Traffic Technician Dies From Fall While Changing Traffic Signal Bulb

Kentucky Case Report: 03KY028

Date of Incident: March 31, 2003

Report Release Date: May 10, 2005

Summary

On Monday, March 31, 2003, a 39-year-old male (decedent) highway traffic technician, working alone, received fatal head injuries after falling out of the bucket of an aerial boom truck. Injuries sustained in the fall resulted in his death four days later. He was changing a burned-out green traffic bulb in a traffic signal suspended over 2 lanes of traffic. As he worked from the aerial lift suspended over traffic to change the burned out bulb, a cargo truck drove underneath the bucket, striking it, and causing the decedent to fall to the asphalt below. As the worker fell approximately 10 feet, an eye witness called emergency services. Paramedics arrived within minutes and transported the technician to a nearby hospital. From there, the technician was airlifted to a trauma level hospital where he died 4 days later due to head injuries.

To prevent future occurrences of similar incidents, the following recommendations have been made:

- Employees should use personal fall protection equipment in an aerial lift bucket at all times.

- A Competent person should conduct a hazard assessment of the highway work zone and implement a safety plan.

Background

On April 11, 2003, via newspaper surveillance, the Kentucky Fatality Assessment Control and Evaluation Program was notified of an occupational fatality involving a fall from a height of approximately 10 feet. The KY FACE team met with the decedent’s employer to gain permission to perform an evaluation of the incident. A site visit was made on November 8, 2004. During the site visit, the decedent’s supervisor and co-workers were interviewed and photographs were taken. A traffic control officer at the scene was interviewed by phone on May 5, 2005.

The traffic technician had worked for 11 years for the highway district employer. The district employed approximately 340 employees. At the time of his death, the technician had worked for the signal crew for over 5 years. Prior to working for the signal crew, the technician had worked for the sign crew.

Safety training was provided by the employer on a number of topics throughout the year. During the 11 years of his services with the employer, the technician completed 55 safety courses. Of the safety courses the technician had completed, four dealt with personal protective equipment, one was on aerial lift safety, one was on fall protection, and one was on highway work zone safety. Personal protective equipment was provided to employees. Also, the decedent had been trained by the manufacturer of the aerial lift boom truck on the operation and safety features of the truck involved in the incident.

The aerial boom truck had been purchased in 2002 and was delivered to the employer in December of 2002. It was the first truck used by the employer to be equipped with safety features such as an eye hook on the boom for safety harness tie-off. The arm of the truck was 42 feet long and capable of a 35 foot swing (42 feet minus 7 feet for the truck and width of the road). After the incident, the truck was inspected by a dealer for possible malfunctions of the truck equipment. Testing included stability, dielectric, unit controls, boom and articulating arm. All tests results were negative for malfunctions. The manufacturer supplied two safety harnesses with the truck. There was a hook in the cab of the truck for the technician to hang his safety harness. Regular maintenance was performed weekly on the truck to ensure optimal performance.

Work duties for the technician included changing bulbs in traffic signals, installing new signals, and changing the timing of the signals. At the time of this incident, it was common practice for technicians to work alone during the day and in pairs after regular work hours (8:00 am – 4:30 pm). After this incident occurred, when feasible, technicians work in pairs during normal work hours.

According to a state-wide weather service, the temperature on the day of the incident ranged from 24 degrees Fahrenheit to 51 degrees Fahrenheit with no precipitation. Pictures taken at the scene showed that the sky was cloudy and gray.

Investigation

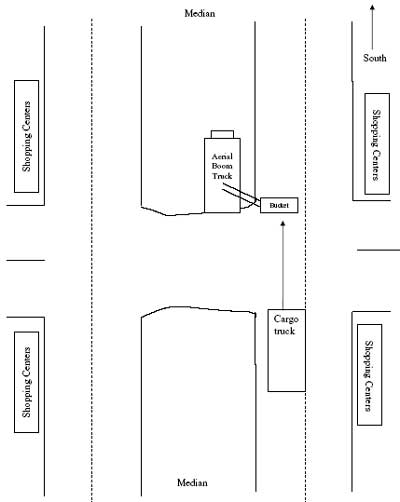

On March 31, 2003, a 39 year-old male, highway traffic technician was dispatched to a busy four-lane highway intersection to replace a burned out green traffic signal bulb suspended over the left hand lane of an southbound highway. The four-lane highway runs north and south intersecting with a local two lane street that leads into a busy shopping area (see Diagram). According to the Kentucky Highway Department, 30,000 vehicles travel through this particular intersection daily.

