Farmer Dies When Tractor With Front-End Loader Overturns In Ditch and Pins Him

Investigation: # 03MI103

SUMMARY

|

|

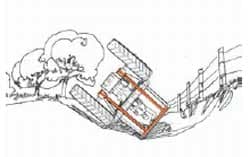

Figure 1. Access path/ditch leading to woodlot.

|

On July 28, 2003, a 77-year-old male farmer was driving a 1954 77 Oliver tractor equipped with a front-end loader with 12-inch bucket tines to a woodlot on his property. He was carrying a salvage flail mower chained to the loader. The tractor was not equipped with a roll-over protection structure (ROPS). He traveled east along a lane between his cornfields to the back of his property and made a right turn (south) around a 10-foot deep by 15-foot wide drainage ditch. There was a variable width path to the wood area on the east side of the ditch (See Figure 1). It appears that after he turned the corner and was on the path to the woodlot, he tried to avoid damaging a field of planted corn with the flail chopper. In trying to avoid the corn, he got too close to the drainage ditch and the tractor overturned to the side, landing on top of him. When he did not return home, his wife went looking for him and saw the overturned tractor. She called a family member who called 911. Emergency response arrived and the victim was declared dead at the scene.

RECOMMENDATIONS

- Use equipment properly – a front-end loader bucket isn’t designed to carry a flail chopper.

- Equip older tractors with a roll-over protection structure (ROPS) and a seat belt; the local county extension agent, local equipment dealer or equipment manufacturer should be contacted to see if a retro-fit ROPS/seat belt system is available.

- Utilize open fields after crop harvest to access areas without established paths/roadways that have adequate width and distance from the edge of a ditch.

- Establish crop-planting limits/boundaries to maintain farm machine access roads to other fields/areas.

- When mowing or planting, leave a visual cue to identify the edge of drainage ditches or other land depressions.

INTRODUCTION

On July 28, 2003, a 77-year-old male farmer died as a result of being pinned under a front-end loader-equipped tractor that overturned in a ditch. MIFACE learned of this incident from a newspaper clipping. On April 26, 2004, MIFACE researchers interviewed the wife of the deceased, visited and photographed the incident site and flail mower. During the course of writing this report, the medical examiner’s report, death certificate, and police department report were obtained. MIFACE took pictures of the incident site and the flail mower in the woodlot. After the incident, the victim’s wife gave the tractor to a local dealership. The dealership used the tractor for salvage parts; therefore, MIFACE was unable to see the tractor. Pictures taken at the scene by MIFACE were in the spring of the year following the victim’s death. According to the victim’s wife, the ditch was dry at the time of the incident.

The victim was a lifelong farmer, born and raised on the farm he was working. He loved tractors and enjoyed maintaining all of his equipment. The victim had approximately 80 acres that were leased, and 80 acres in the Conservation Reserve Program. He had rented out his acreage and the renter planted and harvested the corn grown on those acres. The victim did not have a farm safety plan.

The victim wore glasses. He had previously had an injury to his right eye and had limited vision from that eye. The victim had been taking prescribed medication 3-5 days for a medical condition but had stopped taking the medication due to side effects experienced. Side effects as reported by his spouse were making him unsteady.

INVESTIGATION

The tractor operated by the victim was a wide-front 1954 77 Oliver that he had purchased “pre-owned” at an auction. The rear tires were filled with air and there were no weights in the rear. The victim’s wife stated that the brakes were functioning properly. The tractor was not equipped with a ROPS or a seat belt nor did it have an operator’s manual. The tractor was equipped with a front-end loader and 12-inch bucket tines.

The victim had two flail choppers, one that he had salvaged for parts and one for use. Because of a fire on his property, he had lost the storage building for the choppers, and they were currently being stored where they could be seen behind the house. The victim wanted to move the salvage flail chopper to a remote location so that it would be out of sight. Therefore, he decided to take the salvage chopper to a woodlot at the rear of his property. MIFACE researchers measured the flail chopper dimensions during the visit; the chopper measured 17 feet 10 inches from front-to-back and seven feet wide.

MIFACE estimated the salvage flail mower to exceed 700 pounds (See Figure 2).

|

| Figure 2. Salvage flail mower in woodlot. |

The victim had cleaned out the drainage ditch the year before and had made it deeper. The ditch was approximately 15 feet wide and 10 feet deep, with the sides sloping approximately 60 degrees.

