Worker Killed when Caught Inside a Palletizer Hoist Area - Massachusetts

Massachusetts Case Report: 04-MA-006

Release Date: August 28, 2007

Summary

On March 16, 2004, a 45-year-old male machine operator (the victim) was fatally injured while operating and training a co-worker on a palletizing machine in an ice cream manufacturing facility. Palletizers place and stack product from the production line onto pallets to be shipped. Although un-witnessed, it appears that the victim entered the machine’s hoist area to adjust the position of a pallet when the hoist began to rise with the victim on top of the pallet. A co-worker heard the victim yelling for help and ran to press one of the machine’s emergency stop buttons. The victim was crushed between the empty pallet and the top portion of the hoist before the hoist stopped rising. The co-worker manually lowered the palletizer’s hoist and the victim fell to the floor below. The co-worker in training was also an Emergency Medical Technician (EMT) and attended to the victim while Emergency Medical Services (EMS) were notified. When EMS arrived at the incident site, the victim was breathing on his own but was unconscious and unresponsive. EMS transported the victim to a local hospital where he was pronounced dead. The Massachusetts FACE Program concluded that to prevent similar occurrences in the future, employers should:

- Minimize the number of times palletizers cycles are interrupted because of failures to detect pallets in the hoist area by routinely:

- inspecting pallets for cracks and broken pieces

- evaluating the mechanism that transports pallets into the hoist area to ensure pallets are loaded into the hoist area properly;

- Ensure that accessible moving parts of machines are guarded at all times to minimize access by employees; and

- Develop, implement, and enforce a comprehensive hazardous energy control program including a lockout/tagout procedure and routinely review and update the program and training.

In addition, palletizing system manufacturers should:

- Explore the feasibility of adding sensors to detect unplanned obstructions during the hoist’s movement which would stop the hoist when obstructions are detected.

Introduction

On March 16, 2004, the Massachusetts FACE Program was notified by a local police department through the 24-hour Occupational Fatality Hotline, that on the same day, a 45-year-old male was fatally injured when he was crushed in a palletizer hoist at an ice cream manufacturing facility. An investigation was initiated. On April 22, 2004, the Massachusetts FACE Program Director and a co-worker traveled to the incident location where several company and union representatives were interviewed. The death certificate, corporate information, police incident report, and the OSHA fatality and catastrophe report were reviewed during the investigation. In addition, photographs were taken of the machine involved and the incident location.

The employer, a manufacturer and marketer of branded packaged ice cream and frozen novelty products, had been in business for over 80 years at the time of the incident. The company has six manufacturing facilities across the United States. The manufacturing facility involved in the incident is located in Massachusetts. Nationwide the company employs approximately 2,400 people. Of these employees, approximately 231 are located in the Massachusetts. The victim had been employed by the company for approximately eight years. He started as a laborer, providing general help and then a few years later transferred to a chessman position. Prior to 1999, a chessman’s primary task was to manually place containers of ice cream onto pallets. In 1999, the company switched to an automated palletizer, and the victim’s main task then became operating the palletizing machine. The company’s work schedule consists of a five day work week with three shifts per day, with some overtime and Saturday work. The victim typically worked second shift, and on the day of the incident, he had worked the second shift and volunteered to stay and work four hours of overtime.

The company had designated individuals in charge of employee safety and health and had a written safety and health program that included lockout/tagout procedures. The employer provided employees safety training and documented this training. The written safety and health program was developed at the corporate level and tailored for each facility at the local level. The victim was part of a union collective bargaining unit.

Investigation

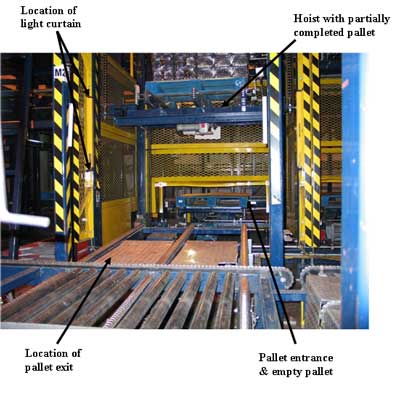

The manufacturing and packaging of ice cream products takes place in the cold section of the manufacturing facility. Once the ice cream products are packaged, the products travel via a conveyor to a palletizing system located in the “warm room” of the manufacturing plant. The machine involved in the incident, an automatic high level case palletizing system (palletizer), was purchased new by the company in 1999 (Figure 1). This particular machine was designed to place single packages of ice cream products onto 24-inch by 48-inch wooden pallets. At the time of the incident, the products being palletized were individual half-gallon containers of ice cream. The palletizing machine is computer controlled and equipped with multiple emergency stops located around the machine. At the time of the incident, the palletizer was operating in the automatic mode. The automatic mode allows the palletizer to continuously cycle, as long as the pallets and/or ice cream containers do not jam.

