Field Technician Dies When Struck By Geofoam Block

Michigan Case Report: 06MI193

Summary

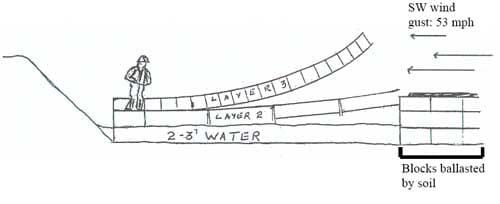

On December 1, 2006, a 59-year-old male field technician died when a 24-inch high by 32-inch wide by 8-foot long expanded polystyrene (geofoam) block struck him in the head and chest. A 15-foot deep excavation had been dug as part of a brownfield redevelopment site to provide the foundation for an add-on to a large retail store. At the base of the excavation was a French drain system that permitted the water to be drained away. A part of the excavation had been laid with geofoam blocks and had already been ballasted with soil. The incident occurred on the section of geofoam foundation that was not ballasted. The French drain had backed up causing the geofoam blocks to float on the water. After the water was drained, a section of geofoam did not settle to grade. After entering the excavation and standing on the top layer of geofoam pad, the decedent spoke with a representative from the company that had laid the block (Company A) about upcoming work at the site. A wind gust of approximately 53 miles per hour (mph) came from the southwest direction. The force of the wind caused geofoam layer #3 to rise up about 12 feet like a wave (Figure 1). The wave of geofoam block collapsed and the wind began to blow the individual blocks at the decedent and the Company A employees who were removing the block from the pad. Six or more Company A employees and the decedent were struck by the wind-blown blocks. Emergency response was called when the decedent was found lying on the pad, bleeding from his nose and having difficulty breathing. The decedent was transported to a local hospital where he was declared dead.

|

|

Figure 1. Drawing of incident scenario

|

Recommendations:

- Contractors should secure/ballast geofoam block edges in accordance with manufacturer specifications for installation and storage.

- Construction employers should conduct a daily hazard assessment to determine if environmental working conditions have changed or will change. They should inform their employees of their findings and how the changing conditions may affect the work to be performed.

- Trade groups involved in the manufacture and installation of geofoam should develop a guideline for geofoam applications as foundation material in excavations.

Introduction

On December 1, 2006, a 59-year-old male field technician died when a 24-inch high by 32-inch wide by 8-foot long expanded polystyrene (geofoam) block struck him in the head and chest. On December 1, 2006, Michigan Occupational Safety and Health Administration (MIOSHA) personnel received a report on their 24-hour-a-day hotline that this work-related fatality had occurred. MIOSHA informed MIFACE of this work-related death on the same day as the report was received. MIFACE contacted the decedent’s employer. On May 16, 2007, the MIFACE researcher interviewed the Corporate Health and Safety Manager at the company headquarters. During the course of writing this report, the medical examiner’s report, police report, and MIOSHA file were reviewed. All pictures and drawings used in the report are courtesy of the MIOSHA compliance officer.

The company for whom the decedent worked was a civil and environmental engineering consulting firm that was providing quality assurance/quality control (QA/QC) on the construction site. One of its responsibilities was to ensure that the geofoam blocks were placed properly. The incident occurred at a shopping development on a brownfield site. The U.S. Environmental Protection Agency (EPA) defines a brownfield site as real property, the expansion, redevelopment, or reuse of which may be complicated by the presence or potential presence of a hazardous substance, pollutant, or contaminant. The project was an add-on to an existing box store. The decedent’s employer had been at the site for approximately two years. The employer had been in business over 30 years. The decedent was a full-time employee, and had been working at the consulting firm for 25 years. He had been working at the incident site for three weeks as a field technician. The company had monthly tool box handouts and quizzes regarding the safety and health material that were placed in the first paycheck of the month. After reading this material, employees were required to complete an enclosed quiz, sign and date the quiz, and return it to Human Resources. The construction sites were visited on a quarterly basis by the Project Manager to determine employee compliance with the firm’s written health and safety program.

MIOSHA Construction Safety and Health Division personnel conducted an investigation. The Division did not issue any citations to the decedent’s employer. However, one Serious citation was issued to the general contractor laying the geofoam for violation of GENERAL RULES, Part 1, Rule 119(5): Material which may dislodged by wind and that could create a hazard when left in an open area shall be secured.

After the incident, the decedent’s employer implemented the following: (a) the Beaufort Scale (wind speed scale) was distributed to all field employees and is to be kept in their toolbox, and (b) laptops are used to monitor wind speed. If wind speed is in excess of 20 mph, geofoam blocks are not to be laid.

The employer did not monitor the wind speed at the incident location at the time of the incident. All wind speeds cited in this report were obtained from National Weather Service local airport historical data.

