Farmer Dies When Grain In Grain Bin Engulfs Him

Investigation: # 03MI108

SUMMARY

On August 20, 2003, a 40-year-old male farmer entered a 49-foot diameter Chief grain bin to clear corn that had clogged the unloading holes. The bin was approximately one-half full, with approximately 30,000 bushels left in the bin. The bin was equipped with a power sweep head unit that was not running. He was standing on the grain with the augers running so he could identify the location of the unloading holes. The bin’s two outside one-foot square holes were flowing. The victim may have been attempting to clear the hole next to the center hole. He entered the grain bin from the top hatch and used a 20-foot long ½-inch pipe to clear the plugged hole. It appears that due to the pattern of grain flowing from the unloading holes, that the remaining grain in the bin was at a 20-30 degree slope up one side of the bin. When the hole was cleared and the grain started flowing, it is postulated that the sloped grain wall sheared upon the movement of the grain at the base of the pile and the victim was engulfed. When he could not be found, rescue persons were called. After nearly three hours he was found by his brother in the bin and removed. He was declared dead at the scene.

RECOMMENDATIONS

- All equipment used to fill or empty a grain bin should be stopped and the power source locked out before workers enter the bin.

- Grain bins should be identified as confined spaces, posted with hazard warning signs, and written confined space entry procedures should be established and followed.

- A safety harness and safety line should be used when entering grain bins if the structure is equipped with appropriate anchoring devices.

- Grain handling facility owners should consider installing elevated grates or “chairs” over the center unloading auger openings.

- Farmers and grain storage operators should ensure that adequate measures are taken to avoid spoilage of grain during storage and possible bridging of grain.

- Use a mechanical raking device or a power sweep that is able to withstand high grain load to ensure grain movement within the bin.

- Grain bin ventilation fans should be turned on and operating properly before workers enter bins which are either full or partially full.

- Employers should provide and have in place equipment for rescue operations that is specifically suited for the task being conducted.

- Additionally, MIFACE recommends that rural emergency personnel become familiar with confined space rescue in agricultural grain bins found on farms.

INTRODUCTION

On August 20, 2003, a 40-year-old male farmer died as a result of engulfment while attempting to dislodge a “hot spot” or jam in the bin in a 49-foot diameter grain bin containing 30,000 bushels of corn. MIFACE learned of this incident from a newspaper clipping. On February 24, 2004, MIFACE researchers interviewed the deceased’s brother. During the course of writing this report, the medical examiner’s report, death certificate, police department report and pictures were obtained. Pictures depicting Figures 1, 2, and 3 were taken by MIFACE researchers at the time of the site visit. Figure 4 and Figure 5 were taken by the responding police agency.

The victim and the victim’s brother interviewed by MIFACE had a partnership in running the farm. The victim’s father owned the land. Three family members in addition to the victim were at the farm at the time of the incident. His parents were in their home and another brother was mowing the grass. The brother interviewed by MIFACE was off-site hauling soybeans, but had returned in time to be part of the recovery operation. The family farm grew corn on approximately 1500 acres. The deceased was a full-time farmer. There was no written farm safety program, but he did have equipment manuals. On the day of the site visit, the brother could not find the bin manual. He thought that another family member had it in their possession. The deceased had attended several farm safety presentations.

INVESTIGATION

The farm had two Chief metal grain bins. The Chief grain bin involved in the incident was 49-feet in diameter with a conical top and had a capacity of 69,000 bushels. It was approximately half-full of shelled corn at the time of the incident. A metal ladder is attached to the outside of the bin leading up to the entry hatch.

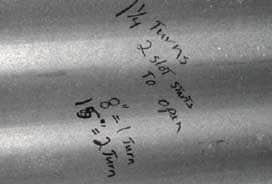

The corn was unloaded from this grain bin by a bottom-unloading auger system. The horizontal auger mounted below the raised steel floor of the bin had multiple auger intake openings. The center auger intake was the largest, 8-10 inches wide and two feet long. The remaining auger intakes were one foot square. The auger intake openings were fitted with a steel safety grid that allowed grain to pass through them but prevented workers from being directly exposed to the auger intake located below the bin floor. The auger intake openings were opened outside of the bin by manually turning a handle. The directions as to how far to turn the handle were hand written on the outside of the bin. The auger housing contained many warning signs (See Figures 1 and 2).

|

|

| Figure 1. Auger unloading system | Figure 2. Auger unloading instructions on grain bin wall |

The Chief bin was equipped with a power sweep located near the bin floor that could be operated only when the bin was nearly empty according to his brother.

