Golf Course Worker Dies After Being Pinned Under an Overturned Tee Box Mower.

Michigan Case Report: 05MI060

Summary

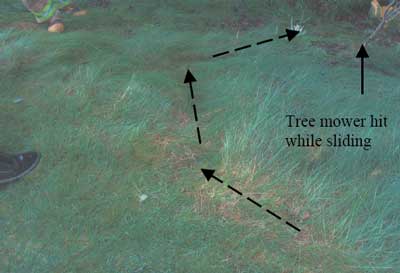

On June 13, 2005, a 19-year-old male golf course worker died after being pinned under an overturned tee box mower. The oval tee box was on a plateau with three gently sloping sides except for the east-side bank, which dropped off 19 feet with a 49-degree slope into trees. The deceased had made three passes in a diagonal motion across the tee box, turning at the edge of the tee green on the collar (longer grass area) after each pass. When he reached the collar area, he raised the reels, turned the mower, and then engaged the reels down. After this third cut, the incident occurred. The back wheel of the mower went over the edge of the collar, and the mower began to slide down the slope (Figure 1, arrow). The mower hit a small tree (Figure 1, box), and the mower overturned. The mower came to rest on top of the deceased at the base of the slope against some trees. A coworker found him under the mower. 911 was called and emergency personnel arrived. They pronounced him dead at the scene.

|

|

Figure 1. Mower path down slope, tree the mower hit on way down

|

Recommendations:

- Golf course superintendents should conduct a full, hole-by-hole vehicle rollover risk assessment, measuring slopes and drop heights, in order to determine the best method of machine operation and machinery to be used.

- Course designers should provide adequate clearance for mowers to operate safely on the perimeter of an elevated tee or green.

- MIOSHA should consider updating the General Industry Safety Standard Powered Groundskeeping Standard, Part 54 to reflect the updated ANSI B71.4-2004 safety specification standard for commercial turf care equipment.

- MIOSHA/OSHA should consider requiring a certified operator protection system (such as rollover protection structure (ROPS)/seatbelt) for groundskeeping equipment that could be operated in a location where a rollover potential exists.

- Riding mower manufacturers are encouraged to develop a ROPS/seatbelt retrofit attachment for existing equipment under 20 HP.

- Employee training should include review of written material, such as the machine operator’s manual.

Additionally, MIFACE recommends that:

- All workers on the course, when working alone, should be equipped with a company-supplied communication device.

Introduction

On June 13, 2005, a 19-year-old male golf course worker died when he was pinned under the overturned riding tee box mower he was operating. On June 13, 2005, the Michigan Occupational Safety and Health Administration (MIOSHA) personnel received the work-related fatality report from a company representative on their 24-hour-a-day hotline. MIOSHA personnel notified MIFACE investigators of the fatality on the same day. On November 11, 2005, the MIFACE researcher interviewed the golf course superintendent and another employee who was familiar with the work being performed by the deceased. The superintendent escorted the MIFACE researcher to the site of the incident, and permitted pictures to be taken of both the incident site and the type of mower operated by the deceased. During the course of writing this report, MIFACE reviewed the mower operator’s manual, death certificate, the medical examiner death scene investigation and autopsy reports, police report and pictures, and MIOSHA citations. Pictures used for Figures 1 and 5 were taken by the local police agency at the time of their investigation. Figure 2 is courtesy of the MIOSHA compliance officer and was taken at the time of the MIOSHA investigation. Figures 3 and 4 were taken by the MIFACE investigator at the time of the MIFACE investigation. Pictures were modified to preserve the confidentiality of the employer.

The company was a resort that provided both summer and winter sport options. The resort had been in business for approximately 50 years. The resort employed 68 people at the time of the incident. Three people were assigned to the golf course the deceased was mowing at the time of the incident. The resort hired the deceased as a full-time, temporary employee to work in the summer as a mower operator. It was his first season and the deceased had been on the job for five weeks. He had mowed tee boxes and approaches. His 8-hour shift began at 6:00 a.m. He did not work overtime. The company had a safety and health program and provided on-the-job training for mower operators. A disciplinary policy for health and safety violations was in place. There was no health and safety committee.