Investigation

Geofoam Blocks

Geofoam is expanded polystyrene (EPS) formed into a block shape and was selected to provide support for the new construction. Geofoam is used in geotechnical applications because of its properties of low density, good insulation, low hydraulic conductivity, as well as strength and deformation properties that complement soil behavior. Geofoam weighs as little as 1/100th that of soil, thus it is a good fill medium for construction on soft grounds. The blocks used in the incident were 24 inches high by 32 inches wide by 8 feet long. They varied in density from 1.25 pounds to 2 pounds per cubic foot. Three different sizes of blocks (A-C) were utilized:

- Block A

- Density: 1.25 pounds per cubic foot

- Weight: 53 pounds

- Block B

- Density: 1.5 pounds per cubic foot

- Weight: Unknown

- Block C

- Density: 2.0 pounds per cubic foot

- Weight: 80 pounds

Construction Site

The construction site was a former hazardous waste site that had been capped with clay. The 15-foot deep excavation site was located on the top of the clay cap and was elevated approximately 30 feet above the surrounding area due to the remediation cap. Vegetation at the site consisted of newly planted deciduous trees devoid of all leaves. To provide appropriate drainage, a weep-tile type drainage grid had been installed in the clay cap. A weep tile system collected water from the cap and channeled it to a French drain that permitted water to be gathered and directed to the proper drains. Over this grid was a 4-inch layer of compacted sand. On top of this sand, geofoam blocks were placed in a series of tiers. Each tier of the blocks was laid 90-degrees to the one below it, creating an interlocking pattern. Once the tiers reached a height of 16 feet, then more sand was placed and compacted. Actual building construction would then be done on this large mat of geofoam. One section of the geofoam foundation had been completed and six inches of soil had been placed on the top of the blocks (Figure 2).

|

|

Figure 2. Ballasted edge of geofoam foundation

|

Day Prior to Incident

There had been 1.05 inches of rain on the day prior to the incident. During the month of November there had been almost three inches of rain. According to the decedent’s field notes, the storm line had been bulk-headed with sand bags on November 30, 2006. Heavy rains combined with the restricted outflow of the drainage system led to water collecting in the French drain at bottom of the excavation where the geofoam had been set. The accumulation of water caused the geofoam to float on the water and become displaced. Five layers of foam blocks were to be set in place. Three layers had been placed.

Day of Incident

The decedent’s employer was one of three companies on the site. Company A set the geofoam in the excavation. When Company A’s employees arrived at work at 7:00 a.m., rain and sometimes sleet was falling, and the wind was gusting to 29 mph. Approximately four feet of water in the bottom of the excavation caused the geofoam layer #3 (top layer) and a portion of layer #2 blocks that were not covered with soil (ballasted) to float. Portable pumps were used to lower the water level, but layer #3 and layer #2 did not settle properly. The result was an elevated layer #3 and a portion of layer #2 above the ballasted portion of the geofoam.

The decedent arrived at the construction site at approximately 7:30 a.m. His field report noted that water had entered the geofoam excavation and caused the geofoam that had been installed to float. It appeared the geofoam had risen between two and three feet. Wind speed was approximately 30 mph from the northeast. After seeing the pumping operation, the decedent left the construction site and traveled to the office to file his field report and complete his time sheet. He left the office at 10:30 a.m. to give a ride to another person from his company to the site so that person could pick up his personal vehicle.

Meanwhile, a foreman for Company A decided to remove the displaced layers. Company A employees waited for rain suits to arrive and paired up as necessary to remove the blocks. Some carried the blocks and some pushed them to form a stack of blocks along the southwest edge of the excavation. Wind velocity was 8 to 15 mph during this time. The work was progressing from the west/northwest towards the northeast. A pair of rough terrain forklift trucks was used to transport stacks of blocks from the northeast side of the excavation to a parking lot storage area (Figure 3).

|

|

Figure 3. Incident site looking North

|

When the decedent returned to the site at a little before 1:00 p.m., he saw eight employees of Company A removing the top two layers of the geofoam blocks in the excavation and walked over to the excavation to talk with them. At the top of the excavation ramp he met a Company A employee. As they walked down the ramp onto the foam blocks, the decedent talked to him about work to be performed the next day. The decedent and Company A employees were on a five-foot-thick layer of geofoam blocks. The blocks on which they were walking, which were not ballasted and were approximately eight feet down in the 15-foot excavation.

Standing on blocks at the northwest edge, the decedent spoke with the Company A employee as the other Company A employees moved the 24-inch high by 32-inch wide by 8-foot long (weight 53-80 pounds each) blocks from the foam pad. At approximately 1:00 p.m., the wind changed direction (from northeast to southwest) and increased in velocity to nearly 35 mph. A 53 mph wind gust picked up the unsecured/unballasted blocks and blew them into the workers. Just prior to the gust of wind Company A employees noticed foam blocks being blown off of an unsecured/unballasted pile located directly southwest of their work area. Company A employees saw the wind lift the edge of the layer #3 blocks that were to be moved, and then the blocks rose up like a wave as the wind blew under them. This wave of blocks reached approximately 12 feet in height before it broke apart. The individual blocks broke loose and were then blown into the area where the decedent was standing and Company A personnel were working.

