Electrocution of Family Member When Welding on Rotary Disc Mower on Farm

Investigation: # 02MI121

SUMMARY

|

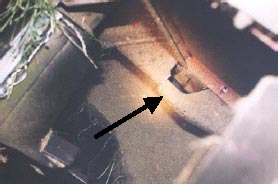

| Figure 1. Overall poor welder condition |

On July 9, 2002, a 43-year old male was welding to repair a rotary disc mower on his family’s farm. The rotary disc mower had a broken disc and stone guard. The portable 240V plug-in-cord connected welder was in disrepair, both welder cables had exposed wiring, and the ground cable wiring was almost completely exposed. (See Figure 1) The ground cable was attached to a metal piece on the rotary disc mower. The victim’s brother directed the victim as to the repairs needed on the mower, and went to do other work at the farm. The victim had completed the weld on the disc and appeared to be repositioning to repair the stone guard when his face touched the mower. The mower was energized, and the victim was electrocuted. Upon finishing his chores, the brother walked over to the mower to see the progress on the mower repair and found the victim lying motionless on the ground. He went to get help at the farmhouse. His mother came down to the area, touched the mower and received a shock. The dog also touched the mower and yelped, at which time the victim’s brother then turned off the circuit breaker. Emergency response was called, and the victim was declared dead at the scene.

RECOMMENDATIONS

- Equipment should be maintained in good operating condition.

- Appropriate personal protective equipment should be worn and ensured that it is in proper working order.

- All circuit breaker circuits should be labeled as to the outlets covered by each breaker.

INTRODUCTION

On Tuesday, July 9, 2002, a 43-year old male welder was killed while welding on a rotary disc mower. On September 11, MIFACE researchers were informed of the farm work-related fatality by a newspaper article and faxed report. On October 29, 2002, a MIFACE researcher and the county extension director interviewed the brother of the deceased, viewed the welder and rotary disc mower, and the site of the incident. During the course of writing the report, the Death Scene Investigation Report from the Medical Examiner’s office and state police department report were obtained.

The dairy farm has been in operation for over 20 years, with forty+ milking cows and a total of 80-90 head of cows. They also have over 250 tillable acres. Three family members work on the farm. The family farm did not have a voluntary written farm safety program.

INVESTIGATION

|

| Figure 2 – Ground prong loose and damaged insulation |

On Tuesday evening, July 9, 2021, a 43-year old male was welding to repair a rotary disc mower used on the family dairy farm. The victim was a certified welder and he worked full-time as a maintenance person at another business location. He had worked an 8-hour shift at the other business before going to the farm.

The welder was a portable, plug-in-cord Miller Electric 240V arc welder. The family bought the welder used in the 1960’s. The welder was kept inside the farm shop, plugged in at an outlet. The welder’s ground wire inside the plug was broken off; the ground tong could be easily moved by hand. The insulation was in poor condition on both the welding lead and the ground cable. (See Figure 2).

The rotary mower was a New Holland Discbine, Model 441. With use that year, part of the disc had broken and the stone guard also had to be fixed (See Figures 3 and 4 – state police photographs).

|

|

| Figure 3 – Damaged Mower Disc | Figure 4 � Damaged Stone Guard |

The victim arrived at the farm approximately 8:00 p.m. that evening, after the brother could not find anyone else to fix the disc mower. The brother showed the victim what needed to be fixed on the equipment (disc and stone guard), and went to milk the cows and do other chores. The brother was gone for at least an hour.

|

| Figure 5 – Ground attached to mower |

The disc mower was connected to a tractor and was parked just outside of the machine tool shed. Both the brother and the victim were aware of the welder’s faulty ground cable and both individuals had talked together about replacing the cable.

The victim placed a plastic sheet on the dry ground. He was not wearing welding gloves, and, according to his brother, due to high temperature that day (97 degrees), was wearing only a tee shirt, long pants and work boots. The victim’s welding helmet did not have head suspension and would have needed to be held by the victim to protect his face/eyes. The victim attached the welder’s ground clamp to the metal of the mower (See Figure 5 – state police photograph). He had finished welding the disc using a E-6011 rod; the stone guard was untouched.

The sequence of events leading to the electrocution is unknown. The victim was alone prior to this farm work activity. At some point, the right cheek of his face touched either the disc mower or perhaps a portion of the exposed wiring of the welding cable. The electrical current entered the right side of his face and exited from his chin on the left side of his face.

|

| Figure 6 – Position of victim |

His brother came by to check on him after completing his chores. He saw him laying on the ground and thought he may have fallen asleep after a long day (See Figure 6). The brother went to the house and spoke with his mother about the victim. She said to go back and check on him. He went back to the machine shed and rolled the victim over. He was going to give CPR but the obvious condition of his brother made it unnecessary. The mother, upon arriving at the incident site, touched the mower and received a shock. The dog also touched the mower and yelped. While the victim’s brother turned off the circuit breaker, the mother called for emergency response. When the state police arrived, the welding mask and welding rod apparatus were on the ground several feet from where the victim was laying. The victim was declared dead at the scene.

CAUSE OF DEATH

The cause of death as stated on the death certificate was cardiac arrhythmia due to accidental electrocution. The results of all toxicological tests were negative.

RECOMMENDATIONS/DISCUSSION

• Equipment should be maintained in good operating condition.

The brother of the victim indicated that they both knew about the condition of the “ground” cable insulation and the overall condition of the welder. They talked about repairing the welder, but never got around to it. Maintaining equipment is integral to safe operation of the equipment so that it can provide the protection it was designed to do.

The family has purchased another welding unit and has scrapped the unit that was involved in the death.

• Appropriate personal protective equipment should be worn and ensured that it is in proper working order.

The victim was not using the appropriate personal protective equipment for the welding operation. Laying on a plastic sheet on the ground most likely induced him to sweat more than he already would have been in the heat, lowering his resistance to electricity. He was not wearing leather protective gloves, which would have protected his hands and arms. The welding helmet did not have a head suspension unit, which would have required him to hold the helmet in one hand while he was trying to weld with the other. This could have affected his balance and may have contributed to the fatality.

An insulated electrical safety mat could have been laid on the ground to provide a surface for the victim to work on as well as provide additional protection– the safety mat is nonconductive and provides protection for the individual on the mat to prevent the individual from being a “path” for the electrical current to ground. Several sources of safety mats can be found on the Internet using the search term of “non-conductive mat”. One non-conductive mat source identified by MIFACE had a mat of 4’x10′ retailing for under $275.00.

|

| Figure 7 – Unlabeled circuit breaker box in shed |

• All circuit breaker circuits should be labeled as to the outlets covered by each breaker.

The circuit breaker in the machine shed did not have labels on the box (See Figure 7). It is recommended that labeling of all breakers be done to, not only identify the breaker and the system it is responsible for, but also to aid in an emergency situation so that individuals trying to turn off power to a system can quickly identify it.

REFERENCES

National Ag Safety Database (NASD), http://www.nasdonline.org/index.htmlexternal icon, Topic Area: Electrical Safety (Link updated 8/5/2009)

MIFACE (Michigan Fatality and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 5/30/03

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.