Race Car Fuel Dispenser Operator Killed when Methanol Tank Exploded

Michigan Case Report: 05MI077

Summary

On July 30, 2005, at approximately 5:20 p.m., a 49-year-old male auto dealer/ buyer working as a race car fuel dispenser, died from injuries received when a methanol tank at an automobile racetrack exploded in the fuel building (Figure 1). The wooden fuel building was constructed of sheet plywood supported by 4- by 4-inch and 2- by 4-inch wood supports. The fuel building housed both the pit concessions and the fuel storage and dispensing area. The decedent had filled several plastic fuel containers for the racers at the racetrack. It is unclear if he was filling another container, or was transferring methanol from a 55-gallon drum to a 1,000-gallon methanol holding tank when the explosion occurred. Although on fire, he was able to exit from the burning building. A racecar driver who was also a firefighter wrapped a shirt around the decedent’s face and pulled him away from the burning building. Emergency response personnel who were already on site provided medical assistance and transport to a local hospital. He sustained burns over 80 percent of his body. He died the next day at the hospital. Michigan Occupational Safety and Health Act (MIOSHA) personnel found that there were no grounding straps used and that the wiring was not rated for the area.

|

|

Figure 1. Site of burning storage shed

|

Recommendations:

- Racetrack owners should ensure that flammable material use and storage is in compliance with applicable safety standards and NFPA recommendations.

- Racetrack owners should train employees who dispense/transfer racing fuel to do so in a manner that will minimize the production of static electricity.

- Racetrack owners should develop, implement and enforce a comprehensive health and safety program that includes, a job hazard analysis and employee training in hazard recognition and avoidance. The safety program should include provisions for fuel distribution personal to use fire rated clothing.

- Racetrack owners should contact MIOSHA Consultation, Education and Training (CET) or other safety and health professional to conduct an inspection of the racetrack to identify potential hazards and racetrack compliance with applicable health and safety laws.

- Racetrack owners should comply with NFPA 610, Guide for Emergency Response and Safety at Motorsports Venues standard.

- Racetrack owners should contact their local jurisdiction’s building inspector to review any changes in existing building use.

Introduction

On July 30, 2005, at approximately 5:20 p.m., a 49-year-old male auto dealer/buyer who was dispensing race car fuel was killed when a methanol tank at an automobile racetrack exploded in the fuel building where he was working. On Monday, August 1, 2005, the MIOSHA personnel notified MIFACE that a work-related fatal incident occurred on July 30, 2005, and that the individual died on July 31, 2005. MIFACE contacted the employer (racetrack owner) and a MIFACE site visit was performed on January 30, 2006. MIFACE interviewed the racetrack owner at his primary place of business, a car dealership. The owner shared pictures taken at the scene. The police report and pictures, medical examiner report, the MIOSHA file and MIOSHA citations were reviewed in preparation of this report. Figures 1 and 3 are courtesy of the racetrack owner. Figure 2 is courtesy of the MIOSHA file.

The decedent had worked for the racetrack owner’s dealership as a salesperson selling motorcycles and cars for the last six years. The racetrack owner had leased the raceway to another individual for four years (1999-2003) and had assumed the racetrack’s operation during the 2004-2005 season. The racetrack venue was the racing of late-model, modified, sprint cars, and dirt track oval racers. The racetrack owner employed 20 individuals at the racetrack. The decedent had worked as a fuel man, tire man, and performed general track work at the racetrack.

The racetrack hosted races one night per week (Saturday) during the months of May through September. The decedent had not received training in how to safely dispense fuel prior to his job assignment at the racetrack. The racetrack owner did not require personal protective equipment to be worn. According to the MIOSHA file, the racetrack had an unwritten, partially implemented health and safety program.

The racetrack owner stated that he did not build the structure housing the concession stand and fuel dispensing and storage area. He stated that the firm that leased the property in the 4-year window installed the tanks and built the building.

A local fuel supplier supplied the tanks on a no-cost lease basis and gave the pumps to the racetrack if the racetrack purchased the racetrack fuels exclusively from the supplier. According to the MIOSHA interview statement with the local supplier, the pumps were not supplied “wired for use”, and a licensed electrician would have been required to wire the pumps appropriately. The supplier could not remember if he had sold bonding and grounding devices due to the fact that the original lease agreement and tank delivery occurred seven to eight years ago. The racetrack owner stated to the MIFACE investigator that the fuel supplier installed the tanks/pumps.

