Truck Driver Dies in Excavation Cave-In During Diesel Tank Removal

Investigation: # 01MI022

SUMMARY

|

On April 17, 2001 a 43-year old male died from injuries sustained from a trench cave-in during the removal of a 6,000-gallon diesel storage tank. During the removal of dirt around the tank, the excavator began to come close to a water line around the tank. To assist the excavator, the victim went into the trench and began to remove shovel loads of dirt from around the water line. The excavator had just finished excavating a load of dirt and was turning to the right to unload the dirt from the bucket into the spoil area. Without warning, the side of the excavation wall collapsed, pushing the victim against the diesel tank. 911 was called and emergency personnel arrived. Emergency personnel removed the victim from the excavation hole. The victim was taken by ambulance to a local hospital, and then air-lifted to a regional hospital where he died.

RECOMMENDATIONS

- Employers should ensure that employees working in excavations are protected from cave-in by an adequate protection system such as shoring, sloping or excavation box designed in accordance with MIOSHA Construction Safety Standard, Part 9, Excavation, Trenching, and Shoring, R408.40941.

- Employers should ensure that excavations are inspected by a competent person prior to start of work and as needed throughout a shift to look for evidence of any situation that could result in possible cave-in.

- Employers should design, develop and implement a comprehensive safety training program. This program should include training workers to recognize and avoid unsafe conditions, and required safe work practices that apply to their work environments.

INTRODUCTION

On April 17, 2001, a 43-year old male died from injuries sustained from a excavation cave-in during the removal of a 6,000-gallon diesel storage tank. On April 18, 2001, MIFACE investigators were informed by the Michigan Occupational Safety and Health Administration (MIOSHA) 24-hour fatality report system that a work-related fatal injury occurred on April 17, 2001. On April 24, a MIFACE researcher accompanied the MIOSHA compliance officer to the interviews at the company and at the site of the incident. Following the MIOSHA interview, the MIFACE researcher interviewed the company owner and witnesses. The MIFACE investigator did not interview the operator of the excavator. The death certificate, autopsy results, police reports, and a copy of the citations issued to the employer were obtained during the course of the investigation.

INVESTIGATION

The company contracted to deliver the excavator did primarily concrete flatwork. The owner acknowledged that the company occasionally excavated septic tanks, and that the victim had worked on some septic tank excavation projects.

The company had been in business for approximately 11 years, and employed 10 people. The victim’s job title was truck driver but also did general labor on work sites. The victim had been driving a truck for the company for approximately 7 years, but had been employed with the company for nearly 15 years. The company did not have a written health and safety program, did not have a person in charge of safety, did not have written safety rules or procedures in place and did not have a health and safety committee. Some on-the-job safety training was given to employees, but no records were kept of the training.

The event occurred on a family owned farm. The farm owner contracted a firm (Firm A) to perform the task of removing a 6000- gallon underground diesel storage tank. The tank had been in place since 1983. The size of the diesel storage tank was 8 feet by 16 feet. Firm A contracted with another firm (Firm B) to provide and deliver a crawler excavator to the tank excavation site. The victim was an employee of Firm B. The victim’s responsibilities were to deliver the crawler excavator to the site, wait for the tank removal by Firm A to be completed, and after loading the crawler backhoe on the flatbed, deliver the crawler excavator to another Firm A job site.

The victim loaded the equipment approximately 7:30am and delivered the excavator to the site sometime between 8:00 am – 8:30 am. He unloaded the crawler backhoe and parked the delivery truck across the street.

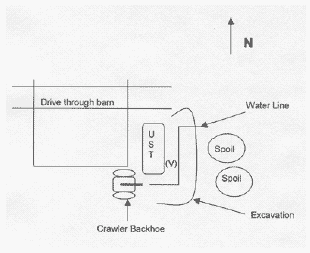

The diesel tank was oriented north-south, and about 180 feet from the road. Firm A began excavation around the tank’s east side. The soil was brown sandy gravel on top of black peat or marl. The witnesses, on their way to breakfast, stopped at the tank excavation site a little after 9:00 am. Excavation on the tank’s east side was being performed. A 1″ PVC water line to the barn runs from the well of the house. This water line tees off at south corner of the barn, runs along south edge of barn and then curves north-east around the storage tank. During excavation of the east side, the crawler backhoe hit the water line that was approximately 5′ deep and damaged the line so water was leaking into the bottom of the excavation. Excavation stopped until the witnesses turned off the water pumps. Water was not extracted from the bottom of the excavation; there was standing water at the bottom when excavation continued along the south side of the tank.

The witnesses stated that they told Firm A not to worry about the broken water line; they would take care of it later. The witnesses could not confirm if the victim heard them talk to Firm A about the water line.

|

The crawler backhoe was repositioned to begin work on the tank’s south side. As excavation of the south side continued, the backhoe neared the water line around the tank. At this point, the excavation was approximately 5′ wide, 7′ deep at the north end tapering to approximately 5′ at the south end. As the backhoe extracted a bucket of dirt and was spinning to unload the dirt from the bucket into the spoil area, the victim entered the excavation. The victim appeared to be trying to help expose the waterline as it went around the south end of the tank to where it connects to the main line near the front south-west corner of the barn. He began to remove shovel loads of dirt from around the water line. One witness observed the east wall of the excavation “begin to move” and yelled to the victim “to get out of there”. The wall collapsed, striking the victim from the backside, and pinning the victim, who was facing west, against the south-east corner of the tank. The soil was waist-high on the victim. The collapsed portion of the excavation wall measured approximately 1 cubic yard.

