Boat Handler is Fatally Crushed While Placing Wooden Blocks Under a Partially Supported Boat - Massachusetts

Investigation: # 01-MA-037-01

Release Date: July 2, 2003

SUMMARY

On October 25, 2001, a 35-year-old male boat handler (the victim) was fatally injured when he was crushed underneath a 33-foot vessel. The victim was part of a marina yard crew using a hydraulic trailer to haul boats out of the water for the winter season. The boat involved in the incident had been removed from the trailer and placed onto boat stands, which were designed to stabilize but not completely support the boat’s weight. The victim crawled under the boat in an attempt to add wooden blocks at the rear of the boat’s keel to support the boat’s weight, when the boat fell on him and crushed him. A resident from across the street placed a call for emergency assistance and personnel from the local police and fire department and emergency medical services (EMS) responded to the scene within minutes. OSHA and the medical examiner’s office were then also contacted and responded to the scene a short time later. The medical examiner pronounced the victim dead at the incident site. The Massachusetts FACE Project concluded that to prevent similar occurrences in the future, employers should:

- ensure that employees inspect how the boat is sitting on the boat trailer before completely hauling the boat out of the water

- establish and enforce standard operating procedures (SOP) for hauling boats and storing them out of the water

- ensure that boats are stored on stable ground

- establish and enforce a comprehensive health and safety program, including but not limited to, providing training for boat handlers on hazard recognition and safe work practices for assigned tasks

- develop a health and safety committee that includes worker participation and meets regularly

INTRODUCTION

On October 26, 2001, the Massachusetts FACE Project was notified by the Occupational Safety and Health Administration (OSHA) through the 24-hour Occupational Fatality Hotline, that on October 25, 2001, a 35-year-old male was fatally injured when he was crushed beneath a boat in a boatyard storage area. An investigation was immediately initiated. On November 7, 2001 Massachusetts FACE Project Director and a field investigator traveled to the marina where the marina’s general manager was interviewed. The police report, death certificate, corporate information, OSHA information and photographs were reviewed during the course of the investigation.

The marina had been in business approximately 13 years at the time of the incident and employed approximately 35 workers during the peak season (spring – autumn). Of these employees, approximately four held the same job title as the victim, boat handler. The marina had a written safety and health program, which consisted of basic safety topics, such as lockout/tagout procedures, but did not include specific written procedures for other assigned tasks, such as boat hauling. The marina did not have a designated employee in charge of safety but the general manager and the yard crew foreman did discussed safety issues at their daily meetings. It was stated that the marina had an open door policy and employees could talk to the general manager about any issues including safety.

The victim, a Canadian resident, had been employed with the marina for approximately nine months. The marina provided the victim on-the-job training, which was conducted by the yard crew foreman. This training lasted approximately one month or when the yard crew foreman felt the trainee could perform tasks without constant supervision. There was no union representation at the marina.

INVESTIGATION

The incident took place at the marina boat yard, which contained 110 boat slips, 34 boat moorings, and an outdoor storage rack system for 62 boats. The marina also had a full boat repair shop where boat painting, fibrous glass work and mechanical repairs were performed. In addition, the marina had a large outdoor storage capacity for boats.

The victim had been employed with the marina for one full spring and summer season, and this was his first autumn season. Each season has different main tasks to be performed. The main task for the yard crew in the spring was to launch boats that had been stored throughout the winter into the water. The main task during the summer season was to launch the valet stored boats into the water and place them back into valet storage when requested by the owners. The main task for the autumn season was to pull the boats out of the water, winterize, and store them for the winter.

The task of pulling “large boats” (greater than 25 feet in length and not including sailboats) out of the water and storing them for the winter consisted of positioning the boat at the boat ramp and using a large hydraulic trailer (Figure 1) to pull the vessel out of the water. The trailer used by the marina was 70 feet long and included six hydraulic stabilization pads. In addition, the trailer wheels were also hydraulic and were used to raise and lower the entire trailer. A company owned truck was used to pull the trailer.

