Farm Equipment Mechanic Dies from Injuries Sustained After Tractor Overturned

MN FACE Investigation 95MN00701

DATE: June 9, 1995

SUMMARY

A 64-year-old male farm equipment mechanic (victim) died of injuries sustained when the tractor he was driving overturned in a ditch. The tractor was not equipped with either a rollover protective structure or a general purpose cab.

The incident occurred when the victim was delivering the tractor to the owner after he had performed routine maintenance at a farm implement dealership. The victim lost control of the tractor while driving over an ice-covered portion of the gravel country road he was traveling on. The tractor slid into the ditch, overturned, threw the victim forward into the ditch, and came to rest on top of the victim. The victim was removed from the incident site by emergency medical personnel and transported to a hospital where he died approximately three hours after the incident occurred.

MN FACE investigators concluded that to reduce the likelihood of a similar incident, the following actions should be taken:

- all tractors should be equipped with a rollover protection structure and operator restraint system; and

- farm equipment should be operated at reduced speeds when traveling on potentially hazardous roads or roads of changing condition.

INTRODUCTION

On March 23, 1995, MN FACE investigators were notified of a machine-related fatality that occurred on January 18, 1995. A site investigation was conducted by MN FACE investigators on April 5, 1995. The farm implement dealership was visited as well as the location of the incident. During the site investigation, information concerning the incident was provided by an owner of the company employing the victim.

INVESTIGATION

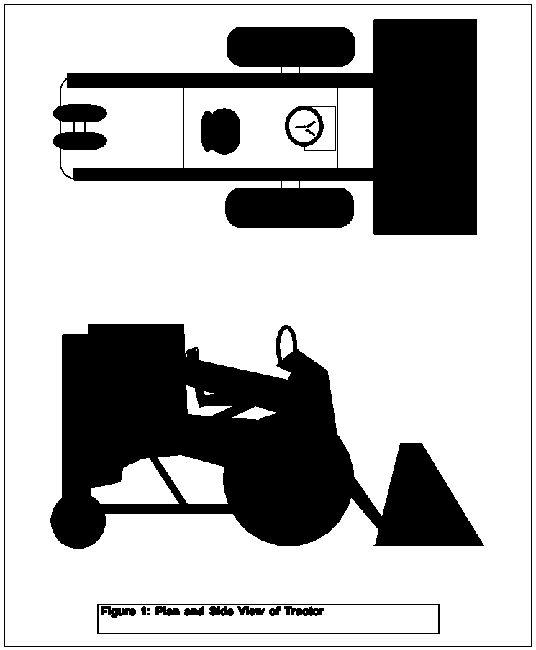

The incident occurred while the victim was delivering a tractor which had been repaired at the farm implement dealership. The tractor was a Honeybee Model 140 (a converted McCormick Farmall “C”, Model 140, manufactured in the 1950’s) which had been retrofitted with a front-end loader. The tractor had four wheels set in a triangular configuration. The drive axle was located at the front of the tractor with two large wheels set on either side of the tractor body. The steering axle was located at the rear of the tractor with two small wheels set together and directly under the body of the tractor. The wheelbase of the tractor (axle to axle) was 5.5 feet and the width and height were both 4.5 feet. The operator position was forward of the tractor engine and access to it was restricted by the loader arms which attached to the rear of the tractor. The tractor was not equipped with a roll-over protective structure, an operator restraint system, or a general purpose cab.

The tractor had been taken to the dealership for routine maintenance. After the victim completed the maintenance, the victim drove the tractor from the implement dealership to the tractor owner’s farm. During the tractor delivery, the victim was followed by a second employee of the dealership (witness to the incident) driving a pick-up truck. The delivery route required the victim to drive on a well maintained, straight and level gravel county road bounded on both sides by ditches approximately five feet deep. Road conditions were fair with occasional patches of ice on the gravel roadway. Weather conditions were good and allowed unrestricted visibility of the road. The front-end loader was positioned approximately six inches above the road and did not restrict the victim’s visibility. As stated by the witness, the victim was operating the tractor at a constant speed of approximately 10-12 miles per hour; the maximum speed of the tractor was estimated to be approximately 18-20 mph.

At the time of the incident (approximately 8:45 am), the victim was driving over an ice-covered portion of the road. For an unknown reason, the rear wheels of the tractor slid off of the road and into the right-hand ditch which caused the entire tractor to be pulled towards the ditch. The tractor began to overturn on it’s right side as it entered the ditch, throwing the victim out of the operator’s position and forward into the ditch. The tractor continued to overturn and came to rest in the ditch pinning the victim underneath.

The co-worker following the victim during the delivery witnessed the incident and immediately called for assistance from a nearby farmhouse. Emergency personnel arrived and extricated the victim. The victim was transported by air to a hospital where he died approximately three hours after the occurrence of the incident.

CAUSE OF DEATH

The cause of death stated on the death certificate was multiple traumatic skeletal and visceral injuries of chest and abdomen as a consequence of a farm tractor accident.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: All tractors should be equipped with a rollover protective structure and a seat belt.

Discussion: Preventing death and serious injury to tractor operators during tractor rollovers requires the use of a rollover protective structure and a seat belt. These structures, either a roll-bar frame or an enclosed roll-protective cab, are designed to withstand the dynamic forces acting on them during a rollover. In addition, seat belt use is necessary to ensure that the operator remains within the “zone of protection” provided by the rollover protective structure. Government regulations require that all tractors built after October 25, 1976, and used by employees of a farm owner must be equipped with a rollover protective structure and a seat belt. Many older tractors are in use on family farms and do not have, nor are they required by government regulation to have, such structures to protect their operators in case of a rollover. All older tractors should be fitted with a properly designed, manufactured, and installed rollover protective structure and seat belt. If the tractor involved in this incident had been fitted with a rollover protective structure and a seat belt, and the seat belt had been in use, this fatality might have been prevented.

Recommendation #2: Farm equipment should be driven at reduced speeds when traveling on potentially hazardous roads and roads of changing or varying condition. Operators should be cautioned of this when operating uncommon equipment or equipment unfamiliar to them.

Discussion: The speed of vehicles (including tractors) will directly affect the period of time during an incident in which the operator can recognize and react to changing conditions. Operation at slower speeds may provide needed additional time to avoid or minimize potentially dangerous situations. Also, unfamiliarity with vehicles being operated may limited the operator’s ability to react to such incidents.

REFERENCES

1. Office of the Federal Register: Code of Federal Regulations, Labor, 29 CFR Part 1928.51(b), U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., April 25, 1975.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.