Truck Driver Dies From Injuries Sustained After Falling From A Truckload of Sheetrock

Minnesota FACE Investigation 95MN00801

SUMMARY

The victim was working alone at the time that the unwitnessed incident occurred. As a result, this report is based upon information obtained during the site investigation interview, an inspection of the incident site, and a telephone interview with the employer’s safety director.

A 61-year-old male truck driver (victim) died of injuries sustained when he apparently fell from the top of a semi-truck load of sheetrock. The victim was delivering the load of sheetrock to a retail lumber company. He arrived before any of the lumber company employees arrived for work and parked the truck in a gravel parking lot directly in front of a locked yard gate. He untied a tarpaulin that covered the load and removed it from the front portion of the load. The victim may have climbed on top of the load to remove the tarpaulin since it had been pulled back from the left front corner of the load toward the right rear corner. Apparently while he removed the tarpaulin, he fell to the gravel parking lot. An employee of the lumber company discovered the victim shortly after he arrived for work and heard the victim’s call for help. The victim was found along the right side of the trailer (when facing the front of the truck) near the location of the rear axles. Emergency medical personnel were immediately called and arrived at the scene a short time later. The victim was transported to a local hospital where he died nine days after the incident. MN FACE investigators concluded that to reduce the likelihood of similar occurrences, employers should:

- ensure that flatbed semi-trailer load covers are removed from the ground; and

- design, develop, and implement a comprehensive safety program.

INTRODUCTION

On March 26, 1995, MN FACE investigators were notified of a work-related fall fatality that occurred on February 13, 1995. The victim sustained severe head injuries during the incident and died nine days later on February 22, 1995. A site investigation was conducted by MN FACE investigators on April 6, 1995. During the site investigation, information concerning the incident was provided by the manager of the lumber yard where the incident occurred. The employer’s safety director provided additional information during a telephone interview with a MN FACE investigator.

The employer in this incident was a freight trucking company that had been in business for 45 years. The company employed approximately 400 truck drivers and 100 office employees. The victim was an experienced truck driver who had worked for the trucking company for 33 years. During his years of employment he made many similar flatbed trailer deliveries as part of his assigned responsibilities. The employer had a safety director who was responsible for safety programs and procedures. Safety meetings were held quarterly for the company’s truck drivers. All truck drivers were “requested” to attend all safety meetings and were “required” to attend at least two meetings every year. The employer did not have written safety procedures for the removal of tarpaulins that are used to cover loads on flatbed trailers.

INVESTIGATION

The victim was working alone at the time that the unwitnessed incident occurred. As a result, this report is based upon information obtained during the site investigation interview, an inspection of the incident site, and a telephone interview with the employer’s safety director.

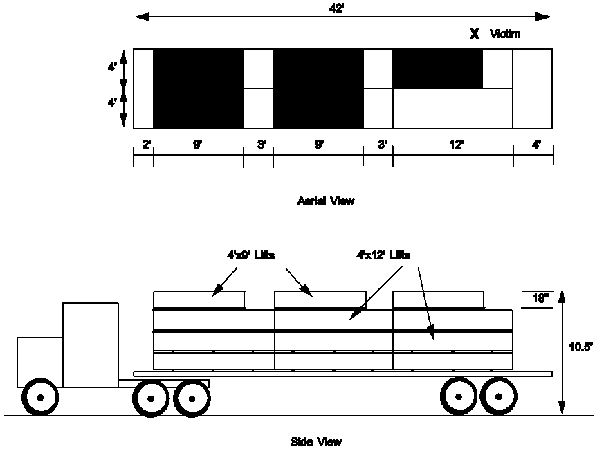

The victim delivered a semi-truck load of sheetrock to a retail lumber company. The flatbed trailer was approximately 8 feet wide and 42 feet long. The truck load consisted of 23 “lifts” or individual stacks of sheetrock and was configured as shown in Figure 1. Eighteen lifts contained 4 feet by 12 feet pieces of sheetrock and five lifts contained 4 feet by 9 feet pieces of sheetrock. Each “lift” was approximately 18 inches thick. Wood spacers, 2 inches by 3 inches by 8 feet, were placed between the lifts and between the flatbed trailer and the first layer of lifts loaded onto the trailer. The wood spacers provided a space for the forks of the forklift during loading and unloading of the sheetrock.

