Guardrail Post Pounder Operator Electrocuted When Hammer Boom Contacts Energized Overhead Electrical Line

Michigan Case Report: 02MI152

Summary

On November 6, 2002, a 23-year old male operator of a guardrail post pounder mounted on a stake truck was electrocuted when the boom of the post pounder contacted an energized overhead power line. The state highway was oriented in a north/south direction. The contract required guardrails on the highway’s east and west sides as well as guardrail placement on the south side of an intersecting road. The company had notified MISS DIG and all underground utility lines were marked. The guardrails on the west side of the highway had been set and the employees were placing guardrails on the east side. It was very windy on the day of the incident causing the overhead lines to sway in the wind. Work had progressed between 150-200 feet along the highway shoulder when, while pounding the guardrail post, the boom contacted an energized overhead 14,000 volt power line that crossed the highway in an east-west direction. The contact energized the truck and the victim received a fatal shock. He fell, breaking contact. Coworkers heard “crackling” and looked over toward the post pounder truck. They saw the victim lying on the ground, under the truck. They carefully pulled him clear from the energized truck and called for emergency responders. The victim was declared dead at the incident scene.

|

|

Figure 1. Guardrail Post Pounder Truck at Incident Site.

|

Recommendations:

- Conduct a jobsite survey (hazard assessment) to identify potential hazards before starting any job and implement appropriate control measures.

- Companies working in the vicinity of overhead power lines should verify that a minimum of a 10-foot clearance could be maintained between equipment and any lines in the area. If adequate clearances cannot be guaranteed, the employer should indicate to MISS DIG that they would be working with equipment that could contact these lines.

- Hazard awareness regarding overhead power lines should be stressed and routinely reviewed so that all employees are cognizant of these energized sources.

- Operating controls for boomed vehicles, when designed for use from ground level, should insulate the operator from the vehicle. An Accident Prevention Program should be developed, written, and implemented in compliance with MIOSHA Construction Safety Standard requirements.

- Company management should consider developing a joint health and safety committee.

Introduction

On November 6, 2002 a 23-year old male post punch machine operator was electrocuted while he was placing guardrail posts into the ground. On November 12, 2002, MIFACE investigators were informed by Michigan Occupational Safety and Health Act (MIOSHA) personnel, who had received a report on their 24 hour-a-day hotline, that a work-related fatal injury had occurred on November 6, 2003. On May 7, 2003 the MIFACE researcher visited the company headquarters and interviewed the co-owners. At this location, the guardrail post pounder truck was also seen. After visiting the company location, the researcher traveled to the incident location. During the course of writing the report, the autopsy results, police report and the MIOSHA citations were obtained. Photographs used for Figure 1 and Figure 5 were taken at the time of the incident by the responding police agency. The MIFACE researcher took the photographs used in Figures 2, 3, 4 and 6.

|

|

Figure 2. “Post Pounder” truck.

|

The company received two alleged willful/serious violations. One citation was for the failure to develop an Accident Prevention Program; no specific instruction to employees, no record of inspection procedures to eliminate recognized hazards, no designated person to administer the company’s safety program. Also contained within this citation was that there was no training in Safety standards or common practices by the company’s type of work operations (industry practices). The second alleged willful/serious violation was that the employer did not maintain proper clearance of a power line crossing work area. Employees were operating a guardrail post pounder truck with the truck boom approximately 22 feet high. The overhead power line voltage was 14,000 volts. The company received a Repeat Serious alleged violation for employee failure to wear a hard hat while operating and assisting the operator of the guardrail post pounder. The company also received two alleged violation designated as other. One citation was for failing to notify the Department of Consumer and Industry Services of a fatal employee injury within 8 hours. The second citation was that the Form 300 for 2002 was incomplete.

The company has approximately 20 employees and has been in business for approximately 5 years. The company installs guardrails. The victim was an hourly, full-time employee, and had been employed with the company for 4 years. His job title was the post pounder truck operator. He was a member of the union. The company was a site subcontractor. The individual experienced a non-fatal electrocution using the same piece of equipment approximately 3 months earlier and required hospitalization for his injuries. At the time of the fatality, the company did not have a written accident program. The post pounder truck was purchased used without an operator’s manual. The company did truck maintenance.