MIOSHA issued two Serious citations and one Other-than-Serious citation to the employer at the conclusion of their investigation.

The Serious citations were for violations of the following standards:

- Powered Groundskeeping Equipment, Part 54

- Rule 5411(a) – The employer provided inadequate training to the operator of powered grounds keeping and related equipment regarding the operating procedures, hazards and safeguards to the assigned job.

- Personal Protective Equipment, Part 33

- Rule 3312(1) – The employer did not assure the use of appropriate eye protection where a hazard exists due to flying objects or particles, harmful contacts, exposures, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, glare, injurious radiation or electrical flash. (No safety glasses worn)

The Other-than Serious citation was for a violation of the following standard:

- Powered Grounds keeping Equipment, Part 54

- Rule 5413(4) – The employer did not provide the deceased and the deceased did not use foot protection as prescribed in Part 33, Personal Protective Equipment. Foot protection is required when operating a power rotary mower. Foot protection was not provided nor used facility-wide.

Investigation

Equipment

The deceased was operating a John Deere 2500E professional greens mower (Figure 2 ). The mower was purchased new in 2005. The three-wheeled, 19.9 HP, diesel-powered, hydrostatic drive, riding mower had three electric reel cutting units; eight blades were used for tees, and eleven blades were used for greens. The reels are offset to the left and are adjustable to the cutting operation. The height of the cut can be adjusted from 5/64 inch to 1.25 inches. The course superintendent indicated that the operator raised the reels during a machine turn on the rough. The third wheel in the back is the wheel that determines the turning direction of the machine. The tires were “balloon-type” tires and did not have an aggressive tread so the grass on the tees and greens is protected from damage. (Figure 3)

|

|

|

Figure 3. John Deere 2500E mower – note tires

|

There was a bar (Figure 2 , arrow) that was affixed to the mower frame behind the operator’s seat. While sitting on the seat, the operator’s head was above the bar. The bar bent backwards towards the engine compartment. The bar was not designed to be a rollover protection structure to protect the operator. The mower was not equipped with seat belts.

Location

The golf club had three nine-hole courses. The tee box the deceased was cutting was on the course that was considered the most difficult to cut. The tee box involved in the incident was at the second hole of the course. The oval tee box was on a plateau with three gently sloping sides except for the east-side bank which dropped off 19 feet with an approximately 49 degree slope into trees. The oval tee area was 28 feet 6 inches wide and 44 feet 3 inches long. ( Figure 4)

The grass was cut short in the middle of the tee and longer around the outside. The grass on the tees was bent grass and could not be mowed in the same direction. Bent grass grows horizontally, and must be mowed in six directions in order for it to stand up vertically. There was a 3 foot 4 inch wide rough (or collar) area from the edge of green to the start of the hill embankment. Generally, tee boxes are cut three times a week. The course superintendent stated that tee box collar width varies over time due to cutting patterns at the tee box.

|

|

Figure 4. Incident site showing green, collar and slope of hill

|

At the time of the incident, the sky was cloudy and the temperature was in the low 70s. The grass was slippery and wet.

Employee Training

A company employee was assigned to train the decedent on the operation and use of the tee box riding lawn mower. Training is hands-on, on-the-job. The operator’s manual was not reviewed with the deceased. The company representative stated that the most experienced tee mower operator conducted the deceased’s training. Generally, the mower operator training procedure is as follows:

The trainer gives the new operator an overview of the machine while the mower is in the garage. The trainer sits in the operator’s seat and identifies and demonstrates the machine controls while the trainee is off the mower. The trainer and trainee proceed to the golf course. The trainer operates the mower to demonstrate how to cut the grass while the trainee watches from a golf cart. Only the trainer operates the mower on the first day of training. On the second and third day of the training period, the trainer and trainee both operate mowers. The trainer makes a determination as to whether the trainee is competent and ready to operate the machinery independently, or whether more training is necessary. When the trainer determines that the trainee is competent and ready to operate the mower independently, the trainer tells the course superintendent. The superintendent talks with the trainee and then final approval is given for the trainee to operate the machine. According to the course superintendent, the trainer accompanies the trainee for a few more days, reviewing the cutting work (e.g., straight lines on the greens/tees). When the trainer is satisfied, the trainee can cut independently.