At the time of the MIFACE visit, the racetrack had removed the remains of the fuel storage building and all fuel tanks from the premises.

At the conclusion of their investigation, MIOSHA General Industry Safety and Health Division issued the following alleged Serious and Other-than-Serious Citations:

- SERIOUS:

- ACT 154 PA OF 1974, SEC. 11(a): Employer did not furnish to each employee employment and a place of employment which was free from recognized hazards that are causing or are likely to cause death or serious physical harm to the employee in that the employer did not have any grounding devices on their 1000-gallon methanol and 500-gallon racing fuel tanks, exposing employees to the hazard of explosions from sparks.

- SERIOUS:

- DESIGN SAFETY STANDARDS FOR ELECTRICAL SYSTEMS, PART 39, RULE 1910.307(b) ADOPTED BY RULE 3902: Employer did not assure that equipment, wiring methods, and installations of equipment in the fuel storage and dispensing area were intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location.

- SERIOUS:

- FLAMMABLE AND COMBUSTIBLE LIQUIDS, PART 75, RULE 1910.106(d)(6)(ii)(b): Employer did not assure a 10-foot separation between outside building wall and nearest container of liquid when quantity stored exceeds 1,100 gallons. The 1,500-gallon capacity of flammable material was within 4-feet of the pit concession area.

- SERIOUS:

- FLAMMABLE AND COMBUSTIBLE LIQUIDS, PART 75, RULE 1910.106(b)(2)(vi)(b): There was a missing vent stack for the 1,000-gallon methanol and the 500-gallon racing grade gasoline tank.

- OTHER THAN SERIOUS:

- RECORDING AND REPORTING OF OCCUPATIONAL INJURIES AND ILLNESSES, PART 11, RULE 1139(1): The employer failed to report the death of the employee to the Michigan Department of Labor and Economic Growth, Michigan Occupational Safety and Health Administration within eight hours.

- OTHER THAN SERIOUS:

- INSPECTIONS AND INVESTIGATIONS, CITATIONS AND PROPOSED PENALTIES, PART 13, RULE 1311(1): The employer did not post the Michigan Occupational Safety and Health Act (MIOSHA) Notice (Poster) in each establishment in a central and conspicuous location with respect to all affected employees to inform employees of the protections and obligation provided for in the Act.

- OTHER THAN SERIOUS:

- FLAMMABLE AND COMBUSTIBLE LIQUIDS, PART 75, RULE 1910.106(d)(6)(iii): The employer did not assure that fuel storage area was graded to divert spills away from building and other exposures or diked by a curb at least six inches high.

Investigation

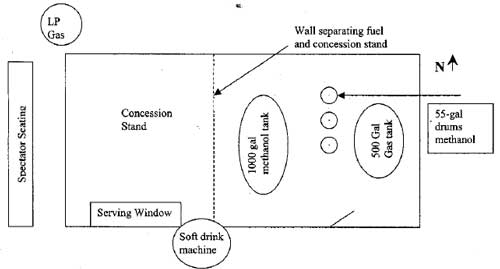

The building the decedent was working within housed both the pit concessions and the race fuel dispensing and storage area. The building was located approximately 16 feet to the east of the spectator grandstand. The wood building was approximately 32 feet long by 16 feet deep and had a concrete floor. The building exterior was constructed of sheet plywood with 4- by 4-inch and 2- by 4-inch wood supports. The concession stand area of the building was located on the west side of the building closest to the grandstand and contained refrigerators, grills, and deep fat fryers. The concession stand had its own wiring system. There was a common wood wall (no firewall) separating the concession area from the fuel dispensing and storage area. The building had a peaked roof and a wood ceiling (Diagram 1 and Figure 2 ).

|

|

Diagram 1. Line layout, not to scale, of concession stand/fuel building

|

The fuel dispensing and storage area was constructed with 8-foot-high walls. At the top of the area’s three walls was an opening approximately 18 inches high that was covered by wire screening material. According to the owner, a No Smoking sign was present. Within this area were two above ground metal fuel storage tanks. On the east side of the fuel dispensing and storage area was a 500-gallon tank containing 110 octane leaded gasoline racing fuel and on the west side was a 1,000-gallon tank containing methanol. The owner estimated that the racing fuel tank held approximately 200 gallons of fuel and the methanol tank help approximately 20 inches of material at the bottom of the tank at he time of the incident. The fuel storage tanks were not portable, but were not permanently affixed to the cement floor. The storage tanks did not have vent stacks. Using MIOSHA Part 39, Design Safety Standards for Electrical Systems adoption by reference of federal standard 29 C.F.R. 1910.399, the fuel dispensing and storage area would be classified as a Class I, Division I location. A Class I Division I location is a location:

- In which hazardous concentrations of flammable gases or vapors may exist under normal operating conditions; or

- In which hazardous concentrations of such gases or vapors may exist frequently because of repair or maintenance operations or because of leakage; or

- In which breakdown or faulty operation of equipment or processes might release hazardous concentrations of flammable gases or vapors, and might also cause simultaneous failure of electric equipment.

|

|

Figure 2. View of Concession stand and fuel storage from spectator stands.

|

The Class I Division I classification usually includes locations where volatile flammable liquids or liquefied flammable gases are transferred from one container to another (in addition to many other example locations).

Entrance into and exit from the fuel dispensing and storage area was through a 6-foot-wide by 8-foot-high, hinged door at the southeast corner of the building. A non-explosion proof fluorescent light lighted the storage area. A 127-gallon propane tank was located outside on the west side of the building. Spectator stands were located close by (Figures 2 and 3 ).

Electrically powered Flowrite FR710 Series pumps that were rated for gasoline pumping were used to draw material from the storage tanks to fill fuel containers brought to the dispensing area by the racecar drivers. The pumps were rated for a Class I Division I Group D area but were not compatible with the methanol according to the pump manufacturer. The pump hoses had internal bonding wires.

|

|

Figure 3. Location of spectator stands in

relation to the fuel storage area |

Wiring for the fuel dispensing and storage area initiated at a single panel box. In the MIOSHA interview statements, wiring was described as housed in PVC conduit, not in ridged metal explosion proof conduit. The receptacle boxes and receptacle plugs in the area were of the non-explosion proof type components. There was one non-explosion proof 8-foot fluorescent light with a regular (non-explosion proof) switch. The pumps’ wiring was wired to one switch to turn both pumps on and off and was not explosion proof. The fuel would not dispense until the pump handle was removed.

A soft drink machine was located on the outside of the building. MIOSHA interviews could not establish if the machine was “on”. Next to the soft drink machine was a bank of two-way radios and chargers. An extension cord was found leading from the chargers to the inside of the fuel storage and dispensing area. No ridged conduit was found in the fire area.

The cement slab supporting the tanks in the fuel dispensing and storage area did not have grounding devices located within it or attached to it. No grounding devices were present for the storage tanks and no secondary grounding devices were available for the decedent when he dispensed fuel into plastic containers for the racers.

On the day before the incident, a local fuel supplier delivered eight 55-gallon plastic drums of methanol. The methanol drums were stored inside of the fuel dispensing and storage area. The methanol was to be pumped from the drums into the methanol storage tank.

The day of the incident was a race day. As per usual procedure, each racer would bring his/her own fuel containers for the decedent to fill. Most of the containers being filled were plastic. The storage tank pumps dispensed five gallons at a time.

The racetrack owner had been at the track for approximately one hour prior to the incident. The racetrack owner had been in the building earlier in the day and stated he did not smell anything. The decedent was wearing a cell phone. An individual who was with the decedent just prior to the explosion stated that the decedent had just finished filling a plastic container for a driver and set it aside. He stated that the decedent was transferring fuel from one of the 55-gallon drums into the methanol storage tank when he left. He was about 20 feet away from the building when the building exploded.

Witnesses stated the explosion was a two-part explosion. One small explosion, then a whoosh and pop, and then the entire storage area was engulfed in flames. The racetrack owner who was

standing 10-15 feet away from the building heard a whistling sound moments before the explosion.

The tank that exploded was the methanol tank. A racecar driver (who was also a firefighter) was approximately 100 yards south of the fuel storage area when he heard the explosion and turned to see a wall of fire. He ran to the building and saw the decedent stumble out of the south door of the building and collapse. The firefighter took off his shirt to protect the decedent’s airway from the invisible methanol fire surrounding the decedent and dragged him away from the building. The decedent told the firefighter he was “filling containers” when the explosion happened, and that he was “filling tanks, and they were not plastic”.

Paramedics who were on scene to provide medical support for racecar drivers who may be injured during the race were attending to their ambulance. They were located several feet away directly east of the fuel shed and observed the north wall of the fuel building explode out and a large fire ball plume out with debris to the north.