A few days prior to the incident, the company owner talked with the victim about job safety, using the equipment safely, and about the dangers posed by overhead power lines. The supervisor on site is responsible for site safety. Employees have the authority to correct on-site safety hazards they see; if they cannot correct the hazard, they are instructed to call the office for assistance in abating the hazard.

Back to Top

Investigation

The hydraulically powered guardrail post pounder was mounted on a stake truck. It had a gravity drop hammer and turntable. The boom had a working height of 22 feet. The truck was referred to as the “post pounder” (See Figure 1 ). The operator (victim) could remotely drive the truck while walking on the ground alongside the truck by activating control levers at the operator station. The victim had approximately 8 months experience operating the post pounder; he operated it on a daily basis when placing rails. The victim was required to wear a hard hat while operating the post pounder. He was not required to wear other personal protective equipment.

The job crew consisted of one foreman, one post punch operator (the victim) and 4 laborers. The crew worked 10- hour days, 5 days a week. The company was contracted to place guardrails on the east/west shoulders of a state highway as well as installation of guardrail on the south shoulder of an intersecting road. The company had been at the job site for 2-3 weeks. To construct a guardrail, the victim would position a steel H-beam approximately 6 feet in length in a vertical position into the post pounder boom below a cable operated hammer device. The victim, standing on the ground at the operator controls, would activate levers to drive the beam into the ground along the road shoulder. After setting the beam, he walked alongside the truck, moving it to the next location to set the next steel beam. Other company employees would follow him and install the guardrail onto the newly set steel beams. (See Figure 3)

|

|

Figure 3. Installed guardrail.

|

Prior to beginning work, the company had contacted MISS DIG and all underground lines were marked. The company did not indicate to MISS DIG that overhead power lines were in the area. The electrical lines contacted were oriented in an east/west direction and traveled across the highway.

The company had completed installation of the guardrail on the west side of the highway; the section of guardrail on the west side did not extend underneath the overhead lines. (See Figure 4). The ground was icy and snow covered. It was a windy on the day of the incident, and the emergency responders noted that the overhead line was moving back and forth in the wind. The victim was setting the steel beams along the east shoulder. He had set beams approximately 150-200 feet, moving the post pounder in a southerly direction. The post pounder truck cab was facing south.

|

|

Figure 4. Incident Site, Facing South.

|

The boom was extended upward when it contacted the overhead power line. It is unknown if the victim was walking alongside the post pounder or if he was setting a beam when the overhead power line contacted the boom. The boom extended approximately one foot above the wire and approximately 4-6 inches from the wire. (See Figure 5 )

|

|

Figure 5. Extended boom and power line.

|

When the energized wire touched the raised boom, electric current arced into the post pounder. The victim was holding the left control lever with his left hand when the electrical current struck him; he acted as a path to ground. The left lever control was bent from the impact of his reaction to the electricity. (See Figure 6). He fell to the ground, landing under the truck, breaking contact with the electricity. His coworkers, working on a separate task at the time of the incident, did not witness the electrocution. They heard a “crackling” sound and looked over and saw the victim on the ground by the rear of the truck. A coworker pulled him from under the energized truck and began CPR. Another employee ran to the foreman who was approximately 1/4 mile away to get help. Emergency assistance arrived and transported him to the nearest hospital where he was dead on arrival.

|

|

Figure 6. Bent control lever on post pounder.

|

There were burn marks on the boom on the side toward the cab. Before the truck was moved to a safe area, the electrical company was contacted and their employees insulated the wire.

Company employees, in retrospect, indicated they thought the electrical line looked low. Several days later when they went back to the job site to complete the guardrail installation, they thought the lines had been raised.

Back to Top

Cause of Death

The cause of death as listed by the medical examiner on the death certificate was death by accidental electrocution from a high voltage electrical line. Toxicological results were negative.

Recommendations/Discussion

Conduct a jobsite survey (hazard assessment) to identify potential hazards before starting any job and implement appropriate control measures.