Figures 3-5 show the path he drove to the woodlot. Before transporting the flail chopper to the woodlot, he chained the chopper to the front-end loader/tines. He traveled down a wide lane between cornfields. This lane terminated into a cornfield and the woodlot was to the operator’s right. The drainage ditch was to the victim’s right and left.

|

|

|

|

Figure 3. Access lane between cornfields.

|

Figure 4. Lane ending at cornfield and turn to woodlot.

|

Figure 5. Mowed path to woodlot.

|

There was a mowed path that directly abutted another cornfield. This mowed path led to the woodlot. This path narrowed as it approached the woods. It was approximately 6-7 feet wide as it entered the woodlot. The distance from the planting row to the edge of the mowed path was approximately seven inches. The victim’s wife thought that this was similarly planted at the time of her husband’s death.

The victim successfully completed the turn to take the path to the woodlot. After traveling approximately 150 feet, it appears that he was too close to the edge of the ditch. The path was approximately 12-feet wide at this point. The police report stated that tire tracks in the grass showed that shortly after the victim made the turn south on the lane he slowly drove the tractor closer and closer to the edge of the ditch until the tractor slipped down the embankment and rolled over landing on top of the victim at the bottom of the ditch.

When he didn’t come home for supper, his wife went looking for him. She saw him in the ditch under the overturned tractor. She called other family members who called 911. Emergency responders arrived and the victim was declared dead at the scene.

CAUSE OF DEATH

The cause of death as stated on the death certificate was compression asphyxia. Toxicological tests were not performed.

RECOMMENDATIONS/DISCUSSION

- Use equipment properly – front-end loader bucket isn’t designed to carry a flail chopper.

Front-end loader buckets are not designed for carrying the large and heavy pieces of equipment, such as the flail chopper. Although a manual for the flail chopper was unavailable, the chopper’s size and weight was close to exceeding the capacity of the tractor and made the tractor unstable even though the victim was driving slowly. It is unknown if the victim set the tractor wheels at the widest recommended setting, since a manual was also not available for the tractor and MIFACE was not able to see the tractor. The victim’s wife indicated she did not think that extra ballast was added to the rear of the tractor to give the tractor extra stability. The ballast would counterbalance the extra weight on the front of the tractor and help prevent an overturn. Additionally, overloading a front-end loader on a tractor can cause instability and steering difficulty.

- Equip older tractors with a roll-over protection structure (ROPS) and a seat belt; the local county extension agent, local equipment dealer or equipment manufacturer should be contacted to see if a retro-fit ROPS/seat belt system is available.

Older tractors can be equipped with roll-over protection structures and seatbelts. Roll-over protection structures (ROPS) have been required by federal and state law for all tractors used by employees in agricultural operations that were built after October 25, 1976. Owners/operators as sole proprietors are not required to have ROPS. There are two basic types of ROPS for farm tractors: protective frames (two- or four- post structures attached to the tractor chassis) and protective enclosures (cabs or enclosures built around a protective frame).

ROPS are designed to help limit a tractor overturn to 90 degrees and to provide the operator a “zone of protection” (See Figure 6). The operator must stay within this zone. The operator may not be protected by the ROPS during an overturn if the operator is not wearing a seatbelt; the operator may be totally or partially thrown off the tractor. The seatbelt keeps the operator within the “zone of protection” provided by the ROPS. Even inside a cab, seat belts are important to keep the operator from being thrown against the frame, through a window, or out a door.

|

| Figure 6 – Operator Zone of Protection |

Therefore, when an older tractor is retrofitted with a ROPS, attention must be paid for ensuring approved seat belts are also installed. Seat belts may be included with the ROPS package.

Seat belts should not be used on tractors that do not have ROPS.

Many older tractors can be retrofitted with a ROPS/seat belt system by a qualified dealer. An Internet resource to obtain approximate costs for retrofitting an older tractor with a ROPS/seat belt may be found from the Marshfield Clinic: http://www3.marshfieldclinic.org/NFMC//?page=nfmc_rops_guideexternal icon (Link updated 4/4/2013)

This information resource lists manufacturers, models, and approximate costs of obtaining retrofit ROPS for tractors. Another option for owners of older tractors to obtain information about ROPS retrofits is to contact their local extension office or tractor dealership. ROPS should be certified to meet the standards and regulations of various agencies that ensure that the frame or enclosure is designed to provide overturn protection- ROPS should not be manufactured in the farm machine shop. Tractor owners should check the manufacturer’s literature or look for a label on the frame or enclosure stating it meets roll-over protection standards.

Although the victim’s farm was on flat terrain, a roll-over hazard was present near the area of the drainage ditches along all of the fields. Even though the addition of the ROPS/seatbelt system to the 77 Oliver would have been expensive (approximately $2,599.00), the presence of a ROPS and the wearing of a seatbelt would probably have prevented his death.