The bin had an access door on the side of the bin that was fitted with a hinged exterior door that opened outward and an interior door that had a confined space sign that opened inward. The bin also had a top hatch with a ladder on the inside of the bin to provide access to the bin’s interior. Both of these entrances to the grain bin appeared to have required confined space warning signs; MIFACE researchers observed a confined space sign on the side grain bin door and the victim’s brother stated that there was a confined space sign on the outside of the top bin hatch (See Figure 3).

|

| Figure 3. Confined Space warning sign on bin door. |

The deceased and his brother had bought the new storage system, including the Chief bins, two years prior to the incident. The summer of the deceased’s death was the first time the bin had been emptied. Shelled corn was dried in a dryer to approximately 160-degrees and was dropped hot into cooling bins that are 36 feet in diameter and hold about 18,000 bushels of corn. The corn slowly cools in these bins and when the corn reaches the approximately 40-50 degrees, it is moved to the Chief bins for bulk storage. When the nights are cool, the deceased would turn on the Chief bin fans to provide floor aeration to assist in further cooling of the corn. The corn is stored at 14% air moisture content.

During the transfer from the small bins to the large bins in the fall of 2002, the brother could see condensation on the outside of the auger. The shelled corn in the silos could have had a lot of “material” in the mix other than just clean, shelled corn. The victim’s brother stated that he and the deceased had handled a lot of wet corn in the big leg transferring the corn from the cooling bins to the storage bins. The corn had “bees wings” – described by the victim’s brother as the red chaff from the part of the corn ear covering the kernel. The victim’s brother thought that there were a lot of “bees wings” in the bottom of the bin. The victim’s brother stated that typically in the wintertime, snow would blow in through the vents and the top of the corn would get wet, moldy, and would form a “crust”. He thought that the crust layer was deeper in the center of the bin, due to the large number of fines or “bees wings” found there.

The victim’s brother told the MIFACE researchers that the Chief bin involved in the incident had bad seals at the top of the bin and that there was condensation of the tubes. The other grain bin had been emptied prior to the one involved on the day of the incident. When this bin was emptied, there were some chunks of corn/“bees wings” in the center, which required the victim and his brother to enter the bin to clear the auger openings.

On the day of the incident, the deceased was unloading the shelled corn from the bin and transferring it to another bin. The victim told his brother cutting the lawn that the auger was plugged and he was going to unplug it. This brother saw him enter the bin alone about 10:30am through the top hatch and continued to mow the lawn. The auger was left running when the victim entered the bin. The brother interviewed by MIFACE said that it was common practice for both he and his brother to enter the bin with the auger running so that they could determine the location of the auger intakes as well as which auger opening(s) could be plugged or running slowly. He said that they entered the bin from the top hatch, went down the inside ladder of the bin to the low side of the corn and use a stick to pry the obstruction from the auger. Their normal work practice was to clear the auger opening next to the center hole first, then to clear the center hole. This work practice had been done multiple times without incident. The brother thought that the center auger opening might have been plugged with corn. The power sweep could not be activated due to the amount of corn still remaining in the bin and the pressure it applied on the power sweep unit.

The brother mowing the lawn checked on the victim at approximately 11:00 am because a neighbor, who was supposed to meet with the victim, couldn’t find him. The neighbor and brother searched the farm and also looked through the open hatch at the top of the bin to see if they could find the deceased (See Figure 4 ). When his brother, saw that the victim’s truck was at the farm and his cell phone in the farm office, thought that the victim had hurt himself in the bin. The brother told the victim’s mother to call for emergency response. Both the victim and neighbor separately entered the storage bin looking for the victim and calling his name. He and the neighbor began to cut open a hole on the southeast side of the bin when paramedics arrived.

|

| Figure 4. Open entry hatch at top of grain bin. |

The brother interviewed by MIFACE was hauling a load of soybeans to another part of the state. When notified by his mother and he came home. He was part of the recovery effort. Rescue workers completed cutting the southeast hole and cut three additional holes in the bin, all approximately 4 feet by 4 feet on the north, south, and west side of the bin to empty the bin of corn (See Figure 5 ).