Prior to the start of work, employers should conduct jobsite surveys to identify potential worker hazards so that appropriate preventive measures to control these hazards can be identified and implemented. Two characteristics of this jobsite combined to produce a serious hazard: 1) a 14,400 V energized overhead power line located approximately 22 feet off the ground and, 2) the use of a conductive truck-mounted boom in the vicinity of the power line. Such potential hazards can be minimized by ensuring that employees maintain a safe distance from energized conductors, by providing employees with non-conductive tools and materials, and /or by de-energizing or covering electrical conductors with insulating material. In this case, neither the foreman or the operator apparently considered the height of the mast when fully raised when assessing the hazards during the guardrail post installation. A safety checklist should be developed as part of a standard operating procedure to conduct the jobsite analysis. This should be used prior to the start of any activity at the work site.

The location of the machine (directly below the power line) and the weather conditions (overcast and windy) may have interfered with the operator’s perception of distance to the power line. Where applicable, a person should be designated to observe clearance of the equipment and give timely warning for operations where it is difficult for the operator to maintain desired clearances by visual means.

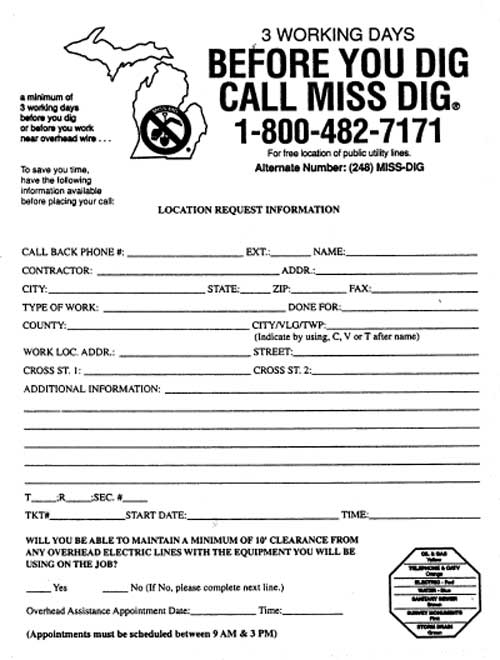

Companies working in the vicinity of overhead power lines should verify that a minimum of 10 feet is maintained between the equipment and the power line. If a 10- foot clearance cannot be guaranteed, the employer should indicate to the MISS DIG system that they would be working with equipment that could contact these lines.

The installation of guardrails near energized overhead power lines is not a task specifically covered by MIOSHA Construction Safety Standards, Part 16. Power Transmission and Distribution, Part 17. Electrical Installations, or Part 30. Telecommunications. The employer was covered by MIOSHA Construction Safety Standard, Part 1. General Rules. Rule 115 of Part 1 requires that an employer may not work or be closer than 10 feet to an energized electrical lines, gears or equipment if the voltage is less than or equal to 50 kv.

The employer contacted the MISS DIG system about working in the area and all underground lines were identified and flagged. The company did not indicate to the MISS DIG system that overhead power lines were in the work area. It is the responsibility of the employer to indicate to MISS DIG that they cannot maintain a minimum 10-foot clearance from an overhead electrical line with the equipment used on the job. If the 10-foot clearance cannot be maintained, MISS DIG will request an overhead assistance appointment; an electrical company representative will contact the company, set up an appointment time and review the jobsite to determine the best method to remove the electrical hazard. The MISS DIG system can be accessed online at http://www.missdig.net/external icon (Link updated 12/11/2007) or by calling toll-free at 1-800-482-7171. To prepare for MISS DIG operator questions about a location request, an employer should complete an “educated caller form”. The form is available free of charge by contacting MISS DIG at (248) 874-3400. A copy of the form is included in Appendix A.

The company indicated that they did have other post pounders that did not have a mast height of 22 feet and that this equipment could have been taken to and used at the job site.

Hazard awareness regarding overhead power lines should be stressed and routinely reviewed so that all employees are cognizant of these energized sources.