Once the ice cream containers reach the palletizer, via the conveyor, they are ejected off of the conveyor and on to a slide plate located on the top section of the palletizer. The palletizer’s hoist raises a pallet to the bottom of the slide plate once the slide plate has a complete layer of ice cream containers. The slide plate then retracts, causing the layer of ice cream containers to drop a few inches onto the pallet below. At this point, the slide plate returns to the start position and the pallet’s height is adjusted to prepare for the next layer of ice cream containers. Electronic eyes located under the slide plate determine the height at which the palletizer’s hoist should stop to accept the next layer of product onto the pallet. This container stacking process continues until 14 layers of half-gallon containers are placed onto a pallet, at which point the pallet is considered complete (Figure 2). The complete pallet is lowered and ejected out of the palletizer through a presence sensing device (light curtain) onto a second conveyor. The completed pallet is transported by this conveyor to a plastic wrap machine where the pallet and the 14 layers of half-gallon ice cream containers are wrapped in plastic. The cycle starts over when an empty pallet moves into the hoist area via a third conveyor (Figure 1).

The palletizer’s hoist area has four sides and three of these four sides are guarded by a fixed cage. The fourth side, the location where completed pallets exit the machine, is guarded by a light curtain (Figure 1). The hoist area’s pallet entrance is located across from the pallet exit where empty pallets automatically enter the hoist area by passing under the section of the fixed cage.

The hoist is equipped with two sets of electronic eyes that assist in properly positioning the empty pallets on the hoist once it enters the machine. The electronic eyes are located at the pallet exit and the pallet entrance. When a pallet enters the hoist area it is first detected by the electronic eye located at the pallet exit, which reverses the conveyor’s motion moving the pallet backward to the electronic eye located at the pallet entrance. When the electronic eye located at the entrance detects the pallet, this signals the hoist to rise up to the slide plate and the machine begins loading product onto the pallet. This also turns on the light curtain located at the machine’s exit. The light curtain will stay activated throughout the pallet loading process. Once a pallet is complete and is ready to exit the machine, the light curtain deactivates and remains deactivated until another pallet is properly positioned on the machine’s hoist. Broken or askew pallets entering the hoist area sometime are not detected by the electronic eyes thereby stopping the palletizing process: the hoist fails to rise and the light curtain remains deactivated.

One of the main tasks of the palletizer operator (the victim), is to monitor the pallets as they are fed into the hoist area. The palletizer operator will manually adjust a pallet’s position only if the palletizer stops due to an incorrectly positioned pallet within the hoist area. The palletizer operator enters the hoist area through the deactivated light curtain at the pallet exit to complete this task.

On the day of the incident, the victim had worked his normal shift (3:00 p.m. – 11:30 p.m.) and volunteered to work an additional four hours of overtime. In addition to his normal task of operating the palletizer, the victim was training an employee on the palletizing machine. The company had four automatic palletizing stations that typically were operated by five employees during a shift. At any given time there were two operators, each in charge of two palletizing stations, two employees by the plastic wrap machine and one employee on break. All five employees rotated their tasks throughout the shift.

At the time of the incident, approximately 1:30 a.m., an empty pallet had entered into the hoist area but it was not detected by the machine. Although un-witnessed, it appears that the victim then entered the hoist area through the deactivated light curtain at the pallet’s exit and started to adjust the pallet’s position. The pallet was then detected by the palletizer and the hoist began to rise with the victim caught on top of the empty pallet. Co-workers heard the employee yelling for someone to shut off the machine. The palletizer hoist continued rising to its preset position to load the first layer of product. This preset position brings the empty pallet within a few inches of the slide plate. As the palletizer’s hoist rose, the victim was crushed between the pallet and the slide plate. A co-worker went to an emergency stop button and engaged it, stopping the machine. Then this co-worker unsuccessfully attempted to lower the palletizer hoist using the control panel. Another co-worker was able to manually lower the hoist. Once the hoist started to lower the victim fell off of the raised pallet to the ground below. Co-workers then moved the victim away from the machine.

Emergency Medical Services (EMS) were notified immediately after the incident and arrived within minutes of the call. Two co-workers, the co-worker in training who was also an Emergency Medical Technician, and another co-worker attended to the victim until the arrival of EMS. When EMS transported the victim to a local hospital he was breathing on his own, but was unconscious and unresponsive. The victim was pronounced dead at this hospital the same day of the incident.

At the time of the fatality investigation, the plant manager stated that the palletizer involved in the incident was evaluated after the incident and found to be in the automatic mode and not locked out at the time of the incident. In addition, the company reported that they planned to have a second light curtain installed on the palletizer. They had also developed a pole type tool to assist in straightening askew pallets.

Cause of Death

The medical examiner listed the cause of death as blunt force abdominal trauma.