|

| Figure 5. Example of hole cut in grain bin to empty bin of grain. |

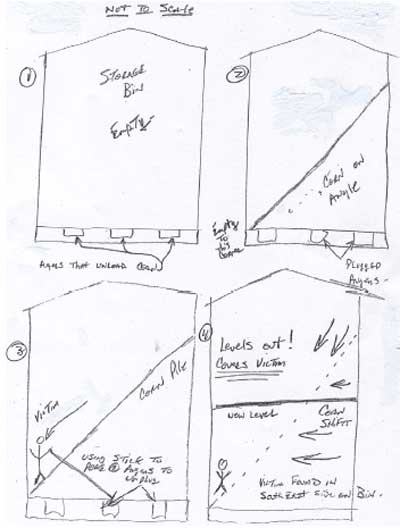

It appears the victim was in the process of clearing one of the auger openings when the grain wall to collapsed upon him. See Appendix A for a possible sequence of events as depicted by the responding police agency. The victim was found on the southeast side of the bin approximately 2.5 hours after the 911 telephone call was made and was declared dead at the scene. The victim was located near the bottom of the storage bin and had been covered with approximately 20 feet of shelled corn. The auger drawing corn out of the bin had not been shut down before entry and the victim was apparently covered by the corn both by the leveling or collapse of the shelled corn that was sloped against the bin wall and the auger pulling him down to the bottom of the bin. The corn outside of the bin was removed by a front-end loader. The victim may have been wearing a respirator to protect himself from potential respiratory hazards because a respirator was present with the victim at autopsy.

After the incident, the victim’s brother instituted two engineering changes in the grain processing system. One change was to add a vacuum pump “light trash” removal system after the drying process before the grain is loaded to the cooling bins. The other change was a modification of the bin’s power sweep unit. The power sweep, used originally to clear out the last remaining grain once the bin was emptied, was retrofitted to withstand the weight of the corn so that it could be operated during the unloading process if the center auger opening becomes plugged during unloading.

CAUSE OF DEATH

The cause of death as stated on the death certificate was compression asphyxia. Toxicological tests were not performed.

RECOMMENDATIONS/DISCUSSION

Note: This incident happened on a privately owned farm that does not fall under the Michigan Occupational Safety and Health Administration (MIOSHA) jurisdiction. However, the MIOSHA standards, which are referenced in the Recommendations/Discussion, are accepted guidelines for safe entry into grain structures. Even though a business may not be subject to MIOSHA jurisdiction it is recommended that MIOSHA guidelines be followed to enhance safety in the workplace.

- All equipment used to fill or empty a grain bin should be stopped and the power source locked out before workers enter the bin.

The number one risk factor that contributes to death due to grain engulfment is the condition of the grain. If the grain is in poor condition, it tends to clump together and stop flowing. To break up the clog and increase the flow of grain, the farmer may enter the bin to break up the clumps of grain. If the unloading equipment is not turned off, when the clump is broken up, he/she may end up getting caught in the grain flow.

The majority of grain entrapments (79%) involve shelled corn. Ninety-two percent of individuals who are engulfed die. If an individual enters a grain bin with the discharge augers running, the grain removal below will almost instantly submerge the person to over the knees. It takes less than 5 seconds to render the individual completely helpless. Typical auger unloading rates are often high enough that an individual will be pulled below the surface of the grain (completely submerged) in less than 20 seconds. Because of these hazards, all power sources should be locked out to ensure that the loading and/or unloading equipment cannot start accidentally or be started inadvertently by someone else. This may require locking out all electrical circuits that operate electrical motors, etc.

The auger was still in operation at the time of this incident and its action may have caused the grain to begin to flow over and onto the victim. It is recommended that any time a worker enters a grain bin or other storage area, the supply and discharge of materials should be stopped and the supply and discharge equipment should be locked out.

- Grain bins should be identified as confined spaces, posted with hazard warning signs, and written confined space entry procedures should be established and followed.

Grain bins meet the MIOSHA definition of a confined space. A space is considered “confined” if it has any one of the following characteristics: (1) large enough and so configured that an employee can bodily enter and perform assigned work, (2) has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults and pits are spaces that may have limited means of entry, and (3) is not designed for continuous employee occupancy.

In this incident, the warning signs were posted at each entry point and legible. It is important that the entrants of a confined space adhere to the warnings contained on the signs.