It was the third traffic light bulb the technician was to replace that day. He arrived at the intersection at approximately 10:45 am, parked his truck facing south in the median next the southbound side of the highway and activated the strobe flashers and outriggers on the truck. The technician climbed into the bucket and waited for the southbound light to change to red and traffic along the highway to stop. When the light changed to red, the technician swung the bucket to the left of the truck and extended the arm 12 feet over the traffic lane, raised the bucket to the traffic signal, and proceeded to change the bulb. While the technician was changing the bulb, the traffic signal changed back to green. At the intersection, a southbound cargo truck had stopped for the red light. When the light changed to green the truck driver, seeing the technician in the bucket, thought he could clear the bucket and proceeded through the intersection. When the driver drove underneath the bucket, the driver heard something hit the top of the cargo section of the truck. The driver of the cargo truck stopped the vehicle and got out to find the technician lying on the pavement. The impact of the truck hitting the bucket had caused the bucket to break away from the boom, resulting in the technician falling 10 feet to the ground. Another driver traveling behind the truck saw the technician fall from the bucket. An off-duty police officer was sitting in the northbound lane at the red light and observed the traffic technician changing the bulb. The officer noticed there were no cones or a flagger to direct traffic around the truck. As the light changed to green, the officer proceeded through the intersection when he noticed commotion in the southbound lanes. The officer observed that the truck and bucket had collided and called emergency services to the scene at 10:59 am. A nurse driving by the incident also stopped and rendered aid to the technician until emergency services arrived. Emergency services arrived within minutes and transported the technician to the nearest hospital. At approximately 10:55 am, the technician was airlifted to the nearest trauma hospital in a neighboring state. He never regained consciousness and died four days later from his injuries.

The investigating police officer arrived at the scene at 11:16 am to find emergency services had transported the technician to the nearest hospital. Witnesses were interviewed at the scene. None of the witnesses remembered the technician wearing a safety harness, nor was a safety harness observed attached to the safety hook on the boom of the truck. The technician’s safety harness issued by the highway department was found hanging in the cab of the truck and according to the employer’s internal documentation, it was wet. Two safety harnesses issued by the truck manufacturer were also found in the truck, unused, wrapped in plastic. There was no evidence the harnesses issued by the truck manufacturer had ever been used. No cones had been placed around the truck to warn motorists of a highway work zone; nor had signs been set along the highway to warn motorists they should proceed with caution.

As part of the investigation, distance measurements from the pavement to the traffic signal were taken by an engineer. Included measurements were: 1) from the highway pavement to the bottom of the signal (wind/sun guard) measured 16.06 feet; 2) from the pavement to the bottom of the signal head measured 16.49 feet; and 3) from the pavement to the center of the green lens measured 16.98 feet. Typically when working on traffic signals, the technician would work at eye level with the signal. The technician involved in this incident was 5 feet 6 inches tall. Working at eye level, this would put the bottom of the bucket at approximately 11.47 feet above the pavement. The police report states that measurements taken of the height of the dent in the cargo truck created during the incident put the bottom of the bucket at 10.41 feet from the pavement. The height of the truck including cargo section was 11.66 feet. According to highway department personnel, standard procedure for changing green bulbs at the time of incident, was to put the traffic signal in the bucket, raise the bucket higher to create more clearance for traffic, change the bulb, wait for traffic to stop again, then lower the bucket and return to the truck.

Since this incident occurred, standard operating procedures for working on traffic signals have been modified by the employer. When feasible, workers now work in pairs and traffic is diverted to another lane so that the worker can work over an empty lane; not over moving traffic.

Cause of Death

The Death Certificate listed the cause of death as “an unspecified fall”.

Recommendations and Discussion

Recommendation No. 1: Employees should use personal fall protection equipment in an aerial lift bucket at all times.

Employers have a responsibility to provide a safe working environment for all their employees. Employees have a responsibility to themselves, their fellow employees and to their employer to use all applicable safety training and personal fall protection equipment provided by the employer. The safety harness was not worn at the time of the incident. There were two other harnesses in the truck provided by the truck manufacturer which had not been used and only needed adjustment to fit the user. A safety harness should have been worn and tied off to the eyehook on the boom.

Recommendation No. 2: A Competent person should conduct a hazard assessment of the highway work zone and implement a safety plan.

There are several methods of working safely while changing the traffic signal. Besides wearing appropriate personal fall protection, the traffic lane(s) over which the bucket is suspended should be clear of all traffic and remain clear until the worker is back to a safe place. This eliminates the worker or drivers estimating if there is enough space under a bucket to pass safely by. According to highway personnel it takes approximately 2 light changes to change a green bulb. During this time, traffic can be routed into the next lane around the bucket, or the traffic can be stopped while the light bulb is changed. Cones should be placed around the work zone prior to work beginning to warn motorists of an upcoming work zone area and to direct them to the unoccupied lane, and to proceed with caution. Traffic in the work zone lane could have been closed off. To inform motorists of the lane closure, A Shadow Vehicle, equipped with flashing or rotating lights and an appropriate directional arrow could also have been used.

References

- KY Department of Transportation

- KY OSH Compliance Officer

- KY OSH Training Officer

- 29 CFR 1910 KY OSH Standards for General Industry, General Duty Clause 5(b)

Acknowledgements

- KY Department of Transportation

- KY OSH Compliance Officer

- KY OSH Training Officer

- Traffic Officer

Photographs and Figure

|

|

|

Diagram of incident scene.

|

|

|

Photograph depicts the attachment of the boom to the bucket and the eye hook for harness attachment.

|

Kentucky FACE Program

The Kentucky Fatality Assessment & Control Evaluation Program (FACE) is funded by a grant from the Centers for Disease Control and the National Institute of Safety and Health. The purpose of FACE is to aid in the research and prevention of occupational fatalities by evaluating events leading to, during, and after a work related fatality. Recommendations are made to help employers and employees to have a safer work environment.

To contact Kentucky State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.