The four feet by 12 feet lifts were loaded on the flatbed in three layers with each layer containing six lifts. Each layer was configured in two parallel rows with a 4 foot edge of the two forward most lifts approximately 2 feet from the front edge of the trailer. The 4 feet by 12 feet lifts were loaded on the trailer without any space between the ends of the lifts. A portion of the back end of the flatbed trailer approximately 4 feet wide by 8 feet long was not covered by the lifts of sheetrock. The five 4 feet by 9 feet lifts were loaded on top of the third layer of 4 feet by 12 feet lifts. One lift of 4 feet by 9 feet sheets was loaded directly above five of the 4 feet by 12 feet lifts with the 4 foot front edge of a small lift aligned with the 4 foot front edge of a large lift. This resulted in a space 3 feet wide by 18 inches deep by 8 feet long behind the first two small lifts and a space 3 feet wide by 18 inches deep by 4 feet long behind the second two small lifts. The load was covered with a large tarpaulin that was securely tied to the perimeter of the flatbed trailer.

Figure 1. Semi-truck and load – Not to Scale

The truck driver arrived at the lumber company on the day of the incident before any of the lumber company employees arrived for work. He parked the truck in the lumber company’s gravel parking lot, directly in front of a locked yard gate. He untied the tarpaulin and partially uncovered the load. He may have climbed on top of the load since the tarpaulin had been pulled back from the left front corner of the load toward the right rear corner. Apparently while he removed the tarpaulin, he fell to the gravel parking lot. He was discovered by an employee of the lumber company shortly after the employee arrived for work and heard the victim’s call for help. The victim was found on the ground along the right side of the trailer (when facing the front of the truck) near the location of the rear axles. The victim’s location along the side of the trailer indicated that he probably fell from the top of the load versus the empty trailer space at either the front or the back of the trailer.

Emergency medical personnel were immediately called and arrived at the scene a short time later. The victim was transported to a local hospital where he died nine days after the incident.

CAUSE OF DEATH

The cause of death listed on the death certificate was closed head injury with skull fractures due to fall from truck load.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that flatbed semi-trailer load covers are removed from the ground.

Discussion: Generally, when material is transported on flatbed semi-trailers, it is protected from moisture with a tarpaulin or similar type of flexible protective cover. These covers are tied to the flatbed trailer at various locations around the perimeter of the trailer. The placement of the 4 feet by 9 feet by 18 inch lifts of sheetrock created gaps in the top of the load that were 3 feet wide by approximately 20 inches deep. These gaps were hidden by the tarpaulin and probably were not noticeable to an individual walking on the top of the load. Whenever a driver climbs onto a flatbed trailer or the material being transported on the trailer, the potential for a fall and for a serious injury exists. If a driver climbs on top of a load similar to the load in this incident, he will be exposed to a potential fall of approximately 10 feet or more. If after untying the tarpaulin, the driver had remained on the ground and pulled the tarpaulin off to either side of the trailer or to the back of the trailer, he would not have been exposed to a fall, and this fatality probably would have been prevented.

Recommendation #2: Employers should design, develop, and implement a comprehensive safety program.

Discussion: Employers should ensure that all employees are trained to recognize and avoid hazardous work conditions. A comprehensive safety program should address all aspects of safety related to specific tasks that employees are required to perform. OSHA Standard 1926.21(b)(2) requires employers to instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury. Safety rules, regulations, and procedures should include the recognition and elimination of hazards associated with tasks performed by employees.

REFERENCES

1. Office of the Federal Register: Code of Federal Regulations, Labor, 29 CFR Part 1926.21 (b)(2), U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., July 1, 1994.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.