According to the police report, evidence at the scene indicated that the decedent was filling the 1,000-gallon tank from the 55-gallon drums using a different pump to transfer the methanol from the 55-gallon drums into the 1,000-gallon methonol tank. After the explosion, the pumps were found either still attached to the tanks or directly in the area. The pumps were melted. Six of the eight drums were found melted.

The Fire Marshal/MIOSHA investigation found:

- In between the two storage tanks were melted remnants of three 55-gallon plastic drums.

- Remnants of three more 55-gallon drums were found approximately 15 feet south of the fuel storage area.

- Melted remnants of the non-explosion proof fluorescent light fixture wiring and orange extension cords and wiring with melted plug ends were found in the storage area. It could not be determined if ground prongs were with the extension cords.

- Melted fuel pump with plug-in cord attached.

- Several two-way radios in a charger base on the floor.

Back to Top

Cause of Death

The cause of death as listed on the death certificate was burns/incendiary injuries due to (or as a consequence of) an explosion. Toxicology results were negative for alcohol, but positive for pain medications and a metabolite of cocaine.

Recommendations/Discussion

Racetrack owners should ensure that flammable material use and storage is in compliance with applicable safety standards and NFPA recommendations.

Race cars use highly flammable material for fuel. It is critical that bulk storage containers, transfer containers, and the buildings used for storage conform to applicable standards. Bulk containers must be properly stored, grounded, have appropriate wiring, and be properly vented. Bulk drums of flammable liquids must be grounded and bonded to containers during dispensing to transfer containers. Storage buildings must be properly constructed, including explosion-proof wiring and lighting, with a provision for adequate ventilation.

Most racetracks use outside storage buildings to protect the bulk containers and to fill driver’s portable containers. MIOSHA General Industry Safety Standard Part 75, Flammable and Combustible Liquids has specific requirements for portable tank design, venting, installation, and both indoor and outdoor flammable container storage. Part 75, Section (d) contains specific requirements for portable tanks containing flammable materials, including requirements for both indoor (d)(4) and outdoor (d)(6) storage of the tanks.

Racetrack owners should train employees who dispense/transfer racing fuel to do so in a manner that will minimize the production of static electricity.

Employees should receive training on how to safely transfer flammable materials to avoid the buildup of static electricity. Static electricity is the electric charge generated when there is friction between two objects made of different materials or substances. Electric charges can build up on an object or liquid when certain liquids (e.g., petroleum solvents, fuels) move in contact with other materials. This can occur when liquids are poured, pumped, filtered, agitated, stirred or flow through pipes. This buildup of electrical charge is called static electricity. The amount of charge that develops depends, in part, on how much liquid is involved, how fast is it flowing or is being agitated or stirred, and the material(s) it flows through.

When transferring petroleum-based fuels or other flammable materials from one container to another, it is important to bond dispensing and receiving containers together before pouring to prevent static electrical sparks. The best way to bond containers is to securely attach a special metal bonding strap or wire to both containers.

Employees should also be instructed that in the flammable liquid storage and dispensing area, dispensing drums must also be grounded. Grounding is accomplished by connecting the container to an already grounded object that will conduct electricity. All grounding and bonding connections must be bare metal to bare metal. Specially designed and approved bonding and grounding wire assemblies are available from safety equipment retailers.

MIOSHA Consultation, Education and Training Division published an Onsite Consultation Abatement Method for Flammable and Combustible Liquids (Publication OSC-6165)word iconexternal icon. The publication illustrates bonding containers and other issues of concern when working with and storing flammable materials. The publication may be found on the MIOSHA website at: http://www.michigan.gov/documents/cis_wsh_osc6165_137874_7.doc.

The Canadian Centre for Occupational Safety and Health (CCOSH) also has a good resource for information on static electricity and handling of flammable and combustible materials. Visit the CCOSH websiteexternal icon at: www.ccohs.ca/oshanswers/prevention/flammable_static.html

Racetrack owners should develop, implement and enforce a comprehensive health and safety program that includes, a job hazard analysis and employee training in hazard recognition and avoidance. The safety program should include provisions for fuel distribution personal to use fire-retardant clothing.

The reduction or elimination of health and safety hazards is the primary goal of a health and safety program. The employer did not have a comprehensive safety program, nor did the employer provide employee safety education and training that included hazard recognition. Employee education and training is one of the important elements of a safety program. Although the decedent was an experienced worker, the incident still occurred.