Day of Incident

The deceased had cut this tee box successfully 15 to 20 times in the past. At approximately 6:30 a.m., the decedent drove the John Deere 2500E greens mower to the golf course to cut the tee boxes. The employee who changed the cup placement on the greens was also responsible for moving tee markers off the tee box. The tee box mower, after mowing the tee box, would replace the tee markers. Another employee was cutting the rough areas on the sides of the fairways and tees on the same course.

The incident was unwitnessed. The deceased was working alone and was cutting the short grass (tee area) in the middle of the tee box. When the deceased mowed the tee area, he mowed in a diagonal direction. He had made three passes in the diagonal motion, turning at the edge of the green on the collar after each pass. When he reached the collar area, he raised the reels, turned the mower, and then engaged the reels down. His first cut was in a southeasterly direction, his second cut was in a northwesterly direction and his third cut was in a southeasterly direction. After this third cut, the incident occurred. After talking with the company representatives, three possible scenarios were developed.

Scenario #1. He may have misjudged the location of the collar edge. After his turn, he engaged the mower reels down, but his back wheel was over the edge of the collar and the mower started to slide down the embankment.

Scenario #2. He completed the turn and had engaged the reels down. Instead of pressing forward pedal, he pressed the reverse pedal, causing the machine to move in reverse.

Scenario #3. As he was turning, he misjudged the location of the rear wheel in relation to the edge of the collar and while still moving forward, the rear wheel extended over the edge and the mower proceeded over the edge.

Under each scenario, the back wheel of the mower went over the edge of the collar. Because the engine was over this wheel, the weight distribution caused the rest of the mower to go over the edge and roll over. The mower came to rest approximately 19 feet down the 49-degree slope, upside down against some trees. The police report indicated in Figure 5 that the rear wheel made the mark on the embankment grass as the machine went down the hill. The mower may have struck a small tree on the way down the embankment causing it to overturn.

|

|

Figure 5. Path of tire down slope

|

His coworker, a rough mower, was working his way from the 9th hole of the course back to the first, cutting the rough around the tee boxes when he noticed the tee markers were still in the rough, not on the tee box. At approximately 10:45 a.m., he began to cut the tee box rough that the deceased had been cutting. His coworker thought that the deceased had mechanical problems with his mower and that he had probably headed back to the maintenance garage.

While mowing, he noticed the mower upside down resting against a tree at the bottom of the slope on the east side of the tee box. It appears that the deceased rode the mower down the embankment. He was found pinned under the bar that was affixed to the mower frame. Police found that the mower blades were engaged and down. After discovering the deceased did not have a pulse, he called management and then called 911. The police and emergency response arrived minutes later. The deceased was declared dead at the scene.

Back to Top

Cause of Death

The cause of death as stated on the death certificate was traumatic asphyxia due to being pinned underneath an overturned tractor. Toxicological tests were negative for alcohol and other screened drugs.

Back to Top

Recommendations/Discussion

Golf course superintendents should conduct a full, hole-by-hole vehicle rollover risk assessment, measuring slopes and drop heights, in order to determine the best method of machine operation and machinery to be used.

Conducting a hazard assessment of all tasks performed by workers is essential in identifying and ultimately controlling potential job-associated hazards. Employers should conduct a hazard assessment of all tasks performed by workers. Once potential hazards are identified, written safe work procedures should be developed that will control these hazards. Employees should then be trained in the implementation of the safe work procedures for any job they might perform.

Had the course been assessed for the potential of a groundskeeping machine overturn on a slope, the tee box where the incident occurred might have been identified, and work procedures developed to minimize the risk of groundskeeping equipment overturn.

Course designers should provide adequate clearance for mowers to operate safely on the perimeter of an elevated tee or green.