Stored shelled corn in a grain bin or silo is an unstable material, therefore, at all times there is a potential for engulfment. Specific procedures for safe entry should be developed and implemented that identify and evaluate the hazards and work practices necessary for safe entry. This could include locking-out all equipment, posting a standby attendant to maintain communication with the individual entering the bin, wearing appropriate personal protective equipment, such as safety harness/lanyard and rescue and emergency equipment needed in case of an emergency. Several resources are available to farmers to assist them in establishing grain bin entry procedures. Two MIOSHA General Industry Standards, Part 90, Confined Space Entry Standard and Part 77, Grain Handling Facilities contain the elements that should be considered when entering a confined space, such as a silo. NIOSH Publication No. 80-106, “Working in Confined Spaces” also provides useful information to a farm owner to assist in establishing a grain bin entry procedure.

- A safety harness and safety line should be used when entering grain bins if the structure is equipped with appropriate anchoring devices.

A national database of agriculture-related engulfment cases has been maintained by Purdue University since 1978. Five hundred two (502) cases of fatal and non-fatal engulfments in the United States and Canada have been documented. From 1980-2001, 197 engulfment cases were identified occurring in on-farm grain bins, 156 of them were fatal. Approximately seven fatal and two non-fatal cases per year were reported during that time period. (Kingman et al, 2003) Most farmers appear to be aware of this hazard, yet many take the risk and enter grain bins during unloading without a safety harness or standby person. Safety harnesses and lifelines although not commonly used on farm grain bins, are commonly used during bin entry at commercial grain handling facilities. The difficulty is that farm grain bins don’t usually have a suitable anchor tie-off point for the safety line. The structure of the grain bin roof is not designed to withstand great forces, and the location of the entrance is usually at one side of the bin. MIFACE encourages manufacturers to add suitable anchor tie-off points to grain bins. Fall protection while climbing up the outside of grain bins is another safety issue and a harness and lanyard could also be used here if suitable protective modifications are built into the ladder structure.

- Grain handling facility owners should consider installing elevated grates or “chairs” over the center unloading auger openings.

The “chair” is typically used in commercial elevators, but could be used on family farms as well. The “chair” is a metal structure covering the grain auger opening. It is commonly about 2-feet high with open sides and a perforated top that allows grain to flow through. If there are clumps in the grain, they will likely enter from the center and be pushed against the perforated top, which breaks them. Even if the top gets plugged, grain can flow through the sides.

- Farmers and grain storage operators should ensure that adequate measures are taken to avoid spoilage of grain during storage and possible bridging of grain.

An important method to prevent grain suffocations is to ensure that the grain is in good condition for storage. This will avoid problems with spoilage, obstructions in grain flow and respiratory exposure to mold spores and other hazardous organic dusts while handling spoiled grain. As the Purdue research demonstrated, the condition of the grain is the number one risk factor. Drying or aeration must be used if it is not possible to harvest the grain at adequately low moisture content. A structural examination of the storage facility looking for leaks should be performed and remediated to minimize the possibility of grain spoilage. The victim’s brother, after the incident, did have the grain bins seals replaced and the bins’ leaks fixed.

- Use mechanical raking device or a power sweep that is able to withstand high grain load to ensure grain movement within bin

Grain bins, silos, hoppers, or tanks where unstable materials are stored, handled or transferred should be equipped with mechanical leveling or raking devices or other means for remotely handling materials. Devices of this nature would minimize the need for workers to enter storage facilities. Usually cone-shaped piles of loose material can be leveled and bridging of material prevented by mechanical agitation or vibration of stored materials. After the incident the victim’s brother modified the power sweep system to be able to be operated under high grain load. This system may now be used even if the grain bin is not almost empty and minimizes the need to enter the grain bin.

- Grain bin ventilation fans should be turned on and operating properly before workers enter bins which are either full or partially full.

Electric ventilation fans are used primarily to circulate unheated air through the stored grain. Ventilation fans force outside air into a space between the concrete bin foundation and a raised steel floor contained small holes. The air is forced upward through the grain and escapes through seams in the bin roof. When ventilation fans are operating, they are capable of providing a continuous flow of air through the stored grain. Confined spaces can have the potential for a build-up of air contaminants and the introduction of air movement into the bin may reduce the airborne levels of any air contaminants present. The presence and use of ventilation fans does not lessen or eliminate the confined space hazards of grain bins nor does their use reduce the need for workers to follow confined space entry grain bin procedures.

- Employers should provide and have in place equipment for rescue operations that is specifically suited for the task being conducted.