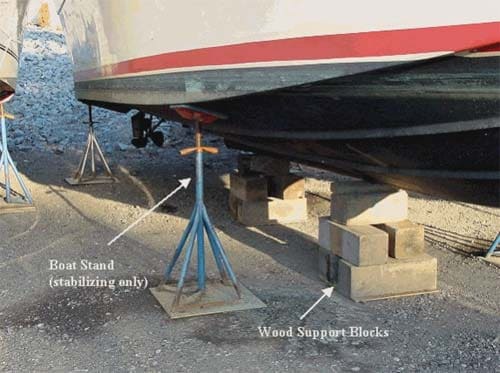

The marina’s process for storing boats for the winter consisted of pulling the boat out of the water, as described above, and moving it to a storage location. Once the boat was positioned in a storage location, wooden blocks would then be set at the rear of the boat’s keel to support the boat’s weight while the boat was still on the trailer. The trailer, using the hydraulic system, would be lowered placing the rear of the boat onto the wooden blocks. The trailer would then be moved forward eight feet so that additional wooden blocks could be placed at the boat’s keel. Boat stands, which are designed to stabilize the boat but not designed to support a vessel’s entire weight, would then be added to both sides of the boat. This process of pulling the trailer forward eight feet and adding wooden blocks and boat stands would be repeated until the boat was totally offloaded from the trailer. The boat stand manufacturer recommends that a minimum of four boat stands, with plywood underneath them if the ground was soft, should be used on each boat. In addition, the boat stand manufacturer recommends selecting an area to store the boat where the ground was hard and stable to prevent sinking.

The incident occurred at approximately 8:10 am. The eight-person yard crew had already pulled the boat involved in the incident out of the water using the hydraulic trailer. The boat was moved to its winter storage location in the rear of the marina yard. This area of the marina yard was sloped and was not paved, whereas other sections of the yard had been, but reprocessed asphalt had recently been put down as the ground layer (Figure 2). The reprocessed asphalt, appeared to pack down better than dirt, but it seemed not to provide as strong a footing as paved asphalt or poured concrete. Therefore, when storing boats on the less stable reprocessed asphalt, the marina placed sections of plywood under the wooden blocks and boat stands, as recommended by the boat stand manufacturer, for additional support.

According to the yard crew foreman, the boat was not sitting on the hydraulic trailer squarely when the crew pulled it out of the water, which prohibited them from placing the wooden blocks at the rear of the boat’s keel prior to offloading the vessel. In an attempt to complete their task, the yard crew positioned three boat stands without plywood footings, underneath the boat. Two stands were placed at each rear corner of the boat (Figure 3) and one stand, a V stand, was placed at the bow. At this point, the yard crew foreman wanted to try and stabilize the boat. It was mentioned by the marina manager that the victim thought the foreman wanted to try and place wooden blocks at the centerline (Figure 4), but the foreman had wanted to set up additional boat stands. The victim climbed underneath the boat in an attempt to place wooden blocks at the keel when the boat slipped off the boat stands and onto him.

A call was placed for emergency assistance by the wife of a witness who lived across the street from the marina. The local police and fire department along with EMS arrived within minutes of the incident. The medical examiner was notified and upon arrival pronounced the victim dead at the incident site. Evidence suggests that because the unpaved incident location was recently covered with reprocessed asphalt, there is the possibility that the reprocessed asphalt was not completely compacted resulting in the ground being unstable contributing to the incident.

CAUSE OF DEATH

The medical examiner listed the cause of death as crushing injuries of chest.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that employees inspect how the boat is sitting on the boat trailer before completely hauling the boat out of the water.

Discussion: It was stated during the investigation that the boat was not sitting squarely on the trailer bed. This first problem led to subsequent problems and hazards, including the inability To place wooden blocks underneath the boat, the inappropriate use of the stabilization boat stands, the failure to use a plywood base under the boat stands, and the miscommunication that led the victim underneath the boat.

When it was discovered that the boat was placed on the trailer improperly, the boat should have been launched back into the water and repositioned squarely on the trailer. Immediately rectifying the first hazard might have eliminated the sequence of problems that followed leading to the incident.

Recommendation #2: Employers should establish and enforce standard operating procedures (SOP) for hauling boats and storing them out of the water.

Discussion: At the time of the FACE investigation, the marina, with advice from the Occupational Health and Safety Administration (OSHA) inspector, was developing a standard operation procedure (SOP) for hauling and storing boats. A SOP for hauling boats out of the water should include, but not be limited to, ensuring that a boat is properly loaded onto the hydraulic trail before leaving the boat launching area as discussed in recommendation #1. The SOP should also state that when off-loading a boat from a trailer, a combination of boat stands and plywood, and wooden blocks should be used, as discussed in the investigation section above. In addition, the SOP should state that boat stands should never be used to support the weight of a boat, unless specifically stated otherwise by the manufacturer.