Elevated tees and greens pose a special safety risk to operators of greenskeeping equipment. Elevated tees and greens, by definition, requires the machine operator to mow grass on a slope in the rough areas and turn greenskeeping equipment on the collar of the tee box that abuts the slope. Usually, this grass is cut early or late in the day when no golfers are present. The time of day that the mowing is completed often occurs in conjunction with dew still remaining on the grass or watering the course. A greenskeeping machine does not have aggressive tire tread and cannot “grip” the grass to prevent the equipment from sliding if the machine begins to slide on a slope. Course designers should ensure that there is sufficient room to safely operate and turn the machine around on the tee or green to mow in a different direction.

MIOSHA should consider updating the General Industry Safety Standard Powered Groundskeeping, Part 54 to reflect the updated ANSI B71.4-2004 safety specification standard for commercial turf care equipment.

The MIOSHA General Industry Safety Standard, Part 54, Powered Groundskeeping Equipment Rule 5442 states “that a new powered lawn mower, lawn tractor or a garden tractor and its attachments, purchased after the effective date of this part, shall meet the requirements of ANSI B 71.1-1972 standard, “Safety Specifications for Power Lawn Tractors,” which is incorporated herein by reference and shall bear a permanently attached tag or label so indicating.” The referenced ANSI standard is over 30 years old. The B71.4-2004 standard is the fourth revision of ANSI/OEPI B71.4-1999. The first edition of this standard was approved and published by ANSI in 1980. The present edition was prepared by the Outdoor Power Equipment Institute (OPEI). Turf care equipment has been significantly modified since the MIOSHA Part 54 standard effective date of 1974, and its amended December 1, 1983 date. ANSI B71.4-2004 includes changed stability requirements for zero-turn machines equipped with ROPS, changes to the safety sign requirements to allow for no-text signs, and the addition of definition and requirements for stand-on machines and sulky units, which are common pieces of turf care equipment.

MIOSHA/OSHA should consider requiring a certified operator protection system (such as ROPS/seatbelt) for groundskeeping equipment that could be operated in a location where a rollover potential exists.

MIOSHA Part 54, Rule 5443 (4) states “riding groundskeeping equipment shall not be operated up or down a slope of more than 26 degrees or move across the face of a slope of more than 17 degrees.” Rule 5443 (5) states that “a deviation from the requirements of subrule (4) may be obtained from the department of labor by presenting special design or modification criteria which shows an ability to perform safely on a specific slope of a greater degree without slipping or tipping.” Although subrule 5 addresses design or modification criteria for the machine to perform safely, it does not require the equipment to have a certified operator protection system (such as a ROPS/seatbelt) if the machine is operated in excess of the slope requirements in subrule 4.

Most vehicle ROPS performance testing standards center upon agricultural tractors, forestry and earthmoving machines, which are significantly heavier. The empty weight (with cutting units, full fluids, no operator) of the 2500E was 1290 pounds (585 kg). There has been concern by mower manufacturers that the addition of a ROPS/seatbelt to lighter machines may increase the risk of a rollover due to a change in the center of gravity of the machine. ROPS research performed in the United Kingdom suggests that appropriately-engineered conventional ROPS solutions would appear to be suitable for application to 660-1322 pounds (300-600 kg) operating mass vehicles where a rollover potential exists. To keep the operator within the protective zone provided by the ROPS, a seat belt and its use is also necessary (CFR 1928.51(b)(2)).

If the greens mower the deceased was operating had been equipped with a ROPS and the operator was using the seatbelt, he may have survived. MIFACE encourages manufacturers of greens mowing equipment to develop a ROPS/seatbelt system for this equipment. There is at least one manufacturer of greens mowers that already provides equipment with ROPS/seatbelt system.

This recommendation is also applicable to Federal OSHA.

Riding mower manufacturers are encouraged to develop a ROPS/seatbelt retrofit attachment for existing equipment under 20 HP.