There are many resources available to employers to access in the development of a health and safety program. The MIOSHA Consultation Education and Training (CET) Division provides free guidance and assists employers in the development of their company specific health and safety program. Other health and safety resources available to employers to assist them in developing a company health and safety program are: health and safety consulting firms, insurance company health and safety representatives, and the Internet.

A job hazard analysis is a procedure used to review each job, identify potential hazards, and design actions and procedures to eliminate or control the hazards. Input from workers who usually perform the task(s) is important. Of primary importance is the recognition that hazards exist. Racetrack policies and training should be implemented based upon the findings of the job hazard analysis. The racetrack’s health and safety program should include a section about performing a job hazard analysis for existing and new work procedures and for providing employee job hazard analysis training. Job hazard analysis training should ensure employees can recognize unsafe work practices and potentially hazardous work conditions when setting up the job. The employer (or outside consultant) can provide hazard analysis training as part of the development and implementation of the company health and safety program.

Written standard operating procedures (SOPs) provide many benefits to an organization. Among the benefits are: removing variation in work performance caused by different people doing the same job, facilitating employee job training as well as cross-training, providing a common understanding of the job and expectations for job performance, helping to provide a safe work environment by assessing hazards and providing ways to minimize the identified hazards/risks.

The federal OSHA websiteexternal icon has Job Hazard Analysis publication that can be downloaded from the Internet: www.osha.gov/. Click on the Newsroom Publications link, and scroll down the OSHA publications until the “Job Hazard Analysis” document is found.

The MIOSHA General Industry Safety Standard, Part 33, Personal Protective Equipment Rule 3308 requires the employer to assess the workplace to determine if hazards are present, or likely to be present, which necessitate the use of personal protective equipment (PPE). If such hazards are present, or likely to be present, the employer shall select, and have each affected employee use, the types of PPE that will protect the affected employee from the hazards identified in the hazard assessment. Because of the possibility of a buildup of static electricity during container filling (both drums and race driver portable containers) fire retardant clothing should be considered. To protect the employee from splashes, chemical resistant gloves and appropriate face protection should also be worn.

Racetrack owners should contact MIOSHA Consultation, Education and Training (CET) or other safety and health professional to conduct an inspection of the racetrack to identify potential hazards and racetrack compliance with applicable health and safety laws.

The individual interviewed for this report strongly urged fellow racetrack owners to contact MIOSHA CET to conduct a site visit to look for potential hazards. MIFACE concurs and supports this recommendation. Racetrack owners may be unaware of the MIOSHA safety and health requirements that must be met to comply with the regulations. Employers in the private sector may request a voluntary MIOSHA inspection of their workplace (full or partial) without the attachment of fines or penalties. These on-site consultations are conducted by occupational safety consultants or industrial hygienists in the CET onsite consultation section. Employers must agree, prior to the start of this inspection, to correct all serious violations found during the voluntary inspection. The CET Division, upon employer request, will also conduct a non-enforcement hazard survey of an employer’s site (full or partial). The hazard survey is a training tool, which affords the employer and selected employees the opportunity to learn how to identify unsafe or unhealthy acts or conditions, and MIOSHA violations. The hazard survey results in formulating ways to correct any noted deficiencies.

Racetrack owners should comply with NFPA 610, Guide for Emergency Response and Safety at Motorsports Venues standard.

A Technical Committee was appointed by the NFPA Standards Council in 1998 to address the subject of safety at motorsports venues. The guide assists facility owners, operators, promoters, and emergency management personnel to develop and implement a system that provides for effective emergency operations at motor sports facilities and events. The guide is intended to assist with the planning for emergency operations, training and equipping emergency workers, and deploying resources at the time of an incident. This in turn can lead to more effective fire suppression in the event of a fire and to improved rescue and medical care for competitors in post crash situations, while providing for the safety of emergency response personnel working at the venue.

Chapter 4 of NFPA 610 suggests that owners/operators of motorsports venues, in conjunction with their emergency service providers, prepare an emergency action plan. An emergency action plan checklist is contained in the standard. Chapter 5 of NFPA 610 addresses the training and competency of any paid or volunteer personnel having an assignment or defined responsibility with a motorsports facility or a designated function at a motorsports venue should be informed or trained commensurate with their assigned function. Training levels include Safety Awareness, Safety Operations, Safety Technician, Safety Specialist and Safety Command Manager.