Recommendations/Discussion

Recommendation #1: Employers should minimize the number of times palletizers cycles are interrupted because of failures to detect pallets in the hoist area by routinely:

- inspecting pallets for cracks and broken pieces

- evaluating the mechanism that transports pallets into the hoist area to ensure pallets are loaded into the hoist area properly.

Discussion: In this case, the main reason for employees to enter the hoist area was to adjust pallets that were not detected by the palletizer causing the palletizer to automatically stop the manufacturing process. To reduce the number of times the palletizer automatically stops, employers should routinely inspect pallets to identify pallets with cracks and broken pieces. These identified pallets should then immediately be either repaired or removed from service. In addition, the design and operation of the mechanism that transports empty pallets into the palletizer’s hoist area should be evaluated in an attempt to identify solutions that would minimize the number of pallets entering the hoist area askew.

Recommendation #2: Employers should ensure that accessible moving parts of machines are guarded at all times to minimize access by employees.

Discussion: Three of the four sides of the palletizer’s hoist area were guarded by a cage. The fourth side of the hoist area, the pallet exit, was guarded by a presence sensing device, a light curtain. Light curtains typically consist of an emitter and receiver that create a nonphysical barrier using multiple beams of infrared light in front of or around an area where a potential hazard exists. Light curtains are usually directly connected to a machine’s emergency stop system. When any of the multiple beams of infrared light are blocked or interrupted, such as by an employee entering the area where the potential hazard exists, the light curtain system will engage the machine’s emergency stop and shut down the machine.

During normal operation of the palletizer involved in the incident, the light curtain was deactivated from the time when a completed pallet exited the palletizer until an empty was properly positioned on the hoist. While the light curtain was turned off, the hoist area was directly accessible to employees, who would routinely enter the hoist area to adjust pallets.

Since the incident, the employer reported that they were having a second light curtain installed at the hoist area’s exit. This second light curtain would ensure that the hoist area’s exit was continuously guarded by having one of the two light curtains activated at all times.

Recommendation #3: Employers should develop, implement, and enforce a comprehensive hazardous energy control program including a lockout/tagout procedure and routinely review and update the program and employee training.

Discussion: In this case, the employer had lockout/tagout procedures and provided some training to employees that addressed these procedures. A hazardous energy control program is required by OSHA (OSHA regulation 1910.147). This regulation requires that employers establish procedures for isolating machines or equipment from the input of energy by affixing appropriate locks or tags to energy isolating devices. This is done to prevent any unexpected energization, start-up or release of stored energy that would injure workers during servicing and maintenance of machines and equipment. All forms of energy must be considered including electrical, hydraulic, pneumatic, and mechanical. Therefore, for each machine an individual lockout/tagout procedure is needed that specifies how to properly perform lockout/tagout on that machine and when the lockout/tagout procedure should be implemented, such as when any employee enters the palletizer’s hoist area.

A hazardous energy control program is only going to be effective if the employer provides adequate training and strictly enforces the procedures outlined in the program. Enforcing a hazardous energy control program should include random inspections of employee work habits related to procedures outlined in the hazardous energy control program.

Reviewing the comprehensive hazardous energy control program including the lockout/tagout procedure and the associated training should be performed at least once a year or when safety concerns arise. Involving the employees in the process of updating the hazardous energy control program and training is important. The employer should seek input from employees by having employees evaluate the effectiveness and limitations of the hazardous energy control program. Employers should ask employees about techniques involved in completing tasks that require them to expose any part of their bodies to machine hazards, especially maintenance activities and common procedures that are not typically thought of as part of the everyday operation, such as adjusting pallets inside the palletizer’s hoist area. Employees who operate and perform maintenance tasks on palletizers will be able to contribute valuable information that might have been overlooked and these employees will also be able to contribute information about the effectiveness and limitations of the hazardous energy control program.

Recommendation #4: Palletizing system manufacturers should explore the feasibility of adding sensors to detect unplanned obstructions during the hoist’s movement which would stop the hoist when obstructions are detected.

Discussion: At the time of the incident, the victim was adjusting an empty pallet inside the hoist area when the hoist lifted the pallet and the victim to the preset height to accept the first layer of product. This height was approximately one inch from the top of the hoist area. If the palletizer had been designed such that the hoist would stop or reverse its motion when unexpected obstruction was detected during hoist movement, the victim’s injuries might have been minimized.

References

- Code of Federal Regulations, 29 CFR 1910.212, General requirements for all machines. Washington, DC: U.S. Printing Office, Office of the Federal Register.

- Code of Federal Regulations, 29 CFR 1910.147, The control of hazardous energy (lockout/tagout). Washington, DC: U.S. Printing Office, Office of the Federal Register.

|

|

|

Figure 2 – Palletizer with a complete pallet getting ready to exit the hoist area

|

To contact Massachusetts State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.