Federal OSHA requires that agricultural tractors (CFR 1928.51(a)), or industrial tractors (CFR 1926.1002(j)(2)) of more than 20 engine horsepower be equipped with rollover protective structure (ROPS) to provide operator protection during a rollover or turnover event. MIOSHA General Industry Safety Standard, Part 22, Tractors also has the same engine horsepower/ROPS requirement. The OSHA and MIOSHA standards cited above do not consider the weight of the machine or the operation of the machine on a slope as operative factors for operator rollover protection, only the horsepower of the machine.

Many types of golf course groundskeeping equipment, such as rough mowers, fairway mowers, and trim mowers are equipped with ROPS. Most are over 20 HP. The 19.9 HP (gross) mower (18.0 HP net) the deceased was operating did not have a ROPS, nor was it required to have ROPS based upon the OSHA/MIOSHA requirement of 20 horsepower. Many greens mowers do not have a ROPS/seatbelt because of the less than 20 HP engine design characteristic. The equipment is often operated on raised greens/tee boxes where the potential for rollover is present.

Several manufacturers have developed a ROPS retrofit unit for their zero-turn-radius mowers that were not originally sold with a ROPS/seatbelt. MIFACE encourages all manufacturers to develop a retrofit ROPS for greens mowers and other riding equipment used for groundskeeping, whether in the golf course industry or general landscaping.

Employee training should include review of written material, such as the machine operator’s manual.

Employee health and safety training should strive to ensure that the employee has the ability to identify work place exposures and control risks. A comprehensive health and safety program should include training in hazard recognition, avoidance of unsafe conditions, and equipment operation. The employer provided the deceased with ample on-the-job experience, and by company accounts, the most experienced individual to conduct the training. Operator manuals provide a basis for consistent and thorough employee training. The company did not use or provide the manual as part of the deceased’s training. The operator’s manual contained a section entitled “Avoid Tipping.” Several recommendations specifically addressed the incident site:

- Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution.

- Do not mow or operate machine on wet grass, tires may lose traction; tires may lose traction on slopes even though the brakes are functioning properly.

- Do not mow near drop-offs, ditches, embankments or bodies of water. The machine could suddenly roll over if a wheel goes over the edge or the edge caves in.

If the on-the-job training the deceased received did not adequately deal with the issues of wet grass and slope, reading the operator’s manual may have alerted him to these issues with the mower.

Additionally, MIFACE recommends that:

All workers on the course, when working alone, should be equipped with a company-supplied communication device.

The course superintendent indicated that the course personnel equipped with communication devices (walkie-talkies) are the workers responsible for cup placement and course irrigation. Working alone poses special communication issues. Other employees on the course are operating equipment, which can break down or cause injury to both the employee and golfers. Communication equipment would provide the employee an opportunity to communicate with the office (check-in) on a periodic basis, make a call to the office concerning equipment breakdown or malfunction, report an emergency situation such as injury to self or golfers. It is unknown if the deceased could have used a communication device to report his accident or summon help. The communication device could also provide office personnel an opportunity to check in with employees working in remote areas to make work assignment changes or check on their well-being.

Resources

MIOSHA standardsexternal icon cited in this report may be found at and downloaded from the MIOSHA, Michigan Department of Labor and Economic Growth (DLEG) web site at: http://www.michigan.gov/mioshastandards. MIOSHA standards are available for a fee by writing to: Michigan Department of Labor and Economic Growth, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan 48909-8143 or calling (517) 322-1845.

- MIOSHA General Industry Safety Standard, Part 54, Powered Groundskeeping Equipment

- MIOSHA General Industry Safety Standard, Part 22, Tractors

- Scarlett, AJ, Reed JN, Semple DA et al. Operator Roll-over protection on small vehiclespdf iconexternal icon. Prepared by Silsoe Research Institute for the Health and Safety Executive 2006. Research Report 432. Internet Address: http://www.hse.gov.uk/research/rrpdf/rr432.pdf

Michigan FACE Program

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicineexternal icon, 117 West Fee Hall, East Lansing, Michigan 48824-1315. Internet Address: http://www.oem.msu.edu/MiFACE_Program.aspx. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 01/05/2007 (Link updated 8/5/2009)

MIFACE Investigation Report # 05MI060 Evaluationpdf iconexternal icon (see page11 of report)

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.