The NFPA 610 standard may be reviewed for free at the NFPA websiteexternal icon: http://www.nfpa.org/. (Link updated 8/13/2013) Type NFPA 610 in the search box on the NFPA homepage. Click on NFPA 610: Guide for Emergency Response and Safety at Motorsports Venues. Scroll down the page until you see Preview This Document and click. Click on I Agree after reading the Online Access Agreement. The standard will be displayed. The standard may be purchased by accessing the NFPA Online catalogueexternal icon at: www.nfpa.org/catalog/product.asp?pid=61003&src=nfpa&cookie%5Ftest=1. (Link updated 4/1/2009)

Racetrack owners should contact their local jurisdiction’s building inspector to review any changes in existing building use.

The shed was originally constructed as Use Group S-1 (moderate hazard storage for equipment sheds) and Construction Type VB (wood frame construction). According to the individual MIFACE interviewed, the previous owner of the racetrack constructed the building. The purpose/use of the building at the time of its construction is unknown. Under the current use, storage of flammable and cumbustible materials, the building did not meet construction requirements. MIFACE recommends that racetrack owners contact their local jurisdiction’s building inspector so a plan review may be conducted when an existing commercial building is altered, enlarged, structurally repaired, moved, or converted to different use group (as defined in the building code) to ensure all safety requirements are met.

Resources

MIOSHA standards cited in this report may be found at and downloaded from the MIOSHA, Michigan Department of Labor and Economic Growth (DLEG) websiteexternal icon at: www.michigan.gov/mioshastandards. MIOSHA standards are available for a fee by writing to: Michigan Department of Labor and Economic Growth, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan 48909-8143 or calling (517) 322-1845.

MIOSHA Consultation, Education and Training (CET) division provides free health and safety consultation to assist Michigan employers in their efforts to provide a safe and healthful workplace. MIOSHA CET personnel can conduct an on-site consultation without the attachment of fines or penalties but employers must agree prior to the start of the inspection to correct all serious violations found. The MIOSHA CET Self-Help Program assists employers in conducting their own evaluations of hazardous exposures in their workplaces. This free service provides limited technical industrial hygiene guidance, monitoring and measuring equipment, sample analyses and general information. For more information about these free services, contact MIOSHA CET divisionexternal icon at 1-517- 322-1809 or via their website www.michigan.gov/miosha.

- Act 154 PA Of 1974, Sec. 11(A).

- MIOSHA General Industry Safety Standard, Design Safety Standards For Electrical Systems, Part 39, Rule 1910.307 Adopted By Rule 3902.

- MIOSHA General Industry Safety Standard, Flammable And Combustible Liquids, Part 75.

- MIOSHA General Industry Safety Standard, Personal Protective Equipment, Part 33.

- Recording And Reporting Of Occupational Injuries And Illnesses, Part 11, Rule 1139.

- Inspections And Investigations, Citations And Proposed Penalties, Part 13, Rule 1311.

- NFPA 30, Flammable and Combustible Liquids Codeexternal icon. 2003 Edition.

National Fire Protection Association, 1 Batterymarch Park, PO Box 9101, Quincy, MA 02269-9101. NFPA 610 can be viewed on-line and/or purchased from NFPA. Internet Address:

http://www.nfpa.org/codes-and-standards/document-information-pages?mode=code&code=30&DocNum=30&cookie%5Ftest=1 (Link updated 8/13/2013) - Canadian Centre for Occupational Health and Safety. How Do I Work Safely with Flammable and Combustible Liquids? (Static Electricity).

Internet Address: www.ccohs.ca/oshanswers/prevention/flammable_static.html

- NFPA 610, Guide for Emergency Response and Safety at Motorsports Venuesexternal icon. 2003 Edition.

National Fire Protection Association, 1 Batterymarch Park, PO Box 9101, Quincy, MA 02269-9101. NFPA 610 can be viewed on-line and/or purchased from NFPA. Internet Address:

http://www.nfpa.org/codes-and-standards/document-information-pages?mode=code&code=610&DocNum=610&cookie%5Ftest=1 (Link updated 8/13/2013)

Michigan FACE Program

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicineexternal icon, 117 West Fee Hall, East Lansing, Michigan 48824-1315; http://www.oem.msu.edu/MiFACE_Program.aspx. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 8/24/07 (Link updated 8/5/2009)

MIFACE Investigation Report # 05MI077 Evaluationpdf iconexternal icon (see page 12 of report)

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.