The danger of overhead power lines appears to be obvious, however, contact with power lines and the subsequent occupational-related fatalities continue. Employers must stress and routinely review the hazards associated with overhead power lines. The victim had experienced a previous non-fatal electrocution requiring hospitalization. The company owner had made him aware of the hazards of overhead electrical power lines several days prior to the incident. The fact that the victim in this case was aware of the hazard of overhead electrical lines emphasizes that employers must demonstrate that they are truly concerned about this aspect of job site safety and will not tolerate even one instance of unsafe conduct.

Operating controls for boomed vehicles, when designed for use from ground level, should insulate the operator from the vehicle.

Regulations concerning boomed machinery and overhead power lines provide operator protection when followed; however boomed equipment, when operated from ground level should have electrically insulated operating controls. The post pounder is used may be operated in areas both with and without an overhead electrical hazard, as was true in this incident The control levers should have an insulating material placed on them as well as the operator wearing insulating gloves when working within the vicinity of electrical power lines to provide operator protection at all times. MIOSHA Construction Safety Standard, Part 6, Personal Protective Equipment, Rule 641, Rubber protective equipment; certification; use and storage, details the requirements for insulating equipment, such as gloves, matting, blankets, covers, line hose and sleeves.

An Accident Prevention Program should be developed, written, and implemented in compliance with MIOSHA Construction Safety Standard requirements.

MIOSHA Construction Safety Standard, Part 1, General Rules require that an employer develop, maintain and coordinate with employees a written accident prevention plan. Subsequent to the fatality, the company is working with a trade group to develop and implement the program and provide employee health and safety training. The foreman is providing weekly tailgate safety talks. The victim in the incident received no formal training in the hazards associated with boomed vehicle operations. Written procedures should detail the tasks to be performed and should identify the safety hazards associated with these tasks. Training should be developed and implemented that addresses these proper work procedures. The employer should assure that safety policies are enforced. A safety program provides many benefits to both the employer and employee, such as hazard identification, training, safe operating procedures and personal protective equipment. Even small companies should evaluate the tasks performed by workers, identify potential hazards, develop and implement a safety program addressing these hazards and provide worker training in safe work procedures.

Company management should consider developing a joint health and safety committee.

The company owners indicated that employees are empowered to take care of safety hazards in the field. Only if the employees cannot rectify the hazards do they notify management. They do not have a health and safety committee. The development of a Health and Safety (H&S) committee would encourage and heighten employee involvement in the company safety program. Employee input is a critical part of a successful safety program; management would become more aware of potential recurring safety hazards in the field and employees can participate in developing safe work procedures. The level of involvement by employees and degree of management commitment will determine if an H&S Committee is successful.

H&S committees have many benefits; identify safety and health concerns that workers/management consider most critical, help find creative solutions, shows a good faith effort toward health and safety regulations, boosts coworker loyalty, morale and enthusiasm by getting involved in an issue that’s important to everyone, and if new safety rules are needed, an H&S committee can help make sure employees accept and follow them. Employee training needs can also be identified.

References

MIOSHA Standards cited in this report can be directly accessed from the Michigan Department of Labor and Economic Growth, MIOSHA web site http://www.michigan.gov/lara/0,4601,7-154-61256_11407_15368—,00.htmlexternal icon. (Link updated 3/27/2013) The Standards may also be obtained for a fee by writing to the following address: Michigan Department of Labor and Economic Growth, MIOSHA, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan, 48909-8143. MIOSHA Standard Section phone number is (517) 322-1845.

- MDCIS, MIOSHA Construction Safety Standards, Part 1. General Rules

- MDCIS, MIOSHA Construction Safety Standard, Part 6, Personal Protective Equipment

- “One Call Excavation Handbook – Dig Safely”. MISS DIG System, Inc. 1030 Featherstone Road, Pontiac, MI 48342external icon

NOTE: as of 7/27/06

- All references to the Michigan Department of Consumer and Industry Services (MDCIS) in this report have been retained because the department was so named at the time of writing of the report (7/15/03). This department is now the Michigan Department of Labor and Economic Growth (MDLEG).

- In the first paragraph under References, the current information to obtain MIOSHA standards has been incorporated.

Michigan FACE Program

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 7/15/03

MIFACE Investigation Report # 02MI152 Evaluation (see page 11 of report)

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Appendix A – MISS DIG “Educated Caller” Form

|