swung nearly ten feet to the right and created a three foot by ten foot hole in the decking before swinging to the left and striking the beam that supported the ends of the decking sheets that the bolt bin was on. The force of the swinging column bent the beam causing the ends of the decking sheets to fall from the beam. The bolt bin and it’s contents fell through the eight floor decking and continued to slam through each of the lower floors until it reached the first floor. The two victims who were working on the sixth floor directly beneath the falling bin were apparently struck by it and also fell to the first floor. Emergency medical personnel were immediately called to the scene and arrived shortly after being notified of the incident. The victims were removed from the scene and a county medical examiner determined that both victims died within moments of falling to the ground floor with the bolt bin.

CAUSE OF DEATH

The cause of death listed on the death certificates was multiple blunt force and crushing injuries resulting from fall from height (6 stories) with subsequent impact by falling object.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that heavy items placed on preliminary flooring are placed over structural beams that can adequately support the weight of the items.

Discussion: During new construction at large commercial construction sites, the use of corrugated steel decking provides preliminary flooring which allows workers to be able to work while structural framing continues above them. The steel decking, which eventually becomes part of each level’s permanent floor, was installed to provide a surface for workers to walk on as well as to protect workers on lower levels from falling materials. If materials that exceed the load bearing capacity of the decking must be placed on the decking it is necessary to place them over structural beams that can adequately support their weight. The ironworkers’ bolt bin involved in this incident was mounted on two I-beam skids that were long enough so that when the bin was placed on a floor, the skids would extend across two of the parallel structural beams. On the day of the incident, the bolt bin was not placed with its I-beam skids extending across two parallel structural beams, but instead was rotated 90 degrees and placed on the eighth floor decking with it’s skids parallel to the beams. If the bin had been rotated 90 degrees and had been placed with its skids over structural beams, rather than having its entire weight resting directly on only the steel decking, the bin probably would not have fallen and these fatalities would have been prevented.

Recommendation #2: Employers should ensure that heavy construction materials, whenever possible, are only raised to elevations as they are needed.

Discussion: Heavy construction materials that are used in new construction should be kept at ground level and raised to elevations as they are needed, rather than temporarily stored at elevations. The employer in this incident changed their policy on where the structural columns are placed before they are set in their permanent position. Prior to this incident, due to space constraints on the ground,� the structural columns were raised and placed on the steel decking before they were set in their permanent position by the crane. After the incident, the structural columns were kept at ground level and raised only when they were ready to be set. In this incident, if the structural columns had not been temporarily placed on the decking before being set in their permanent position, these fatalities may have been prevented.

Recommendation #3: Employers should ensure that construction materials “such as columns” are placed in the safest locations available if they cannot be stored on the ground.

Discussion: During new construction, as discussed earlier, the use of preliminary flooring, (i.e. steel decking) allows workers to work at lower levels while structural framing continues above them. The corrugated steel decking, which eventually becomes part of each level’s permanent floor, is installed to provide a surface for workers to walk on as well as to protect workers on lower levels from falling materials. The decking, is installed in a manner that results in continuous seams at the ends of the sheets every 30 feet from the outer edge of the building with seams at every third structural beam of each floor. Although this method results in continuous seams above certain structural beams versus random seams scattered throughout each floor, it creates 30 foot by 45 foot areas on each floor that do not contain any seams between the ends of the sheets of decking. The central portions of these areas may be safer than the areas near the seams for the placement of heavy materials and equipment. In this incident, the structural column was placed horizontally on the eighth floor decking with the bottom end of the column near a 45 foot long seam in the steel decking rather than in a central portion of the decking. If the column had been placed with its lower end in a central area of the decking, the decking may not have collapsed when the structural beam was bent and these fatalities may have been prevented.

[1] The following employment ranges, 1-4, 5-19, 20-49, 50-99, 100-199, 200-499, 500 or more are used to provide greater employer confidentiality.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.