It is important for farm owners to have an emergency action plan, communication devices for the standby person, and appropriate rescue equipment available when an individual enters the grain bin. Rescue equipment includes a tripod with winch or a fixed and portable support arm with a winch should be explored to determine if it could be used with the structure. Time is of the essence in the case of an emergency situation. Of the four people documented in the Purdue study who survived after being completely engulfed in grain, each of the individuals had a standby person, was wearing a safety harness and lanyard, and was rescued within minutes.

- Additionally, MIFACE recommends that rural emergency personnel become familiar with confined space rescue in agricultural grain bins found on farms.

The victim’s brother, although very appreciative of the work of the emergency responders to save his brother requested that MIFACE address the issue of grain engulfment and emergency response. The emergency personnel, in their mission to find the victim, created not only an additional hazard (30,000 bushels of grain outside of the bin) but also economic loss when they cut the holes in the side of the grain bin. The victim had been engulfed in the grain bin for well over the time it takes to succumb to the pressure of the grain on his body. According to the victim’s brother, every effort must and should be taken during rescue operations. Once a rescue has been classified as a recovery operation different grain bin unloading procedures could have been followed. Instead of cutting three additional holes in the bin and the grain pouring out outside of the bin, the unloading auger could have been used to empty the bin.

REFERENCES

- MIOSHA standards cited in this report may be found at and downloaded from the MIOSHA, Michigan Department of Labor and Economic Growth (MDLEG) website at: http://www.michigan.gov/lara/0,4601,7-154-11407_15368—,00.htmlexternal icon.(Link Updated 4/1/2013) Also, MIOSHA standards are available for a fee by writing to: Michigan Department of Labor and Economic Growth, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan 48909-8143 or calling (517) 322-1845.

- MIOSHA General Industry Safety Standard, Part 90, Confined Space Entry

- MIOSHA General Industry Safety Standard, Part 77, Grain Handling Facilities

- NIOSH (1987) Alert: Request for assistance in preventing entrapment and suffocation caused by the unstable surfaces of stored grain ad other materials. Cincinnati, OH: US Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 88-102.

- Study: Post-harvest is Danger Season for Grain Entrapments. Ag Answered. An Ohio State Extension and Purdue Extension Partnership. Internet address: http://www.agriculture.purdue.edu/agcomm/aganswers/index2.aspexternal icon Press Archive tab at top of page, then press 1996 Archive on right side of page. (Link Updated 11/17/2011)

- The Dangers of Flowing Grain, Bill Field, Purdue University Cooperative Extension Service, West Lafayette, IN 47907. Internet address: http://www.extension.purdue.edu/extmedia/s/s-77.htmlexternal icon (Link Updated 4/1/2013)

MIFACE (Michigan Fatality and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 7/1/04

APPENDIX A

Note: MIFACE modified this drawing to remove personal identifiers.

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

MIFACE

Investigation Report # 03 MI 108

Evaluation

| To improve the quality of the MIFACE program and our investigation reports, we would like to ask you a few questions regarding this report. | |||

| Please rate the following on a scale of: | |||

| Excellent | Good | Fair | Poor |

| 1 | 2 | 3 | 4 |

| What was your general impression of this MIFACE investigation report? | |||

| Excellent | Good | Fair | Poor |

| 1 | 2 | 3 | 4 |

| Was the report… | Excellent | Good | Fair | Poor |

| Objective? | 1 | 2 | 3 | 4 |

| Clearly written? | 1 | 2 | 3 | 4 |

| Useful? | 1 | 2 | 3 | 4 |

| Were the recommendations … | Excellent | Good | Fair | Poor |

| Clearly written? | 1 | 2 | 3 | 4 |

| Practical? | 1 | 2 | 3 | 4 |

| Useful? | 1 | 2 | 3 | 4 |

| How will you use this report? (Check all that apply) | |

| O | Distribute to employees/family members |

| O | Post on bulletin board |

| O | Use in employee training |

| O | File for future reference |

| O | Will not use it |

| O |

Other (specify) __________________________________________ |

Thank You!

Please Return To:

MIFACE

Michigan State University

117 West Fee Hall

East Lansing, MI 48824

FAX: 517-432-3606

Comments:

| If you would like to receive e-mail notifications of future MIFACE work-related fatality investigation report summaries, please complete the information below. | |

| Name: __________________________________________ | |

| e-mail address: ___________________________________ | |

| I would like to receive summaries for reports involving: | |

| ___ Construction | ___ Agriculture |

| ___ Manufacturing | ___ All |