The witnesses jumped into the excavation and began to dig out the victim. The excavator spun to the return position and saw the men in the excavation. Emergency responders were called and arrived 7 minutes later to the scene. The victim was extricated from the excavation by rescue personnel, and transported by ambulance to a local hospital. The victim was then airlifted to a regional hospital where he died.

When MIFACE conducted the on-site investigation, the excavation was already filled in with dirt.

CAUSE OF DEATH

The medical examiner recorded the cause of death as multiple trauma. No alcohol or drugs of abuse were found in the victim’s blood or urine.

RECOMMENDATIONS/DISCUSSION

• Employers should ensure that employees working in excavations are protected from cave-in by an adequate protection system such as shoring, sloping or excavation box designed in accordance with MIOSHA Construction Safety Standard, Part 9, Excavation, Trenching, and Shoring, R408.40941.

The MIOSHA Construction Safety Standard Part 9, Excavation, Trenching and Shoring R408.40925 defines an excavation as any man-made cavity or depression in the earth’s surface, including its sides, walls or faces, formed by earth removal. When earth is removed from the ground, the walls are left unsupported and pressures are generated at the face of the excavation. Where the soil can no longer withstand the pressure, the wall will shear and break away. Usually, soil at the base of the excavation falls into the hole first, then, as support is lost from below, higher wall failure may occur. One cubic foot of soil can weigh 100 pounds or more, depending on the soil’s composition. Each cubic yard of soil may weigh more than one ton (2,500 pounds), producing a crushing injury to anyone caught in the wall collapse. A cubic yard of soil weighs nearly the same amount as a mid-size automobile. In this incident, MIOSHA estimated at least 1 cubic yard of soil collapsed from the excavation wall face onto the victim.

To protect workers from the danger of wall collapse, the Excavation, Trenching and Shoring Standard requires that the excavation, 5 feet or more in depth (unless soil conditions mandate protection in excavations less than 5 feet) be protected from cave in. Rule 942 of the Excavation standard explains what must be evaluated during an excavation to protect workers inside the excavation. The selection of preventative measures are based on this evaluation. Methods such as sloping (angle of repose), sloping and benching, tight sheeting, or trench boxes and shields may be used to protect personnel in the excavation.

• Employers should ensure that excavations are inspected by a competent person on an ongoing basis to look for evidence of any situation that could result in possible cave-in.

Rule 932(5) requires that excavations have an ongoing inspection by a competent person.. Although the operation was not designed for the victim to enter the excavation, a competent person should have made it clear to all persons near the excavation that it was not to be entered because it was not properly protected for worker occupancy.

It is unknown if the company doing the excavation knew about the active water lines near the tank, or if the farmer contracting the company told the company about the water lines. After the lines were initially damaged, Rule 932 (3) states that an employee shall not work in an excavation in which there is accumulated water or in which water is accumulating unless precautions have been taken to protect employees against the hazards posed by water accumulation. To determine the appropriate protective system for the excavation operation, employers can consult with manufacturers of protective systems to obtain detailed guidance for the appropriate use of these products.

• Employers should design, develop and implement a comprehensive safety training program. This program should include training workers to recognize and avoid unsafe conditions, and required safe work practices that apply to their work environments.

MIOSHA R408.40114(2)(d) requires that the employer have an accident prevention program that provides instruction to each employee in the recognition and avoidance of hazards. Training in recognizing and avoiding hazards should be given to all workers, coupled with employer assessment that workers are competent in the recognition of hazards and safe work practices. The employer did not demonstrate that adequate knowledge about safe work practices in excavation techniques. When questioned by the MIOSHA compliance officer about excavation practices, the employer gave incorrect answers about how to adequately slope and bench a excavation. This lack of knowledge not only limited the employer from adequately training his personnel about proper excavation techniques, but also to provide adequate health and safety training, including hazard recognition and prevention.

RESOURCES

MIOSHA Standards cited in this report can be found at the Consumer and Industry Services, Bureau of Safety and Regulation Standards Division website at http://www.michigan.gov/lara/0,4601,7-154-61256_11407_15368—,00.htmlexternal icon. The Standards can also be obtained for a fee by writing to the following address: Department of Consumer and Industry Services, MIOSHA Standards Division, P.O. Box 30643, Lansing, MI 48909-8143. MIOSHA phone number is (517) 322-1845. (Link updated 3/27/2013)

MIOSHA Construction Safety Standard, Part 9. Excavation, Trenching and Shoring.

www.michigan.gov/documents/lara/lara_miosha_CS_9_3-18-2013_414603_7.pdfpdf iconexternal icon (Link updated 8/12/2013)

Excavations. OSHA Publication 2226 (2000), 2.3 MB PDF file.

https://www.osha.gov/Publications/osha2226.pdfpdf iconexternal icon

Trenching and Excavation: Safety Principles. National Ag Safety Database.

http://ohioline.osu.edu/aex-fact/0391.htmlexternal icon (link updated 9/7/2005)

Excavations: Hazard Recognition in Trenching and Shoring. OSHA Technical Manual (TED 1-0.15A), Section V – Chapter 2 (1999, January 20)

www.osha.gov/dts/osta/otm/otm_v/otm_v_2.htmlexternal icon

MIFACE (Michigan Fatality and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer.

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.