- Utilize open fields after crop harvest to access areas without established paths/roadways that have adequate width and distance from the edge of a ditch.

The victim wanted to move the salvage flail chopper to a remote site. While not wanting to damage the corn in the field, he had little maneuvering room on the path. If he had waited until crop harvest, he could have entered the fields and have been well away from the ditch edge.

- Establish crop- planting limits/boundaries to maintain farm machine access roads to other fields/areas.

The outside row of corn was planted approximately six inches from the edge of the access path to the woodlot. This limited distance between the edge of the field and the path further narrowed the maneuvering room the victim had to travel to the woodlot due to the presence of the growing corn plants along the outside planting row. A planting boundary should be established so that the outside planting row does not impinge on an access road to other fields/areas.

- When mowing or planting, leave a visual cue to identify the edge of drainage ditches or other land depressions.

Mow away from the edge of the ditch and leave the tall grass as a marker. The tall grass boundary from the edge of the ditch should be at least equal to the depth of the ditch. If possible, when equipment movement occurs between the crop field edge and a depression such as a ditch, make a best effort to have a 12-20 foot access area (path) to accommodate equipment movement. It is unknown how well the ditch was defined at the time of the incident. The path, as shown in Figure 7 has tall grass and shrubbery at the very edge of the ditch and growing up from the sides of the ditch, making it difficult to determine the ditch edge.

|

| Figure 7. Undefined ditch edge. |

A visual cue is especially important for individuals with impaired vision, like the victim. He had monocular vision (vision in only his left eye). This decreased the size of his field of view by approximately 25%. His depth perception was probably not an issue since after three feet, and since he was free to move his head from side to side, other distance cues could substitute for vision out of both eyes. (binocular vision). He had probably developed a compensatory mechanism moving the head back and forth to gather information about relative distance. It appears that he was concentrating on not damaging the corn on his left side, and may not have been checking his right side as frequently as he would have normally been. His peripheral vision was compromised on his right side, the location of the ditch into which the tractor overturned. It is possible that a wide area of untrimmed pathway would have provided enough of a visual cue in his impaired peripheral vision to alert him to the ditch location.

REFERENCES

- Farm and Ranch Safety Management, Deere and Company, Moline, IL Fourth Edition, 1994.

- Politzer, Thomas, OD, FCOVD, FAAO. Implications of Acquired Monocular Vision (loss of one eye), Neuro-Optometric Rehabilitation Association Online. Internet address: http://nora.cc/content/view/26/70/external icon (Link updated 12/11/2007)

- A Guide to Agricultural Tractor Rollover Protective Structures, A Publication of the National Farm Medicine Center, Marshfield, Wisconsin. http://www3.marshfieldclinic.org/NFMC//?page=nfmc_rops_guideexternal icon (Link updated 4/4/2013)

MIFACE (Michigan Fatality and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 7/1/04

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

MIFACE

Investigation Report # 03 MI 103

Evaluation

| To improve the quality of the MIFACE program and our investigation reports, we would like to ask you a few questions regarding this report. | |||

| Please rate the following on a scale of: | |||

| Excellent | Good | Fair | Poor |

| 1 | 2 | 3 | 4 |

| What was your general impression of this MIFACE investigation report? | |||

| Excellent | Good | Fair | Poor |

| 1 | 2 | 3 | 4 |

| Was the report… | Excellent | Good | Fair | Poor |

| Objective? | 1 | 2 | 3 | 4 |

| Clearly written? | 1 | 2 | 3 | 4 |

| Useful? | 1 | 2 | 3 | 4 |

| Were the recommendations … | Excellent | Good | Fair | Poor |

| Clearly written? | 1 | 2 | 3 | 4 |

| Practical? | 1 | 2 | 3 | 4 |

| Useful? | 1 | 2 | 3 | 4 |

| How will you use this report? (Check all that apply) | |

| O | Distribute to employees/family members |

| O | Post on bulletin board |

| O | Use in employee training |

| O | File for future reference |

| O | Will not use it |

| O |

Other (specify) __________________________________________ |

Thank You!

Please Return To:

MIFACE

Michigan State University

117 West Fee Hall

East Lansing, MI 48824

FAX: 517-432-3606

Comments:

| If you would like to receive e-mail notifications of future MIFACE work-related fatality investigation report summaries, please complete the information below. | |

| Name: __________________________________________ | |

| e-mail address: ___________________________________ | |

| I would like to receive summaries for reports involving: | |

| ___ Construction | ___ Agriculture |

| ___ Manufacturing | ___ All |