In addition, employers should ensure that employees follow the SOP by periodically monitoring the employees work practices in comparison to what is stated in the SOP. The SOP should be routinely evaluated and updated before changes are implemented, such as introducing new equipment, launching or hauling new style boats and when there has been an injury or near miss.

The American Boat & Yacht Council (ABYC) develops voluntary consensus safety standards for the design, construction, equipment, maintenance, and repair of small watercraft. ABYC has developed the TY-28 standard “Boat Lifting and Storage”. Marinas and other boatyards can use this standard to help develop their own SOP for hauling, launching, and storing boats. TY-28 covers the use of straddle lifts and forklifts for hauling boats and cradling guides. In addition, it addresses the boat manufacturer’s responsibility to provide certain information on handling and storing boats out of the water (www.abycinc.orgexternal icon).

Recommendation #3: Employers should ensure that boats are stored on stable ground.

Discussion: Employers should ensure that the sections of the marina where vessels will be stored have stable ground. In this case, it was reported that reprocessed asphalt had recently been applied to the ground in the section of the marina where the victim was fatally injured. The reprocessed asphalt in this section of the marina was not as solid as the paved sections of the marina. In addition, because the reprocessed asphalt was recently applied, there is the possibility that it was not as compacted as it could have been, reducing the ground stability in this area.

Recommendation #4: Employers should establish and enforce a comprehensive health and safety program, including but not limited to, providing training for boat handlers on hazard recognition and safe work practices for assigned tasks.

Discussion: In this case, the marina had a limited health and safety program that did not include employee training. As part of a comprehensive health and safety program, employers should provide training based on the SOP, as discussed in recommendation #2, for all employees, in the proper and safe use of equipment and how to safely complete tasks. A summary of OSHA’s draft proposed safety and health program rule, which discusses employee training, has been included at the end of this report.

Worker training should be updated routinely with employees’ input, when safety concerns arise and when new equipment and new tasks are going to be introduced into the workplace. When updating training, employees should participate by evaluating possible hazards associated with equipment and techniques involved in completing their tasks. Employees will know the most about the effectiveness, limitations, and inconveniences of the equipment and procedures to complete tasks.

Employers should make clear to employees during training that when performing tasks, if they come across an element of that task that could pose a possible hazardous condition, they would be expected to rectify the hazards as outlined in the training. In addition, if a hazard is encountered that is not addressed during the training, the task should be stopped and that hazard should be discussed with the appropriate personnel and a protocol developed to rectify the hazard.

In this case, each season had different main tasks to be performed. The marina did provide new employees with some hands on training, which lasted approximately one month or when the yard crew foreman felt that the new employee could perform tasks without constant supervision. Annually, at the beginning of each season, when the main tasks change, all employees should be provided refresher training. In addition, hands on training and extra supervision for new employees should be reinstated at the beginning of each season throughout their first year of employment.

Recommendation #5: Employers should develop a health and safety committee that includes worker participation and meets regularly.

Discussion: During the investigation it was stated by the general manager that the health and safety committee consisted of himself and the yard crew foreman and they would discuss different topics daily including any safety concerns. Employees are a great source of information especially when it comes to the tasks they routinely perform. Employees might have knowledge of safety hazards that would not be noticed by the general manager and yard crew foreman.

REFERENCES

American Boat & Yacht Council, TY-28, Boat lifting and Storage, July 1998, Edgewater, MD, www.abycinc.orgexternal icon

Code of Federal Regulations, 29 CFR 1910.176 Safety and Health Regulations for Handling materials, Materials Handling and Storage, Government Printing Office

Brownell Boat Stands, Inc, User’s Guide, Mattapoisett, MA, http://www.boatstands.com/external icon (Link updated 11/15/2011)

FIGURES

Figure 1 – Hydraulic Trailer

Figure 2 – Incident Location

Note the reprocessed asphalt

Figure 3 – Boat involved in the incident

Figure 4 – Properly supported boat

|

SUMMARY OF OSHA’S DRAFT PROPOSED |

|

Core elements

Basic obligations

Employee participation

Identify and assess hazards to which employees are exposed

Investigate safety and health events in the workplace

|

Safety and health program record keeping

Hazard prevention and control

Information and training

Program evaluation and maintenance

Multi-employer workplaces

|

Date issued November 23, 1998. Full text available on https://www.osha.gov/dsg/topics/safetyhealth/nshp.htmlexternal icon. (Link updated 3/20/2013)

To contact Massachusetts State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.