At least six Company A employees reported getting hit by the flying/tumbling blocks of foam (Figure 4). Some lost consciousness for a short while. No one saw the decedent being struck in the face and upper chest by one of the blocks. Company A employees found him lying on the foam pad bleeding from his nose. A Company A employee noticed that the decedent was having trouble breathing and rolled him on to his back and then onto his side to keep the air passage clear. The employees called 911 and began First Aid/CPR. Emergency response arrived and transported him to a local hospital where he was declared dead.

|

|

Figure 4. Incident site looking East

|

MIOSHA calculated that the wind exerted 110 pounds of force on the blocks.

Back to Top

Cause of Death

The cause of death as listed on the death certificate was blunt trauma to the head and chest. Toxicological tests were negative for alcohol and illicit drugs.

Recommendations/Discussion

Contractors should secure/ballast geofoam block edges in accordance with manufacturer specifications for installation and storage.

The MIFACE researcher looked on the Internet for geofoam block manufacturers in an effort to identify common installation and storage instructions. When geofoam installation instructions were present on the manufacturer’s webpage, every geofoam block manufacturer instructed the end user to ballast and/or secure the blocks during placement and storage. The geofoam block sections that had been completed had been ballasted with soil. The section of geofoam that had not been completed was not ballasted. Stacks of geofoam blocks in the storage area were also not ballasted/secured prior to the MIOSHA inspection.

The American Association of State Highway and Transportation Officials in cooperation with the Federal Highway Administration developed the National Cooperative Highway Research Program (NCHRP) Report 529 Guideline and Recommended Standard for Geofoam Applications in Highway Embankments. Report 529 provides a design guideline and recommended standard for geofoam applications in the design and construction of highway embankments. The guideline and standard is designed to assist highway agencies in designing and constructing highway embankments using expandable polystyrene (EPS) blocks.

Although this incident did not involve a highway embankment, Section 11: Placement of EPS-Block Geofoam of NCHRP Report 529 recommends “with the exception of sand bags or similar ‘soft’ weights used to temporarily restrain EPS blocks against wind, no construction material other than that shown on the contract drawing shall be placed or stockpiled on the EPS blocks.”

Construction employers should conduct a daily hazard assessment to determine if environmental working conditions have changed or will change. They should inform their employees of their findings and how the changing conditions may affect the work to be performed.

A daily hazard assessment of a worksite will provide management the tools they need to determine that the work that can be safely performed and also what work practices may need to be changed to perform the work safely.

As part of a hazard assessment, weather conditions should be evaluated and considered when determining how and when a job should be performed. As illustrated in this incident, weather conditions are a factor in work place injuries and fatalities. The employer now has a policy in place for monitoring wind speed during the installation of geofoam blocks.

Trade groups involved in the manufacture and installation of geofoam should develop a guideline for geofoam applications as foundation material in excavations.

As was accomplished with Report 529, MIFACE recommends that trade groups involved in the manufacture and installation of geofoam blocks and/or geosynthetic materials develop a similar type of guideline for the use of geofoam blocks in foundation applications. As companies receive tax credits from state governments for brownfield redevelopment, the use of geofoam as a foundation will most likely increase. Guidelines for installation and securement would assist designers and contractors in the placement of the geofoam and identifying safety considerations, such as securement, wind, storage conditions, etc.

References

MIOSHA Standards can be directly accessed from the Michigan Department of Labor and Economic Growth, MIOSHA websiteexternal icon www.michigan.gov/mioshastandards. The Standards may also be obtained for a fee by writing to the following address: Michigan Department of Labor and Economic Growth, MIOSHA, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan, 48909-8143. MIOSHA Standard Section phone number is (517) 322-1845.

- MIOSHA Construction Safety Standard, General Rules, Part 1.

- Beaufort Scale. University of North Carolina at Chapel Hillexternal icon. Internet Address: http://www.unc.edu/~rowlett/units/scales/beaufort.html

- National Cooperative Highway Research Program (NCHRP) Report 529: Guideline and Recommended Standard for Geofoam Applications in Highway Embankments, 1994. Document may be found on the National Transportation Research Boardexternal icon website: Internet Address: www.TRB.org/Main/Home.aspx (Link updated 11/17/2009)

- U. S. Environmental Protection Agencyexternal icon. Internet Address: http://www.epa.gov/brownfields/overview/glossary.htm (Link updated 3/25/2013)

- National Weather Serviceexternal icon. Internet Address: http://www.weather.gov/ (Link updated 4/1/2013)

Michigan FACE Program

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicineexternal icon, 117 West Fee Hall, East Lansing, Michigan 48824-1315. Internet Address: http://www.oem.msu.edu/MiFACE_Program.aspx. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 10/23/07 (Link updated 8/5/2009)

MIFACE Investigation Report # 06MI193 Evaluationpdf iconexternal icon (see page 8 of report)

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.